Introduction

We all carry around a lot of preconceived notions about clothing performance. These preconceptions may result from personal experience, exposure to marketing campaigns, or a misunderstanding of clothing function. I think it pays, from time to time, to check whether our preconceived notions hold water.

I have not worn merino wool garments of any type for years. I have made that choice because merino fibers, like cotton, are hygroscopic—they absorb and hold onto moisture. So, I reasoned, I would remain dryer and warmer by wearing polyester base layers, which wick moisture but do not absorb water into the fibers.

In this paper, I subject base layers in various weights made from merino, merino blends, and alpaca to the suite of tests I have developed to evaluate base layer performance. I then compare the performance of these base layers with those of the polyester base layers I have recently reviewed. We also see if my preconceived notions about merino hold water. Finally, we will see how to choose the fiber for our base layers.

In summary, here is what I found:

- As I have demonstrated in prior articles, the rate at which moisture dries from a polyester fabric is a function of drying conditions: ambient temperature, humidity, and air movement. This finding is also the case for merino, alpaca, and blends. The drying rates of all these fibers show modest variation and, as a practical matter, can be considered equivalent. Fiber choice does not significantly influence the rate at which moisture evaporates from a base layer.

- The time a garment will take to dry depends on the quantity of moisture trapped in the fibers. The more water a garment can hold, the longer it will take to dry. A fast-drying garment is simply one that cannot trap a lot of moisture. A fabric built to be warm will trap a lot of air but also a lot of water so that it will dry slowly. Fiber choice does not significantly influence drying time in a base layer.

- The amount of air trapped in a fabric determines its warmth. The knit pattern and yarn characteristics determine the amount of air trapped in a fabric. It does not seem to make much difference whether those fibers are natural or synthetic. Polyester can provide an exception: as we saw with the Mountain Hardwear Airmesh’suse of Octa fibers, warmth is influenced by complex fiber extrusions that trap more air than a typical circular fiber. Fiber choice does not significantly affect the warmth of a base layer.

- Despite the claims made by some manufacturers, merino and alpaca do not wick (except through chemical treatment, which, in the limited examples observed, results in poor wicking performance). The exterior of these fibers is hydrophobic, meaning water will not bond to their surfaces. They do not support capillary action. When exposed to liquid water, the force of diffusion can drive water into merino and alpaca fabrics. Liquid water or water vapor may then enter the hydrophilic core of the fibers, where it will bond to interior proteins and remain trapped until enough energy is present to drive evaporation. Some manufacturers utilize the chemical treatment of merino to render a fabric either more hydrophobic or more hydrophilic. These treatments seem to have a limited impact on performance. Fiber choice does influence moisture management performance. If you desire a wicking fabric (and you may not), you may need to rely on treated polyester or hydrophilic natural fabrics such as cotton, lyocell, or various blends. It may be possible to find a treated merino fabric that wicks well. However, my limited testing did not encounter that fabric.

So, if natural fibers such as merino and alpaca do not offer drying or warmth advantages over polyester, how can we choose our base layer fibers? To make that decision, we need to examine other characteristics of our base layer garments and other personal objectives. These include our moisture management strategy, price point goals, garment durability, garment comfort, laundering requirements, and environmental impacts over the life of a garment.

Review Stephen Seeber’s past work on base layers to get more out of this article and better understand the testing methods used.

- By the Numbers: Do Moisture-wicking Fabrics Work?

- By the Numbers: Why is My Base Layer Soaked?

- By the Numbers: Testing the Performance of Mountain Hardware AirMesh Garments

- By The Numbers: Patagonia Capilene Thermal Weight vs. Patagonia Capilene Midweight Performance Comparison

catch up on the entire By the Numbers series here.

Table of contents

Table of Contents • Note: some sections may only be available to Premium or Unlimited Members.

- Introduction

- Table of contents

- How I tested

- The test fabrics

- Discussion of Test Results

- Fiber diameter – the key to itchy fabrics

- Table 3. Measured fiber diameters

- Which Fiber is Warmest?

- Table 4: R-value in ascending order

- Table 5: R-value per ounce of fabric weight in ascending order

- Table 6: Summary of measured and calculated values for three fabrics

- Which fiber dries the fastest?

- Which fiber wicks the best?

- Table 7: Wet/dry and drop test results

- Commentary: how to choose a base layer fabric

How I tested

Garment manufacturers claim numerous benefits from their garment’s fibers. These include claims about warmth, moisture management, comfort, durability, environmental impact, and more. Investigating all of these claims for fibers would be an exhaustive task. Measurements of actual fiber performance for warmth and moisture handling are beyond the capacity of my test instruments. In this article, I don’t investigate fiber performance. Instead, I measure fiber performance when incorporated into fabrics.

The performance characteristics that I measured include physical characteristics, air permeability, insulative ability, wicking, wetting, and drying.

Fiber diameter

Fiber diameter influences garment comfort. Fiber diameters below 20 microns tend to eliminate itching. As fiber diameters increase above 20 microns, they are more likely to result in itching. Human hair is 40-50 microns in diameter. Wool from sheep tends to have a range of diameters ranging from 17 to 33 microns. Merino sheep fiber diameters range from 17-24 microns. Alpaca fibers can range from 15-40 microns. The finest fiber is from Angora rabbits at 11 microns. Typically, market scarcity forces finer-diameter natural fibers to command higher prices. Garments made with finer diameter fibers will tend to command higher prices. We measured the fiber diameter for each fabric under a microscope.

Garment weight

In this article, we test garments or fabric samples. We weighed all garments. We list the size of each garment. When possible, we attempted to obtain men’s extra-large garments. Arms of Andes provided women’s extra small garments.

Fabric thickness

Fabric thickness is determined utilizing a method that applies consistent compression to the fabric as part of the measurement process. A 50-gram weight applies compression to the fabric. The weight measures 1.27mm x 76mm x 76 mm. An iGAGING digital thickness gauge measures fabric thickness. The gauge applies slight additional pressure onto the 50-gram weight. The average thickness of each sample is calculated based on 3-5 measurements.

Fabric weight per unit area

The fabric area and weight were measured to determine grams/square meter and ounces per square yard. When garments were tested, we used the manufacturer’s specifications for fabric weight per unit area.

Air permeability

This measurement determines how much air flows through the fabric at a pressure difference of .5 inches (1.27cm) of water column. The higher the reading, the greater the amount of air that can flow through the fabric at any wind speed. Higher air permeability enables greater ventilation and improved moisture vapor transfer through the fabric.

Porosity

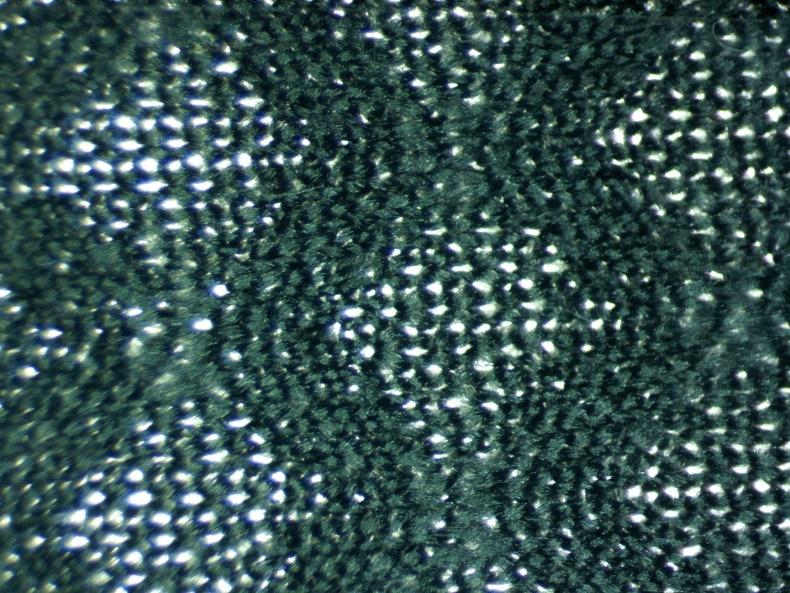

This measurement is generally related to air permeability. The measurement indicates the looseness of the knit or how much of the fabric is void or air space. Porosity is measured by placing the fabric sample on the microscope using backlighting. We set the magnification at .8 and produced a photomicrograph. The resulting image is analyzed using Photoshop to determine the portion of surface area through which light can penetrate. If you hold two fabrics in front of a light source, the fabric with higher porosity will permit more light to penetrate.

R-value

R-value measures a fabric’s resistance to heat transfer from the wearer to the environment. Higher R-value means a fabric will help reduce heat loss in cool weather or prevent the body from shedding heat in warm weather. I measured R-value on my guarded hot plate.

R-value/ounces/square yard

This is a measure of thermal efficiency. Higher efficiency occurs when more resistance to heat transfer occurs with lower material weight. As ultralight backpackers, we like to experience the insulating value required for our comfort at the least possible garment weight.

Wicking tests – wicking, infab, evap

This test demonstrates how well a fabric wets, wicks, and dries. I conducted using my permeation kettles. I place a sponge containing a predetermined quantity of water on the 120F (49C) kettle surface. Then, the test fabric is draped over the kettle surface and rests directly on the wet sponge. The fabric can absorb water which may wick across the fabric’s surface. An overhead thermal imager observes and records the progress of water as it spreads. The test continues for 30 minutes. At the end of that time, the fabric is removed and weighed. An increase in fabric weight occurs from water retained during the process and is called INFAB. Next, we weigh the sponge. The difference between the sponge’s starting weight and the finishing weight is the amount of water wicked into the fabric from the sponge. The difference is called WICKING. Finally, we subtract INFAB from WICKING to determine the amount of water that evaporated from the fabric during the process. Using these three values and watching the time-lapse drying video, we can readily determine which fabrics can remove sweat effectively from the skin and those that provide little or no ability to move sweat away from the skin.

Wetting tests – 200 and 400 microliter (ul) drops

The drop test measures how rapidly water contacting a fabric is absorbed. Drops can sit indefinitely on a hydrophobic (water-hating or water-repellent) fabric. Water drops can be absorbed rapidly into a hydrophilic (water-loving, absorbent) fabric. The industry-standard test places a 50ul drop on the fabric using a pipette. The test ends if a drop is not absorbed within 60 seconds. In our test, we use larger drops – four and eight times larger, respectively. These larger drops will hasten the wetting and absorption process. If the drops do not wet and absorb into the test fabric, we can be confident that the fibers are hydrophobic and do not support wicking.

Drying tests – water added, water dried, time to dry and drying rate

This test examines the following question: How long does it take for a saturated fabric to dry? Saturation for this test is the maximum amount of water a fabric can hold without dripping. This quantity is determined by dunking and carefully squeezing out excess water five times and then calculating the average weight after each dunking. We install the saturated fabric on the 120F permeation kettles’ surface. The moisture begins to dry. We record the drying process with the thermal imager. When the fabric is dry, the surface becomes uniformly warm and shows no further temperature rise. At this point, the test ends, and we weigh the test fabric to determine how much water evaporated. We calculate the drying time by measuring the elapsed time to dry from the thermal imager video. The drying rate is the weight of dried water/drying time.

The test fabrics

We base our findings on the performance of 16 base layer fabrics. Some were provided as complete shirts by their manufacturers. Others are fabric samples. We cut the garments and fabrics to fit the permeation kettles and the guarded hot plate. Table 1 shows the fabric breakdown:

Table 1: Test fabric distribution

| Fiber | Samples |

|---|---|

| 100% Merino | 5 |

| 100% Alpaca | 5 |

| 100% Polyester | 4 |

| Merino/Polyester Blend | 1 |

| Merino/Polypro Blend | 1 |

| Total | 16 |

Member Exclusive

A Premium or Unlimited Membership* is required to view the rest of this article.

* A Basic Membership is required to view Member Q&A events

Home › Forums › By The Numbers: What’s the Best Base Layer Fabric? Wool vs. Alpaca vs. Polyester