Introduction

StoveBench defines a protocol that is used to measure two important backpacking stove performance features (power and efficiency) in order to determine a single, quantifiable performance factor called the StoveBench Score.

Power is important because it characterizes a stove’s ability to perform well in adverse conditions (e.g., wind, cold temperatures, cold water). Efficiency is important because it defines a stove’s ability to conserve fuel and save weight for the hiker. Most consumers are enamored by reported boil times (a measure of power), while most ultralight backpacking gram-counters are enamored only by fuel usage amounts (a measure of efficiency). In actual use outdoors, both are important to consider.

This article introduces the StoveBench protocol and presents the definition of the StoveBench Score and how to determine it using the protocol.

As a case study, the protocol is applied specifically to the testing of upright canister stoves. Future applications of StoveBench will be applied to other types of stoves. In addition, special considerations, limitations, potential sources of error, and other applications of StoveBench are discussed.

Listen to our podcast about StoveBench to learn more (click here for the podcast show notes):

Context

Backpacking stove manufacturers often report the performance of their stoves in terms of:

- Boil time (i.e., the time required to boil a given volume of water) – a measure of a stove’s power; and

- Burn rate (e.g., the amount of fuel burned in a given amount of time) – another measure of a stove’s power.

In addition, ultralight backpackers, in particular, are interested in a metric that defines the mass of fuel required to boil a certain amount of water (a measure of the stove’s efficiency). Calculating this metric is popular amongst the more serious kitchen-counter stove testing enthusiasts.

However, the conditions during which these metrics are determined are not necessarily standardized from manufacturer to manufacturer or stove tester to stove tester and can’t necessarily be used to compare stove models from different brands.

Therefore, we have developed a protocol at Backpackinglight.com that we’ll be using in our stove reviews, called StoveBench (a portmanteau derived from the term benchmark, a type of test that defines a standard point of comparison).

In particular, we don’t see metrics that define “power” (e.g., boil time, burn rate) or “efficiency” (mass of fuel required to boil a certain volume of water) as mutually exclusive performance indicators. After all, any manufacturer can optimize stove performance for one vs. the other. However, balancing both power and efficiency with system weight is a design and engineering challenge of developing and using any cooking system (which may include multiple components, such as the burner, fuel container, windscreen, heat exchanger, pot, and lid). After all, a stove that is 100% efficient but takes 20 minutes to boil a pint of water, or doesn’t have the power to boil water in cold temperatures or breezy weather is as disadvantageous as a stove that boils a pint in three minutes but requires 50 grams of fuel.

Thus, the real purpose of StoveBench is to provide a meaningful way to compare different stoves so that efficiency, power, and fuel economy are implicitly defined in a single quantifiable performance factor.

The StoveBench Score

The goal of the StoveBench Protocol is to produce a numerical “performance factor” that considers both a stove’s power output (proportional to its boil time) and its fuel efficiency (proportional to the amount of fuel used during the test) during a standardized stove operation test, during which a stove will be used to heat some predetermined amount of water.

This StoveBench Score (“F”) can be described as follows:

F = output ÷ input

In any cooking scenario, output is defined primarily by water volume and temperature change (heating). More energy is required to heat larger volumes of water, and to change the temperature by more degrees.

Input is defined primarily by time (more energy is used the longer a stove boils) and fuel mass (more energy is used by a greater amount of fuel).

It follows that higher values of F are better, as they represent higher levels of output (water volume boiled) for a given amount of input (energy expenditure).

Therefore, F can be written in these terms:

F = [ V ⨉ ΔT ] ÷ [ t ⨉ M ]

where

- V = volume of water used in the test

- ΔT = difference in starting and ending water temperatures

- t = time of test duration

- M = mass of fuel used during the test

For example, a test performed under the following conditions at sea level might look something like this:

- V = 0.5 L

- ΔT = 100°C (i.e., start with 0°C water and end when the water boils at 100°C)

- t = 4 minutes (boil time)

- M = 15 g (mass of fuel used to boil the water)

The calculated StoveBench Score would thus be:

F = [ 0.5 L ⨉ 100°C ] ÷ [ 4 min ⨉ 15 g ] = 0.83 L•°C/min•g

Which can be read in layman’s terms like this: in this test, this stove was capable of heating up 0.83 liters of water by 1 degree Celsius (or, 1 liter of water by 0.83 degrees Celsius) in one minute using one gram of fuel.

The StoveBench Score will vary across different test conditions, being influenced by factors such as:

- Pot geometry

- Ambient air temperature

- Fuel type

- Presence of air current (e.g., wind).

However, because the StoveBench Score is normalized for water volume and temperature differential, it has the potential to be less sensitive to factors such as the elevation of the test location or starting water temperature, which means that across a narrow range of test environments and materials used, results should compare relatively well. Unfortunately, manufacturers seldom publish the details of their test protocols, emphasizing the importance of testing stoves using a standard methodology when comparing stoves from different brands, or in different environments.

For example, let’s consider two tests using a well-known canister stove from a major US brand.

Test #1, performed by the manufacturer, is conducted with water having a starting temperature of 70 °F (21.1°C), an ending temperature of 212 °F (100°C), and water volume of 1.0 L. In this test, the manufacturer reports a boil time of 3.5 minutes and 14 g of fuel consumption. The StoveBench Score is thus calculated as follows:

F = [ 1.0 L ⨉ 79°C ] ÷ [ 3.5 min ⨉ 14 g ] = 1.61 L•°C/min•g

Test #2, performed by the author, is conducted with water having a starting temperature of 32.9 °F (0.5°C) and an ending temperature of 199 °F (92.7°C), noting that these tests are conducted at an elevation of 7,205 feet, where water boils at a lower temperature than at sea level. A 0.85 L titanium pot was filled with 0.5 L of water for the test, and the stove operated at full power. The boil time was 3 min 5 sec and 11.3 g of fuel was consumed. (Full details of the test protocol are described below in the “Materials and Methods” section of this article.) The StoveBench Score for this test is thus calculated as follows:

F = [ 0.5 L ⨉ 92.2°C ] ÷ [ 3.08 min ⨉ 11.3 g ] = 1.30 L-°C/min-g

The differences between the two results are not dramatic (F is only 20% lower in Test #2), given significant differences in starting water temperature, water volume boiled, and elevation of the test location. However, the differences highlight the need to ensure standardized testing when comparing the performance of different stoves.

This is important because the vast majority of “gear guides”, “best stoves” comparisons, and stove reviews simply re-publish manufacturer-reported performance data, and make judgments accordingly, without regard for the factors that influence stove test results.

Considering Efficiency

A stove’s efficiency can be loosely defined as its ability to minimize waste heat. Heat is wasted via a number of processes, including incomplete combustion of fuel, a flame pattern that causes heat to spill up the sides of a pot vs. being targeted to the bottom of the pot, and heat losses from the pot itself (e.g., always use a lid!).

Efficiency is a function that balances fuel economy with flame power. A high-power stove aids efficiency by delivering more heat in a shorter period of time which can combat system heat losses. However, a high-powered flame can also waste more heat because the heat cannot be absorbed into the water fast enough.

Consideration of efficiency is built into the StoveBench Score, which is calculated from both boil time and fuel usage. Short boil times (high power) and low fuel requirements (high fuel economy) both contribute to higher StoveBench Scores.

Specifically, the fractional contribution of stove performance by fuel economy is defined by the Feconomy = [ V ⨉ ΔT ] ÷ M part of the StoveBench Score equation, and the fractional contribution of stove performance by flame power is defined by the Fpower = [ V ⨉ ΔT ] ÷ t part of the StoveBench Score equation.

Since efficiency can be defined as the ratio between the actual amount of fuel used in the test and the theoretical amount of fuel that should have been used in the test if the stove was operating at 100% efficiency (i.e., no heat loss), the StoveBench Score is particularly useful for comparing stoves of different types (e.g., alcohol vs. compressed gas vs. liquid gas), where inherent inefficiencies in both the heat capacity of fuels and heat losses in stove systems will be reflected by both Feconomy and Fpower.

Often, there is a direct correlation between heavier stoves and stoves that are more efficient. Thus, the StoveBench Score is a versatile metric that can provide a backpacker with valuable information about which stove type might be best for a given set of water heating requirements based on trip duration and required water volumes. The StoveBench Score can provide the foundation for a variety of subsequent analyses to aid the hiker in evaluating different stove systems. For example, the StoveBench Score divided by the total cook kit weight (which might include the stove, fuel container, pot, windscreen, etc.) would provide valuable insight into the performance:weight ratio of a particular stove and cooking system.

The StoveBench Test Protocol: Overview

What follows are the materials and methods used in a standardized protocol for determining the StoveBench Scores for any stove type.

Environment and Instrumentation

In general, the standard (“control”) boil test of the StoveBench protocol measures stove performance under the following conditions:

- Indoor room temperature (ambient)

- No ambient air flow (wind)

- Measure the time and fuel required to boil water originally near its freezing temperature

- No stove windscreens or other accessories unless they are integrated into the burner design.

The following table describes my own test environment and instrumentation in more detail.

| Ambient Environment | Indoors; Air Temperature = 19.5 °C +/- 0.5 °C, thermostat-controlled fanless convection heater; RH = 20-40% (monitored); elevation = 7205 feet above sea level. |

| Water | 500 g of water (0.5 L) +/- 2 g; measured starting temperature = 0.5 to 5.0 °C (water temperature stabilized by ice); stopping ("boiling") temperature = 91.0 °C (measured temperature at the beginning of a rolling boil at this elevation) |

| Water Temperature Measurement | HTI HT-9815 Digital Thermometer w/K-type Thermocouple Sensors (±1 °C accuracy, 0.1 °C resolution) |

| Weight Measurement | Adam Equipment CBK 8a scale, 4kg capacity, 0.1g accuracy (calibrated) |

| Stove System Thermal Imaging | HTI HT-18 Thermal Imaging Camera, -20 °C to +300 °C range, image resolution 220x160 pixels. |

| Infrared Temperature Measurement | Etekcity Lasergrip 1080 Infrared Thermometer, 0.1 °C resolution. |

| Water Heating Container | titanium pot with lid (0.85 L capacity, 5.0 in wide x 3.75 in height, 4.0 oz dry weight) |

General Test Procedure:

- Prepare ice water using a 50/50 mixture of ice cubes and tap water in a gallon container that can be easily stirred so as to ensure uniform temperature distribution of the water. Store the water in a cold environment when not in use.

- Record the ambient air temperature of the test environment to within 0.1°C regularly throughout the test.

- Using infrared temperature measurement, ensure that the temperature of the fuel is the same as the ambient temperature of the test environment by comparing the temperature of the test fuel to the temperature of fuel stored nearby that isn’t being used in the test. This is important because different material types can emit different levels of infrared radiation, and the surface temperature of the material itself may differ from the ambient room temperature. Ensure that the surface temperature of each batch of fuel is within 0.1°C of each other.

- Measure the starting weight of the fuel (this generally requires measurement of the stove plus fuel) to within 0.1 g.

- Place the water heating container on the bench scale, tare the scale, and add the specified amount of ice water (filtered so as to remove the ice) to within +/- 0.5% of the target weight. The target weight should be converted to water volume, and water volume used as V in the StoveBench Score (F) formula above.

- Place the water heating container on top of the stove burner (centering it on the stove’s pot supports), insert the thermocouple into the water so that it measures the temperature of the water halfway down the water column and does not touch the sidewall of the container. Place the lid on the container. The thermocouple wire should be suspended vertically over the pot, so waste heat from the stove system can’t materially cause damage or temperature measurement interference with the thermocouple wire.

- Measure the starting temperature of the ice water to within 0.1°C resolution. Ensure that the starting temperature is less than 5.0°C.

- Within the span of 1 second, light the stove burner/fuel, open the stove valve to a fully open position (not applicable for stove types with no fuel flow regulation), and start a stopwatch.

- When the water temperature reaches a predetermined temperature defined as the boiling point (to within 0.1°C resolution), record the elapsed time to the nearest second and extinguish the stove (i.e., turn off the fuel flow) immediately. This elapsed time shall be recorded as the “boil time”. Boil time should be converted to decimal minutes, which will be used for t in the StoveBench Score (F) formula above.

- The difference between the starting and ending water temperatures will be used for ΔT in the StoveBench Score (F) formula.

- Measure the ending weight of the remaining fuel to the nearest 0.1 g (or as applicable, the stove plus fuel assembly). The difference between this weight and the starting weight shall be recorded as the “fuel consumed”, and used for M in the StoveBench Score (F) formula above.

- Calculate the StoveBench Score (F) for the test.

- Repeat the test as needed to ensure statistical confidence in the result (1-2 additional times in a highly-controlled test environment with accurate instrumentation; up to 6 times in less controlled environments).

StoveBench Protocol Application: Upright Canister Stoves

What follows are the specific materials used in the application of the StoveBench Protocol for upright canister stoves:

| Fuel | 80/20 mixture of isobutane/propane; 227 g net weight canisters between 30% and 80% of their fuel capacity* |

* Canisters are retired when fuel capacity reaches 30% or less when changes in internal canister pressures can skew results materially. At high canister capacities, high canister pressure causes excess heat losses that can skew results materially when stoves are operated at full throttle. See below for more details.

Specific Procedural Notes When Using Upright Canister Stoves:

- Fuel Weight Measurements. During the fixation to and removal from a canister, a stove may cause small amounts of compressed gas to leak out of the canister, which could skew results. Thus, fuel weights are determined by calculating the difference in weights of the entire stove-canister assembly at the start and end of the test.

- Fuel Temperature Measurements. The surface temperature of the canister is measured with an infrared thermometer to ensure that it’s the same temperature of a nearby control canister that isn’t being used in the test (and is thus, at ambient temperature).

- Starting the Test. A lighter is held to the stove burner while the stove gas valve is turned on very slowly until the burner is lit. Within one second, the stove valve is turned to its maximum at the same time a stopwatch timer is started.

- Ending the Test. When the thermometer readout reaches the stopping temperature, the stopwatch timer is recorded and the stove gas valve is immediately turned off.

Proof of Concept: Preliminary Stove Test Results

Comparing Upright Canister Stoves

As part of a series of new Backpacking Stove Gear Guides, we are planning on releasing our upright canister stove gear guide later this month.

What follows is a small selection of control boil test results (using the protocol above) from one test batch that included 18 models of upright canister stoves (the final gear guide will include approximately 25 models). For the purpose of this article, brand and model names have been hidden. They will be revealed with the rest of the results in the upcoming gear guide.

Results have been sorted by order of highest to lowest StoveBench Scores.

| Model ID # | Boil Time (mm:ss) | Fuel Usage (g) | StoveBench Score - F (L•°C/min•g) |

|---|---|---|---|

| 1 | 3:30 | 8.3 | 1.56 |

| 2 | 2:45 | 13.2 | 1.25 |

| Average | 3:30 | 12.3 | 1.16 |

| 3 | 4:05 | 10.9 | 1.02 |

| 4 | 3:10 | 19.7 | 0.73 |

The StoveBench Score rewards not only stoves that have good fuel economy (low fuel usage), or stoves that have high power output (low boil times), but stoves that are efficient – that can deliver a high amount of power for the least amount of fuel.

Sources of Error

- Scale accuracy. Calibration standards were used to monitor and verify scale accuracy using the USBR 1012 protocol. The accuracy of measured standards was determined to be less than 0.04 g, resulting in an error % of reported fuel consumption amounts of less than 0.3%. The scale manufacturer reports linearity of +/- 0.2 g, which could contribute an error of up to about 2% in reported fuel consumption amounts.

- Fuel usage at start and end of test. Up to one full second of time was required to start and stop the stove during which the valve was turned (two seconds total). Thus, up to two additional seconds of unnecessary fuel consumption may have occurred. The average amount of fuel used in the tests was 12.3 g over the course of a burn time of about 210 seconds (i.e., 0.059 g/sec). Therefore, over the course of 2 seconds, up to 0.12 g of additional fuel may have burned, amounting to an overstatement of approximately 1% of reported fuel usage. This error was consistent over all tests.

- Temperature measurement accuracy. Thermocouples were calibrated in both ice water and boiling water. Measurement accuracy proved to be within 0.1°C. Since the test was stopped when the water temperature reached 92.7°C, and if heating is assumed to follow a fairly linear progression from 0°C to 92.7°C, then over the course of the average boil test (210 seconds), the approximate rate of heating was 2.3 seconds/°C. A temperature inaccuracy of 0.1°C would thus introduce a boil time error of only 0.23 seconds, which corresponds to a fuel consumption error (see #2 above) of only 0.014 g (about 0.1% error).

- Starting and Ending Canister Temperatures. Starting canister temperatures were measured with a laser infrared thermometer (Etekcity Lasergrip 1080) and were always within 0.1°C of another canister (not in use) that was used as a room temperature control. Ensuring consistent starting canister temperature in all tests was critical to minimizing error. Canister temperatures often dropped 4 to 6°C during the course of a test due to the heat of vaporization principle, the process by which heat is converted to energy required for liquid gas to become vapor. Starting the next test immediately after resulted in boil times that were as much as 20% slower than the previous test, since lower-temperature canisters had lower vapor pressures (i.e., lower fuel flows, lower burn rates, and thus, longer boil times). While some method of controlling canister temperatures during the test (e.g., placing it in a water bath with temperature controlled by a thermostat) might be valuable in order to prevent the canister temperature from decreasing, doing so would add significant complexity to the protocol and further decrease the protocol’s relevance to how stove systems are used in the field by most users.

Error percentages will be higher when using consumer-grade instrumentation (e.g., digital kitchen scales and meat thermometers). For example, a typical made-in-China digital kitchen scale has an accuracy of 0.1 oz (3 g) with linearity of up to 0.2 oz (6 g). With this much potential error introduced in the measurement of fuel consumption during a single boil test, replicate testing becomes even more important. Verification of scale accuracy with calibration standards is important, even for at-home stove testing enthusiasts.

Other Considerations

What about using tap. vs. distilled vs. water from a lake or stream?

This concern is propagated by Betty Crocker et al., based on the common kitchen practice of putting a teaspoon of salt into a pot of water to make it boil faster. In other words, do differences in the concentration of solutes have an effect on boiling time?

For those of you that think physicochemistry is fun (you have a copy of the CRC-HCP by your bedside), consider the basic principles that:

- Solutes will lower the boiling point (water will boil faster) because the specific heat capacity of those solids (e.g., salts) is lower than the specific heat capacity of water.

- However, solutes will also increase the boiling point of water (water will boil slower) because they raise the vapor pressure of the solution, requiring more heat energy to boil.

So, at what sort of solute concentrations does this make a difference?

A 1% solution of salt water (e.g., 10 g of salt dissolved in 1 kg of water) will increase the boil time by about 1% (physics fans: use the heat equation Q=MCΔT) to determine this). Adding more salt starts to tip the scales, however, and by the time we reach a 5% solution of salt, the boil time is decreased by about 1.5%. Of course, these calculations are based on a perfectly efficient system (where 100% of the heat produced by the fuel is transferred to the water). But even with highly inefficient (10% to 40% efficiency) stove systems characteristic of solid fuel, alcohol, and gas stoves without pressure regulation, the effects of solutes on boil times are likely negligible relative to the other sources of variability inherent in performing testing like this.

In other words, we are talking about minute effects on the boil time and concentrations of salt that would make your water unpalatable.

For my own testing, I use tap water that has a total dissolved solids (a measure of solutes) concentration of less than 100 mg/L (0.01%).

Do changes in canister pressure skew results?

For tests involving canister stoves, the amount of fuel remaining in the fuel canister could impact results.

As a fuel canister is used, the volume of fuel inside a canister decreases (which also decreases the pressure and resulting flow rate of fuel that is delivered to the burner).

In addition, fuel mixture composition could change, but that effect is probably not as dramatic as it’s assumed to be.

To evaluate this effect, the control boil test described above was repeated using a stove that does not include a pressure regulator (since the effects will be less dramatic on a stove that has a built-in pressure regulator). A 227 g (net weight) canister containing a mixture of 80/20 isobutane/propane was used for this test.

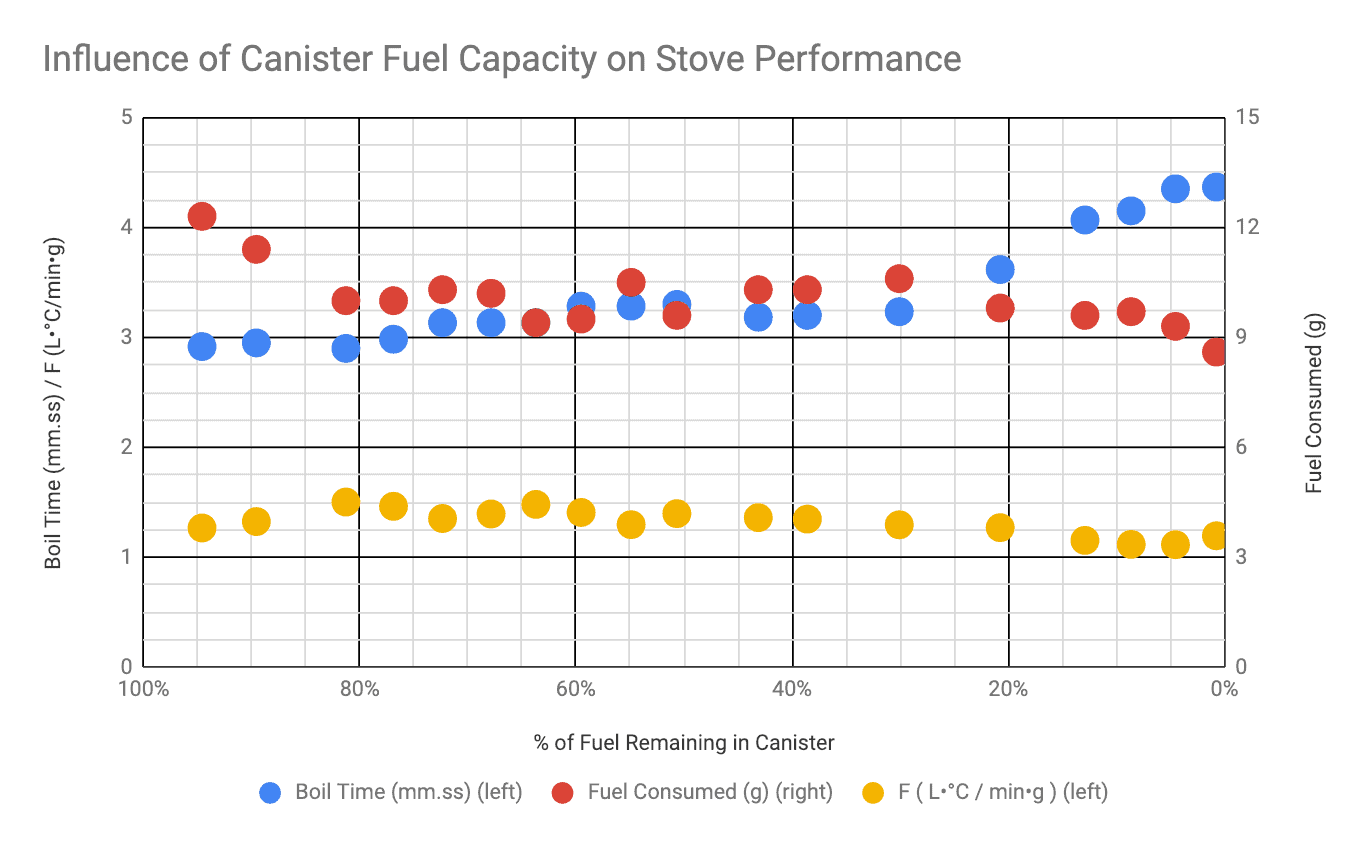

Boil times, fuel consumption, and StoveBench Scores are presented in the following chart as a canister is used from full capacity to nearly-empty capacity.

The following table provides a basic statistical analysis of all tests performed for this canister:

| Boil Time (mm.ss) | Fuel Consumed (g) | StoveBench Score - F ( L•°C / min•g ) | |

|---|---|---|---|

| Average | 3.4 | 10.08 | 1.32 |

| Standard Deviation | 0.49 | 0.83 | 0.12 |

| StDev% (100 x Standard Deviation / Average) | 14.5% | 8.2% | 8.9% |

Based on examining the graph above, I attribute the high variability to the high pressures in the canister when full (or nearly full), and the low pressures in the canister when nearly empty. Here are my conclusions when examining the graph, noting, in particular, those values that are near to or exceed +/- one standard deviation from the average values. StDev% is a useful statistic for estimating the range of error of experiments that should be repeatable. For the purposes of this protocol, I’m hoping for a range of StDev% of +/- 5%. From the table above, all three ranges are outside this criterion.

- Boil times are abnormally high at low canister fuel capacities (<30%).

- Fuel consumption is abnormally high with a full canister (>80% capacity) and abnormally low with a nearly empty canister (<5%).

- StoveBench Scores (F) are abnormally low at low canister fuel capacities (<20%), and (possibly) abnormally high at high canister fuel capacities (>80%).

Based on these observations, the most reliable repeatability for the two measured performance metrics (boil time and fuel consumption), and the calculated StoveBench Score, occurred when canister fuel was in the range of 30% to 80% of its capacity.

With this restriction in place, if all tests performed at capacities exceeding 80% and lower than 30% are discarded, we can examine the resulting statistics:

| Boil Time (mm.ss) | Fuel Consumed (g) | StoveBench Score - F ( L•°C / min•g ) | |

|---|---|---|---|

| Average | 3.16 | 10.1 | 1.39 |

| Standard Deviation | 0.13 | 0.41 | 0.07 |

| StDev% (100 x Standard Deviation / Average) | 4.1% | 4.1% | 5.0% |

This constraint results in StDev% values for boil times, fuel consumption, and StoveBench Scores that are 5% or less.

Consequently, all tests measuring StoveBench Scores will be performed when the canister is within the 30% to 80% range of fuel capacity.

These results indicate that (at least for upright canister stove tests adhering to the control protocol defined above), a StoveBench Score can be interpreted to have an experimental standard error (defined by +/- 1 standard deviation) in the range of +/- 5.0%.

What are the problems associated with running stoves at full throttle?

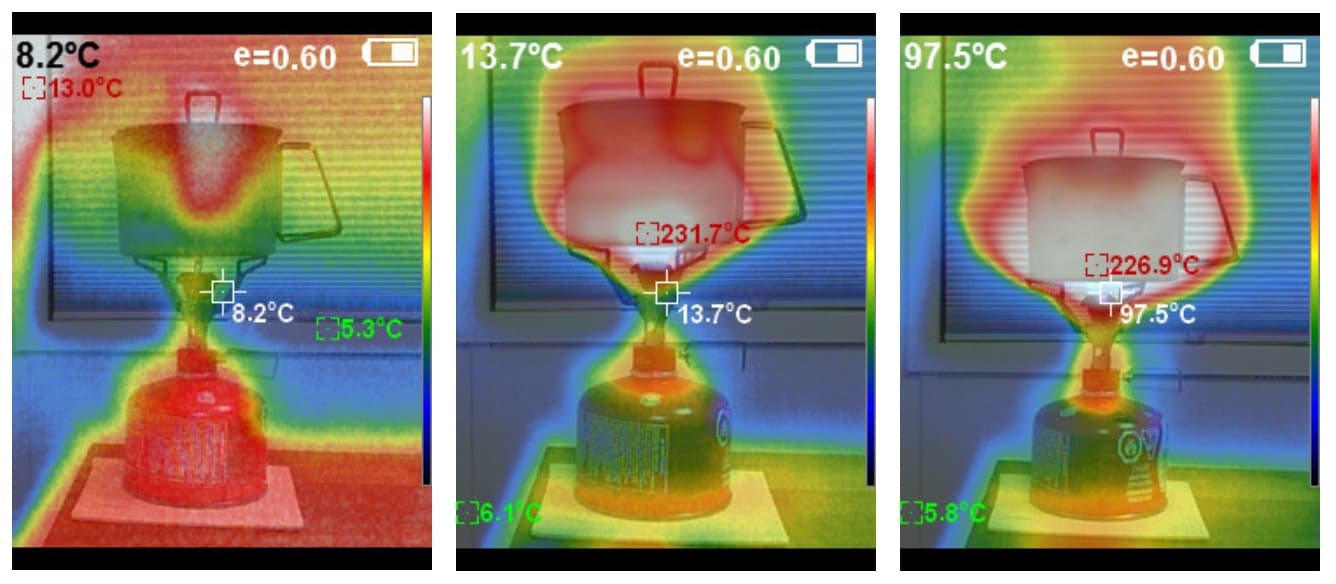

Running a stove at full throttle probably wastes unnecessary heat when using stoves that don’t have built-in pressure regulation. Most users will “feel” that their stove needs to be turned down a little in order to run it more efficiently, but thermal imaging can reveal the effect more objectively.

Unfortunately, without (extremely difficult to make) direct measurements that correlate the fuel valve orifice opening, fuel valve handle positioning, and a stove’s heat output, running a stove at any output level less than 100% (fuel valve handle turned all the way counterclockwise so the fuel delivery orifice is at its maximum) will introduce too much subjectivity that may interfere with test repeatability and/or performance comparisons between stove models.

That said, having a control test at full throttle provides a good foundation for further testing where stove output is controlled by the fuel valve handle, and results of this type of comparison testing will be presented in our forthcoming Upright Canister Stove Gear Guide.

Interestingly, the effect of wasted heat was much more significant for canisters having a fuel capacity that was greater than 80% (see “Do changes in canister pressure skew results?” above), suggesting that operating a stove at full throttle has more detrimental impacts when using fuller canisters. I used thermal imaging to verify this.

What about mismatched burners and pots?

Large pots don’t necessarily match so well with small burners, or low power fuels (e.g., solid fuel tablets). On the other end of the spectrum, small pots get overwhelmed by large burners, resulting in significant heat loss and fuel waste.

I recognize that burner-pot mismatches will result in a stove system that perhaps scores lower than it should in the control test protocol defined here.

This control test protocol is optimized for solo cooking in three-season conditions (small pot volume, low water volume). Users should consider StoveBench results for large pots and large water volumes as part of any burner’s overall performance, and not rely solely on the control test described above before choosing a stove for boiling larger volumes of water.

“No wind, full throttle, not my pot, this test isn’t representative for me.”

This is a controlled testing environment where we’ve arbitrarily defined a set of test conditions and a test protocol that gives us repeatable results that can be used to identify one performance metric benchmark that we can:

- Use to compare different stoves; and

- Use as a point of reference for different test environments and conditions (see next section).

Is the StoveBench test useful for other types of stoves, and how do F factors compare?

Yes, of course. The rationale for determining a StoveBench Score is applicable for any type of stove and fuel, including solid fuel (e.g., hexamine tablets), alcohol, upright/inverted/integrated canister stoves, liquid fuel (e.g., white gas, kerosene) stoves, or wood stoves.

We’ll be developing protocols for each of these stove types as part of the StoveBench program.

StoveBench Scores for stoves using different fuel types will differ primarily as a result of the specific energy capacity of a fuel (i.e., energy per weight), and the efficiency of the benchmarked stove system (e.g., stove/pot/burner combination).

When we publish stove reviews and gear guides, we’ll also include a metric equal to the StoveBench Score divided by the stove system weight. This will (perhaps) represent at least some of the benefit of carrying so-called ultralight stove systems (e.g., solid fuel and alcohol), even though these stoves use fuels that don’t contain as much specific energy (energy per gram of fuel) in them as gas stoves.

Variations of the Control Protocol

In addition to Control Boil Tests (described above), we are devising a number of other performance scenarios that will be featured in upcoming reviews and gear guides, including:

- Wind Test: add a low-speed fan to the test environment to create a wind speed characteristic of a light breeze. We performed a test similar to this in a recent comparison of integrated canister stoves and the differences in stove performance results was dramatic.

- Large Water Volume Test: 1500 g of water in a titanium 2-liter pot, a common scenario for groups of 2-3 hikers sharing a cook kit.

- Cold Temperature Test: a test performed at an ambient temperature of 32 °F (0°C) or less, a common scenario for winter backpacking environments and/or snow melting.

- Stress Test: 1500 g of water, ambient temperature of 32 °F (0°C) or less, and wind induced by a fan.

Our first round of StoveBench Scores will be released later this month when we publish the results of our new Upright Canister Stove Gear Guide, which will include StoveBench Scores for all of the above scenarios from a subset of the approximately 25 canister stove models being reviewed in the Gear Guide.

How to Perform Your Own StoveBench Tests and Contribute to the StoveBench Database

You don’t need fancy instrumentation to run your own StoveBench tests. In fact, your own tests can be extremely valuable for our community!

If you can reasonably measure the temperature of your water and measure fuel consumption weights, then you are well on your way to running your own StoveBench tests.

Here’s a short video that illustrates how I run a StoveBench Control Boil Test for an upright canister stove:

I use the following spreadsheet template for each test I run:

Here’s a video that shows how I use the spreadsheet test template:

We are building a user database of StoveBench Scores calculated from your own test environments and protocol parameters.

We’ll be publishing this information in a subsequent article to be published in early February 2019. In addition, if this information proves to be valuable to our community, we’ll be releasing a live version of the database (with real-time updates as new user tests are submitted) as well.

StoveBench Testing Services

- If you are a stove manufacturer and would like to have your stove tested using the StoveBench protocol, here is some more info.

- If you’re interested in starting your own StoveBench Lab, click here.

Final Commentary and Disclaimer

When interpreting StoveBench Scores, do so with an understanding of this protocol’s limitations and error sources (outlined above). When interpreting StoveBench Scores calculated from user-submitted test data to our database, consider that different test environments, different types of measurement instrumentation, and differences in protocols may result in StoveBench Score variability that may not be present when we perform our own StoveBench tests in our own laboratory environment. The StoveBench database will distinguish between user-submitted stove testing data and stove testing data we perform on behalf of Backpacking Light that adheres more strictly to the protocol described herein.

Finally, the StoveBench Score is not the holy grail of stove performance. While it can factor into your decision-making process to purchase a stove, or select a type of stove for a particular trip, there are other issues of importance as well: the dry weight of the system, the starting weight of the system including fuel, the environment you are cooking in, the cost of the fuel, the allure and satisfaction that comes with making a homemade stove, brand loyalty, and so much more. So, let StoveBench be one of your guides in making decisions, but not your only one.

Acknowledgments

The author wishes to acknowledge Roger Caffin, Hikin’ Jim Barbour, Gary Dunckel, and Jerry Adams for their helpful and critical reviews of the StoveBench protocol.

Home › Forums › StoveBench: A Stove Testing Protocol for Comparing the Performance of Backpacking Stoves