Introduction

Managing moisture (including perspiration and precipitation) while backpacking in cold temperatures can be challenging. It’s easy to reach a level of physical exertion that causes significant sweating and body heat generation, even during winter conditions. The primary challenge arises from the stop-and-go nature of backpacking, where the hiker generates heat and perspiration while active, and undergoes rapid cooling due to evaporation of that same perspiration while inactive.

In this article, we present:

- moisture transport mechanisms in base layer fabrics;

- the problem with wicking and cold temperatures: the Mancusi Dilemma;

- the idea that wicking isn’t all it’s cracked up to be;

- the case for fishnet fabrics; and

- ventilation options for outer layers.

Moisture transport mechanisms in base layer fabrics

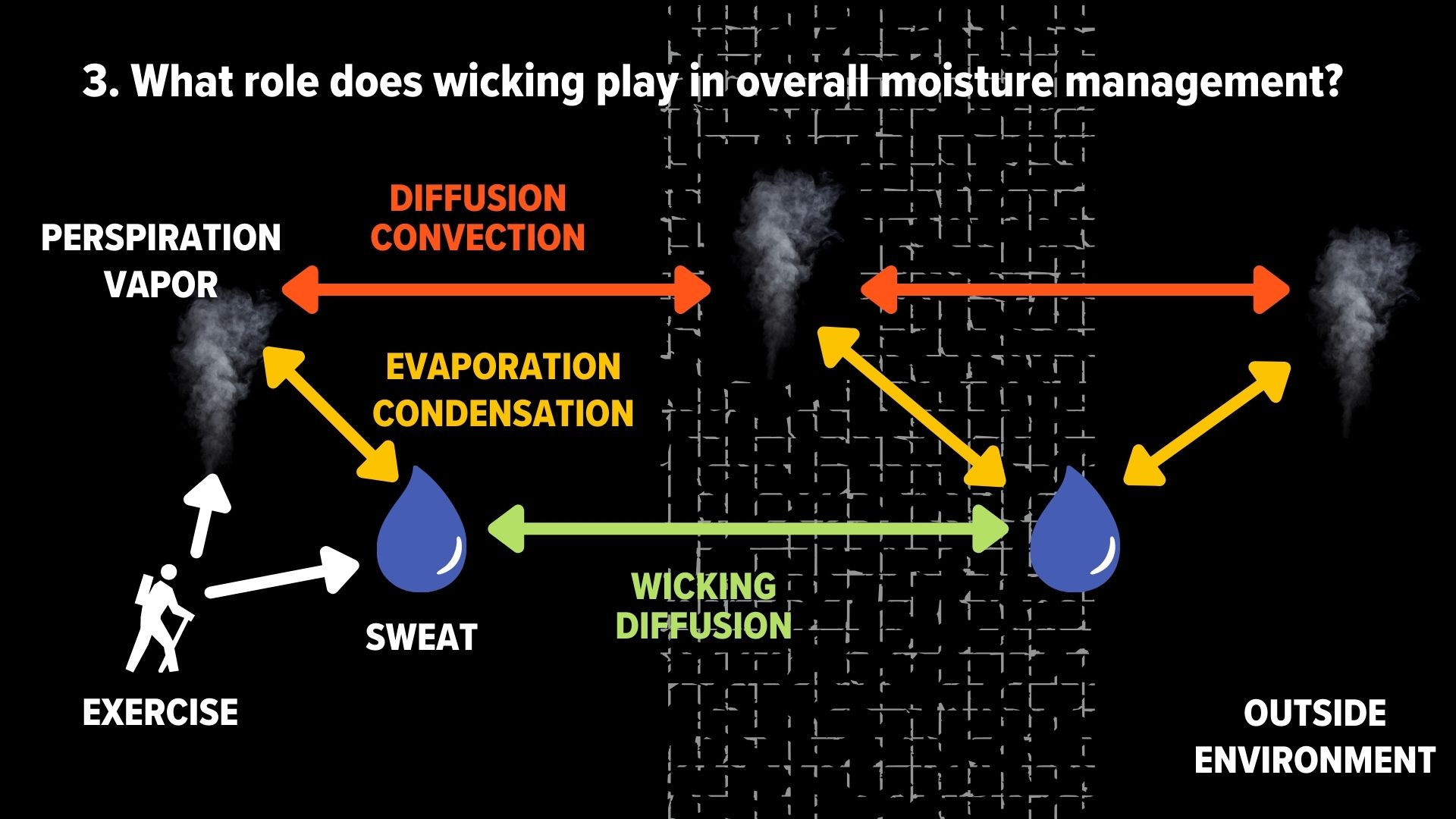

The transport of perspiration moisture in both vapor and liquid form in a layered clothing system is controlled by a complex system of interrelated processes including diffusion, convection, evaporation, condensation, and wicking. These processes occur in the following transport pathways:

- As you hike (or exercise), your skin temperature warms and accumulates water vapor that results from either insensible perspiration or the evaporation of liquid sweat at the skin surface. Because your skin is now a warm, humid environment, that increases the vapor pressure near the skin surface, which drives moisture vapor towards cooler, lower-humidity areas (your layered clothing system, and eventually, the outside environment). These vapor pressure-driven processes include both diffusion and convection. These processes are represented in the diagram below by the orange lines.

- In addition, as you perspire and generate liquid sweat against your skin, that liquid enters into your clothing system via wicking (e.g., a diffusive analog known as capillary action). Liquid travels along the surface of individual fibers and through pores (capillaries) within the textile structure of the fabric. This process is driven by surface tension forces and drives moisture from areas of high liquid moisture content to areas of low liquid moisture content. These processes are represented in the diagram below by the green lines.

- Evaporation and condensation also occur in this system: at the skin surface, inside the layered clothing system, and between the outer surface of the clothing system and the outside environment. These processes are represented in the diagram by the yellow lines.

The problem with wicking and cold temperatures: the Mancusi Dilemma

In a conventional knit-fabric wicking base layer, the fabric pores are very small, and the fibers are hydrophilic. This creates high levels of surface tension forces that drive wicking. Therefore, it’s presumed that wicking is the dominant transport mechanism of moisture away from the skin surface and into the outside environment.

However, a problem arises after a very short period of time following the onset of sweating: the fabric starts to become saturated with perspiration. At this point, the liquid water concentration gradient approaches zero, capillary action halts, and wicking no longer occurs. You just get wetter and wetter. Mancusi et al. (Mathematical modeling and numerical simulation of heat and moisture transfer in a porous textile medium, Journal of the Textile Institute, Vol. 107 No. 5, July 2015) showed that this occurs much faster than we think. During steady exercise, relative humidity reached 100% across 90% of the fabric thickness within 20 minutes. Once the air inside of the fabric becomes saturated with moisture vapor, condensation occurs, and at that point, you are wearing a ticking time bomb of fabric that’s only going to get wetter. I call this the Mancusi Dilemma.

Then, when you stop, evaporation becomes the dominant moisture transport mechanism at the skin surface and inside your layered clothing system. Since evaporation requires heat, if outside temperatures are cold, that source of heat is your body, and you get chilled within minutes. This is commonly known as the “flash-off” effect – the rapid drop of body temperature that results in evaporative cooling when you stop hiking.

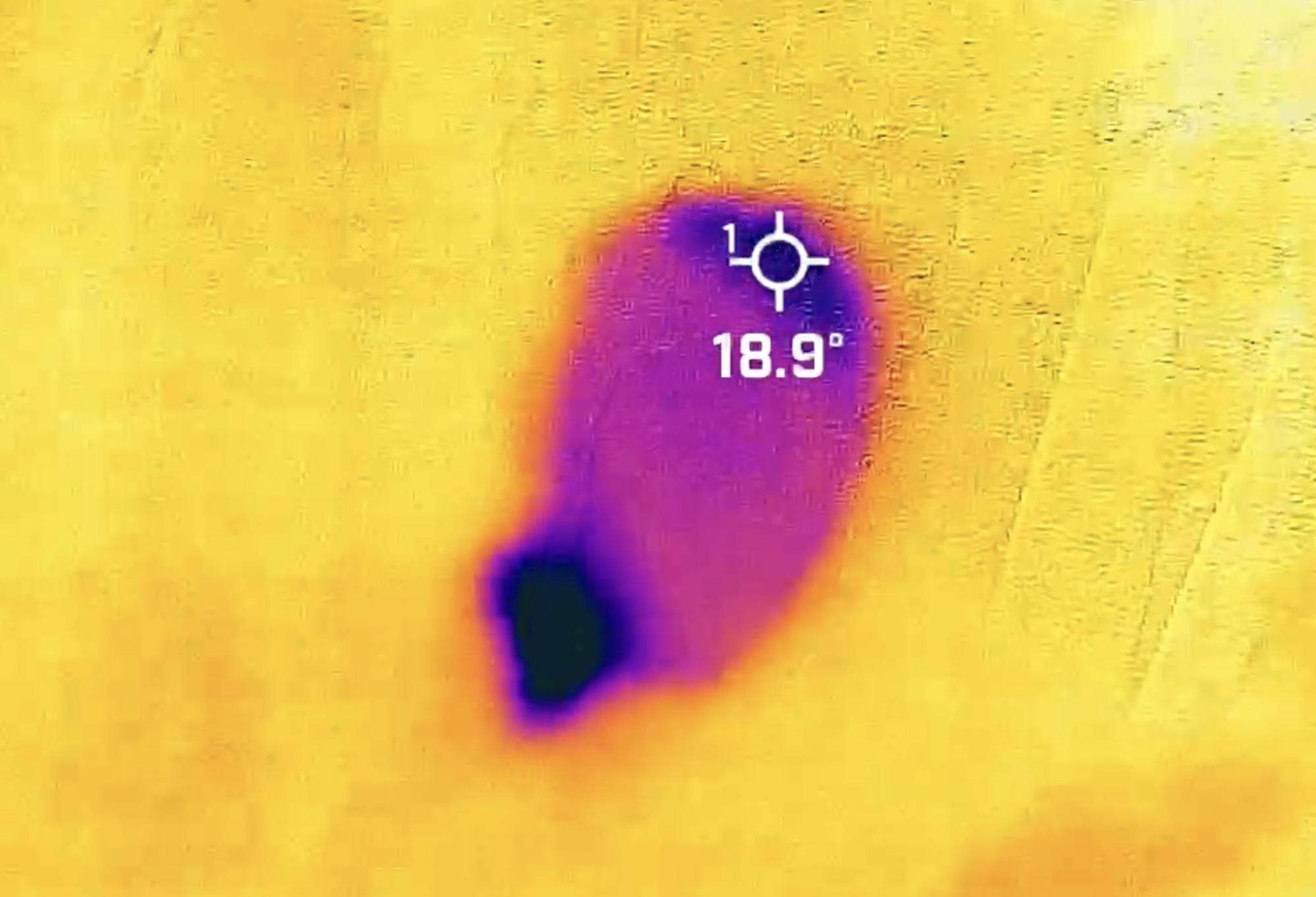

Some of my recent research investigates the impact of wicking at the micro-scale using infrared microscopy. The following image shows a 50-microliter drop of water wicking through a hydrophobic polyester base layer fabric. The ambient air, water, and starting fabric temperatures were 22.2 °C (72 °F). As the water droplet wicked through the fabric, the edges become areas that were dominated by evaporation. The heat driving that evaporation resulted in a drop in temperature of the fabric in these regions by more than 3 °C (6 °F). This is a notable temperature drop. Not only can there be a loss of body heat driving the evaporation phase change, but now we have a cold fabric next to skin that has the potential to drive conductive heat loss from the body. This is why it’s so easy to feel chilled if you’re wearing a damp base layer next to skin if you’re not exercising at a high enough intensity to combat this heat loss.

So maybe wicking isn’t all it’s cracked up to be

We’ve been investigating the wicking process for the past few years. You can catch up by reviewing the Related Content section at the end of this article.

My research into the impact of wicking on physiological comfort continues to validate the idea that maybe we shouldn’t trust that wicking is the be-all-end-all of fabric performance for hiking in cold temperatures.

Here’s why.

If we can avoid the Mancusi Dilemma described above (i.e., rapidly achieving moisture vapor-saturated air inside the clothing system), then we can short-circuit the process of moisture vapor condensing inside the clothing system and wetting it.

The Mancusi Dilemma can be minimized when:

- Rapid transport of moisture vapor away from the skin surface and through the base layer fabric;

- Minimal wicking inside the fabric structure (to minimize liquid water surface area and subsequent rapid evaporation); and

- Rapid convective expulsion of moisture to the outside environment.

These three factors can be optimized with the strategic application of a layering system where a fishnet made with hydrophobic fibers constitutes the base layer and outer layers are highly ventilated.

The case for fishnet

Rapid transport of moisture vapor away from the skin will occur in two scenarios: (1) when vapor diffusion through the fabric is maximized and (2) when external convective forces (e.g., caused by normal bellowing of clothing during physical movement) can reach the skin surface.

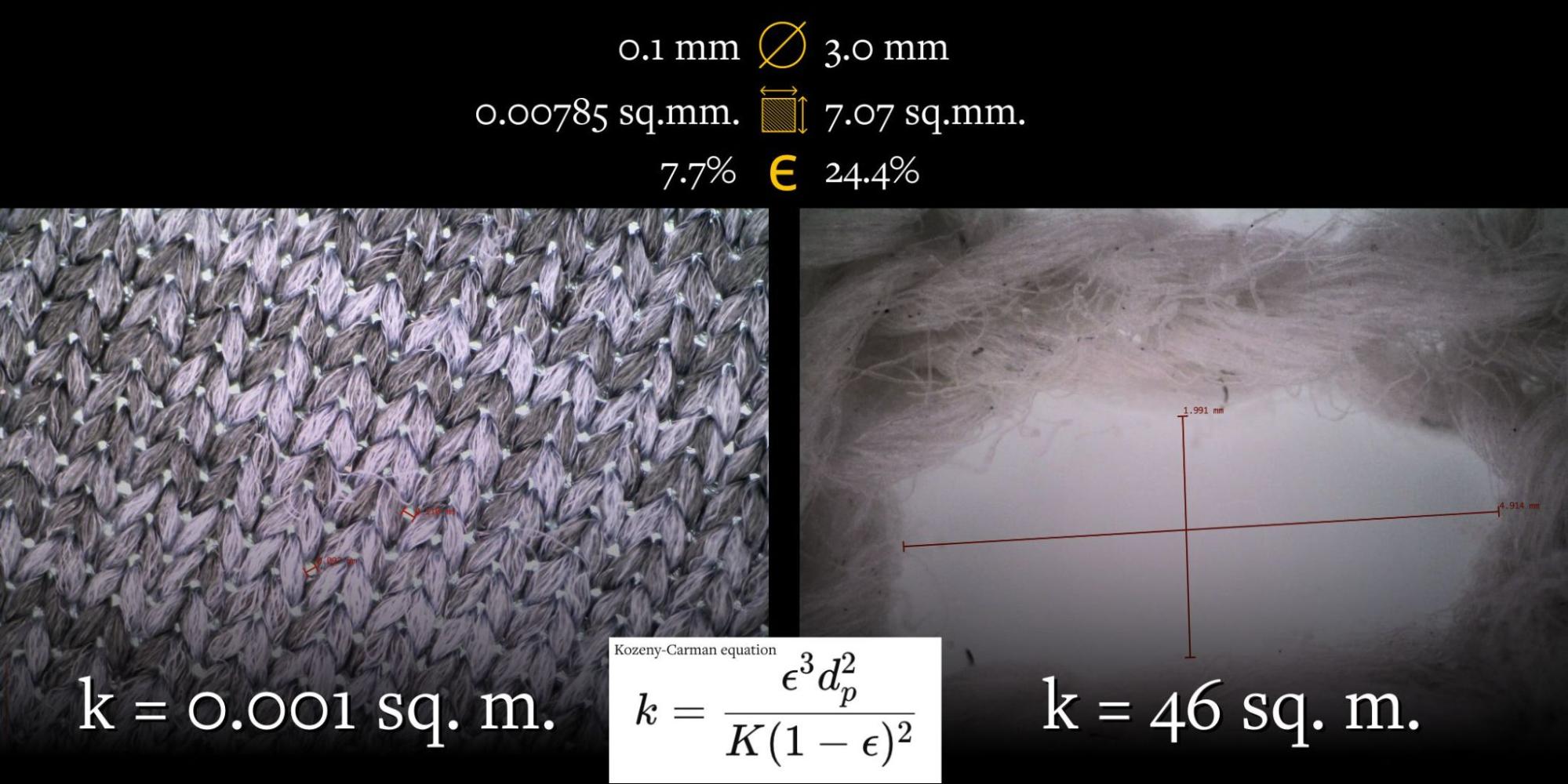

Vapor diffusion is governed primarily by pore size (diameter) and overall fabric porosity.

In this example, the fishnet has holes that are 30X larger than the knit and an overall porosity that is 3.2X higher than the knit. However, the compounding effects of these differences are dramatic – the vapor transport coefficient through the fishnet is orders of magnitude higher than through the knit.

The larger holes of the fishnet serve another purpose – they allow for cool, dry air (e.g., from the outside environment) to be exchanged with warm, humid air next to the skin (through the bellows effect that occurs during movement). As a result, moisture vapor can be rapidly transported away from the skin surface, lowering humidity underneath and inside the base layer.

In addition, the case for fishnet (or any base layer, for that matter) is strengthened if we consider the hydrophobicity of the fibers.

Because wicking works “best” (sic) when fibers are hydrophilic, and wicking is the process we are trying to short-circuit (minimize), then it follows that hydrophobic fibers may be the best option. Barring hydrophilic chemical treatments, fibers that maintain intrinsic hydrophobicity throughout their life cycle include polypropylene (synthetic) and alpaca wool (natural).

My personal preference is a fishnet base layer made with polypropylene fibers. It retains the highest degree of hydrophobicity, the lowest amount of water absorption, and the fastest dry time.

The author wearing a polypropylene fishnet base layer underneath an alpaca wool shirt during a winter trek in the Colorado Rocky Mountains.

Ventilation options for outer layers

Recently, I proposed spending a few ounces of pack weight on raingear with extensive ventilation options, such as a full-zipper, adjustable hood, cuffs, and waist, and pit zips. After all, even if you wear a hydrophobic fishnet base layer, if you encapsulate it in an outer layer of clothing that’s poorly ventilated, you’re still going to suffer the Mancusi Dilemma and eventually reach 100% RH inside your clothing system (and subsequently suffer the same consequence of liquid moisture condensation and accumulation).

Outer layers with extensive ventilation options allow two things to happen – warm, moist air can exit the system (minimizing condensation), and cool, dry air can enter the system (allowing for additional humidity to be generated during exercise without condensation).

Summary

In this article, we explored the challenges of moisture management in cold-weather backpacking, focusing on the limitations of traditional wicking base layers. It introduces the “Mancusi Dilemma,” where wicking fabrics quickly become saturated, leading to condensation and discomfort. I propose fishnet fabrics as a solution – their open pore structure and hydrophobic properties facilitate rapid moisture vapor transport and minimize condensation. Don’t neglect the importance of well-ventilated outer layers to enhance moisture expulsion. By combining fishnet base layers with breathable and ventilated outerwear, backpackers can potentially achieve superior moisture management and comfort in cold conditions.

Learn more

- Our clothing systems module in Basecamp Live dives deep into the science of thermoregulatory comfort, which forms the basis of various layering system frameworks for different environmental conditions. Basecamp Live is our most comprehensive live online skills course for backcountry users.

- Sometimes, a wet base layer just can’t be avoided. Soaked-based layers happen. Here is why it will happen to you.

- Moisture-wicking fabrics (base layers and underwear) are designed to move sweat away from the skin. In this study, we test if Polartec and other base layer fabrics meet manufacturer claims.

- An example of how and why some fabrics are prisoners of wicking physics.

- Listen to one of our podcast episodes about fishnet base layers.

- See our recent review of Brynje fishnet base layers.

Disclosure

This article is sponsored by Brynje of Norway. The sponsor did not participate in any way whatsoever in defining the topic, editorial direction, outline, link or product placements, review, or editing of this manuscript. This article is the original work of the author and was developed solely by the Backpacking Light editorial team with no participation from the sponsor. The author has been wearing and using fishnet base layers made by Brynje and others since 1987.

Sponsor’s Message:

Take advantage of innovative fabric structure (big holes) for more effective thermoregulation.

👉🏽 Fishnet (mesh) has big holes. That means the warm, moist air generated during moderate- and high-exertion exercise (like backpacking) can be transferred away from your skin rapidly, before it has a chance to condense into sweat. That sweat then causes both conductive and evaporative cooling.

👉🏽 Fishnet made of merino wool is comfortable and soft next to skin, but when it’s made of polypropylene, the fabric is more hydrophobic and doesn’t absorb as much moisture. This means it dries faster, and doesn’t wet out like more hydrophilic base layers (e.g., so-called “wicking” polyester knits).

👉🏽 Those big holes do double-duty as you layer over your fishnet base layer by trapping warm air. That makes fishnet very warm for its weight – when paired with another layer over it – and much more breathable than conventional knits when well-ventilated. These two properties are rare in base layer fabrics. Fishnet mesh with these properties makes for a very effective type of fabric construction for cool- and cold-weather hiking.

Brynje of Norway has set the gold standard for manufacturing technical fishnet base layers for more than a century. It’s no surprise that you’ll find Brynje base layers on the backs (literally) of the world’s most prominent alpinists, explorers, and Nordic skiers.

Home › Forums › How fishnet works (base layer fabric structures)