Introduction

The effectiveness of a tent stake is critical to the security of a shelter in a backcountry storm. Tent stake holding power, especially in adverse wind conditions, relies on principles of engineering and physics. These principles are governed by stake properties (including cross-sectional shape and length), soil properties (type and density of soil), and the interaction of the stake with the soil (e.g., insertion angle).

This article examines the principles that govern tent stake holding power, analyzing how different designs and lengths interact with various soil types to ensure stability. It explores key elements such as surface area, friction, soil compaction, and load distribution, which are integral to a stake’s performance. Additionally, the impact of insertion angles and soil composition on holding power is discussed.

I close with a series of recommendations for building a stake kit based on my personal experience and preferences.

Table of Contents • Note: some sections may only be available to Premium or Unlimited Members.

Tent stake holding power

This article builds on a previous study we performed by providing additional insight into the reasons why tent stakes hold and fail in response to the forces transferred to them by shelters buffeting in windy conditions.

The holding power of tent stakes can be described using core principles of engineering and physics. Holding power is related primarily to a stake’s cross-sectional shape, length, interaction with the soil, and insertion angle.

Surface area and friction

Cross-sectional shape: Stakes with cross sections that have a large perimeter have more contact with the soil. This increased contact area results in greater frictional resistance, which enhances holding power. Conversely, stakes with smaller coss-sectional perimeters have less surface area and, therefore, lower friction, leading to reduced holding power.

Length: Longer stakes penetrate deeper into the ground, increasing the surface area in contact with the soil. This also increases overall frictional resistance and holding power. Deeper penetration can reach more compact soil layers, which may offer better resistance than layers of soil near the surface.

Soil compaction and displacement

Cross-sectional shape: The shape of a stake determines how it displaces soil as it is driven into the ground. Stakes with sharp edges (e.g., Y-shaped) tend to cut through the soil, causing less displacement. However, the displacement occurs between the stake fins, resulting in compaction of soil coming from both fins. This compaction increases the soil’s density around the stake, enhancing holding power. Thin stakes with rounded profiles (e.g., skewers and needles) displace small amounts of soil without significant compaction, reducing their holding power. Large-diameter tubular stakes displace a lot of soil (due to their high cross-sectional area) and offer good holding power.

Length: Longer stakes compact soil over a greater depth, which can increase the density and resistance of the surrounding soil. This is particularly beneficial in loose or sandy soils, where deeper penetration is necessary for good holding power.

Load distribution

Cross-sectional shape: Stakes with a broad or angular cross-section (like large-diameter tubular stock or Y-shaped stakes) distribute applied loads over a larger area. This reduces the stress on the soil at any single point, which helps prevent the stake from being easily pulled out. Stakes with small, circular cross-sections (like skewer stakes made with small-diameter rod stock) focus the load on a smaller area, increasing the risk of the stake rotating or being pulled out under tension.

Length: The longer the stake, the more evenly it can distribute the load through a greater depth (and thus, volume) of soil. This makes the stake less likely to be dislodged when subjected to strong forces.

Anchoring and soil interaction

Cross-sectional shape: Some stake designs, like corkscrew or twisted shapes, are specifically engineered to “anchor” themselves into the ground. These designs twist into the soil as they are driven in, creating a mechanical grip that significantly increases holding power. Straight, smooth stakes lack this anchoring ability and rely solely on friction and load distribution.

Length: With increased length, stakes can interact with different soil strata, some of which may have different mechanical properties (e.g., clay vs. sand). A longer stake is more likely to encounter soil layers that provide better anchoring or resistance to pullout.

Soil type considerations

The interactions between stake shape, length, and soil type contribute to holding power. For example:

- Wider and longer stakes are generally better in soft or sandy soils, as they increase surface area and friction.

- In hard or rocky soils, shorter, more rigid stakes with a narrow profile may be more effective because they can penetrate without bending or being deflected.

Insertion angles

There is some controversy (and plenty of backyard test results) about tent stake insertion angles. Claims that a particular insertion angle is more optimum than another are generally based on data sets that are too small to draw any meaningful conclusions. The holding power of a tent stake as a function of its insertion angle is highly dependent on both the length of the stake and soil properties.

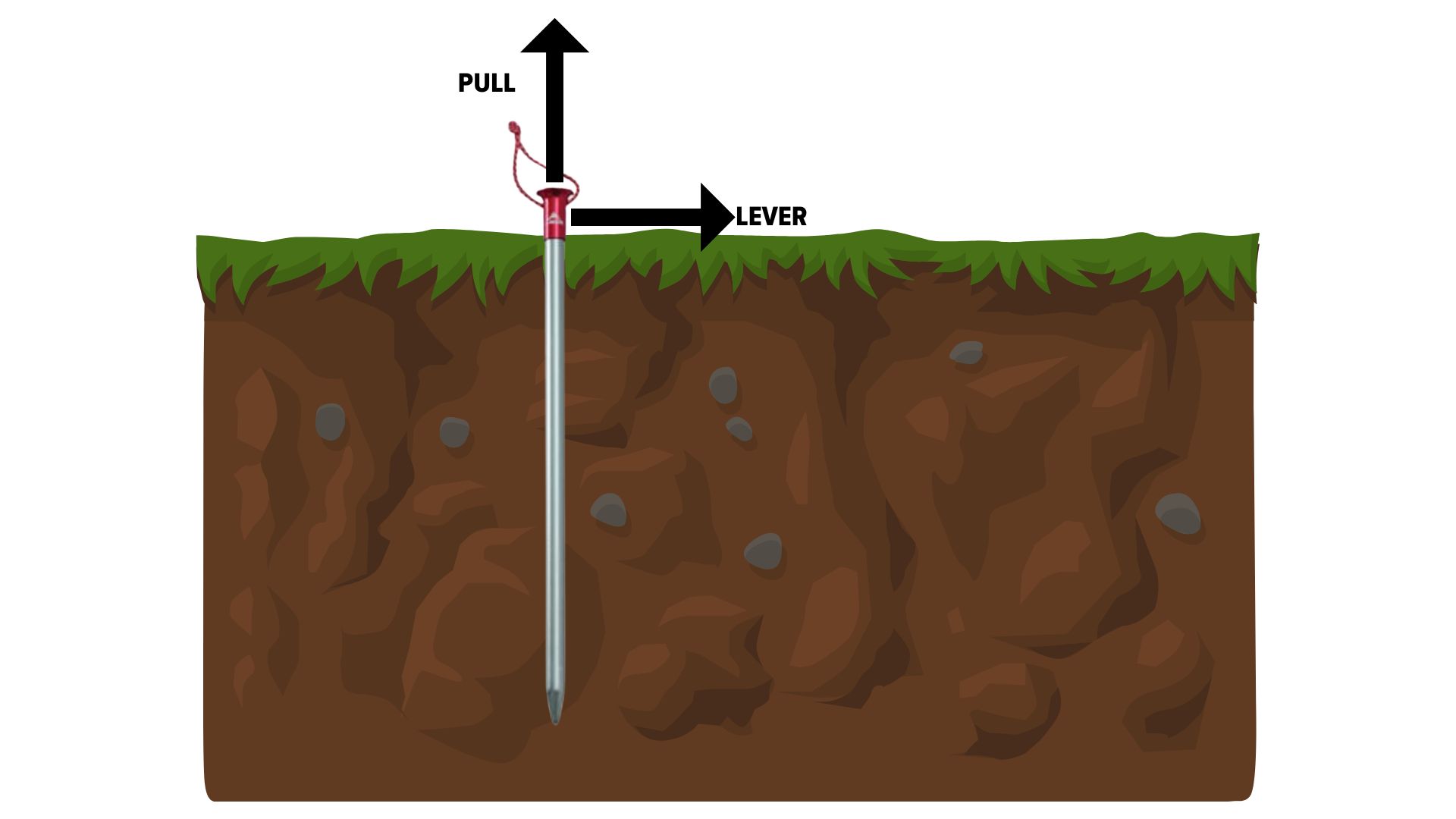

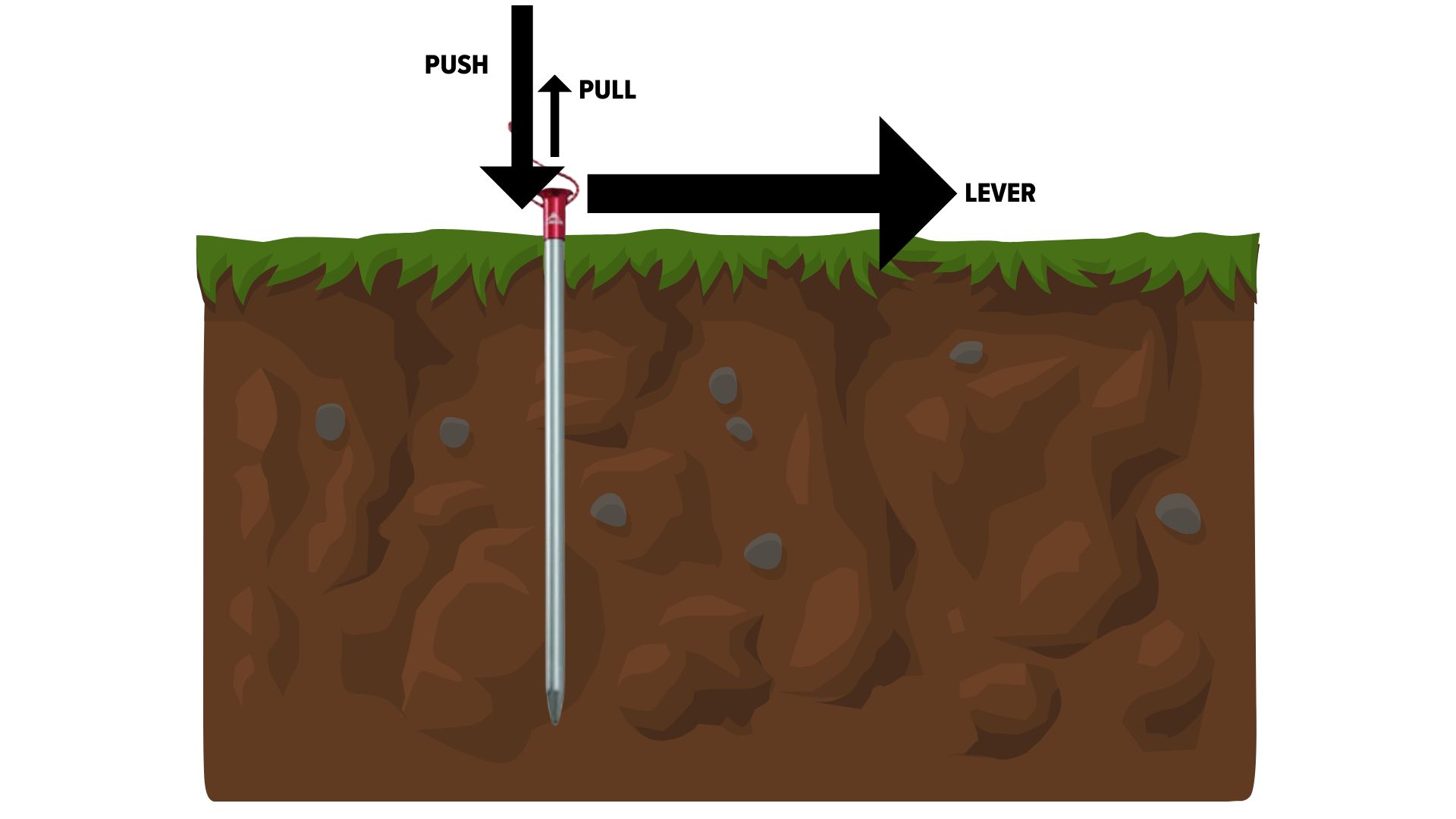

The tension force applied to the head of a tent stake (via its guyline or shelter stake-out point) can be split into two components:

- The pulling force, which is parallel to the length of the stake; and

- The levering force, which is perpendicular to the length of the stake.

When any stake is inserted into soil, it displaces soil along its length, which results in a much lower pulling force required to remove the stake than the pushing force required to insert it. This pulling force is always less than the levering force required to dislodge a stake. The size of the arrows in the following image shows the relative magnitude of each of these forces.

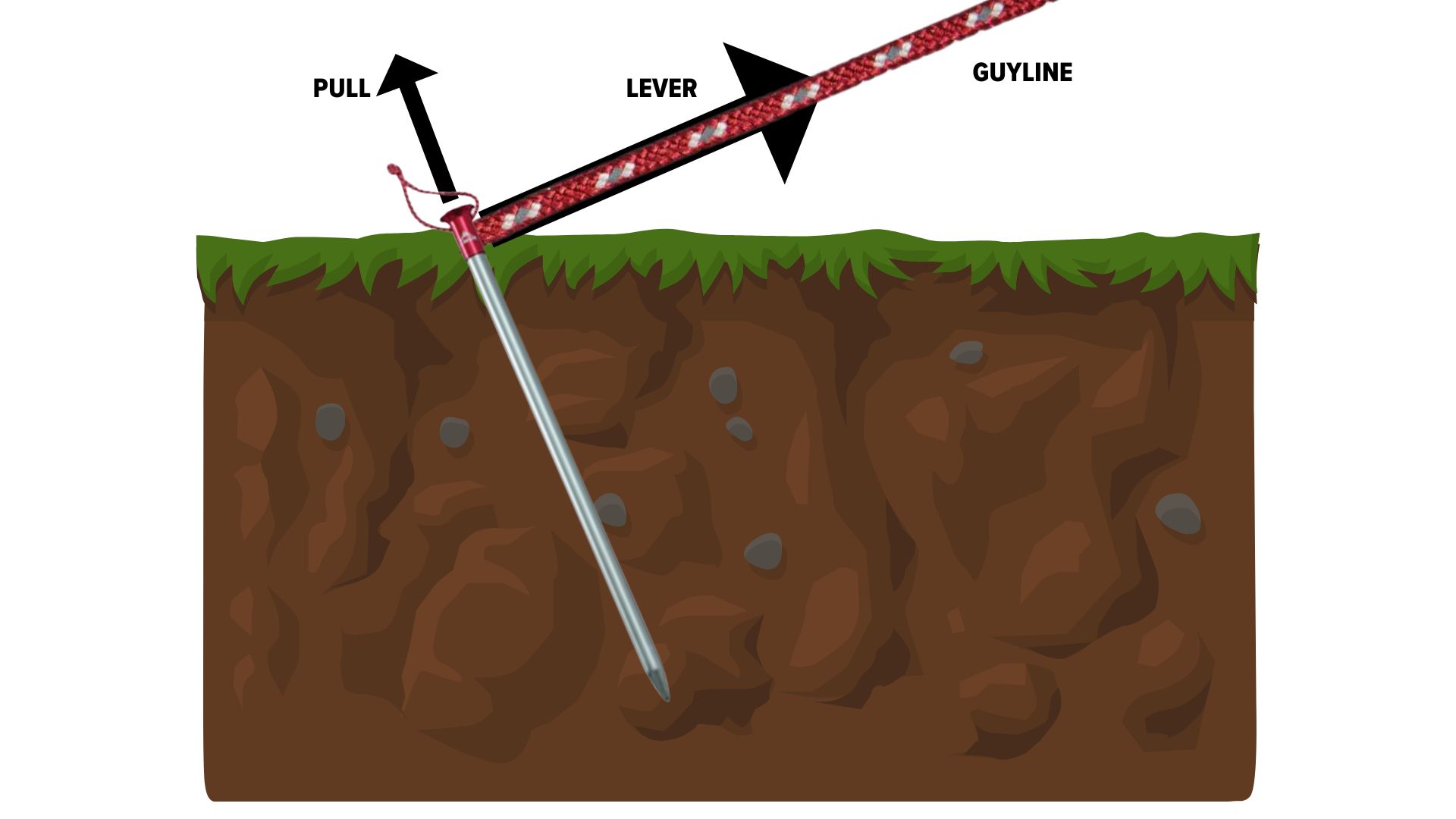

Because nonuniform soils are usually more compact at deeper depths, the maximum resistance to levering of a tent stake will occur when that stake is inserted vertically relative to the ground surface. In this case, the strongest holding power will occur when the tension pulling on the stake is parallel to the ground surface. However, except in the case of ground sheets under tension, this orientation is rarely optimal – guylines and most shelter stakeout points will exert forces at an angle that is not parallel to the ground surface. Consequently, the user may place the tent stake into the ground at an angle that is offset from vertical, to maintain perpendicularity between the length of the stake and the levering force of the guyline. The following image shows this:

However, with stakes that are too short, or in soils that lack good compaction in its upper layers, placing the stake an an angle offset from vertical can be problematic. In this case, the stake may be poorly anchored, and the benefit of perpindicularity between the levering force and the stake length may be offset by weaker anchoring, which creates less resistance to levering. This makes a compelling argument for long guylines and shallower guyline angles (which allow the stake to be placed in an orientation closer to vertical).

By now, it should be clear why there’s no one “optimum angle” for placing a tent stake in the ground. Because of the wide variability in soil compaction as a function of depth, a little bit of engineering intuition that acknowledges these competitive factors, combined with experience in different soils and a dose of quick and dirty tests performed at your shelter pitch site go much further than dogmatic recommendations about what angle to insert your stake in the ground.

Let’s explore this further with a brief case study,

Case study

In this case study, I performed a series of tests using short and long stakes (6″ and 9″ MSR Core stakes), in loamy vs. sandy soil plots. All stakes were placed vertically. A load tester was used to measure the pulling and levering forces to failure. Each test was repeated 6 times in different locations. The results represent the average of each test. Standard error percentages were 15 to 25%.

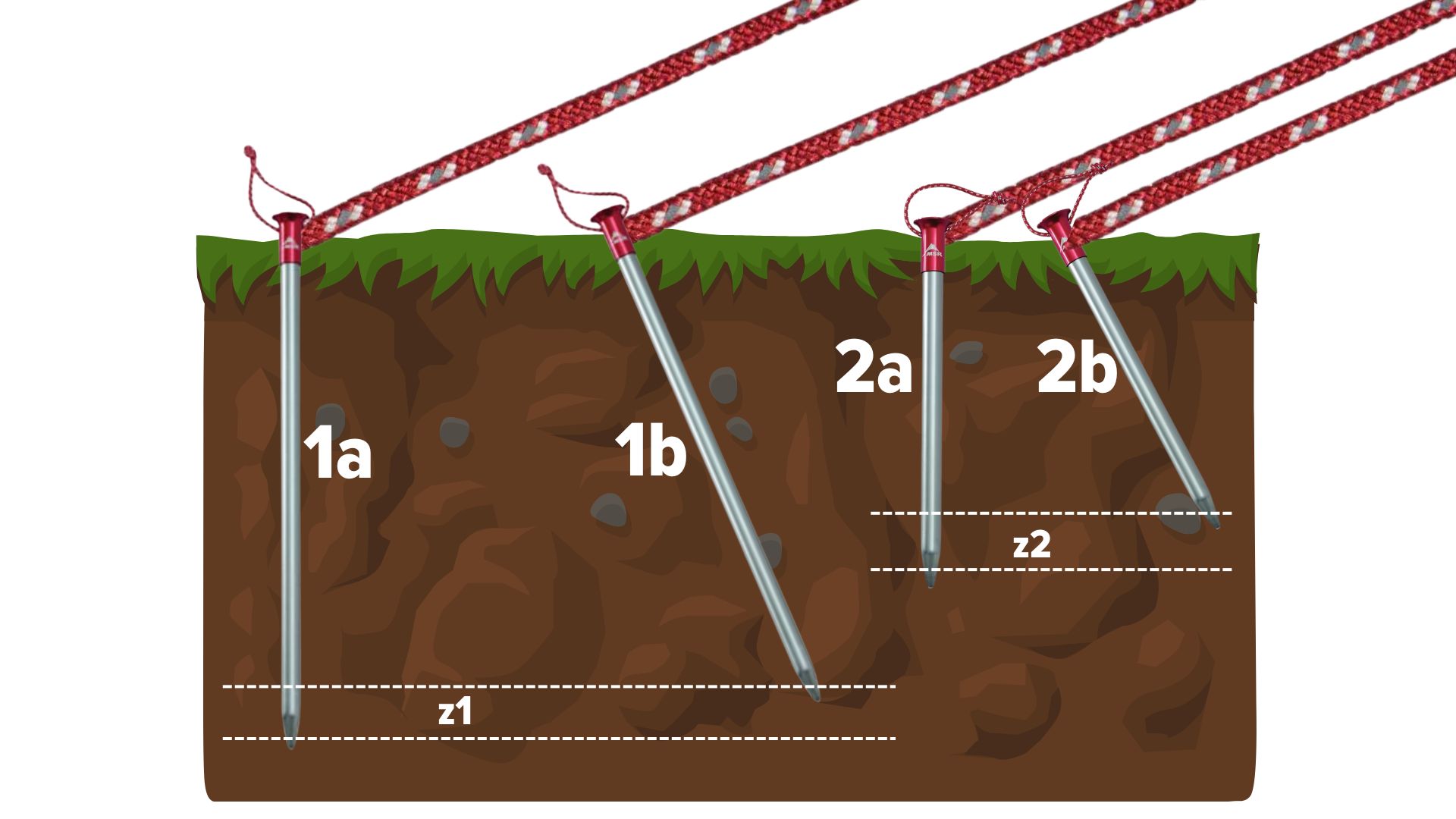

In a typical loamy soil near the ecological edge of a forest and meadow, soil compaction is not uniform across its depth. It may be a less compacted, low-density mixture of sand and organic litter in the upper few inches, and a compacted, dense mixture of sand, silt, and clay in the lower layer.

In this type of soil, the pulling force required to dislodge a 9-inch Easton tubular tent stake is generally around 12 to 15 pounds, while the levering force required to dislodge the same stake is 50 to 60 pounds.

It follows that the force required to dislodge the same stake from the same soil when the force is applied at a 45 degree angle is around 15 to 22 pounds, and that the primary mode of failure will be pulling (not levering).

What happens if we repeat the same test in a more uniformly-compacted (sandy) soil or with a shorter stake with lower holding power?

Table 1. Case study data showing the forces required to dislodge short and long stakes in loamy vs. sandy soils.

| pulling failure | lever failure | 45-degree failure | type of failure | |

| 9-inch stake, loamy soil | 12.2 pounds | 54.7 pounds | 16.3 pounds | pulling |

| 6-inch stake, loamy soil | 5.5 pounds | 18.7 pounds | 8.5 pounds | pulling |

| 9-inch stake, sandy soil | 8.4 pounds | 24.2 pounds | 13.0 pounds | pulling |

| 6-inch stake, sandy soil | 3.0 pounds | 7.1 pounds | 4.0 pounds | pulling |

These tests emphasize the importance of encouraging a lever vs. a pulling failure because there is so much more resistance to levering than to pulling. The reason for this is that as a stake is pushed into the ground, it displaces the soil that’s replaced by the stake body. Where does that soil go? It gets pushed outward – thus compacting the soil immediately adjacent to the outer walls of the stake. Two things are happening here – the displaced soil creates a conduit through which the stake can pull out (low resistance), and the newly compacted soil adjacent to the outer wall of the stake creates additional resistance against levering.

Therefore, choose and secure your tent stakes accordingly:

- Set your stake as close to vertical as possible, to maximize the probability that you’ll reach more compacted soils deeper down (Figure 5).

- Align (angle) your stake to minimize the angle between the tension (guyline) force and the ground surface, to minimize the probability that pulling forces will pull the stake upward (Figure 4).

- Stake length may be more important than cross-sectional area in loamy soils than in sandy soils (Figure 5, Table 1).

Recommendations

Stakes for holding power

MSR, Hyperlite Mountain Gear, Tarptent, Mountain Laurel Designs, Outdoor Vitals, Big Sky, and others all distribute their own styles of tubular aluminum stakes. I’ve had several heads and tips break off of Big Sky Tube Steaks, and can’t recommend them. The Mountain Laurel Designs stakes offer a more robust machined head that keeps guylines in place at the top of the stake head, but I never found that feature particularly useful.

I recommend the MSR Core – it’s the most durable and resistant to bending and breakage in hard, rocky soils (it’s also a little heavier than the others). Otherwise, the Hyperlite, Tarptent or Outdoor Vitals versions offer a good balance between affordability and quality.

With a machined aluminum head, long tubular aluminum shaft, and outstanding holding power, the MSR Core represents one of the most durable and strongest stakes on the market.

A very high-quality tubular aluminum stake with high holding power for large shelters, softer soils, and critical stake-out points (e.g., ridgelines) on ultralight shelters. 7075-T9 aluminum, length 8.0 inches (20.3 cm), diameter 0.35 inches (0.9 cm).

Tarptent and Outdoor Vitals both stock the most modern versions of Easton-branded 8.75-inch tubular stakes, which offer good holding power for the weight, reasonable durability, and are more affordable than tubular stakes from Hyperlite or MSR.

Some readers will wonder why the ubiquitous V-channel and Y-channel style of tent stakes are not on my list of recommendations. Longer, larger-diameter Y-channel stakes made with 7000-series aluminum, like the MSR Groundhog, have some of the highest holding power of any stake on the market.

A Y-channel 7000-series aluminum stake that is long, strong, and light, with extremely high holding power. Sharp edges make inserting the stake into the ground without a hammer or rock somewhat problematic.

However, I’ve generally stopped using Y-channel stakes because they are painful to insert into hard ground with the palm of my hand, and they tear up the soles of some of my running shoes when I try to use my foot. Some users rave about the MSR Groundhog Mini, which is shorter, lighter, has less holding power, and still hurts your hands.

As for V-channel stakes, I have set of size L DAC J-Stakes that were shipped with my Slingfin Crossbow, which have about triple the holding power vs. the size S J-Stakes that are shipped with many lightweight tents from mass-market brands such as NEMO, Big Agnes, and others. I’ve swapped some of the J-Stakes in my Crossbow kit out for lighter stakes to save a few ounces, but have kept the J-stakes in my kit instead of tubular stakes to save some bulk (8 to 12 tubular stakes take up a lot of space).

Ultralight stakes

I used to use skewer-style shepherd-hook stakes made with 1/8-inch (3 mm) titanium rod stock. They are light, compact, and very easy to insert and remove in hard soils. However, they are prone to rotation under high tension loads (causing guylines to slacken) and provide low holding power in softer soils.

The OG of ultralight titanium tent stakes. Low holding power in soft soils, but extremely easy to insert and remove from hard ground.

I’ve used a variety of carbon fiber shaft stake options, but find them to be more fragile and more expensive than they’re worth. Another way to save weight on stakes is by using very short stakes (3 to 4 inches / 8 to 10 cm) but their holding power is limited to soils that offer a firm upper crust, and stake-out points that don’t get a lot of tension.

I use the Suluk46 Atani for low-load stakeout points and the more versatile MSR Carbon Core for general usage. The latter has better holding power, but are bulkier.

A high-quality, all-purpose ultralight stake that takes advantage of the weight savings of a carbon core and molded head, with a 7000-series aluminum sheath and a sharp, machined tip. Some user reviews report "breakage in rocky soils" - just keep stake hammers and rocks away from them and recognize that if you can insert them into the ground with your hand, these stakes will serve you for many years.

A truly ultralight tent stake with enough strength for hard soils. We use this for accessory guyline tieout points like sidewalls and mid-points. Combine with stronger stakes for a high-performance stake kit.

Durable stakes

I generally consider the MSR Core to be the strongest practical stake available. By practical, I refer to its holding power-to-weight ratio. And by strength, I’m referring to durability. It’s more resistant to breaking and bending than other aluminum tubular stakes on the market. I use it for high-load anchor points for most of my shelters when I need reliable storm protection in most soil types.

However, it’s not durable enough for the toughest situations I face. For example, when I’m using a rock or stake hammer to pound the stake into extremely hard or frozen ground. In these situations, I care less about holding power (because the ground is firm) and more about durability. Titanium rod stock (5 mm, not the 3 to 4 mm rod stock used in ultralight titanium stakes) is about the only material strong enough to withstand abuse while being thin enough to penetrate extremely hard or frozen ground.

My stake of choice here is the Vargo Titanium Nail Peg (note: don’t confuse this with the 4 mm diameter “ultralight” version of this product). I use these in the early winter, when the ground is frozen but the snow isn’t deep enough to use deadmen or snow stakes. When doing so, I also carry the MSR Stake Hammer, which is easier to use in cold temperatures than my hand, boot, or a rock, and prevents me from having to pry frozen rocks out of the ground.

Important: this is not the "ultralight" version - which we do not recommend (lack of durability). This version is made with 5 mm bar stock titanium and is much stronger. We recommend it for extremely hard and rocky or frozen ground.

This is the most practical (usable) stake hammer available that's light enough for backcountry use. With a stainless steel head and light aluminum shaft, it is more effective (more power) than plastic hammers on the market and much lighter than hammers marketed for front-country camping.

Snow and sand stakes

I spend a lot of time camping in the snow with tarps, pyramids, and alpine tents. My goal with pitching a shelter in the snow is to reduce effort and get the shelter up as fast as possible with a minimum of fuss.

Below the treeline, I’ll happily use buried sticks for deadmen anchors, tied to the shelter with a self-releasing tension hitch (e.g., trucker’s or McCarthy). Then, when it’s time to break camp, I can release the hitch, leave the anchor, and pack quickly.

Above the treeline, I like to use skis, snowshoes, ice axes, or poles (assuming I don’t need them for activities away from the shelter). However, I also carry a handful (four to eight, depending on the shelter) of purpose-built snow stakes. I used MSR Blizzards for years, but a set of eight weighs half a pound (I do like that they double as a trowel if necessary).

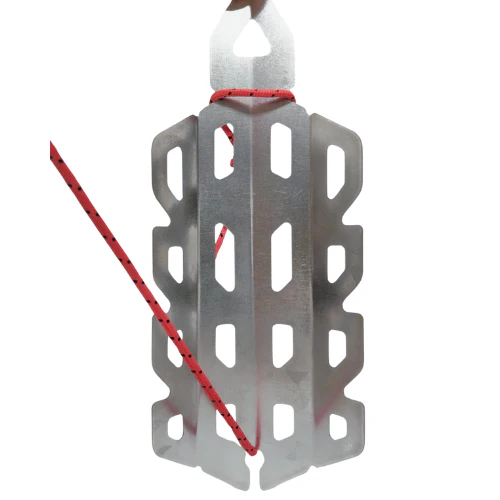

In 2012, I purchased my first set of Suluk46 titanium stakes, upgrading to their most modern design, the Suluk46 Olik Titanium Snow Stake, most recently.

I’ve also used fabric anchors, 24″ carbon fiber arrow shafts, stow bags, bollards, and other strategies for anchoring shelters in the snow, but I keep returning to the ultralight Oliks. (I use them for sand camping as well.)

With an engineered beam design that resists bending and cutouts + thin-walled titanium to reduce weight, the Suluk46 Olik stakes have the highest holding power-to-weight ratio of any snow stake available. Easy to set, easy to retrieve, and the cutouts improve snow sintering and holding power in low-density snow.

Guylines

Designer ultralight guylines? I understand the appeal. Being able to claim exorbitant breaking strength-to-weight ratios, miniscule diameters, and UHMWPE ingredients should drive up margins pretty good for guyline marketers! However, I look at other features as well: knottability, water absorption, tensioner slippage, and whether or not the guylines can be purchased in bulk quantities.

First things first – I buy a LOT of guyline cord. I rig custom sets of guylines for every shelter I own and use. This keeps things easy for me. I don’t want to have to dig around a guyline bin and rig whatever shelter I want to use on a trip from a limited supply of guylines prior to a trip, remove the guylines from the shelter and return them to the bin after the trip, and repeat the process. For me, each shelter gets its own guyline set. So, considering that I use several different tarps, pyramids, trekking pole tents, and conventional tents every year (it comes with the job), I build and maintain several hundred feet of guyline cordage.

That’s why I stopped buying 50-foot hocks of designer guylines several years ago, and shifted to a guyline that I could purchase in bulk quantities.

I went through a 100% Spectra phase in the 1990s and 2000s, but grew tired of poor knottability and the cord slicing through stakeout loops and fingers.

I used to use the same 1.5 mm polyester with a UHMWPE core that’s now sold by Ripstop by the Roll. It’s cheap (about 20 cents a yard from wholesalers, 50 cents a yard at retail) and light (about one ounce / 28 g per 50 feet), but not very durable. Same goes with 1.4 UHMWPE Core from Hyperlite Mountain Gear. Unfortunately, both of these cords suffer from a low-density polyester sheath that is poorly durable, highly water absorbent, stretches when wet, and stingy when it comes to releasing tightly-bighted knots.

In my hunt for a UHMWPE-core guyline with a high-tenacity, tightly-woven, less absorbent sheath that still didn’t slip when knotted or strung through a tensioner, I discovered Lawson Guywire (non-reflective), Glowire (reflective) and Ironwire (higher strength, stiffer hand). With a slightly larger (2 mm) diameter and a high-density polyester sheath, it tangled less and was easier to unknot than any other guyline material I tried. It absorbed a bit less water, which I appreciated in the winter (my guylines didn’t freeze water inside them to the point where they became unusable). In retail quantities (50 foot hocks), Lawson cordage runs about 60 to 90 cents a yard.

The new gold standard for lightweight shelter guylines, Guywire and Glowire cordage holds knots, absorbs little water, is lightweight, has minimal stretch, and holds well in both cam and line-loc style tensioners.

Tent stake pull cords & ultralight guylines

Most of my tent stakes are rigged with pull cords, to make extraction easier and to give a bit of a visual color cue to my stakes to prevent them from getting lost. I use Atwood 1.18 mm Reflective Micro Cord, which is also available in bulk spools. It’s lighter, thinner, and cheaper than most guyline cordage, and may serve users who have more knot patience than I for ultralight guyline usage. I’m also still working through a supply of ZPacks 1.3 mm Z-Line, which has a stiffer hand (which is nice for tent stake pull loops) that makes for less-tangly ultralight guylines than the Atwood cord but is a little more expensive and a little more difficult to knot.

For ultralight guylines, or rigging tent stakes with pull loops or stuff sacks with drawcords.

Stiff hand, low water absorption, minimal stretch. The 1.3 mm version slides through lineloc tensioners under high loads, but holds knots well.

Stake bags

Ultralight stake bags are a funny thing, and I have an unhealthy obsession with their design. Few pieces of gear have irritated me as much through the years as a stake bag. They’re either too small, made with fabrics that are too fragile, poorly sewn, use tiny toggles designed for tiny fingers on tiny people that do not exist, or shaped in such a way that makes the process of stowing and retrieving the stakes more effort than necessary.

Before I interviewed gear designer Livio Melo on the podcast, I had the chance to try one of his creations – the little Hölster stake bag – a very functional little bag that’s perfect if you carry an ultralight stake kit that includes half a dozen short and skinny pegs (e.g., titanium skewers).

I became very fond of that bag, but I found myself transitioning to longer pegs for stormier weather, and they didn’t fit. So I returned to Livio, confessed my dilemma, and went through a few prototypes with him. We finally landed on a design we’re calling the Hölster PRO (i.e., a larger and more durable version of the Hölster). I ordered a batch of stake bags for some marketing giveaways and new membership bundles (I also kept one for myself).

They have a tapered opening for easy retrieval and stowage of stakes. They are long and wide enough for a BIG stake kit full of stakes, many of which can be long and tubular. The drawcord has a reverse-pull mechanism that makes the stake bag easy to open and close with cold fingers. And it’s made with heavier fabrics to protect the rest of your gear, and ensure that the stake bag lasts a long time.

It holds up to two dozen stakes + guylines, including MSR Blizzards, Suluk46 Oliks, and Easton 9″ tubes; it’s made of 1.5 osy DCF, and weighs less than half an ounce (14 g).

What I use

My stake kit most commonly includes the following selection:

- 2x MSR Core stakes for shelter ridgelines

- 4x MSR Carbon Core stakes for shelter corners

- 8x Suluk46 Atani stakes for side panels and edge mid-points

For camping below the treeline, I may replace the MSR Core stakes with additional short tubular or size M DAC J-stakes.

For extremely stormy conditions above the treeline, I may replace the MSR Carbon Core stakes with longer tubular stakes, and half of the Atani stakes with size M DAC J-stakes.

I don’t skimp on guylines. In addition to rigging all of the guyline tie-out points on a shelter, I’ll take 4 to 6 additional guylines (6 to 8 feet long) to extend existing guylines to trees, etc.

Related Content

- Webinar: How to Pitch an Ultralight Tent

- Webinar: Your Tent, Your Campsite, Your Comfort

- Test Report: Tent Stake Holding Power

Use the coupon code HOLSTERPRO at checkout to become an Unlimited Member today ($20 off your first year) and claim your free allmansright × Backpacking Light Hölster PRO Stake Sack.

DISCLOSURE (Updated April 9, 2024)

- Backpacking Light does not accept compensation or donated/discounted products in exchange for product mentions or placements in editorial coverage. Some (but not all) of the links in this review may be affiliate links. If you click on one of these links and visit one of our affiliate partners (usually a retailer site), and subsequently place an order with that retailer, we receive a commission on your entire order, which varies between 3% and 15% of the purchase price. Affiliate commissions represent less than 15% of Backpacking Light's gross revenue. More than 70% of our revenue comes from Membership Fees. So if you'd really like to support our work, don't buy gear you don't need - support our consumer advocacy work and become a Member instead. Learn more about affiliate commissions, influencer marketing, and our consumer advocacy work by reading our article Stop wasting money on gear.

Home › Forums › How do tent stakes interact with soils to create holding power?