Topic

How did your DCF shelter age (and expire)?

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

Home › Forums › Gear Forums › Gear (General) › How did your DCF shelter age (and expire)?

- This topic has 199 replies, 27 voices, and was last updated 2 years, 1 month ago by

Murali C.

Murali C.

-

AuthorPosts

-

Dec 21, 2021 at 6:26 pm #3735318

So, the question remains for me at least. Will my tent continue to fall apart in other places because of the poor materials, or is it just confined to this area that is patched? I would hate to have a total failure in the middle of a rain storm.

Dec 21, 2021 at 6:45 pm #3735320Arthur – that damage looks pretty severe to me. Sadly I would be quite hesitant to trust that shelter any longer.

For general reference, here are pictures of two of the corners on my first generation (Nov 2013) 0.74 duplex. I see absolutely no deterioration of any kind with the possible exception of some wrinkling from being packed and unpacked. And as Joe mentioned, you can clearly see the black hybrid fabric reinforcements. Another obvious difference between these corners and those on Arthur’s shelter is the double row of stitching at the corner attaching the tie-out, and the lack of the box stitch near the top of the reinforced patch. Could that box stitch be a contributing factor?

Dec 21, 2021 at 7:04 pm #3735322

Dec 21, 2021 at 7:04 pm #3735322Hi Monte,

Thanks for your efforts to follow up with Joe and for sharing his interesting response. It’s great to get his take. I was also here on BPL way back in the beginning when Joe started Zpacks and remember those days with fondness (e.g. the rumors of a 9oz shelter which turned out to be the Hexamid). I had some of his earliest packs, so I have no ill will towards them and think your sentiment/defense for Zpacks is great and provides a more balanced discussion.

As you say, I am now in a conflicted situation since I have commercial interests of my own, where my posts can be viewed with suspicion. Please note that I didn’t bring up this issue as an unsolicited criticism of them. Rather, the issue was raised by someone else while I only explained why it can occur. I did so because I don’t want people to think this type of failure is a normal issue for DCF where it would affect all DCF tents, but rather relates to the construction methods where it only affects certain tents. I don’t expect you to trust what I say about my intentions, but ultimately what matters is the truth of what I was saying. If you look at Joe’s response, you can see there is a fair bit of agreement. He’s also saying it’s not a core problem with DCF but rather relates largely to how it was constructed (e.g. reinforcement slippage, bias stretch, and adhesive gooiness). He suggests a different mix of these construction related factors (e.g. a smaller role for bias and larger role for adhesives) but he does agree that bias probably contributes. We’re not going to fully agree on the relative importance of those factors (e.g. you can see the material is pulling apart on the bias so this type of failure wouldn’t be possible with parallel strands), but ultimately the main takeaway is that this likely is a construction related failure and thus can be avoided and shouldn’t be seen as something normal for a DCF tent.

Disclaimer (if it’s not obvious from my post): I also design and sell DCF tents.

Dec 23, 2021 at 12:13 am #3735403“So, the question remains for me at least. Will my tent continue to fall apart in other places because of the poor materials, or is it just confined to this area that is patched? I would hate to have a total failure in the middle of a rain storm.”

I would be tempted to try patching that with a larger patch of dyneema, glued down with some polyurethane glue. Or some mylar repair tape used for repairing sails. or MLD repair patches (probably the most elegant) https://mountainlaureldesigns.com/product/dcf-repair-sheets/

Dec 23, 2021 at 12:29 pm #3735416Arthur, I would tape it and put it out in your backyard when it is windy etc and test it out for a few days. Since the strands that make the tent are supposed to be very strong, it should be fare well is my feeling. And as long as you are camping such that trees/rocks etc offer natural barriers against wind, the stresses can be alleviated to a certain degree. This may be a good experiment as well:-) Maybe next year end, you will comment on how well the tent has held up:-) I doubt that the tent will fall apart so badly that you will get drenched.

Dec 23, 2021 at 3:28 pm #3735429The back yard is a great idea. Unfortunately for this exercise, I live in the SW and storms are rare here until summer. I posted this earlier, here is the patch that Zpacks suggested with their patch own material. Stay tuned.

Dec 23, 2021 at 5:12 pm #3735437

Dec 23, 2021 at 5:12 pm #3735437Some unattributed statements from this thread:

“Its the 0,5. probably a bad call buying that thin.”

“I have a ZPacks Solo Hexamid in .74 that I have used about 100 nights and it shows no signs of failure, but it admittedly hasn’t faced very strong winds.”

“It’s always been known that .51 DCF has a shorter life span than .74”

“I see a lot of comments here and there about people who have tested a tent only to discover, buried within their review an admission such as saying that they had never faced strong winds during use.”

“It’s a shame that this potentially practically useful thread has degenerated into speculation about personal motivations.”

“I still don’t know if this degradation is from me pitching the tent tight, which I don’t think I have, or material failure.”

“I’m not surprised that Zpacks responded to you by saying that this was normal wear. It exactly what they said to me about baffle failures on a sleeping bag.”

“DSM had some quality issues with their fabric a few years back.”

Taken together, these statements seem consistent, and make me more determined than ever to find some alternative to DCF. But not at the expense of ‘mission creep’. Will not elect something that is heavier than what I began with.

Dec 24, 2021 at 11:03 am #3735461Comment of possible interest here from another thread:

Dec 24, 2021 at 12:28 pm #3735465Yeah good comment. I think what he’s saying there is similar to what I’ve been saying, where pulling on unreinforced bias is going to harm the fabric. The causes permanent deformation pretty quickly, and potentially worse outcomes over time.

Dec 24, 2021 at 2:11 pm #3735468Mostly just needed a larger initial reinforcement corner patch.

Dec 24, 2021 at 2:57 pm #3735469IMO, reinforcement patch size depends on how much the stress is spreading/fanning out. If you have stress from a single point that is fanning out (sketched below) then by definition the stress will be lower as you get further from that point. In this type of situation, you need the reinforcement to extend until the stress is sufficiently low/fanned out.

Conversely, if you have stress acting between two points (e.g. along a ridgeline) then the stress is not fanning out. Rather, you have similar stress along the entire path between those two points. In that case, if you have a failure it may not work to just make the reinforcements larger because it can just move the point of failure to somewhere else along that path that has similar stress yet isn’t reinforced.

Fanning stress typically occurs in tents that use traditional tent poles since the canopy is anchored and supported along lines (where the poles are), whereas trekking pole are supported only at single points (where the poles, guyouts, and/or stakes are) so most of the stress runs along straight lines and does not fan to nearly the same extent. With that said, in the real world stress does still dissipate on trekking pole tents due to factors like stretch, catenary cut, and because it’s getting further from other lines of tension that are also converging at that corner. So yes a larger reinforcement will help for these reasons (and a few others like spreading the strain of stitching) but because the tension that caused the failure is mostly along a straight path (between the corner and pole tip) it may just move the failure point outwards. That’s why almost all DCF tents have a reinforcement tape running the entire length of the span if there is substantial tension on the bias.

Disclaimer: I own Durston Gear where we design DCF tents.

Dec 24, 2021 at 9:51 pm #3735471Hi Dan

If the stress in your tents is as wobbly as those red arrows, then no wonder you have problems!

(Xmas joke)

Cheers

Dec 25, 2021 at 8:12 am #3735480Dan, speaking of traditional poled tents, how did your gold DCF dome tent age and expire? I remember seeing photos of that very impressive early DCF experiment on this forum ages ago.

I think your point about fanning stresses is a good one – clearly some designs will have a greater number of radiating lines of stress from a tie-out than others.

But as you point out, if the panels themselves are taut, and I think we can all agree that any decent tent design should pitch with very taut panels, stress will be radiating through a particular panel in a multitude of directions from all the various anchor points, ridges and hemlines associated with, or adjacent to, that panel.

So in mind at least, a truly durable (in other words, one that does not deform over time) DCF tent would require many more reinforcements than we currently see on the market. That, of course, is infeasible. So we’re left again with the only real solution to this problem, one that has been available for more than a decade: High Bias (HB) DCF.

Dec 25, 2021 at 9:58 am #3735481Ahh yeah…that DCF dome tent, which was really a DCF fly I built to fit on an REI Quarterdome T2 tent. On hind sight, that fly must have been one of the first DCF domes ever built (circa 2010). The actual creation of it went pretty well, especially for a first attempt. Most of it was bonded but the few spots where I did sew (e.g. zippers) were a bit unsightly as I had a terrible sewing machine back then.

Unfortunately I don’t know how it turned out. The next year someone offered to buy it off of me and I wanted the money for some other gear, so I sold it and never heard of it again.

Dec 25, 2021 at 2:15 pm #3735482That’s pretty amazing for a first attempt. Looks pretty taut. That iteration of the Quarterdome T2 was great. My wife and I used that tent for years, finally moving to a pyramid tent for family trips when its fabric started flaking and peeling. Old-style PU coating:) I remember when BPL first reviewed that tent – it was kind of the first dome that got us into near-UL weights. You must have dropped at least a pound by going with a DCF fly.

It was interesting to hear, in the BPL DCF Podcast (#2, I believe), the DSM rep say that DCF has bias stretch, which makes it feasible for curved-panel designs, like a dome. Do you think HB DCF would offer the foregiveness necessary for use in domes?

Dec 25, 2021 at 4:53 pm #3735483From personal experience, the problem with dome tents is that you get condensation inside the tent up at the top. Then it sprinkles down onto you.

(I made a couple in the 60s.)Cheers

Dec 26, 2021 at 2:32 pm #3735496Regarding DCF and domes, any “stretch” that DCF has is more like deformation. Certainly you can stretch it on the bias, but it doesn’t rebound and that stretch is hard on the material (in addition to distorting it, it leads to delamination). So I certainly wouldn’t be comfortable relying on that stretch to make it work for a dome. Rather, I’m quite opposed to stretching DCF in that way. However, not all dome shapes need that.

If you think of DCF rolled up onto a roll of fabric, of course it rolls up nicely. That’s because even though the material is created flat, you’re only bending that plane onto a single (simple) curve. There are no wrinkles. Conversely, if you tried to fit a piece of DCF around something curving on multiple axes (e.g. a sphere) it wouldn’t work well at all. Imagine trying to put wrapping paper on a baseball – there’s a ton of wrinkles because it’s curving in multiple directions/axes.

Circling back to tents, a trekking pole tent almost always has the panels as flat planes so no problem using DCF there. Then for a dome tent, the panels could be single/simple curves where DCF can also work great, or they could be multiple/compound curves where wrinkles are going to happen unless you have a lot of stretch, so DCF is not going to work well there. To illustrate, consider the Locus Gear Djedi:

The Djedi is a dome tent, but all four sides are just simple curves so when you break up the shape into those 4 panels then it’s easy to construct with DCF. If you tried to create the fly with a single piece of DCF it would be massively wrinkly (obviously) because it’s a complicated shape, but when that shape is broken up into 4 panels they now just have simple curves where the fabric will fit perfectly. That’s the key thing – the shape needs to be broken up to give panels that only contain a single curve.

Unfortunately that’s not always possible because some shapes are curving in multiple ways at the same spot. Consider the Sierra Designs Mojo (below). It had a much more complicated shape where the panels are curving in complicated ways and you’re simply not going to fit DCF to that shape and have it look good. Flat panels like the door look good, and some parts with simple curves look good, but the sides with compound curves are always wrinkly and loose. I haven’t given this tent too much thought, but I don’t think it would be possible to break it up enough more panels so that you get everything to simple curves – DCF simple doesn’t work with this shape.

So to sum it up, I’d only use DCF on a dome tent where I can break the pattern up into simple curves. I wouldn’t rely on stretch to fit the material to the shape. With that said, some other companies are doing just this. It can be done – I just don’t think it’s ideal design. I’d prefer to work with a shape that doesn’t have those issues – and also needing to break the shape up into a ton of panels adds a lot of weight and cost so it’s the opposite of minimalist design.

Disclaimer: I own Durston Gear where we design and sell DCF tents.

Dec 28, 2021 at 4:55 pm #3735594How about apex guylines? The post by Stumphges on this page about the tarptent li mentions them and then the thread ( 24 pages – yikes!) over on treklite also mentions them and evidently H Shires incorporates them into some of his designs. Couldn’t that help alleviate stress on the corner ground pegs. Of course it would rely on a well-reinforced peak attachment. And maybe some shock cord?

Also in those linked threads couldn’t help but notice that H Shires immediately quashed the idea of mid-panel guys on the SS2. It makes sense that putting a guy attachment mid panel on a DCF tent with a more or less wide rectangular panel and then subjecting that to heavy winds just seems to be asking for trouble.

Am I getting that right? Or does some extra panel tension sometimes help shed wind?

Dec 28, 2021 at 5:09 pm #3735595obx hiker, both the Stratospire and X-Mid have apex guy lines. I think they help a lot with both tents. I think they help a lot with single-pole mids as well. I have several monopole mids that have two apex guy lines. They stabilize the top of the pole quite well. And if pitched with an A-frame pole setup oriented orthogonally to the apex guys, the whole structure becomes very solid. Probably they do relieve some stress at other stake points, and I think it is relatively easy to reinforce the DCF for them to be very sturdily anchored to the top of the pole(s). I recall that Dan D. wrote a fair bit about his apex guys at some point, but don’t recall where that was.

If I understand Henry correctly, I think what he wrote about mid-panel guys gets to the heart of the bias instability problem, kind of worst-case maybe. And as Dan wrote, above, he had mentioned very similar things earlier in this thread, and prior to that in the Bias-Stable DCF thread, where he wrote about how unstable the midpanel guys are on the Duplex, the ones near the middle of the two big main panels – ah, several posts from the top in this thread: https://backpackinglight.com/forums/topic/where-is-the-bias-stable-dcf-for-tents/

Dec 28, 2021 at 5:18 pm #3735596That’s an interesting point about the orientation of the apex guylines relative to an A-frame pole setup in a monopole mid. I’m going to have to try that.

‘Nother data point: Xavier (of Tipik) has suggested that it might be better to place the apex guylines slightly below the actual apex (on a monopole design).

Dec 28, 2021 at 5:53 pm #3735597Regarding peak guylines, if you have a situation where there is a problematic line of tension from a peak (e.g. running on the bias from a peak to a stake point) then yes a peak guyline would help in mitigating that since it would shift away some of the load. However you couldn’t be sure users would always use them, as they might pitch without and then a wind picks up, so I wouldn’t do this instead of solving the core problem but it is a nice augment. Of course a guyline helps for any line of tension that sees a lot of stress since issues can always come up (e.g. pulling out a stake). As for the location, the key thing is getting the guyline pulling along the ridgeline (for a 2 pole tent) or off the peak (for a 1 pole tent, ideally opposed with a matching peak guyline on the opposite side). Either way you are trying to pull on the peak, so the closer the guyline can attach the lower the risk of deformation. But as long as you have heavy reinforcement between the peak guyline and peak, there’s probably minimal risk of deformation since you’d never just have unreinforced DCF between a peak guyline attachment and the actual peak.

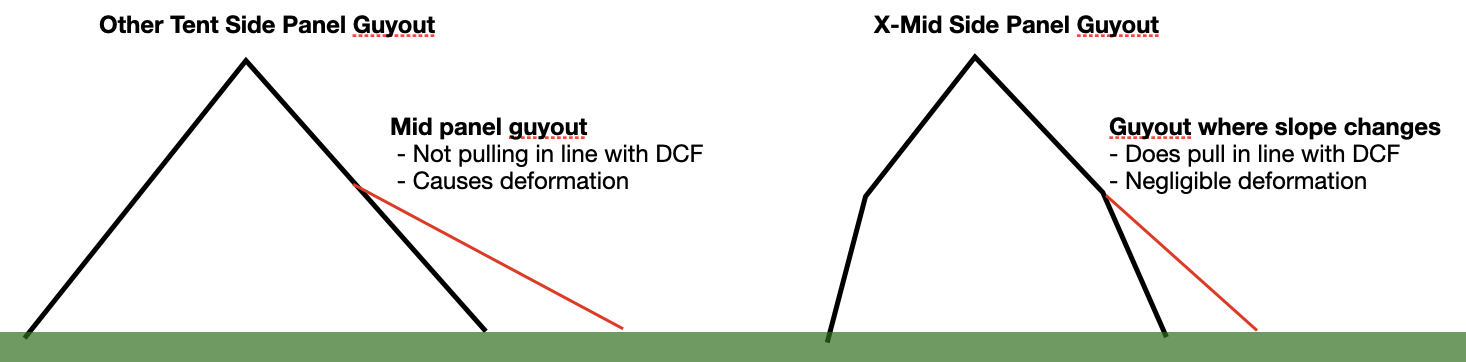

Regarding mid-panel guyouts, Henry mentions avoiding mid-panel guyouts on DCF tents because they pull at angle that are not in line with the material and that deforms the material via permanent pockets/bubbles of loose fabric. I agree with him on this. This point relates to the bias stretch I’ve been talking about (this bias stretch is largely what allows this to happen), but also is a bit more complicated (long story). Anyways, we agree on avoiding mid-panels guyouts on DCF since they are either pulling in a poor direction causing deformation, or if they are pulling parallel to the panel (staked right along the edge of the tent) where they aren’t really doing anything. Of course some other tents mentioned here do have these. They do work for adding space when you use them, but since it permanently deforms the material you have to always use them or you get loose ‘pockets’ on the panel from deformation, and over time it increases the risk of delamination. That’s much different than a woven tent where there is stretch but it rebounds rather than permanently distorting. Even then, you don’t really want to pull out/distort the shape, but rather just avoid it from deflecting inward, as MLD recommends.

With the upcoming DCF X-Mid, we have side panel guyouts, but they are designed to avoid the distortion Henry mentions. That’s because they are not mid panel guyouts (e.g. in the middle of the panel where they pull out at some perpendicular angle), but rather they are along a seam where the side of the tent changes slope, so the guyline extends the slope of the upper panel and thus does pull in line with the material. This sketch may make this more clear:

Disclaimer: I own Durston Gear where I design and sell DCF tents.

Dec 28, 2021 at 9:23 pm #3735607Ahh the original Jumperhome thread complete with Pico des Mulieres and Aneto! I was dreaming about that country and Covid came along. Guess I missed the thread taking a little trip in the Smokies and then spending the rest of October getting ready for my daughter’s wedding. Sorry if I have caused any of you to repeat yourselves but thanks for all the info and Stumphges for the link.

Also nice little sketch Dan. Perfect illustration. Appreciate everyone’s patience and thoroughness!

Ohh and PS props to Arthur for raising the question! Bet he didn’t plan on spending that $ to school us all on the properties of dcf on the bias. What a world.

Dec 29, 2021 at 10:03 am #3735633Dan, that makes sense. So we’ve identified another type of DCF deformation – ‘pocket’ formation at mid-panel guyouts. Anything that obligates the user to use more stakes is a huge problem, IMHO.

What do you think of mid-ridge guyouts and DCF on conventional, single-slope ridgelines? Normally, these are guyed out so as not to change the angle of the slope or deform the adjacent panels, but rather to prevent wind gusts from deflecting all inward, so intuitively they seem OK, but I could be wrong.

Jon, I think the reason for bringing the apex guys down a little from the apex is simply to prevent the line of force from that line pulling the top of the tent off the top of the pole. This probably is not a big deal if there are two guys opposing each other, but with a single guy extended in the direction of the door, for instance, that apex will tend to slip off the pole if the line is actually attached to the apex.

I’d like to thank Dan and Henry for offering their very informed thoughts on this issue. I’ve felt that plastic deformation in DCF tents is the elephant in the ultralight room for some time, and Dan, Henry and Yama Mountain Gear are the only companies working with DCF that have publicly acknowledged this problem, as far as I’m aware. I think that’s a good start.

But what ultimately needs to happen is for DSM to scale up production of bias-stable (“High Bias (HB) DCF) to justify the big price increases they will impose in the new year.

As Dan explained in this post, HB DCF would solve most of these problems.

It appears to me that DCF tent manufacturers are not in a position to demand HB DCF, or perhaps even to fully articulate the problems that bias deformation causes for them and their customers, after all their supplier holds monopoly power on this product.

That means it’s up to the backpacking consumer to agitate for this change.

Ryan Jordan signaled near the end of his DCF Webinar that he may take on bias instability and HB DCF in a future webinar. That would go a long way to bringing awareness and understanding of this problem to backpackers, and perhaps catalyze some change at the supplier.

Dec 29, 2021 at 10:16 am #3735634I’d like to add my voice to Stumphges’ well expressed note of thanks and appreciation to Dan and Henry and also everybody else who has contributed to this thread.

I’d love to see Ryan take on that project on behalf of the “backpacking consumer” and in fact wrote him a PM not so long ago to urge him to do just that.

Stumphges: I suspect that moving the apex guyline down a few inches off the actual apex on a monopole tent allows for greater stability when used in conjunction with woven fabrics like silpoly or silnylon (rather than laminates like DCF) and placed along the ridgeline (which is how Xavier does it).

Dec 29, 2021 at 11:01 am #3735638I agree high bias DCF would be a good thing

I suspect that the backpacking community is not large enough to drive any change. Sails for boats is where most of their market is. I wonder if they would benefit from high bias DCF

-

AuthorPosts

- You must be logged in to reply to this topic.

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

Our Community Posts are Moderated

Backpacking Light community posts are moderated and here to foster helpful and positive discussions about lightweight backpacking. Please be mindful of our values and boundaries and review our Community Guidelines prior to posting.

Get the Newsletter

Gear Research & Discovery Tools

- Browse our curated Gear Shop

- See the latest Gear Deals and Sales

- Our Recommendations

- Search for Gear on Sale with the Gear Finder

- Used Gear Swap

- Member Gear Reviews and BPL Gear Review Articles

- Browse by Gear Type or Brand.