Topic

why tents fail in the wind

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

Home › Forums › Gear Forums › Gear (General) › why tents fail in the wind

- This topic has 172 replies, 33 voices, and was last updated 4 years ago by

Roger Caffin.

Roger Caffin.

-

AuthorPosts

-

Mar 5, 2020 at 10:03 pm #3634454

I’ve been trying to figure out the “mechanism(s)” by which ultralight tents fail (rip out from their stakes) in moderate winds.

Obviously, stake-holding power and the particular tent’s ability to act like a sail rather than spill wind have a big impact.

In years of data collection, I’ve been a little perplexed why so many failures occur in moderate, sustained winds. I always suspected it was related to stake tension (or stake quality, which in turn affects how much tension you can deliver to the stake via the guyline). I also figured it was related to the cumulative effects of dynamic loading over long periods of time (why did my tents always fail in the middle of the night, instead of when the storm started?).

I’ve been using load sensors to measure guyline forces in sustained winds, and the dynamic loading effects are fascinating. My hypothesis was that higher variability (as a % of pre-tensioned guyline force) of guyline forces on a bad stake, like a short skewer, pre-tensioned at a low level, was much worse than the same force variability (but lower %) of guyline forces on a good stake, like an MSR Groundhog.

Here’s my first crack at it in low wind with a non-aerodynamic, very flappy ultralight tent. This is the rear guyline, facing into a 10-15 mph wind.

Red = guyline is pre-tensioned at 5 lbf

Blue = guyline is pre-tensioned at 20 lbf

I used the same stake in both tests – an MSR Groundhog (8″).

I then evaluated the stake hole and “wiggle-ability” of the stake after the test. The stake in the 5 lbf test was much wigglier (I know, it’s not scientific, but measurable differences of several mm) than the stake in the 20 lbf test after running each test for about 30 minutes.

Not a lot of variability in the forces relative to their averages, but definitely variability in the forces as % deviation from their averages, and in the wiggle-ability of the unloaded stakes post-test.

FYI this is ONE data point in sandy soil. The wind hit the tent at an angle of about 30 deg off perpendicular to the rear wall. No gusts, all measured wind speeds (on this graph of a 30+ second window at least) were in the 10-15 mph range.

Mar 5, 2020 at 11:27 pm #3634459Ryan,

I think that it would help to think about the problem as if the Guy lines were a spring. The issue is not so much the force but the what is called the preload and the stiffness. For example, if you had a 5 mm line tensioned to 20 pounds and the length of the line was 1 foot, it would be relatively stiff. Now take a 2 mm line that was 10 feet in length tensioned to 20 pounds, the line would be relatively soft. With the first line, a wind gust would cause a quick rise in force. The second line would have a lower peak force. My 2 cents.

Mar 6, 2020 at 12:01 am #3634460I operate primarily in deserts where the wind can be tenacious, especially in the spring and fall. Several years ago I decided saving weight on stakes and guylines was “stupid light” for my situation. My shelters are mids, a cat0curved flat tarp (~ 9′ X 8′), and a silnylon TrailStar. I use a Scarp 1 for mountain winter snow and not applicable for this conversation.

I installed LinLoc 3 tensioners on all my “tarp” shelters, switched to 3mm line, and only use long ground hogs and/or long Easton stakes. The only exception is if I expect loose sand (think sand dunes), then I will bring long snow stakes. When staking out a “tarp” shelter, my final tensioning on each guy as I go around the shelter (using the LineLocs) is to pull the line as tight as possible. 3mm line in a LineLoc 3 has never slipped at all, as the 2mm and 2.5mm I used prior occasionally would. A quality shelter should be able to take this kind of tensioning, IMO. When I am done the shelters are as tight as a drum and I never have to re-tension during the night — even when using the silnylon TrailStar in the rain. My mids and flat tarp are Cuben.

BTW, how windy does it get? The granite rocks below are called are ventifacts and the grooves in them are caused by the wind sandblasting the rocks :)

Mar 6, 2020 at 12:02 am #3634461

Mar 6, 2020 at 12:02 am #3634461Well, that was weird. I didn’t insert the hyperlinks in my post for the LineLocs.

Mar 6, 2020 at 1:12 am #3634462What Nick says.

I see a lot of flappy shelters by people who should know better.

Was on an ultralight group weekend a year or so ago. 7of us pitched to camp on an open hillside. Wind changed in night, was 30ish with 40mph+gusts, wet snow shower. All shelters survived OK, 3 were well pitched shelters. In my view, 4 weren’t pegged totally securely and wound down tight and had lost stakes and/or flapped annoying all night. A stronger wind would have been trouble. It was like those 4 owners thought it was just due to weather or bad luck, despite our other 3 shelters being fine.

Most of our Scouts seem to get it right once drilled on a couple of trips.

- Appropriate sized/length/design stakes. (many folks skimp trying to save weight)

- Pitch the shelter properly and taut. (many folks are sloppy – hems should be taut too)

- Then wind in all the lines super tight. (many (most?) don’t do it tight enough IMO)

Mar 6, 2020 at 6:04 am #3634466There are a lot of things that are related to loose flapping tents, tent stake placement, length of guylines, etc.

Wind hammer can be bad. Good stakes can be loosened to failure with a flappy tent. This is one area where cuben performs much worse than nylon for a tent body. The impact pressures can be high for the tent, guylines and stakes as the non-resiliant fabric meets a non-stretch guyline and the stake. Impact pressures can be MUCH higher than steady pressure. For example a 16oz hammer can drive a 16D nail in 4-5 whacks. However, the same nail can support a 50pound load easily without being driven or loosened.

As mentioned tent architecture can be good and bad. But this also includes how “air tight” the tent is. Air pressure tends to “lift” a tent (Bernelli’s Law.) Similar to a large barn in a major wind, opening a door increases upwards lift. A tent staked tightly with doors closed will decrease the lift.

A long guyline will hold better than a short one. The angle of incidence is better. A 30 degree angle is better than a 60 degree one. A long guy line will have some stretch, anyway, reducing wind hammer, but, it will also pick up some pressure from any wind.

Lubrication is another factor influencing stake strength. Muddy soil will not hold a stake well. The water tends to lubricate the soil’s particles. Conversly, damp soil can makes the particles stick together. Dry soil can crumble loosely when initially planting a stake.

Ripping out of the fabric can occur with some fabrics (say light poly’s.) A tight tent made from .8oz poly can simply split. 20 year old nylon can do the same.

More?

Mar 6, 2020 at 6:09 am #3634467Ryan – This is great stuff. I hope you keep pursuing this line of investigation. Nick, Mole J and James all make great points could guide further testing.

Mar 6, 2020 at 6:35 am #3634469Agree – This is good stuff

Mar 6, 2020 at 6:56 am #3634470A long time ago I worked in a soils testing lab. But you really don’t need to be a lab tech in a soils testing lab to intuitively know that certain soils with a specific amount of moisture will provide the greatest compaction. That sweet spot looks to be about the same for getting your tent stakes to stay in.

I have a flat 8×10 silnylon tarp. The amount of puffing about in a light breeze is sort of alarming to me, since I’ve got so many bad nights of tents failing in the wind and rain in my memory. I don’t think that having such easily blown around material is good. But my tarp has only failed in very high winds.

My pocket tarp barely moved in a steady breeze. It’s made of DCF. Maybe this lack of movement is worse, but it sure gives me a lot more sense of security so I can sleep.

Mar 6, 2020 at 7:26 am #3634472So, the conclusion is that if you tension the stakes more, they’ll hold up better in the wind because it doesn’t flap so much?

Mar 6, 2020 at 8:15 am #3634475“This is one area where cuben performs much worse than nylon for a tent body”

.+1 to that

… Except when the weather changes from dry to wet sometime over night and the silnylon tent starts to sag all over the place…

Especially from wet, slushy snow…

Mar 6, 2020 at 8:53 am #3634480Generally, I would say that is true, Jerry. Reducing or eliminating wind hammer, aka flapping will definitely help. The downside to this is the increased pressure on the stakes. An object in motion will have less friction than a stationary one. So, any looseness in the stake, say from wind hammer, could simply pull pull it out. Step one is to insure a solid peg point. Then tension any guyline.

I also do a lot of tarp/tebt camping in the ADK’s. There are a large number of loamy duff sites. My usual thin shepherds hook tends to hold moderately to poorly in such stuff. Yet I can about triple the effective holding power of a stake point by adding a second stake. The two together placed in a “V” are quite a bit stronger than two individual stakes. I performed a quick estimate in my yard using a bike scale. A stake perpindicular to the guyline held an average of about 17 pounds or so before coming out. Two stakes maxed the scale at 50 pounds and they didn’t come out. I only did three trials, so in no way was it definitive, but it was telling.

Placement will also help. 45* works for a square tent, but who uses a square tent? A somewhat better placement is angled to the opposite diagonal, not 45*. Example: on say a 7×3’6 tent the angle becomes about 27 degrees…a significant difference.

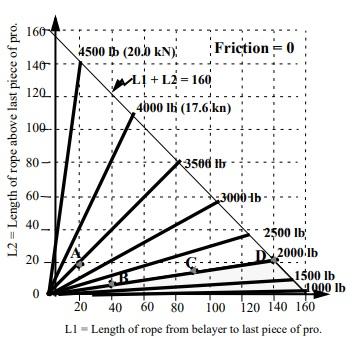

Mar 6, 2020 at 9:24 am #3634483Here is a pretty good article about ropes. The topic is about climbing ropes but that information can be used to discuss guy lines. With climbing ropes, what this paper does is discuss rope elongation with force (not linear) and the force experienced on the protection during a fall. What you can see is that the dynamic load goes up as a function of the rope length: short ropes, higher forces, longer ropes, lower forces.

How does this relate to tents? When you tension a guy line, you preload the rope. When the wind hits the tent, the wind causes the tent to move (temporary displacement) which causes a dynamic increase in tension to the guy line (similar to the fall discussed above). The longer rope has a lower spring rate (stretch per unit force) thereby reducing the peak force on the stake.

Suppose the guy line was a steel rod, a stiff breeze would generate huge forces at the stake. Now replace the guy line with a rubber band. The tent will move, but the force on the stake would be moderate to even.

What makes sense is to have a high pre-load (tension) with a springy guy line to dissipate the shock/high load of a wind gust. That being said, the tent will move around a lot more but the load on the stake will be less. My 2 cents.

Mar 6, 2020 at 9:49 am #3634487that makes sense James and Jon. And everyone else.

worst case, tent/guyline are rigid and loose. You pull on it and when all the looseness is pulled out, then there’s a much higher force on the tent stake

I sometimes put a rock on top of a stake, especially if it’s in loose soil or I can’t get the stake pounded in completely.

Mar 6, 2020 at 10:49 am #3634505The “springy” guyline does work, at least with RV awnings. Most awnings connect to the side of the awning, using two rafter poles connected to a header and then two down poles from the header to the ground. The down poles usually have a metal D-ring to stake then to the ground. Looking at the picture below, you can see the awning is just a sail waiting for a light breeze to take off.

Years ago I bought a hold-down kit: 30’ length of 2” nylon webbing, two heavy duty stakes about 14” long, and an industrial spring. The webbing goes across the top of the awning, pulling down on the two rafters

. The spring goes on one of the stakes.

This works really well. We can leave our awning up in moderate winds while others have to pit theirs away. A few years ago we were camping along the Colorado River in Southern California. While we were out boating on the river, rangers came to the campground to warn everyone that a tornado like event was about to hit the campground and everyone should secure their belongings and take down their awnings. Of course those who had left the campground could not. Late in the afternoon we arrived back and were shocked to see several RVs with shredded and ripped awnings. Not knowing what happened, we were concerned about our own camper. But it was fine, in fact, ours was the only camper with a deployed camper that had survived the storm.

Of course we wound’t take this kind of hardware on a backpacking trip. But I haven’t had a single problem or failure since I started using heavier guys and stakes. That and proper pitched tension is our best “lightweight” solution.

Mar 6, 2020 at 11:18 am #3634511Some time back I had a chat about this with Mike Cecot-Scherer of TentLab. He’s a veteran tent designer for hiking and mountaineering brands.

I don’t think I’m misrepresenting him in saying that he strongly supports the idea of well tensioned panels and rigid guylines.

In his view, a taut panel will shed the wind effectively, as it was designed to do. A loose panel will distort and catch the wind, significantly increasing the tension on the pegs.

He supports the use of composites or poly vs nylon, as it’s more likely the panels won’t sag and distort in cold/wet storm conditions.

And he supports the use of non-stretch guys for the same reasons.

I suspect that this explains the better performance of the tighter guys in Ryan’s test.

It would be interesting to see a picture of the tent and setup involved?

Personally, using my TrailStar in windy places with iffy soil I’ll always use full-size GroundHogs all-round. Maybe it’s overkill, but I’ve never had a peg pop yet. For me, it’s worth an extra few grams for the peace of mind.

Mar 6, 2020 at 11:34 am #3634514PS – Nick

In scenarios where you’ve got a big structure to support and weight isn’t a major issue, you should consider the innovative Delta peg, invented by a little business local to me. Everyone I know who uses them raves about them. I even know a guy who carries a couple for his ridgeline pegs for his lightweight shelter.

The inventor claims they are so effective because:

– They have a large contact area – GroundHog style

– The ideal 45% insertion angle is built into the design

– The remote attachment point reduces leverage – pulling on the guy seems to drive the peg in rather than lever it out.

There’s a nice demonstration of the holding power in a video at the end of this review.

Mar 6, 2020 at 11:54 am #3634521The Delta Anchors are an interesting concept, though I wouldn’t trust a plastic peg many places I go (they break trying to drive them in the soil). I would guess that the physics behind it has to do not only with the large surface area of the stake (compared to the skewer they were using) but also with the way it places the attachment point of the guyline where the force is introduced, away from the stake itself. I wonder if this could be done with aluminum or titanium?

Mar 6, 2020 at 11:57 am #3634522Vortex shedding? More data points please ;-) Cool stuff.

Mar 6, 2020 at 12:04 pm #3634523I like well tensioned panels and strong lines and stakes .. and things to minimize being a sail

Mar 6, 2020 at 1:53 pm #3634541You might consider separating the many variables involved. There’s a literal chain link from shelter, to guy line (and tensioner), to stake to soil. Take it one link at a time.

We already have some information on the static interaction of stake and soil: https://backpackinglight.com/tent_stakes/ . Note that this study did not involve guy lines or tents. It focused on a single link in the chain.

To evaluate stake loading factors, use a mechanical linkage driven by a motor/solenoid so you can control load, loading rate, frequency and duration. The plot in the OP can inform the frequency and load ranges. Establish a quantitative means of evaluating the resultant wiggle; something like a low-force test load applied +/- on some set of horizontal axes (orthogonal, omnidirectional) and measure displacement of the stake at surface level.

To evaluate guy lines, conduct studies on elasticity and dampening of various cord material/diameter/length/brand, wet and dry. This should not involve a shelter, or stake and soil; do it all on a test jig. The loading scheme should be comparable to that applied to the stake testing.

Validate the combined data sets by applying test loads (with the same motor) to guy/stake combinations and compare expectation to measured stake wiggle.

Optimal loading conditions in hand, the last step is to wrangle the multiple variables in tent construction and pitch that generate those loads. You could try identifying some broad variables like form factor, material, panel size and tension, but it might be just as useful to simply test a handful of popular designs with a common set of guy line configurations (i.e. high/low tension values).

Given that we already know a taught pitch of stretchy material is a winning solution, it might help guide the investigation to have some specific questions. How important are drag forces (form factor)? Is there an optimum with a DCF tent and UHMWPE guy lines (minimize the system stretch) if the panels are small and taut?

Mar 6, 2020 at 1:58 pm #3634542James,

Your point about multiple stakes is interesting. I can’t make sense of it. How big was your sample size? Any chance you just hit different soil when you tested it?

Mar 6, 2020 at 2:33 pm #3634546“The two together placed in a “V” are quite a bit stronger than two individual stakes. ”

Nice to know that two stakes like that made such a big difference.

On a similar note, I’ve definitively noticed a BIG increase of stability when I’ve added an entire second guy line off the tent, so the “V” shape is now made from two lines instead of one, and the force is distributed between two separate points on the ground. It’s a bunch of more grams of rope and an extra tent stake, but it’s a real good procedure in strong wind from different directions.

Mar 6, 2020 at 2:47 pm #3634550I have noticed that the peg holding the pitch-lock corners that Tarptent uses on the Stratosphire and other tents did not come loose on a recent trip. The non pitch-lock corner did. The panel that was perpendicular to the wind should have loaded both corners/pegs equally. ….. I can already hear my wife asking why I’m farting around in the backyard this weekend with “all those strings and all those tent pegs” and “what is the fish scale for?”

Mar 6, 2020 at 3:20 pm #3634556Geoff,

Those Delta pegs look really good!

My hesitation would be the types of soil I find. When camping in the desert we have soil we affectionately call “desert cement.” Dirt will lots of small rocks in them… soil you can drive a vehicle on without getting stuck. We aren’t four wheel driving over softer sand towing a trailer. The long pegs we use often require a burly hammer to drive them. Same scenario in most parts of the Sierra Nevada where RVs are allowed to camp.

That is part of the equation with UL shelters — what kind of soil and using a stake that is appropriate for the conditions.

-

AuthorPosts

- You must be logged in to reply to this topic.

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

Our Community Posts are Moderated

Backpacking Light community posts are moderated and here to foster helpful and positive discussions about lightweight backpacking. Please be mindful of our values and boundaries and review our Community Guidelines prior to posting.

Get the Newsletter

Gear Research & Discovery Tools

- Browse our curated Gear Shop

- See the latest Gear Deals and Sales

- Our Recommendations

- Search for Gear on Sale with the Gear Finder

- Used Gear Swap

- Member Gear Reviews and BPL Gear Review Articles

- Browse by Gear Type or Brand.