Topic

Upright Canister Stove Reviews, StoveBench Tests, and Gear Guide

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

Home › Forums › Campfire › Editor’s Roundtable › Upright Canister Stove Reviews, StoveBench Tests, and Gear Guide

- This topic has 162 replies, 38 voices, and was last updated 1 year, 6 months ago by

Roger Caffin.

Roger Caffin.

-

AuthorPosts

-

Jun 16, 2019 at 12:38 am #3598033

Its been reported, that the BRS 3000T pot stand legs of some units will melt and bend after prolonged use.

Well, they don’t really melt, they overheat and slowly bend under the weight of a full pot of water and food.

This doesn’t happen in a single sitting, it tends to happen over repeated overuses.

…

The reports all seem to have a few things in common: long burn times combined with heavy loads of water or food. For example, cooking up a large pot of rice for 20 minutes.

from https://ultralightoutside.com/brs-3000t-review/Independent confirmation of my suspicion: the pot supports do NOT melt; they just soften and sag. The good alloy was replaced by something of poorer quality.

Cheers

Jun 16, 2019 at 12:51 am #3598042Well Ryan has some pretty hot stoves in his StoveBench Tests. Ryan has been around for as long as we can remember and his description says “melt” He knows something we don’t or else he would have been here to tell us. :-) It must be something about his method of testing with the stove valves wide open, don’t know. We are hoping he will join in on the conversation, show us some photos and explain his comments. Hikin Jim’s photos were interesting and showed there is very disturbing accident prone stove out there that should be taken off the market until the flawed pot supports are resolved. 4 out of 7 is not acceptable.

Jun 16, 2019 at 1:31 am #3598047his description says “melt”

I will simply repeat: you can NOT melt titanium with a propane/air flame. But you can soften it.Cheers

Jun 16, 2019 at 1:32 am #3598048” do NOT melt; they just soften and sag.”

Twin Towers in 2001

Jun 16, 2019 at 2:15 am #3598055Ryan said 4 of the 7 he tested melted. The batch of 7 he purchased had 4 stoves that some supports were made of a metal that melted, must not have been made of titanium. Somebody mistakenly introduced a coil of substandard metal when stamping out the small support arms. We don’t doubt you Roger about the melting of titanium. We just need the stoves removed from the commercial sellers here in the USA. Ryan and Hikin’ Jim(Jim Barbour) have the ability to do so, at least try. Their expertise in stove testing can convince the authorities to investigate and find the manufacture responsible and have the stoves recalled. It’s the right thing to do. We won’t tolerate our children to be scalded by stove mishaps and forests started on fire.

We don’t doubt you Roger!

Jun 16, 2019 at 2:25 am #3598058If someone substituted another metal for Ti, then that someone should be in big trouble.

Now, how do we contact BRS and ask?Cheers

Jun 16, 2019 at 2:40 am #3598060Now, how do we contact BRS and ask?

We ask Ryan Jordan to contact the Federal Consumer Product Safety Commision, submit his findings and then that Comission will contact BRS and ask that question and a lot more.

https://www.usa.gov/federal-agencies/consumer-product-safety-commission

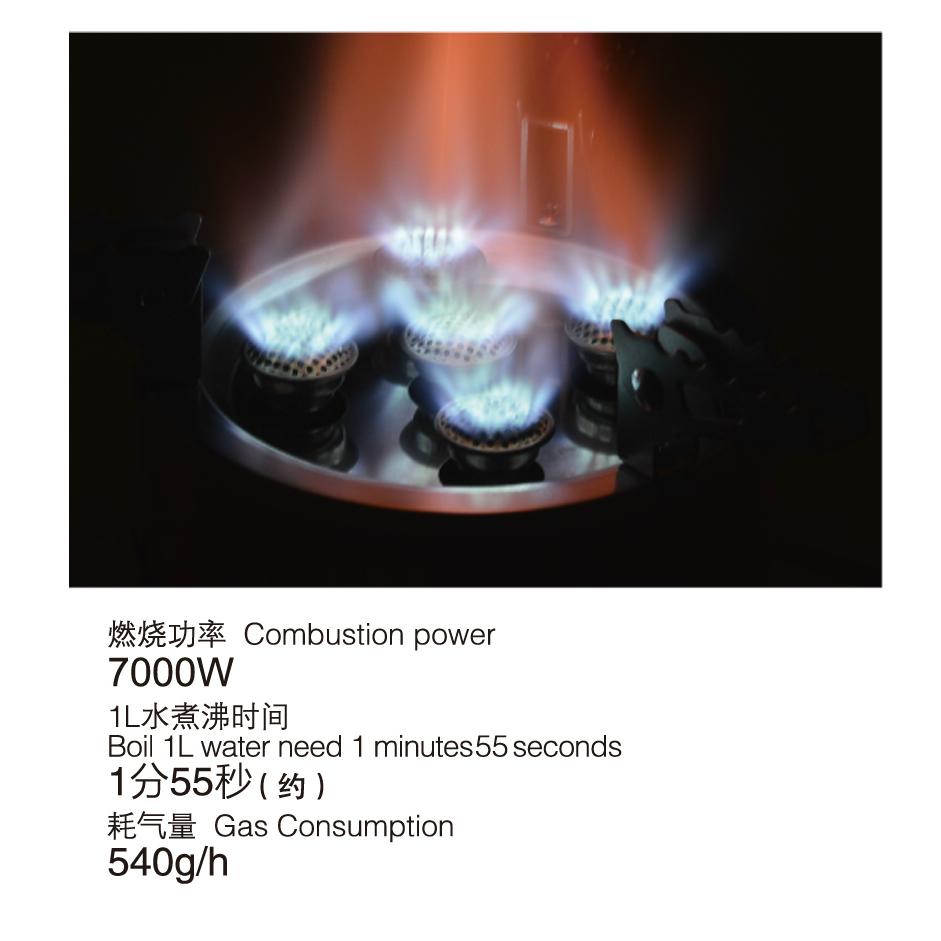

Jun 16, 2019 at 4:13 am #3598062You could alternately buy a BRS-75 stove. Please note the power rating (7 kW) and the boil time for 1 L (<2 min).

Cheers

Jun 16, 2019 at 1:34 pm #3598076Well, being in the business makes it difficult to also let it be known you are a “watchdog.” I suspect BPL is simply avoiding all sorts of issues by not responding.

IFF whoever owns a failed stove would sen in complaints, some action could be had. But I suspect BPL will not do this. The foremost is with any testing protocol in place, you often test prototypes that fail for one reason or another. IFF you go running to some sort of consumer protection organization at every failure, you would quickly loose all testing credibility with manufacturers (they don’t send you items to test,) you loose credibility with your audience (because you are not doing any new tests,) besides loosing any testing support/financial support (to purchase stuff to do independent testing for a wide community base,) for example. Other reasons, of course, this is only a single example. Internationalism, wide base of readers that disagree, support from vendors that sell manufacturers products, etc… I am sure Ryan has thought about it further. As a business, it is hard to make a decision like that, because, it means leaving a potentially faulty item for public use resulting in “accidents.”

No, Dan. Going forward by BPL with a formal report means too many negative effects on the business. As I alluded to previously, Consumer Protection is NOT what BPL wants to get involved in. What the readers do, well, that is a different story… most of us do not manufacture things, even information, for sale…

Jun 18, 2019 at 11:36 am #3598302@jamesdmarco, I am sure Ryan has thought about it further. As a business, it is hard to make a decision like that, because, it means leaving a potentially faulty item for public use resulting in “accidents.”

No, Dan. Going forward by BPL with a formal report means too many negative effects on the business. As I alluded to previously, Consumer Protection is NOT what BPL wants to get involved in.

James, you are right, it’s all about the money(business). What I presented to them was a test. Did they pass or did they fail?

Jul 10, 2019 at 8:51 pm #3601458Does the Fire Maple FMS-300T still have the sintered brass filter that should be replaced?

It seems to have done pretty well on fuel-efficiency, even in the wind test.

Jul 11, 2019 at 6:35 pm #3601552I am curious as to whether the failure rate of the BRS-3000T stoves could be directly related to the fact that the test involved opening the flame valves to maximum output. I have 3 of these stoves, and I always run them at medium-to-medium low flame settings. I only had one mishap, which was using the BRS with one of my JB pot riser disks with a TITANIUM JB pot. One of the support arms must have softened and bent downward when my mate fired up the stove for his dinner pouch. He has a bad habit of running all stoves at very high flame output, and I always chew him out for this (when I catch him). First of all, the pot riser disk requires a lower flame so as to not to quench the flame. The other variable here is that perhaps the titanium JB Sol pot reflects more heat back to the stove than would an aluminum Sol pot. I’ve never had any issues using my aluminum Sol with the BRS-3000T and riser disk, over at least 100 2-cup boils. I easily was able to bend the pot support back to it’s proper position, but I’ve not taken the time to do more testing of that particular stove to see if I could duplicate the failure, and also to test it with an aluminum Sol cup.

Aug 25, 2019 at 4:33 pm #3607528With the recommendation from this project, I bought an MSR Pocketrocket Deluxe. I had read the posts regarding not being able to fit the stove and fuel canister inside the 0.85 liter titan kettle and closing the lid fully. I spent a bit of time on this last night and figured out the puzzle :)

The canister is a bit above the rim of the pot but the slight dome of the lid accommodates this and closes fully. Sorry for the sideways pic; the combination of my phone and the website (and my brain) wouldn’t let me rotate.

Aug 25, 2019 at 4:59 pm #3607538Gary, Roger said titanium pot supports on the BRS 3000 don’t melt. We have to totally disregard what Ryan and his crew said.

I purchased 7 of the BRS 3000 and will do a sensible testing of them. This is backpackinglight. All serious backpackers should reconsider what Ryans said and purchase the BSR’s and use an appropriate size pot….think 650ml max. capacity. I strongly suggest doing what Roger suggested…..run stoves at 1/2 power. Ryans full throttle stove bench method is a joke.

Ryans comment “thank you very much” regarding his purchase of 7 was………heh heh heh, yah right!

Aug 25, 2019 at 10:12 pm #3607569Roger said titanium pot supports on the BRS 3000 don’t melt.

That is true but it could be a bit misleading if not taken in context.

I said two things:* A propane flame can not melt any titanium metal: a propane flame can not get hot enough to do that. That is hard scientific fact. You can look it up on the web.

* I also said that the pot supports on the BRS-3000T stoves which I have, from a couple of years ago, do not soften in use. But, as Dan notes, I never run them flat out. I suggested that maybe BRS had switched from a good Ti alloy to the softer ‘pure’ Ti as it is cheaper to buy and to process, but that was just a guess on my part.

I have not had any trouble using an MSR Titan (titanium) 1.2 L pot on a BRS-3000T stove, with a windshield around it. Works fine. At medium power the canister does not get more than slightly warm, which is fine.

I have a couple of them, and I use them. I think it is a good stove, especially considering its price and weight.

Cheers

Aug 27, 2019 at 10:03 am #3607768A propane flame will reach around 1980c

Melting point of Titanium is 1668c

Aug 27, 2019 at 10:19 am #3607769That is the peak temperature of a propane/oxygen flame – similar to an oxy-acetylene flame. But that assumes complete combustion of a stoichiometric mix of oxygen and propane.

We are not dealing with that here. We are dealing with a propane/air mix, and there is a lot of cold nitrogen gas mixed in with the oxygen. In the field, a propane-butane flame only gets up to about 1225 C as it has to heat up all that nitrogen as well. In addition, a propane/butane flame may entrain extra air up near the top of the flame, just due to gas dynamics. This (1225 C) is a long way below the MP of titanium, which is variously reported as being between 1670 C and 1725 C. I favour the lower of the two.

Titanium may glow of course, and it may even soften somewhat, in a propane/butane flame. Ti 6Al4V needs an extra 200 C (approx) over CP Ti for the same weakening.

Cheers

Aug 27, 2019 at 12:49 pm #3607778Ryan said 4 out of 7 melted, yet there are no photos or videos of such occurance. Sad, sad, sad!!!

Roger said: Well, they don’t really melt, they overheat and slowly bend under the weight of a full pot of water and food.

This doesn’t happen in a single sitting, it tends to happen over repeated overuses.Roger, is that your personal experience or just what you read on the internet?

Aug 27, 2019 at 11:17 pm #3607838I have never had the pot support arms on a BRS-3000T bend on me.

I have worked a fair bit with Ti alloys: machining and forming.

I have seen Ti alloy wire at red heat slowly bend when loaded.

I have bent/formed Ti alloy sheet using heat to avoid cracking.

This is all first-hand experience.Cheers

Sep 2, 2019 at 11:18 am #3608586The test results clearly underline the experience I had last winter with my Kovea Ti burner. It wouldn’t even heat half a liter of water with Coleman extreme gas. I thought the gas was to blame, or the temperatures, even though it was moderate for winter. Now I know it’s the stove. I was about to get a new MSR, when I used the Kovea again this summer in Norway and realized how much difference my titanium windshield makes. It wraps around the pot and the canister completely. Heating times are down to a less then a quarter of the times without the windscreen, fuel consumption is much, much lower and the windshield also traps so much heat that it can easily keep the canister warm (so much so, that I need to open it up on warm days to prevent overheating). I’m now thinking that this will also be good enough to get good performance out of the Kovea in winter. So, not to take anything away from the great test, with a little help from a good windscreen and some understanding of what the strong and weak points of your equipment are, even the lesser burners might still cut it. At least, I’m going to give the Kovea one more chance this winter.

Sep 2, 2019 at 12:45 pm #3608587It is not unusual that anything made for use can simply destroy itself in use. A simplistic example is your car. Park it and press the accelerator peddle to the floor…the engine WILL destroy itself. The BRS 3000 is really no different. As I have said in the past, you can not do a test like this and get meaningful results.

Windscreen over a canister? Cooking in a tent? Running stoves on a flat, level surface? And so on… We cannot say we, as backpackers, always follow all safety rules at all times. In most cases, we can use some item to maximum effect by NOT using it flat out. Some items may operate well flat out. To be more specific, the Windburner and Reactor systems do very well on full- on settings. Others, like the BRS, will fail.

As Jan Paul M points out, even a moderate performer in these tests can still be used effectively in the field. So, we start looking at other methodes to help or exceed manufacturers specs, in Jan’s case a tight windscreen/heat shield.

While Ryan’s Fvalue is a measure of flat out heating, there are simply too many variables to say this is a good methode. Slight differences in jet size, canister fuel make up, flame distribution, style of flame production, radiated heat to the canister (burner style,) etc will make large differences in full open use than is tested. There will always be some “margin of error.” And, the relationship between field use and testing becomes highly questionable. How many of us actually use a stove at full-on to boil two cups of water? And, if you cook anything, as opposed to simply boiling water, how does the longer operation effect efficiency?

As for me, I will likely ignore Ryan’s results. The results have way too many variables to be able to say which stove is better. The BRS failures gives me pause. Why did only 4 out of 7 fail? Why not all 7? Different setups during manufacture? Different batches of raw material? Some people use a BRS-3000 with good results. Others do not. Fuel? Wind? Even setting on a small rock vs the ground vs a table may have effected the reliability.

Sep 2, 2019 at 2:21 pm #3608601The word “melted” is not literal

Way before melting temperature metal starts to lose it’s strength and will bend under load

I have a BRS 3000 and it worked fine, but I just used it a little. Too many failure reports to rely on in my opinion. Also, it’s so short. That means the valve gets hotter. That might cause it to fail. It was designed to be lightweight, not reliable.

Sep 2, 2019 at 9:10 pm #3608668the valve gets hotter. That might cause it to fail.

Unlikely. The O-ring is the only thing in the valve which might fail, and the rubber is rated to over 200 C – 250 C if it is Viton.Just remember the Touch Test for the canister.

Cheers

Sep 2, 2019 at 10:34 pm #3608675I wonder if BRS-3000 has Viton o-rings : )

The failure reports for BRS-3000 did not seem to be the valve

I wonder why other stoves are taller

Sep 3, 2019 at 12:31 am #3608686The word “melted” is not literal

‘Melted’ means to change state from solid to liquid. If you don’t mean that, don’t use the word.I wonder if BRS-3000 has Viton o-rings : )

I would certainly expect so, but I have not tested the rubber.

Viton has a recommended temperature range of about -28 C to +220 C. The next choice would be nitrile, but the recommended temperature range for that is -40° C to +107° C, and we know that stoves do reach boiling point sometimes. So you can see why I expect it to be Viton.I wonder why other stoves are taller

In many cases it is because the so-called ‘designer’ did not know how to manage the gas flow inside the burner, and so resorted to a long column to get the required fuel/air mixing. You can see how well the flames on the BRS-3000T look: that means that they got good mixing with that short column. And a short column gives a more stable stove.Without naming companies, I have found from conversation with several of them that they do not have real designers, just ‘product managers’. And many stoves show that clearly.

Cheers

-

AuthorPosts

- You must be logged in to reply to this topic.

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

Trail Days Online! 2025 is this week:

Thursday, February 27 through Saturday, March 1 - Registration is Free.

Our Community Posts are Moderated

Backpacking Light community posts are moderated and here to foster helpful and positive discussions about lightweight backpacking. Please be mindful of our values and boundaries and review our Community Guidelines prior to posting.

Get the Newsletter

Gear Research & Discovery Tools

- Browse our curated Gear Shop

- See the latest Gear Deals and Sales

- Our Recommendations

- Search for Gear on Sale with the Gear Finder

- Used Gear Swap

- Member Gear Reviews and BPL Gear Review Articles

- Browse by Gear Type or Brand.