Topic

The Joule Thief: Yet Another HX Pot

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

Home › Forums › Gear Forums › Gear (General) › The Joule Thief: Yet Another HX Pot

- This topic has 106 replies, 19 voices, and was last updated 1 year, 9 months ago by

Roger Caffin.

Roger Caffin.

-

AuthorPosts

-

Mar 25, 2022 at 8:08 pm #3744239

A few thoughts and questions I don’t think have come up (sorry, I only skimmed all the responses):

First, what you’re measuring should probably be called efficacy, not efficiency.

Second, how repeatable are your efficacy measurements? You show a 17% improvement…what’s the uncertainty?

Finally, have you checked to be sure there’s not significant evaporation during the test? My gut says it should be small, but who knows. If it is significant, does it vary with the shape of the pot (or anything else you might want to control for)?

Mar 25, 2022 at 9:22 pm #3744245To be sure, the parameter being measured may not be easily converted to how long it takes to boil a pot, BUT it is a good measurement which does not rely on initial conditions, final conditions, etc. So I am happy with it. I say stick with it.

Now, a question. It seems from the photos that the ‘fins’ go radially outwards from the middle. That makes mass production difficult. Have you considered fins more like circles around the middle? I am not sure what the change in efficiency might be: it would probably depend on the depth and number of rings. BUT: it would be a damn sight easier to manufacture!

Cheers

Mar 25, 2022 at 10:45 pm #3744246I would humbly disagree as Joules/gram assumes linearity. In my experience, particularly with the BRS and pot diameter ( and burn rate) it is highly non-linear. The general belief is that pot can be 20% more efficient that mugs. I have seen this as well. My 2 cents.

Mar 25, 2022 at 11:37 pm #3744248I will have to disagree with the claim about non-linear behaviour. Given that a propane/butane flame is well over 1000 C, while the pot is in the range 0 – 100 C, there is no reason for the heating rate to be non-linear – with a canister stove. There could be differences with other fuels.

That seems to be verified by my testing on some of my winter stoves, using a data logger (usually 1 reading per second). The rise on temperature of water in a Trangia kettle on the stove was generally a straight line, except at the extreme ends. At the start it took a little while for the water to start circulating in the kettle, and at the high end the heating rate slowed a little when the kettle started to lose steam out of the spout.

If I changed the stove power half way through a run, the slope of the temperature plot changed accordingly.

On the other hand, the idea that wide pots heat better than narrow mugs is both very logical (differences in heating area of the base) and has been observed by many BPL members. Narrow beercan pots are inefficient.

My 2c

CheersMar 26, 2022 at 8:38 am #3744283Thanks Tyler, that makes sense. And Pithawat.

Given those numbers, and with any of these efficiency measures, if it saves you having to bring another canister, then they can make sense

Cool project

I’m a fan of entrepreneurs. I have seen that successful businesses usually try several products before they find one that makes sense. Enough demand. Enough price markup available.

Mar 26, 2022 at 8:44 am #3744284

Well, an extreme example of stove non-linearity is the BRS 3000. Look at the amout of fuel usel to boil 500 ml of water (all at the same starting point) as a function of pot diameter and burn rate. This is highly non-linear and the Joule Thief uses the BRS 3000.

Other stoves are not as sensative but are also non-linear. My 2 cents.

Mar 26, 2022 at 11:20 am #3744308On the other hand, the idea that wide pots heat better than narrow mugs is both very logical (differences in heating area of the base) and has been observed by many BPL members. Narrow beercan pots are inefficient.

This is very interesting, to me. I did a test on this very thing yesterday between a 8″ wide titanium pan and a titanium MSR Titan at sea level. The pan is 1L and Titan 0.8L, but 0.5L was used to test boil times using a Soto Windmaster at full throttle (as well as partial throttle tests). Maybe the Titan isn’t narrow enough to count in the too-narrow department, which would be a valid counter point. Both without lids.

Boil times were within 10 seconds of each other (2:30 with cold tap water, in slight wind) doing two of the same test alternating. I also measured fuel consumption and it was equal, but that is obvious by the same boil times. 10 seconds is within margin of error, as determining hard boil state is not exact.

What I found on just a surface level observation is that the vast majority of the energy transfer is happening within an area just about as wide as the base of the Titan. On the 8″ wide pan, the non-linear falloff of heat transfer radially from the burner location was very visible. Even at a sustained hard boil, the outer 50% of the pan’s surface area was not inducing a hard boil, even though the flames are still clearly hotter than boiling water. The compression of the flames above the burner seems to play the largest roll in heat transfer for the whole process. Once the flames decompress outward radially, they lose a lot of that thermal compression and ability to transfer heat to the cookware surface.

The fuel efficiency would have probably been in the pan’s favor though if both had lids? Pans have a hard time with losing heat from the large surface area on top.

It will be interesting when I get around to testing the pot and pan for melting snow, as which one is more efficient to melt the snow, but not to the point of boiling the water or heating it beyond melting.

Mar 26, 2022 at 11:37 am #3744309While the BRS 3000 is the most non-linear stove. Keep in mind that this is a non-regulated stove so the dynamic range is rather large. The Soto WindMaster is a very linear stove across various pot diameters. It is also a regulated stove, so the dynamic range of the flame is better controlled. I believe that the main reason for good linearity in micro-regulation along with the fact that the WindMaster has the close burner head to pot distance providing a controllable flame pattern. My 2 cents.

Mar 26, 2022 at 7:11 pm #3744353Hi Jon

Why should the BRS-3000T be non-linear in heating while other stoves are not?

I can imagine that there might be some slowing down in very cold weather with any unregulated upright canister stove if the canister is cooling down. The amount of thermal feedback may very slightly between stoves models, depending on whether the burner column is aluminium or titaninium. There might also be some difference in feedback from the flames to the canister due to a masking effect from a wide burner head.

But that is for the heating rate, not for the amount of fuel needed to boil a volume of water. I can not see why the amount of fuel used to boil some water should vary depending on the stove, UNLESS the test is being run withOUT a windshield. I can well imagine that wind might affect where the flames go.

But who runs a canister stove without a windshield these days????

Cheers

Mar 26, 2022 at 8:58 pm #3744360Mind you, I have yet to begin to understand why I should worry about a non-linear heating rate with any stove ? ? ? ? ? ?

Why does it matter ? ? ?Cheers

Mar 26, 2022 at 9:30 pm #3744361It’s due to the measurement currently not having a defined start temperature, so it’s getting the average increase over some range <100C. So you could end up starting in a fast or a slow part of the curve and get different results. If it was defined as always being 0C to 99C then I’m not sure it would matter.

There’s also another undefined input of how open the valve is, which is a bit tricker since these aren’t marked.

Mar 27, 2022 at 10:12 am #3744380@Roger, I posted a detailed response to your question on an older thread. Here is a broad overview:

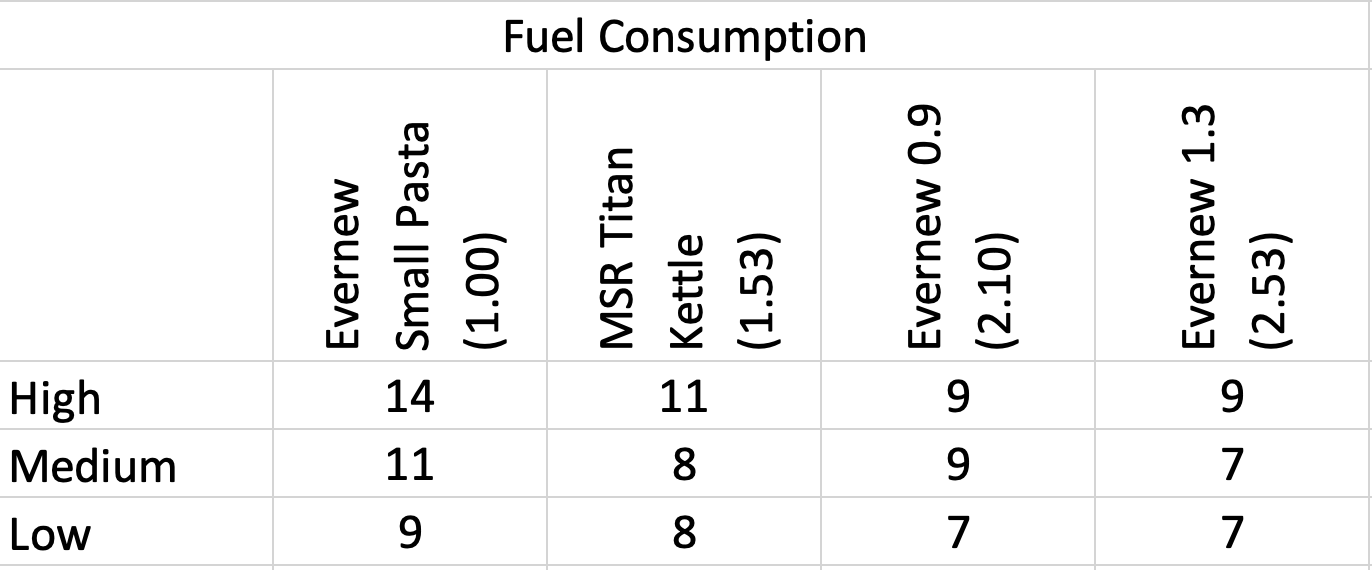

On the last table, if you comapare high burn rate, small pot to low burn rate big pot, there is a difference of about 26% (52.91% to 26.46%) or you are using twice as much fuel depending upon your pot size and burn rate. This is a highly non-linear response and why it matters. My 2 cents.

Mar 27, 2022 at 10:25 am #3744384once you have determined the operating point of your stove (pot size / burn rate) the efficiency of the stove is fairly constant. Efficiency can be defined as (energy needed to heat the water)/(energy supplied).

So boil say 2 cups of ware astarting at 70 F and mearue the fuel usage to determine the efficieny: say 55%. Once you have the efficiency number, you can calculate the response to differnt conditions.

If you start of with 3 cups of water and the startting water temperature is 40 F, you can calculate how much fuel will be required to reach a boil. I’ve been doing this with alcohol stoves for years. If is straight up physics. no magic involved.

Mar 27, 2022 at 1:42 pm #3744399I would humbly disagree as Joules/gram assumes linearity

What metric would you propose? I’ve been giving it some good thought and here is how i’m interpreting the problem.

We want a solid metric to compare the efficiency of varying pot/stove combinations. Ideally, this metric would be decoupled from as many environmental influences as possible. Such as elevation, source water temp, volume of water boiled, etc. Both the (Joules absorbed)/(grams of fuel) metic and the (Joules absorbed)/(Joule emitted) metric do this, and because the Joule/gram metric is only a scalar of efficiency (joule-in/joules-out), but much easier for the average person to compute, I’d argue it’s a good start for a metric choice. But I think Jon brings up a great point (admittedly it took me 3 days to understand it, not the sharpest tool in the shed over here. lol), we have a pretty big issue with this metric.

The Issue:

The non-linear response of a pot/stove systems efficiency in terms of stove output level is the problem with this metric (it’s also a problem with every other metric I know in wide use by the UL community). Because it may lead to misleading information. This is the case with the Joule Thief stats I stated earlier; here is my non-linear response between 3 different prototypes of the Joule Thief. We can see that all three have about the same efficiency at 20% stove output. (Here is the link to the spread sheet for data collection transparency) <- Note this sheet was made before I started using the Joules/gram metric

If we only measure stove/pot combo efficiency at 20% stove level output (which I did in my initial post here on the Joule Thief), then all these pots in this test would have nearly the same efficiency value, but by looking at the graph its clear one pot is definitely more efficient on average over the others. BUT its not consistently more efficient, thus non-linearity exist. If the efficiency difference was linear between the three, we could ignore the stove output differences because they would all be scalars (multiples) of what ever efficiency value was measured initially. This is the issue.

The metric is dependent of the stove output level you measure it at being the same across all test, and offers little to no insight to the performance of the system at a different stove level than an individual tested. Thus different people across the world may experience or measure different values of efficiency using this metric, thus the metric isn’t well suited for accurate stove/pot efficiency comparisons between different test ran by different individuals who probably have different preferences on a stove output level.

<b>Varying Pot Diameter:</b>

The issue of varying pot diameters is null IMO; I think we can ignore the non linear behavior of efficiency given a set stove and vary pot diameters because such an observation is the point of having a nice efficiency metric. We don’t want a metric that squashes this effect because we want to be able to find varying efficiencies between different stove/pot combinations to find the most efficient solution for the weight. So I argue whatever metric we come up with can ignore the issue of non-linear response to pot diameter. Even though is is fascinating! (please correct me if i’m wrong)

Call to arms for a Better Metric:

Now the question is, how do we come up with a metric that isn’t affected as much by the non-linear response of efficiency in terms of stove output level for a given pot/stove combo?

It sounds like both you (Jon Fong) and Roger are more well versed in statistics and interpreting data than I. Are there any statistical tools you two can think of that can be used to express some metric of efficiency that is less affected by, or completely decoupled from, the non-linearity of the stove output level problem?

Half Assed, on the Spot, Solution Proposal:

Off the top of my head, I was thinking of taking the average of Joule/gram across jon’s three “low” “Medium” and “High” stove output levels he does in his test. This isn’t ideal because “Low, Medium, and High” are open to stove user interpretations, HOWEVER, it would be better that just some random Joule/gram value on that curve. <- which is what I initially did for the Joule Thief efficiency measurement and the issue Jon is calling attention to.

Perhaps we could give “Low, Medium, and High” definitive definitions. Some kind of flow rate most stoves can achieve. Something like (2.5 grams)/min for “high”, (1.5 grams)/min for “Medium”, and (.5 grams)/min for “low”.

<b>Conclusions</b>?:

Bad idea? Good idea? Possibly on the right track? let me know! Very curiose over here! If a nice metric is possible to be formulate for all to use when comparing stove/pot combinations, i’m positive it can come from the likes of this community!

Best wishes and kindest regards,

Tyler/TRex

Edit #1: I see I was using Tags wrong, corrected to tag the right people.

Edit #2: I have removed the tags, I sadly can’t figure them out. lol, apologies if you were incorrectly summed to the post by me.

Mar 27, 2022 at 2:23 pm #3744400a surface level observation is that the vast majority of the energy transfer is happening within an area just about as wide as the base of the Titan. On the 8″ wide pan, the non-linear falloff of heat transfer radially from the burner location was very visible

Johan, this observation and interpretation of your test is really fascinating! Especially in the contexts of the data Jon shared. If you graph Jon’s data on varying pot diameters for his BRS-300oT runs on “Low”, you get the following.

We can see it appears to be a linear problem for a bit, which supports Roger’s and many other BL members claim of wider pot generally = more efficient. But at a certain point it switches to a different type linear behavior. This switch is the non-linearity Jon has been mentioning, because a single linear function can’t model the problem entirely. BUT what has had me confused is the WHY. Your observation and hypothesis gives a great explanation that both makes sense and is supported by Jon’s independent data.

It appears that normally the idea of wider pot = more efficiency holds true, until the diameter exceeds some point along what you described as the “the non-linear falloff of heat transfer radially from the burner location” and the non-linear falloff is dramatic enough to appear as a switch to a different type of linear behavior given the very few data points we are working with.

SUPER NEAT! Thanks for sharing, I love it when independent observations appear to converge onto an explanation of some behavior.

Edit #1: Removed the user tags, I think I was using them wrong.

Mar 27, 2022 at 2:27 pm #3744401The only people who really care about metrics and efficiency are people who are trying to maximize fuel usage. People who are trying to do that already know that blasting a stove and picking a narrow mug are negative factors. Since you tend to operate your cooking system at optimal settings, making adjustments is straight forward. If you are trying to maximize fuel efficiency, then you will need to get familiar with the physics. To do that, you will need to understand the input parameters.

Energy needs to heat water q1=M*Cp*detlaT

q1=energy

M=mass (water: 2 cups = 475.6 g)

Cp=heat capacity (4.184 J/gC)

detaT = Final-Initial water temperature (final temperature can be determined by barometric pressure/altitude)

Energy supplied

q2= Energy density* Mass

Isobutane – 45.2088 J/g

Fuel consumed

Efficiency=(q1/q2)% = [M*Cp*detlaT]/[ Energy density* Mass]

If you boil 2 cups of water form 70 F to 100 F using 5 grams of fuel, your efficiency is 69%

If you want to boil 3 cups of ice cold water, you need to solve for the amount of fuel required, in this case, that would be 9.6 grams.

To calculate efficency, you need to know the input paramenters and do the math. Physics is straight forward.

Mar 27, 2022 at 3:12 pm #3744410Hi Jon

Very useful data. I see that going from Low to Medium does not seem to make much difference to the Fuel Consumption for the larger pots. That is interesting. It suggests that most of the heat transfer is happening where the flames initially hit the pot. Fair enough.

It suggests that the flame pattern is relevant, and that too is reasonable. A highly focused flame (eg Pocket Rocket) will heat through a smaller area than a diffuse flame (eg GST-100). That has implications for the question of fuel efficiency.

I still don’t understand what ‘non-linearity’ really means, but I am not sure it matters – not to me anyhow.

Cheers

Mar 27, 2022 at 3:41 pm #3744415In the OP, Tyler states “Joules absorbed by the pot per gram of fuel burned” as being a constant or indepent. If true it I consumed 1 gram of fuel it would ad X amout ouf Joules. If I consumed 2 grams of fuel, the joule transfered would be doubled. This is what is meant by linearity.

By looking at the low, med & high levels, the efficiencioes would be the same (which they are not). They are a highly non-linear response. The sweet spot (most efficient) would be lower burn rates and wide pots. I hope that makes sense.

Mar 27, 2022 at 4:21 pm #3744422OK. But are we talking about 1 g of fuel vs 2 g at a constant burn rate, or over a fixed time?

I would expect that the first case would be ‘linear’, but not the second case.Mind you, I also expect that it would be unfair to single out just the BRS-3000T for the second case. I would expect that any stove with a similar flame spread would behave the same, as it is flame spread which really matters. (imho)

Cheers

Mar 27, 2022 at 4:45 pm #3744424Perhaps I misunderstood your initial reply to Roger.

I would humbly disagree as Joules/gram assumes linearity.

I think Roger was arguing to keep the Joules/gram metric and my assumption was that your response was in opposition of that argument due to the non-linearity issue of the metric. But I’m second guessing my assumption now because your proposed metric of the standard efficiency equation for this problem also assumes linearity… so my assumption of the non-linearity issue being the reasoning to opposition of the Joules/gram metric must be wrong.

For those who would like pros and cons to both the efficiency percentage metric Jon proposes and the Joules/gram metric, here is what I have come up with so far. Feel free to add/takeaway or call me out on my obvious bias for the Joule/gram metric ;)

The Standard Efficiency Equation as a Metric for the UL use Case:

Cons

- Susceptible to the non-linearity issue Jon was talking about earlier

- Because energy density is a scalar in this formula, adding it to the metric complicates the computation for no benefit.

- This metric requires you to accurately know the energy density of your fuel. This can be very hard given the lack of transparency of iso-butane/propane proportions different manufactures use. Which is the defacto fuel of choice for many. It will require one to locate and read many pages of SDS documentation in the hopes its listed there somewhere.

Pros:

- It accounts for the normal sources of error other metrics are prone too like source water temp, elevation, volume discrepancies (weighing your water is more accurate than measuring its volume 1 gram = 1mL)

- Its an equation that is easy to find online if one forgets, lots of source info out there for performing at home calorimetry.

A Note on this method. Jon says you can find the end temperature (boiling point) by using barometric pressure. This is true but it’s harder than it sounds and it is also unnecessary. Simply heat your water and don’t let it boil. Record your start temperature, and record an arbitrary end temperature that is before the point of your water boiling… The efficiency equation will work just as good using this method without the need to add another equation for boiling temperature based on elevation. For anyone wanting to do it this way though, you can calculate boiling temperature from elevation using the following.

Tf=(49.161*Ln((29.921*(1-.0000068753*Alt)^5.2559)mm/Hg)+44.932

Tf = temperature final, or in this case our boiling temperature.

Alt = altitude in meters

The Joule/gram as a Metric for the UL use Case:

Cons:

- Non intuitive value in terms of understanding how much fuel to bring. (See first post on this thread for a calculator that will use this metric to calculate how much fuel to bring based on your predicted environmental conditions for your trip, see notes for an alternative method to using the calculator)

- Susceptible to the non-linearity issue Jon mentions above.

- Although it is a single scalar away from being a true efficiency percentage, as Todd T pointed out, its technically not efficiency in the strictest terms of the definition. Just like miles/gallon for cars isn’t.

- You still have to do some math

Pros:

- Less math over the efficiency equation

- Less initial data finding (no need to know the energy density of your fuel).

- Because it’s a scalar value away from being an efficiency percentage, it still maintains the correct proportional differences in efficiency between different stove systems. What this means is that both this metric and the standard efficiency percentage metric will tell you how much more efficient one stove/pot combination is over another, but the Joules/gram metric is easier to compute.

- It’s in terms of grams so it allows one to intuitively compare the weight consequences of stove systems using dissimilar energy density fuels but without the need to know either fuels energy density. Like an alcohol kit vs canister stove kit, or even different proportions of iso-butane/propane mixes from varring manufactures if you wanted to find out if 100 grams of MSR fuel will get you more boils than 100 grams of Coleman fuel. You will be able to tell by looking at the measured value of the metric without having to do additional math.

Notes on this metric:

Here is how you compute the Joules/gram metric incase one is interested. It’s very similar to what Jon outlines above, just with fewer steps.

Joules_Absorbed = (Water mass in grams)*(4.187)*[(Temperature_Final) – (Temperature_Initial)]

Grams_Burned = [(Grams_Initial) – (Grams_Final)]

Joules/gram = (Joules_Absprbed)/(Grams_Burned)

If the calculator to convert this into fuel consumption no longer exist or is broken when your reading this, you can use the following clusterf**k of an equation to find it. Pardon me french ;). This equation is much more complicated than the one Pithawat V shared on page one of this thread because it accounts for the elevation of your trip and the source water temperature of your trip.

Fuel_Needed_in_Grams = [(Water_Mass_Boiled)*4.187*((49.161*Ln((29.921*(1-.0000068753*Alt)^5.2559))+44.932) – (Temperature_Initial))]/[Joules/gram]

Water_Mass_Boiled = total mass of water you expect to boil in grams. Remember 1 mL of water = 1 gram and 1 cup of water = 236.588

Ln = the nature log, most scientific calculators has a function button for this.

Alt = the expected altitude of your trip in Meters

Temperatur_Initial = the expected temperature of your source water during your trip in degrees C.

Ending Remarks:

Jon, Roger, and Jerry… after writing what I feel like are two very lengthy replies, I get the sense I am only just now starting to grasp the sheer amount of time you three have dedicated to discourse and helping people on this forum. I always come across your contributions here and there, but only now am I realizing the incredible magnitude of your willingness to commit personal time to help others… You guys are FREAKING FANTASTIC!

Kindest of regards and best wishes,

Tyler/TRex

Mar 27, 2022 at 4:49 pm #3744426@Roger,

Tyler can chime in here if he wishes. My belief was that the Joule/g was supposed to be independent of rate. I my example above, I was implying that the 1 g of fuel to add x number of joules compared to 2 g and double the Joules was over the same time period (my bad). Linearity being independent of rate.With respect to the BRS comparison, we may disagree about this but unregulated stoves must operate under a higher pressure range than regulated stoves. While the Fire Maple 300 is similar in design, it does perform much better than the BRS 3000t.

I do want to circle back to the OP. First of all, I think that Tyler has done an amazing with the Joule Thief. The trick in this design is get transform the design into a manufacturable product. The challenge will be that the current UL market is pretty small and I suspect that this will be difficult. To me, the big take away is how Tyler transformed a highly efficient cooking system using an inexpensive stove. What it tells me is that MSR missed the mark. They invested a huge amount of money developing the Reactor stove. If probably would have made a much more cost-effective product if they spent that time developing the HX section of the system. There are good chances that we will see parts of Tyler’s design strategy adopted by a larger scale manufacture.

Mar 27, 2022 at 5:14 pm #3744431My belief was that the Joule/g was supposed to be independent of rate.

Yeah, well, I doubt that is so. Most unlikely.But does it matter? I budget for 30 g per day for the two of us under typical conditions. That has been ‘set’ by past experience over many years. No theory, just experience. To me, that is what matters.

unregulated stoves must operate under a higher pressure range than regulated stoves.

Not really true. Both sorts of stoves take a canister of fuel at the input. The pressure regulated stoves just use a more complicated needle valve, but it is still a needle valve and this has zero effect on the efficiency of the stove.

BPL has a full article on this, at

https://backpackinglight.com/pressure_regulators_myth_part1/

This was published in 2012 – a decade ago. We have known about the spin associated with pressure regulators for a long time.While the Fire Maple 300 is similar in design, it does perform much better than the BRS 3000t.

I have used both. I may even still have both. I have not seen any significant difference in performance myself.Cheers

Mar 27, 2022 at 7:28 pm #3744464What it tells me is that MSR missed the mark. They invested a huge amount of money developing the Reactor stove. If probably would have made a much more cost-effective product if they spent that time developing the HX section of the system

So true! Dont get me wrong, the reactor has a “Cool factor” but it blows my mind the number of reviews the $270 MSR Reactor or $170 windburner systems have on websites like amazon and REI. I find it crazy that many people are paying that kind of money for a stove system that weighs nearly a pound. It gives me hope that if I can eventually manage to make them for less than $250 (that’s going to take a lot of work) and if Jon’s windscreen expertise can fabricate up a compatible windblock for common choice stoves, your looking at a more efficient system for nearly the same cost with a similar performance envelope, all for around 1/4 of the weight. Though the lack of a 1-L capacity does make the weight comparison a little unfair on my part.

Mar 27, 2022 at 8:05 pm #3744466Here’s the designer of the Reactor discussing his approach to HX:

The whole video goes through his rationales around component.

Mar 27, 2022 at 8:38 pm #3744472Very nice pot design Tyler.

It looks as if it was designed for heating water only. Looking inside the pot, the bottom looks like it would be difficult to clean food from it. I like my mac and cheese

Have you cooked in it?

-

AuthorPosts

- You must be logged in to reply to this topic.

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

Our Community Posts are Moderated

Backpacking Light community posts are moderated and here to foster helpful and positive discussions about lightweight backpacking. Please be mindful of our values and boundaries and review our Community Guidelines prior to posting.

Get the Newsletter

Gear Research & Discovery Tools

- Browse our curated Gear Shop

- See the latest Gear Deals and Sales

- Our Recommendations

- Search for Gear on Sale with the Gear Finder

- Used Gear Swap

- Member Gear Reviews and BPL Gear Review Articles

- Browse by Gear Type or Brand.