Topic

How did your DCF shelter age (and expire)?

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

Home › Forums › Gear Forums › Gear (General) › How did your DCF shelter age (and expire)?

- This topic has 199 replies, 27 voices, and was last updated 2 years, 11 months ago by

Murali C.

Murali C.

-

AuthorPosts

-

Dec 8, 2021 at 2:47 pm #3734292

“Now, to make matters worse, many people, in an attempt to get the hems taut, will pull the stakes further apart than is ideal.” Can you explain this in more detail? Are you saying the stakes are farther from the tent in a plane that is aligned with the hem? I am trying to understand if my staking technique of my tent could be an issue. See the picture I posted very early in this thread of the delamination at all 4 corners of the Zpacks tent.

Dec 8, 2021 at 3:37 pm #3734293Hi Arthur,

I’m thinking in terms of a rectangular or square pyramid tent. These are the designs I have experience with and think about. I’m not sure how well the concepts translate to other designs.

But yeah, ideally in either a tent or tarp the lines from the guyouts to the stakes are in-line with the ridge lines (or the curvature of the ridge if they are cut catenary-style). This will allow for the tent to assume the design dimensions, both in height and perimeter; the cat cuts will be true to the design as well. Pithced like this, for the reasons illustrated in John’s diagram as I modified it, the hems will have less tension than the ridgelines; the ridge/hem tension ratio will be relatively great. There are two main pitching deviations from this “pitched to design” approach:

1. Drop the pole height by 5 cm and move all the stakes away from the corners by some distance. This will result in the curvatures of the ridgelines being exaggerated and the hem tension much increased. The ridge/hem tension ratio will be decreased.

2. Increase the pole height by 5 cm and move the stakes in toward the tent by some distance. This will result in the curvatures of the ridglines being straightened out and the hem tension much decreased. The ridge/hem tension ratio will be increased.

Option 1 results in what some have called a “bell-shaped” tent. Some prefer this. By increasing ridgeline curvature it decreases the wind profile and interior space. Some feel this is an OK tradeoff. It also increases hem tension, reducing flap and noise in high winds. With silicone-coated woven fabrics, the resultant dimensional distortion occurs, I think, primarily along the biases of the fabric panels. As mentioned above, this is not a big problem, as the nylon threads, the weave itself and the silicone-coating offer the resilience to accommodate this distortion without long-term damage or plastic deformation.

However, option #2 is, I think, a disaster with DCF pyramids. Probably a slow-motion disaster in most cases.

But option #1 also has problems, primarily those loose hems. They will flap. What is the solution? I’m a fan of hems with caternary curves. This excises the part of the hem that is naturally under-tensioned. We can’t get it highly tensioned without distorting the tent, so just cut away the loose stuff away until you are left with the taut stuff. Gone then is the temptation to overstretch the perimeter to get the hems taut. One can pitch to design height and design perimeter and get nice taut ridgelines, panels and hems. Obviously, the downside is air gaps under the hems, but I think this is a problem that can be got around.

It sounds like Dan has added curves to the hems of the X-Mid. I’d be curious to hear his rationale. It sounds like a good move to me.

Dec 8, 2021 at 4:33 pm #3734296Stumphges, your revision of the cartoon seems correct. I usually go with your option #1 above. My Locus Gear Khufu in silnylon is the tautest pitching and quietest shelter I’ve used. I’m not entirely sure why, but I think its precise construction distributes tension really well. It doesn’t seem to have any cat cuts around the hem.

Dec 8, 2021 at 5:10 pm #3734300John, so you exaggerate the curves a bit? Yeah, that will tighten the hems and prevent flapping. And one of the great things about silnylon is that it can accommodate this pitching modification. And pitched like that cat cuts are not needed on the hems. And I’m sure the Khufu’s cut and sew precision (as Ryan J. would say) contributes to the taut pitches you can achieve. LG’s silnylon is also very good.

One of the interesting things about having cat cut hems is that it allows you to pitch Option #2 – straightening the ridges a little bit – without getting really floppy hems. Straightening the ridgelines essentially amounts to over-tightening them. If the ridges are cut straight and without any curve, this doesn’t accomplish a lot, but if the ridges are cat cut, over tightening them results in the adjacent panels being over-tightened as well. The overall result is a super-taut canopy that takes on a slight cone-like appearance. The hems will be a bit loose, but if they are cat cut this is OK.

With silnylon pyramids, people generally veer toward one or the other of these pitching styles by accident. Either this works out for them OK, or they end up sitting and thinking about it and working out how to get right in the middle and achieve the “design pitch,” so to speak.

I think it’s probably the case that people who have achieved this skill have better luck with their DCF shelters than those who have not. It might be that DCF shelters, if built well, can avoid being distorted if pitched as-designed, but will begin to deform if the pitch veers toward Option (Distortion) 1 or 2.

On the other hand, very high wind-loading, even of a perfectly-pitched DCF shelter, must surely overload the “bias” of the panels and result in distortion and plastic deformation.

High Bias (HB) DCF, which was twice as expensive as standard DCF ten years ago, but is five to ten times more expensive today (!) would solve all these problems. Costly and weighty reinforcements would also not be needed, reducing build complexity, weight and purchase price. MYOG would be easy, reliable and result in long-lasting shelters, as simple tape-bonding would be sufficient for all but the most demanding applications. Further innovations in canopy design would probably also be unlocked by a fabric that is stiff and strong in nearly all directions.

Dec 8, 2021 at 8:21 pm #3734316Stumphges, Thank you for that link to Yama MG. I note that it does not mention permanent distension with respect to silpoly, but does with the cautions about DCF.

Your diagram and text were what I was thinking about in terms of the forces on a pull out beak being spread across an entire vestibule side panel. Kudos. But I did not raise it. Call me chicken. Anyway, you did a far better job than I would have.

With pull out beaks that join with a center zip (or other connector), in the middle rather than off to the side like my Goondie, one of the beaks may be staked, and the other not. Interestingly, with the Goondie, they elected to place the door zipper off to the side where the beak attaches to the tent:

You can tell the zip location from the cover flap.

The Goondie approach may work better than a zipper between the vestibule beaks for several reasons, but I wanted a zipper in the middle to improve access on the next tent, and facilitate opening up the whole front of the tent in hot weather.

Note that the Goondie is less wrinkled when zipped up, but moreso when the zipper is open:

Then when you look at the beak on the staked left side, the stress lines are clearer, much like the lines in your diagram.From this, it looks like that with the zip in the middle between the beaks, the pegged beak will be more wrinkled along the stress lines when the unpegged beak is unzipped in order to open the door. This does not seem a major problem, however. In a major blow, the unpegged beak would be attached to the peg, or to the bottom of the other beak in order to protect the zipper.

The Goondie is a PU coated nylon tent. How the above would work with silpoly or DCF might be another story. If the fabric would not stretch well, then instead of wrinkles, there might be a crater develop in the area of the beak that would flap like hell in a blow. Am not sure.

At this point, I’m thinking about using 0.5 oz DCF for the front and rear beaks that constitute the vestibules, as it would save over 50% in vestibule weight. If the DCF did not work, the beaks could be readily replaced. For the floor, I’m also thinking of using densely woven, double ripstop 29 gram, 20D paraglider PU coated nylon with a thinly applied Tent Sure coat, because if the extra coat did not add much weight, this would knock 0.5 oz/yd2 off the floor weight compared to a heavier 30D 6.6 silnyon.

But for the fly, which must have bias stretch to secure tautly over the double cross pole frame, but not over the vestibules, maybe a 20D silpoly if it has enough bias stretch to conform to the frame. If not, the fly might be the lighter 20D paraglider fabric, again with the added PU coat, assuming that also would have enough bias stretch, and also be able to shed heavy rain with an added Tent Sure coat or coats. Note that the double cross pole frame uses carbon shafts from Gold Peak that weigh .247 oz per running foot, or roughly 1.5 oz for a 6 foot pole, less ferrules, tips and shockcord.

The above are possible ways to shed weight, and lower weight of a self supporting tent at least down to the range of the all DCF tents, perhaps below 20 oz for a solo or 1P TENT with ample space for cooking, eating, canine company and gear storage.

Dec 9, 2021 at 8:09 am #3734327Hi Sam, I don’t know if silpoly would be more susceptible to deformation than silnylon is. The 30d silpoly that ET is selling is extremely similar in appearance and feel to the 30d silnylon that Locus Gear use for their shelters.

If I were a tent maker I would be looking very seriously at that fabric as a possible replacement for the silnylon I’ve been using for many years.

On paper, that silpoly has slightly lower tear resistance than similar denier silnylon (I can’t compare it directly to the Locus Gear silnylon that it resembles, as I don’t have specs for that fabric) but I don’t know how to predict plastic deformation under load from that information.

I have seen plastic deformation in an octagonal pyramid tent made with 20d silnylon of dubious quality. But although nylon is often more compliant than polyester of the same thickness (less stiff), it is usually stronger (greater tensile strength) and more elastic. But I don’t understand these things well enough to predict what a given silpoly could withstand before it showed signs of plastic deformation (which would be stress relaxation rather than creep in a tent, BTW).

I’ve played around with various samples to try to get a feel for this, and I would say without hesitation that the aforementioned 30d ET silpoly is clearly the best of the polyester fabrics that I’ve handled. These have all been fabrics available to consumers at the usual-suspect online retailers.

BTW, for anyone who has not got hold of a DCF swatch and pulled it along the grain and then at various angles to it, I recommend it. To see and feel the mylar layers neck and deform is quite something.

Dec 9, 2021 at 8:11 am #3734328A lot of food for thought here.

Sam’s idea of using DCF for the vestibules and sil for the body is an interesting idea. The only manufacturer I can think of off the top of my head who has put this idea into practice is Lightwave, with their Artic and Mtn series. Would be interesting to hear feedback from people who have actually used these models but since none of them fall into anything resembling a UL category I doubt that we’d be likely to find users among the BPL community. As far as the Lightwave tents go, the designs with DCF have vestibules that use two stake points instead of one, thus considerably reducing the stress associated with a single stake point method. If you look at a lot of DCF designs closely, you can see how stake points tend to create stress that results in “rising sun” type folds or waves that emanate from the stake point outward. With the Lightwave 2 stake vestibule, this effect would be diminished.

Based on what Stumphges has said, however, I’m inclined to think, from the comfort of my armchair, that the ideal construction would be reversed: DCF on the body and sil on the vestibules. The reasoning behind this is because the vestibules see a lot more tension unevenly distributed along the stake point/ridgeline than the body of the tent, which has a much more even distribution due to the poled structure (assuming the panels are cut the right way). Plus, the vestibule has that zipper (sil plays better with zips).

It reminds me of the comments by some users of the Aeon Li who have observed that the vestibule panels tend to deform with use into an M shape. I haven’t found this to be the case with my Aeon Li, but that’s primarily because my gen 1 design has been modded to include tieouts on both sides of the door panel. On uneven ground, this allows me to stake out the panels tightly without having to worry about forming a door seal with the zipper on the gen 2 models. As Gen notes on the Yama Gear materials page, zips and DCF don’t really play well over time. This was also one of the great weak points of Haitao’s symmetrical octagon in DCF, the Mountain House 2P. Since I carry an umbrella in the summer anyway, I can easily seal up the space between the two offset panels on my modded Aeon Li with the umbrella. Works a treat.

The issue here is really one of durability over time. This is surely an advantage when seen from an economics/ecological viewpoint., as well as an aesthetic one (taut tents look better) and a storm resistance one (less flapping is better).

Dec 9, 2021 at 8:13 am #3734329If I were a tent maker I would be looking very seriously at that fabric as a possible replacement for the silnylon I’ve been using for many years.

+1

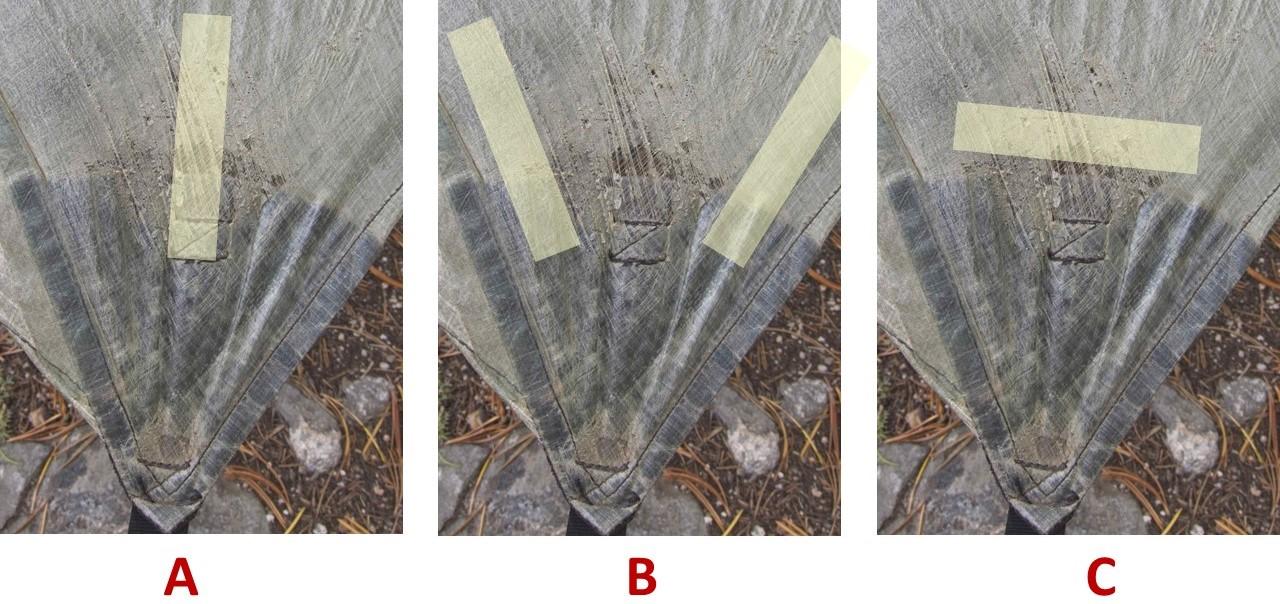

Dec 9, 2021 at 12:30 pm #3734357This is a great discussion and I’ve enjoyed reading along. My knowledge of fabrics and materials is minimal, so honestly a lot of this is way over my head. So I’d like to ask a dumbed-down question: back to Arthur’s original photo, where should he have applied DCF tape to prevent or minimize that damage? Here are some ideas I think the comments in this thread are referring to, but I’m not clear. And how long should that DCF tape be? Thanks!

Dec 9, 2021 at 2:18 pm #3734361

Dec 9, 2021 at 2:18 pm #3734361I put a square DCF patch on the 4 corners. I have not had the courage to try it out yet. Gone back to the non DCF tent for a while. Only did one side.

Dec 9, 2021 at 4:28 pm #3734372

Dec 9, 2021 at 4:28 pm #3734372Looks beautiful Arthur!

Dec 9, 2021 at 8:28 pm #3734382^^ Yes nice patch. JR that diagram represents what I was trying to ask but much better executed.

BTW the tape at Dutchware that Sam mentioned is the .08

Based on Stumphges diagram maybe 4 lines of tape? Radiating from the corner at all tie outs? That’s sort of what I think I did on the Hexamid. I’ll look at it in the morning. Heck it’s negligible weight and $4.00 for a yard.

Dec 9, 2021 at 9:21 pm #3734383J R, I think “A” is the best of the options you’ve put up. But obx hiker is thinking as I’m inclined to do – radiating lines of reinforcement along multiple lines of pull not on the Dyneema “grain.” Problem there is that once you start, where do you stop? An obsessive would end up with lines of reinforcement radiating madly all over the tent;)

But what Arthur has done with the larger patch accomplishes what J R’s “A” would do, and then some.

I think Dan Durston analyzed the damage to Arthur’s corner in another thread on DCF bias correctly. Zpacks kind of screwed it up big time by first orienting the line of tension from the tie out directly onto the unreinforced bias, and then, adding insult to injury, putting some stitching directly along that line of tension. If hideous mistakes like that take a long time to fail, maybe DCF is a bit stouter stuff than I tend to think.

Dec 10, 2021 at 3:02 am #3734388“maybe DCF is stouter than I tend to think”.

That would be a resounding yes.

I have a ZPacks Solo Hexamid in .74 that I have used about 100 nights and it shows no signs of failure, but it admittedly hasn’t faced very strong winds.

I make below national average wage and I don’t like the expensive prices of DCF, however high end silnylon tents by makers such as Hilleberg and Nordisk are almost as much. And the average DIY’er can’t even get their hands on the supreme silnylon they use anyway.

When I look at the prices of goods and services across the board I don’t see $600 to $800 for a shelter that performs like .74 DCF as being all that bad really, especially when you look at the labor involved in manufacturing the material and the fact that DCF tents are mostly made in the US and not in Chinese sweat shops where the average wage is $3 an hour.

I can’t address ZPacks issues, but I would certainly put full confidence in a .74 DCF shelter by MLD, HMG and Locus Gear. I can only imagine what any of the gear makers mentioned here would think reading all of the posts by the “experts” here on BPL.

Dec 10, 2021 at 6:10 am #3734389“I have a ZPacks Solo Hexamid in .74 that I have used about 100 nights and it shows no signs of failure, but it admittedly hasn’t faced very strong winds.”

I have a first gen (Nov 2013) Duplex in .74 and it too shows no (obvious) signs of failing, and also no use in high winds. Cost: $610/9 years = $68/year…so far.

In comparison, the seam sealing tape on my (March 2011) MSR Hubba Hubba fly and floor began to delaminate, and the surfaces become sticky in less than 4 years. Cost: $300/3.5 years = $86/year. If I had stuck with the MSR, I’d have spent over $900 on 3 shelters and sent two to the landfill in the same time period. New replacement Duplex is $700 and by this analysis is still financially, and ecologically, superior.

Not sure I see the “DCF not worth it” argument.

Dec 10, 2021 at 8:13 am #3734390isn’t the difference between 0.51 and 0.74 just an increase in the dyneema strands? That is the mylar thickness used is the same? If so, I am not sure 0.74 should be any different than 0.51 with respect to these de-lamination issues at the corners. There is a camo 0.67 Duplex with similar de-lamination issues on reddit.

I have been using DCF shelters from Zpacks for the last 5 years – Duplex, Altaplex and Pocket tarp – no issues – but not enough nights as I am keep changing the tents – selling and buying newer smaller ones etc.

I guess, it is disappointing that some Zpacks shelters have such de-lamination issues. 0.51 Duplex especially is one of the most popular tents on the trail. So either the number of people who are having such problems are in the minority or there is something more going on here that we do not understand.

Dec 10, 2021 at 8:36 am #3734391Sail making video using a laminate. Checkout how they do the corners.

Dec 10, 2021 at 11:35 am #3734405

Dec 10, 2021 at 11:35 am #3734405Thanks Stumphges!

Dec 10, 2021 at 11:59 am #3734422Arthur and JR – just curious as to how old your tents are.

Dec 10, 2021 at 1:23 pm #3734429nice video Dave

I like the walking foot sewing machine and the huge plotter

I see they tape and sew. Maybe that’s more important for sails that have more stress on them, but that’s what I’d do for a tent

Dec 10, 2021 at 2:52 pm #3734440I found the rectangular reinforcements that overlapped as they met the corner interesting. I had seen the layers of ever larger semi circles on other sails.

Dec 10, 2021 at 3:18 pm #3734456Murali, 4.5 years old. Its been in a couple of heavy thunderstorms with some small hail in the high Rockies, but no heavy winds ever. Lots of SW USA nights. That’s why I was wondering if it has something to do with the way I pitch it in addition to lousy material and/or construction. I make it taught, but not crazy.

Dec 10, 2021 at 3:57 pm #3734459The things that jumped out at me watching that sail-making video are:

1. Whatever fabric that is in the demonstration, it is bias-stabilized. It looks like it has an x-grid, like X-Pac. That grid in X-Pac is there to stabilize the fabric so as to prevent the bias deformation issues that DCF is vulnerable to.

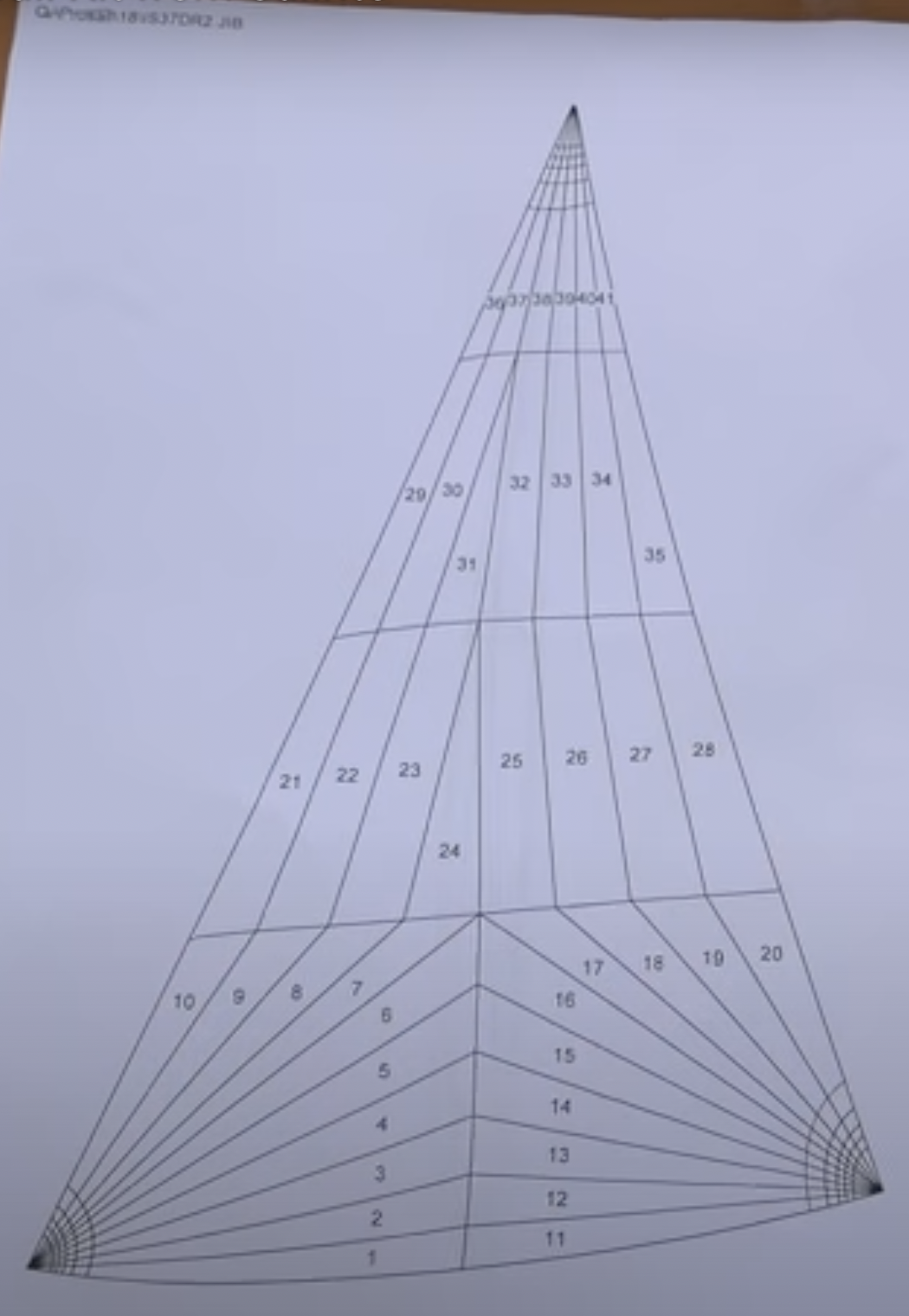

2. Even though the fabric has bias stabilization, the pattern includes long, slim sub-panels radiating from the three tieouts:

Just a little upthread I joked that one could be tempted to add radiating lines of reinforcing tape to try to prevent forces from the tie out deforming the panel along its bias. With this type of sophisticated layout and construction, that type of reinforcement is built in. Each long, triangular panel radiates from the tie-out (or whatever they are called on a sail) so that the strength, not weakness, of each panel is being loaded in tension.

We don’t have such construction methods with tents. And given the relatively lesser tension a tent is subject to, we wouldn’t need them if we had bias-stabilized DCF. “High Bias” DCF, as the manufacturer calls it, has existed for over a decade, but remains virtually unobtainable.

Dec 10, 2021 at 4:57 pm #3734460It’s always been known that .51 DCF has a shorter life span than .74. I don’t understand why people choose it really unless they’re willing to pay any price to be the lightest, knowing full well that their tarp/tent will wear out faster and probably not fare as well in the strongest of winds.

.74 DCF really is a lot stronger and it’s still VERY light. Not acknowledging the true advanced qualities of DCF sounds amateurish . It’s not some passing fad. Get real. With proper construction techniques the stuff is bad a@&. Reading this thread you’d think it was Spinaker.

Silnylon 6.6 is great too, but it’s a sponge compared to DCF and weighs about 60% more. None of the DCF colors are stealthy enough for my tastes though, and I realize most backpackers don’t care about that. Silnylon material also cost about 20% of DCF . It allows DIY’ers like me to experiment

When I see shade being thrown at ZPacks I do have to ask myself about motives. Call me cynical, I plead guilty. I’m sure there are cases of failure on .51 Zpacks shelters and I honestly can’t address the issues, however Joe had been building DCF shelters for about 12 years now so I’m not ready to jump on any kind of “ZPacks is substandard” bandwagon. Not even close.

Dec 10, 2021 at 4:59 pm #3734461I also have over 100 nights with my Zpacks Plexamid with no sign of stress or damage yet. Plenty of high wind and hail. I suspect that I pitch it pretty tight to be prepared for wind, but I really have nothing to compare it to. It’s a little finicky to pitch and prone to condensation if fully closed, but overall I’m quite happy with the pros vs. cons.

The shape and size of the Plexamid have been perfect for me with my relatively small dog. However, I adopted another dog (a big one) this Fall, so unfortunately we’re not all going to fit in the Plexamid next Spring. I will either need to buy a Duplex, or see if I can make due with my old Nemo Hornet.

-

AuthorPosts

- You must be logged in to reply to this topic.

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

LAST CALL (Sale Ends Feb 24) - Hyperlite Mountain Gear's Biggest Sale of the Year.

All DCF shelters, packs, premium quilts, and accessories are on sale.

Our Community Posts are Moderated

Backpacking Light community posts are moderated and here to foster helpful and positive discussions about lightweight backpacking. Please be mindful of our values and boundaries and review our Community Guidelines prior to posting.

Get the Newsletter

Gear Research & Discovery Tools

- Browse our curated Gear Shop

- See the latest Gear Deals and Sales

- Our Recommendations

- Search for Gear on Sale with the Gear Finder

- Used Gear Swap

- Member Gear Reviews and BPL Gear Review Articles

- Browse by Gear Type or Brand.