Topic

A NEW PARADIGM FOR ANALYZING PWPB SYSTEMS LIKE THE COLUMBIA OUTDRY EX FEATHERWEI

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

Home › Forums › Gear Forums › Gear (General) › A NEW PARADIGM FOR ANALYZING PWPB SYSTEMS LIKE THE COLUMBIA OUTDRY EX FEATHERWEI

- This topic has 234 replies, 7 voices, and was last updated 4 years, 1 month ago by

Richard Nisley.

Richard Nisley.

-

AuthorPosts

-

Mar 4, 2018 at 2:49 am #3522184

On 3/3/18 I released a significant update to my original pdf file review of the Columbia Outdry EX Featherweight. This was the first Permanently Waterproof Breathable (PWPB) garment released that was both under 8 oz and warranted for use with a backpack. That original report link can no longer be updated and so of necessity, the 3/3/18 and subsequent revisions can only be accessed in this new forum thread.

Mar 4, 2018 at 2:51 am #3522185The latest pdf file is accessible Here

Mar 4, 2018 at 6:47 am #3522205Thanks Richard, I followed this from the beginning and value your work and I eagerly await the next installment.

Mar 6, 2018 at 3:17 am #3522586Richard,

Thank you very much for your testing and analysis.

What is the outer hydrophobic layer made from? Do you have a sense how long the Featherweight might remain hydrophobic in the face of abrasion from brush?

Also, thanks for providing your HH and CFM measurements for the Montbell U.L. Stretch Wind Parka in the previous thread. Your testing shows this to have a very high HH + CFM combination, one of the highest you’ve tested, I think. I have the earlier Dynamo Wind Parka, which was made with 12d Ballistic Airlight fabric, the same description given for the fabric of the current UL Stretch Wind. I’ve noticed that the Dynamo has become more air permeable with use (according to my uncalibrated breath testing). I had a hard time sucking air through when new and now estimate it at 25 cfm. I’ve used it 10-15 days backpacking, maybe 30 casual walks and 5 or 6 washes. Also, I recently shower tested a bunch of windshells using semi-controlled conditions and this piece let through a lot of water, significantly more than a 2015 Houdini. Initially I thought the increased air permeability/decreased HH was due to deformation of the weave made possible by the bias stretch construction of the jacket; but I was testing sleeves in the shower and don’t think sleeves would be subject to as much stretching as a jacket body. The only other thing I can think of is damage from a too-hot dryer.

Do you think the 12d ballistic airlight fabric has changed since the Dynamo? Any other hypotheses to explain the decline of my Dynamo. (Very soft and quiet fabric that feels nice against the skin, BTW.)

Mar 6, 2018 at 6:19 am #3522620Stumphges,

You said, “What is the outer hydrophobic layer made from? Do you have a sense how long the Featherweight might remain hydrophobic in the face of abrasion from brush?”

Under my microscope, the outer hydrophobic layer appears to have polycarbonate crystals embedded in its surface to provide the armoring function. My guess is that the armoring will still be there when the garment is eventually discarded as a result of liner delamination after too many wash/dry cycles.

You said, “Any other hypotheses to explain the decline of my Dynamo?”

If it is the same 12 denier material; then a drying temp higher that 140F, cumulative abrasion, or wash/dry cycles breaking fibers after ~4 years of use, could explain it. I suspect a combination of abrasion and wash/dry cycles more than excess dryer heat. The dryer lint screen holds the broken and discarded fibers after a drying cycle. Each broken fiber will increase the CFM and decrease the HH some amount. The only windshirt that I have constantly exposed to abrasion, while monitoring its CFM and HH once per year, is a 70 denier WT 1.0 Epic coated military windshirt. I do not know how a 12 denier fabric changes its HH and CFM each year from various factors.

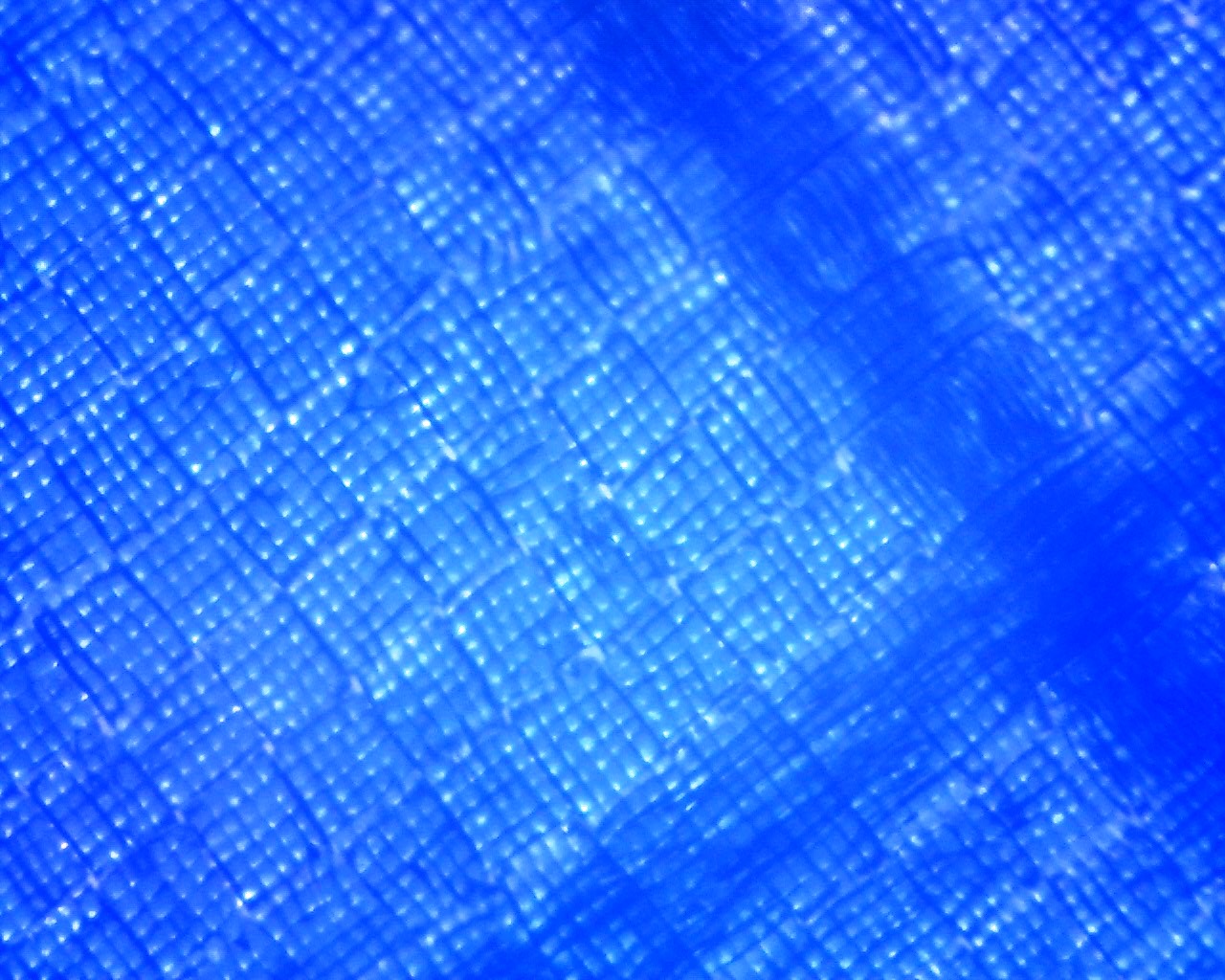

The Fall 2017 Montbell UL Stretch Wind Parka, the model they are still shipping as of today, is cut on the bias to provide stretch. The material has no coatings, that impact HH or CFM, and can wear off. The following micrographs are aligned with the bottom hem to clearly show the bias cut.

20mm FOV

5mm FOV

1.4 mm FOV

We have no way of knowing the exact HH and CFM or your jacket from the 2014 time it was manufactured. What we need to focus on is what is the HH and CFM of it now. You own a 2015 Houdini which I tested at 3.7 CFM and 387 mm HH, when new. Lets compare them now. For the CFM, my DIY coffe filter test is explained Here and my DIY HH test is explained Here

You should be able to assess the current relative CFMs (easy) and absolute CFMs (harder) of your two windshirts and the MB should be higher. The HH of two cups of water that is squeezed, at the pressure that will normally break a fully-inflated-cheap-party-balloon, is ~1200 mm. if you just pour in 2 cups of water and don’t squeeze, the water will quickly leak out at less than 100 mm. At 300-400 mm, not squeezing the fabric will result in a few drips but it would take more than an hour for the 2 cups of water to drain out. The relative pressure for each garment’s squeeze test will tell you if they are both still >300. If the MB leaks at about the same pressure as the Houdini, it is still a viable >300 mm HH active-rain-gear item. If not, it is still an excellent windshirt for moderate aerobic output <7 MET if still at 17 CFM or an optimal 3 season backpacking windshirt for 7 MET if it is now as high as you previously estimated.

Mar 6, 2018 at 12:25 pm #3522643Interesting. A few comments/questions:

- what’s the third PWPB you mention as already announced but not available yet ?

- the fact that Columbia calls Outdry Extreme microporous and since you test the CFM = 0, you conclude that it has to be bicomponent. However, it is not because something is microporous, that it is air permeable. Microporous PU exists already for decades but up to 10-15 years ago, they were not AP. The trick is an even, consistent pore distribution and size. Up to 10 – 15 years ago, they were not able to get an even, consistent pore distribution and size and so membranes made off microporous PU were not AP. Breeze Drytec was (one of) the first.

- you also could argue about the use of the term ‘bicomponent’. Normally, it’s used for membranes that have both an hydrophobic and hydrophilic part to make that membrane breathable but waterproof.

Mar 7, 2018 at 4:33 am #3522850Woubeir,

- Marmot Phoenix Jacket

- Breeze Dry-Tec is microporous and air permeable. The technology of 10-15 years ago is of little interest to forum members. To keep things as simple as possible; old microporous membranes without uniform cell sizes, had low HH from the larger than optimal pore sizes in the mix and low MVTR from the smallest pore sizes in the mix. Lots of uniform optimal sized pores yield good performance such as is the case with Breeze Dry-Tec.

- 3. OK

Mar 7, 2018 at 9:34 am #3522868- the Phoenix jacket is part of their Evodry-collection and that seems to be not a PWPB but a dry method of applying a conventional DWR

- OK, but also today ‘microporous while not being AP’-technology is still being used (I think of Pertex Shield/Shield Pro). To me, it reads now that if a membrane is MP, it is AP and that’s not right.

Mar 7, 2018 at 4:06 pm #35229111. No; it is a long chain polymer, that doesn’t get applied to just the ephemeral surface like all conventional DWRs except Epic. It is permanently bonded into every fiber and fiber void of thin 2D item’s (fabric). It uses different chemicals, a high-pressure plate (~360 PSI), and heat to permanently bond the individual fibers and voids with a cross-linked polymer. There is also a second hyperbaric chamber application process for 3D items.

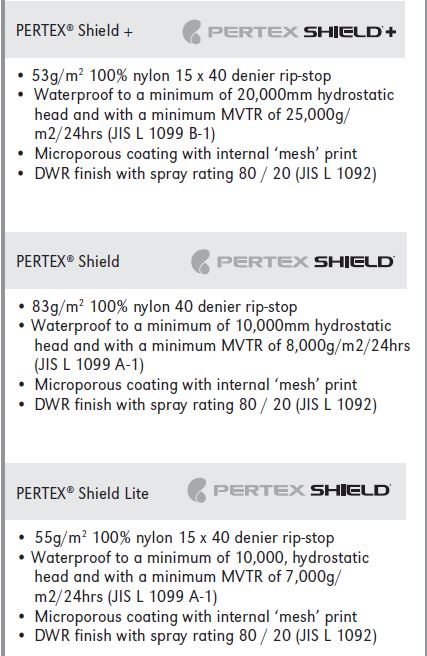

2. Pertex Shield versions described on the European Montane Website:

I just measured a Pertex Shield + garment and it has 0 air permeability By US convention, PU coatings, with 0 air permeability, are not called microporous; they are called monolithic. This is explained in the second paragraph of my PWPB prologue via the embedded link. From the above, it is obvious that this convention is not followed in Europe and hence, the confusion… sorry. The applicable REI page segment is shown below:

Mar 7, 2018 at 8:06 pm #3522950

Mar 7, 2018 at 8:06 pm #3522950OK, but what to say then about e.g. Entrant G2 XT as mentioned on BPL a very, very long time ago.

Entrant G2 XT (Hydrophobic Microporous WP/B Polyurethane)

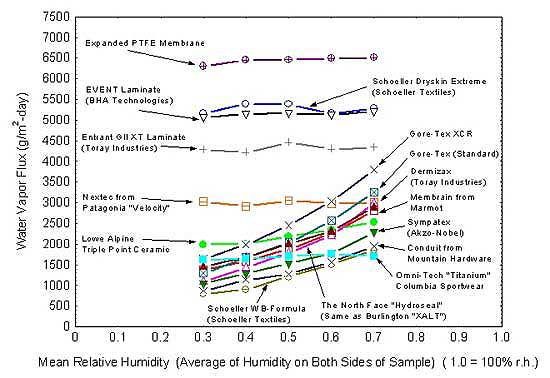

According to the results from the Army’s Natick Labs and Kansas State University’s Institute for Environmental Research, Figure 1 and Table 1 respectively, Entrant G2 XT is more breathable than Gore-Tex fabrics but not quite as breathable as eVENT. In Natick’s DMPC tests, the flat line of breathability vs. relative humidity for Entrant G2 XT is similar to that of eVENT and suggests the use of a hydrophobic micro-porous membrane. Our suspicions were confirmed after speaking with Shunichi Higashi, General Manager of Textiles for Toray America at the 2004 Outdoor Retailer Winter Market in Salt Lake City. He confirmed that Entrant G2 XT employs a hydrophobic micro-porous membrane.

I think there were no claims of it being AP.

http://sportstextiles.toray/en/entrant/index.html

About Evodry: where did you get the pressure number of 360 PSI because I can’t find that ?

Mar 7, 2018 at 9:50 pm #3522972Woubeir,

Alan Dixon wrote the Entrant G2 XT description, you referenced, in 2/4/04 (more than 14 years ago). He described it as a “micro-porous membrane” which to a US audience meant that it was air permeable. His Figure 1 (DPMC test results) clarified that:

Microporous membranes and coatings do not change their MVTR based on the average RH. In contrast, monolithic membranes and coatings do. This also applys to bi-component membranes and coatings that have a monolithic component.

Relative to your second question, the plate pressure reference is in paragraph 14 of the GTI US patent application. The patent application doesn’t provide the specific PSI they use for each scenario, it provides broad coverage by stating that it is a “superatmospheric pressure in contact with the fibrous substrate”. One scenario, I am aware of, used 363 PSI as the upper bound.

Mar 8, 2018 at 9:04 am #3523083Richard,

about the pressure: OK, they don’t mention specifically the PSI in their patent. They do however mention somewhere on their website that they have used a pressure of up to 500 PSI.

Anyway, to me it stays a separately applied DWR that can be applied on more then just WPB’s but also windshirts, fleece, … We just have to see how durable it really is.

About the DMPC-graph: to me it just proofs that these coatings/membranes are hydrobocic and microporous. Nothing more. If they are really AP is said nowhere (and if they would be, wouldn’t they mention that since that’s a property that can be rather easily confirmed ?).

Mar 8, 2018 at 6:08 pm #3523141It is not easy to measure the air permeability of microporous WPB materials. You can’t just blow through them like you can with windshirts. To the best of my knowledge, no one has ever built a DIY air permeability device that can quantitatively measure microporous WPB material.

My commercial equipment gives me an average reading of .17 CFM for a typical microporous PU like Entrant vs .50 for a typical microporous ePTFE like eVent.

You can easily see microporous WPB air permeability with a DIY air bubbler. YouTube has many of these tests posted. Search “eVent fabric”; Prolite Gear’s is the best and they have other WPB air bubbler videos posted under different titles. DIY air bubblers will allow you to rank-order microporous WPB materials but, not quantitatively measure their CFMs.

Mar 8, 2018 at 6:22 pm #3523143OK, but I guess these companies have the money to buy a professional tester.

Mar 9, 2018 at 7:31 pm #3523435Adam Kilpatrick said, “The new Montbell windshirts are out. Different US and Japan market versions; fabrics seem the same but with the usual smaller sizes in Japan windshirts with slightly different features. The Tachyon in the Japan market seems to have no zips, and is called something different.

Montbell are claiming higher water resistance and higher breathability than their previous versions. Both versions (hooded, non hood) seem to have non-zip pit vents as well which is different to the past (my Japan market Tachyon bought 2013 in Japan has no pockets or pit zips). Be interesting to see how they fair.”

Per Adams request, I tested the new Spring 2018 Tachyon Parka as a potential Active Rainwear Garment (ARG), in the Hot Red color. It is a 7 denier Ballistic Airlight Rips-top nylon windshirt. It has two zippered hand pockets, an internal stuff pocket, and 3 gill vents under each armpit. The size I tested was XL and it weighed 2.845 oz. The CFM was 20.2 and the HH was 176 mm. Ideally, we want ≥300 mm for an ARG; so, I can’t recommend it for that function.

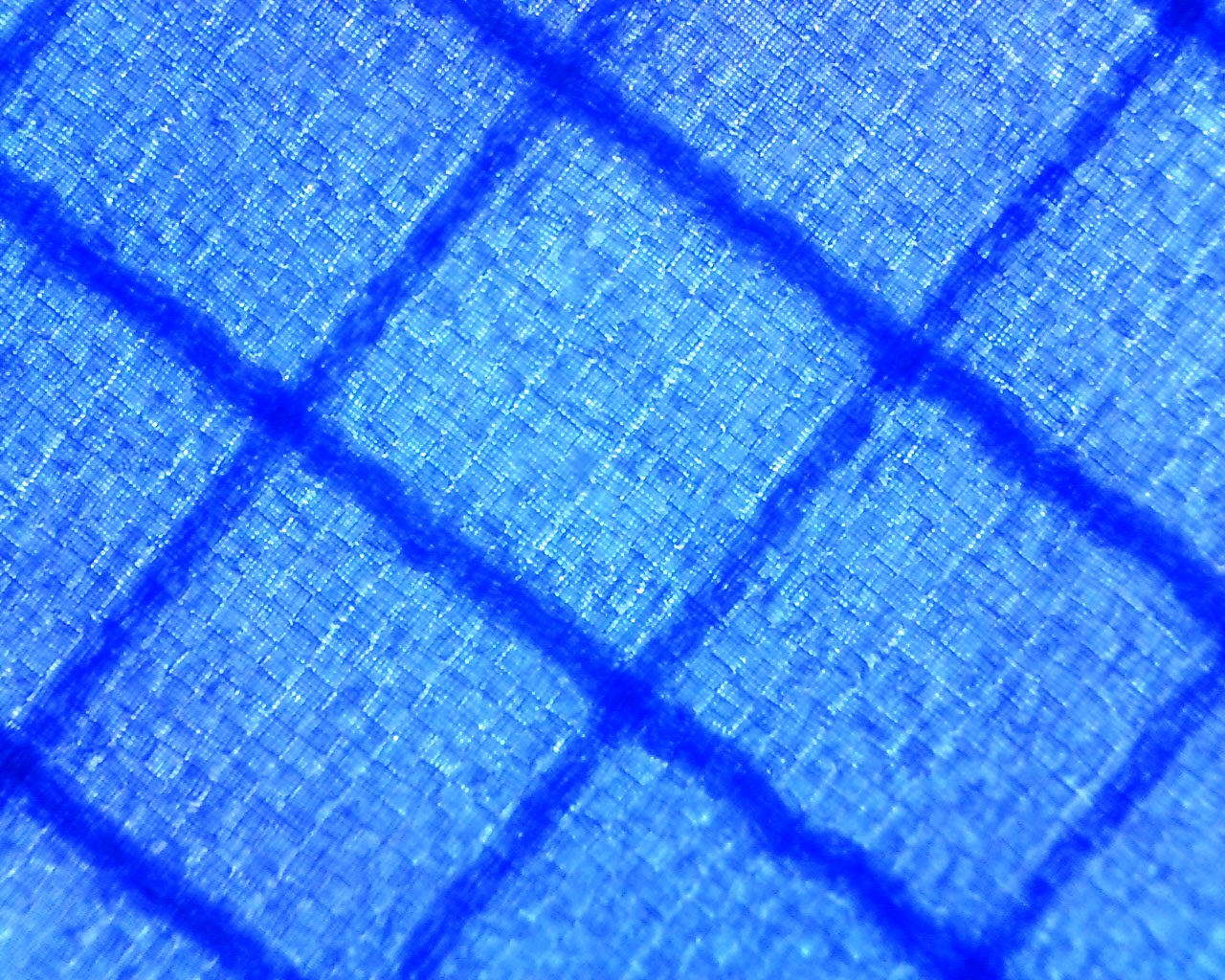

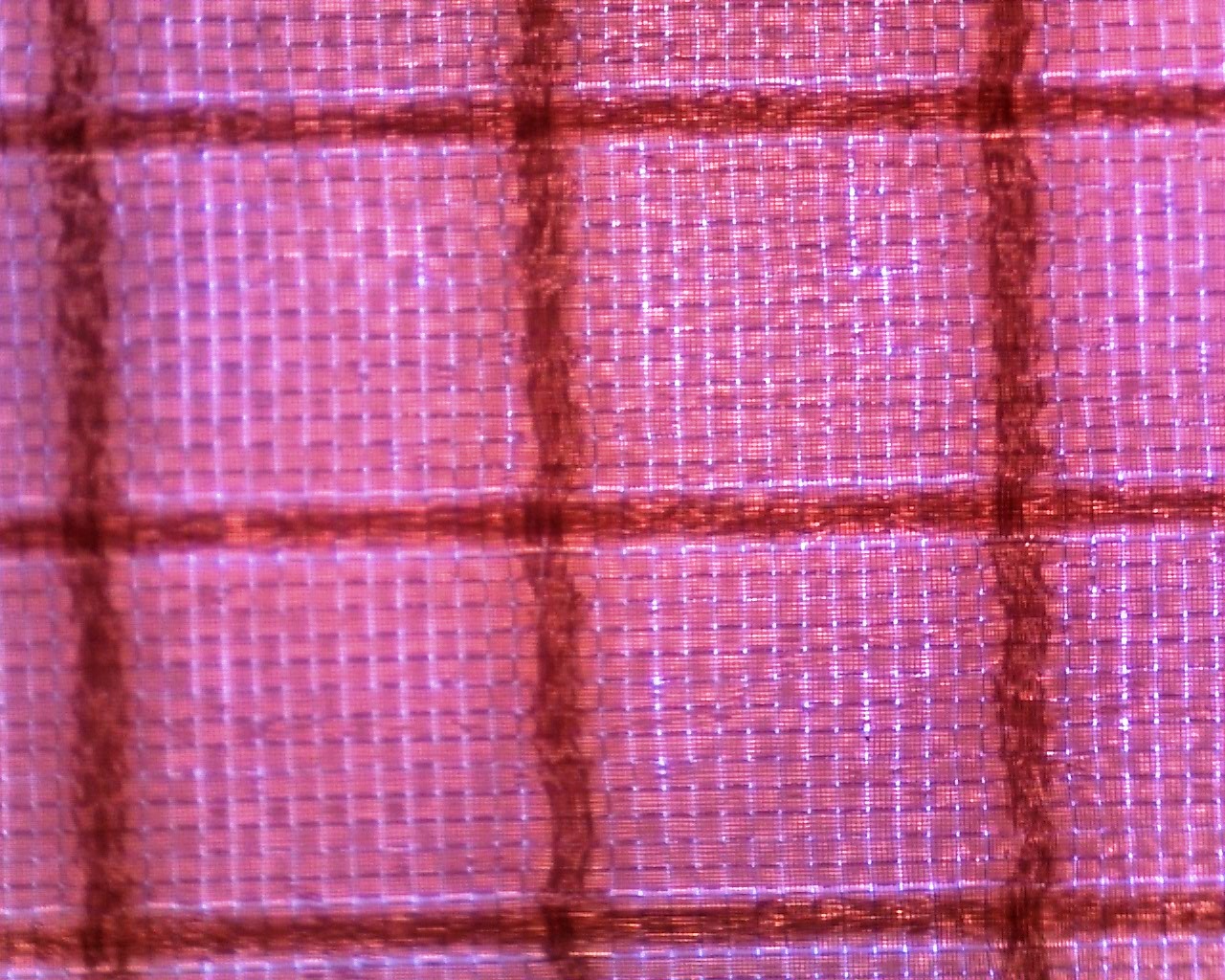

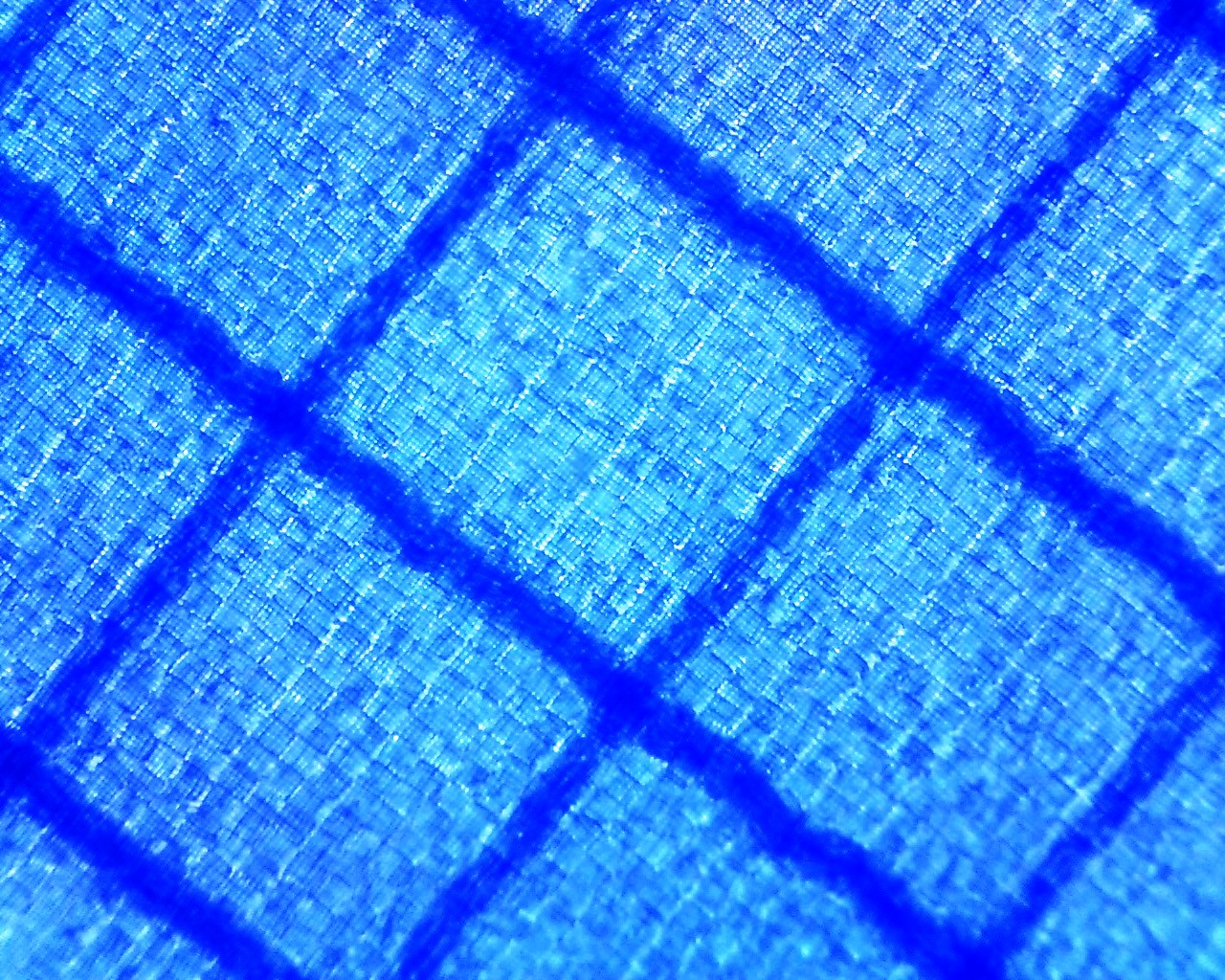

Versus the ARG recommended Montbell UL Stretch Wind Parka’s 17.6 CFM / 422 mm, the CFMs were similar but the HHs were quite different. The problem is caused by the lack of a uniform weave spacing. The following 2 micrographs are both 5mm FOV; the red material is the MB Tachyon Parka and the blue material is the MB UL Stretch Wind Parka. In the micrograph of the red fabric, note the larger pores at the corner of each woven square pattern. That is what caused the relatively low HH. I say relatively, because 176 mm HH is significantly better than the 70 mm HH of the popular bench-mark pre-2013 Houdini.

Mar 10, 2018 at 12:12 pm #3523565

Mar 10, 2018 at 12:12 pm #3523565Richard,

Long-time lurker here; many thanks for yet more highly informative testing. Just wondering if you would describe the process of your ‘32F and torrential rain’ test? As a Scottish hiker, gear tests simulating such conditions are always welcome!

Cheers,

Chris

Mar 10, 2018 at 6:15 pm #3523590Chris,

I use a simple temperature calibration method to insure that the water reservoir is kept at 32F (0C). I add enough ice cubes so that that there are still ample unmelted ice cubes at the end of a 1 hour test cycle.

Mar 10, 2018 at 9:15 pm #3523608Hi Richard,

Thanks for your very detailed response to my questions about Montbell’s 12d ballistic nylon ripstop fabric. As you suggested, I’ve performed some rough CFM and HH tests to see where my Montbell Dynamo Parka stands after 10-15 days backpacking, maybe 30 casual walks and 5 or 6 washes.

Regarding CFM, I compared it to a number of new garments and new fabric bolts with known air permeability numbers, either provided by manufacturers (e.g. Tweave) or yourself over the years. I compared my Dynamo with a new 2015 Houdini (CFM ~3.75), a bolt of Tweave Durastretch 518C (CFM ~35), a new Sierra Designs Solar Wind (50 CFM) and a new Black Diamond Alpine Start (CFM ~70) and estimate the Dynamo’s current air permeability to be 35-45 CFM.

I carried out fewer tests using your suggested 2 cup method to estimate hydrostatic head because about 1 1/2 of the 2 cups drained out in about 15 seconds without any additional pressure applied.

Thanks for noting that the 12d fabric (assuming the Dynamo’s 12d is the same as currently used in the U.S. Stretch Wind) does not have a coating. Another hypothesis for the degradation of the HH of my Dynamo was that it had a PU kiss coat on the interior surface that had abraded off since new.

At this point, I’m favoring the hypothesis that weave distortion secondary to the Dynamo’s 12 fabric being cut on the bias is responsible for the increased air and water permeability observed as the garment has aged. Time and again, your micrographs have revealed weave flaws in fabrics with surprisingly disappointing hydrostatic head measurements. The point of cutting on the bias is to orient the bias stretch in the directions that tend to elongate with body movements. It would make sense, then, that weaves oriented this way would tend to get pulled and distorted with use to a greater degree than garments sewn with conventional fabric orientation. I would be willing to bet (not much) that micrographs of the 12d fabric would show a much greater number of larger pores in the weave after some use.

If so, we might be able to use this to our advantage. You tested four colors of Epic Praetorian for me a couple years ago. One was an outlier, but three tested around 2.7 CFM and 400 HH. Like you, I’ve experimented with Praetorian jackets (a Patagonia Level 4, in my case) and find the low CFM limits their use to pretty sedentary pursuits. Holding these fabrics up to the light, one can see with the naked eye that most interstices are completely filled with the Epic silicone polymer; compared to most permeable fabrics, Praetorian almost looks like a solid sheet of plastic with some patches of holes poked into it, rather than a weave with a little hole at every interstice. I wonder if a Praetorian garment cut on the bias might become more permeable over time as plugged interstices get pulled open by repeated stretching of the fabric. I plan to make a bias cut jacket from the Delft Blue Praetorian you tested at some point; this color was the best of the four, with new values of 2.77 HH and 562 CFM. If my hypothesis isn’t complete BS, such a garment might reach an equilibrium after some use with air permeable more suitable for exercise, a HH that remains above 300 mm, while keeping the awesome water-repellancy of Epic. Nutty project, but worth a try.

Speaking of water-repellancy, do you have a sense of how durable the new “permanent” DWR being used by Marmot might be in the real world. Will this be an alternative to Epic? (Nanosphere was also touted as permanent but is decidedly not.)

Mar 11, 2018 at 3:11 am #3523656Stumphges,

Interesting “bias cut” hypothesis and a way to test it.

I have studied the GTI patents. The GTI permanent DWR, that Marmot used in their EVODry line, looks like a legitimate alternative to Epic for <5 CFM fabric PWPB requirements.

It looks to me like neither of their patents could be applied to create an ~25 – 35CFM and >300mm HH fabric for windshirts.

Mar 11, 2018 at 1:33 pm #3523700Hi Richard,

Thank you. Why don’t you think the GTI permanent DWR could be applied to an appropriate woven to create a 25-35 CFM, >300 mm windshirt? Does the DWR reduce permeability?

Mar 11, 2018 at 2:09 pm #3523710If I remember well, the DWR is pressed in the interstices and I would think that puts a limit on a high CFM.

Mar 11, 2018 at 3:59 pm #3523726Yes, Woubeir shares my assessment.

Mar 11, 2018 at 4:51 pm #3523738Thanks to both of you. If the GTI DWR occludes pores, shouldn’t it be possible to adjust for that using a more permeably woven virgin fabric, so that the pores are a desired size (e.g. correlating to 25-30 cfm) after the GTI DWR has been applied?

Mar 11, 2018 at 5:34 pm #3523748The DWR fills all the space so even if you start with a CFM of e.g. 375, you end with a CFM of <5.

Mar 11, 2018 at 8:48 pm #3523794Ah, thank, so does the DWR also serve as the WPB membrane?

-

AuthorPosts

- You must be logged in to reply to this topic.

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

Our Community Posts are Moderated

Backpacking Light community posts are moderated and here to foster helpful and positive discussions about lightweight backpacking. Please be mindful of our values and boundaries and review our Community Guidelines prior to posting.

Get the Newsletter

Gear Research & Discovery Tools

- Browse our curated Gear Shop

- See the latest Gear Deals and Sales

- Our Recommendations

- Search for Gear on Sale with the Gear Finder

- Used Gear Swap

- Member Gear Reviews and BPL Gear Review Articles

- Browse by Gear Type or Brand.