Topic

Strength of .93 oz Membrane Silpoly vs 1.24 oz Silnylon

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

Home › Forums › Gear Forums › Make Your Own Gear › Strength of .93 oz Membrane Silpoly vs 1.24 oz Silnylon

- This topic has 98 replies, 24 voices, and was last updated 6 years ago by

Jerry Adams.

Jerry Adams.

-

AuthorPosts

-

Apr 8, 2016 at 6:42 pm #3394900

Ripstopbytheroll finished weights

Trying to decide whether to go with the lighter .93 oz 15d Membrane Silpoly or the 1.24 oz 20d Silnylon. Both are Sil/PU double coated with a 1500 mm.

Of course I’d rather use the lighter Membane Silpoly (shelter), but I question whether or not the fabric would be strong enough to handle powerful winds. Thoughts?

RSTBR also has a 1.07 oz Membrane Silpoly with a 4000 mm. It’s 15d and is Sil/ PU on one side and multi pass PU 4000 on the other. Maybe a tad stronger than the .93 oz Membrane.

Apr 8, 2016 at 10:00 pm #3394955Truthfully I cannot attest to the relative strength issue, but…

I am currently building a shelter using the PU4000. It is much nicer to work will than the old 1.4 silnylon, or the Argon silnylon that I have used in the past. Not slippery, doesn’t bunch etc. Also from reports its 4000mm is pretty accurate, and does not fade with time/usage. The Argon was “just” water proof and allowed some spritzing during moderate to heavy rain.

-Dale

Apr 8, 2016 at 10:10 pm #3394958Read page two comments in this thread

https://backpackinglight.com/forums/topic/how-hard-is-it-to-make-a-pyramid-shelter/page/2/#comments

Apr 11, 2016 at 8:51 am #3395373I just ordered fabric for a tarp. I called and spoke with Kyle to ease my mind. I had previously spoken with Jimmy from Jimmy Tarps who uses mostly Silpoly from RSBTR. He has total faith in the .93 Membrane and uses it frequently. However, he has seen one failure with the material on one of his TENTS. I highlight tent because after speaking with kyle at RSBTR, he clearly stated that the .93 Membrane is only recommended for tarps. He said that the force is much more even on a tarp whereas the design and shape of a tent or mid will create odd stress points and could cause failure. As stated on other threads, the .93 without the PU coating has a higher tear strength so you should either use it or bump up to the 1.1 Silpoly depending on what you’re making.

RSTBR also has a 1.07 oz Membrane Silpoly with a 4000 mm. It’s 15d and is Sil/ PU on one side and multi pass PU 4000 on the other. Maybe a tad stronger than the .93 oz Membrane.

No, it will not be stronger, it will actually be weaker in tear strenght due to the PU coating and should really only be used for the floor of a shelter. FWIW, I have my .93 Membrane cut and ready as of last night and I will be sewing the tarp up tonight. After holding the material in hand, I trust it more now as it does seem really strong for it’s weight. I tried my best to tear it and couldn’t.

In summary, use .93 membrane silpoly for tarp, 1.1 non-pu4000 Silpoly for tent or mid. This is according to the owner of RSBTR who I trust to be correct.

Apr 11, 2016 at 9:38 am #3395383er…..why not for a ‘mid? how is that stress different than for a tarp??

I have both the .93 MEMBRANE and the 1.1 silpoly and plan on making pyramids with both of them. Should I not???

Apr 11, 2016 at 9:42 am #3395384Jennifer,

That was just Kyle’s recommendation. After holding the .93, I say go for it if you already have the material. It really does feel strong. You might just add some flexibility to your travel plans and take the heavier one if the weather looks like it could be bad, I.E. strong winds. As I’ve never seen a ‘Mid in person, I couldn’t speak to where the stress points might be.

Apr 11, 2016 at 10:31 am #3395397Jennifer,

My guess is the single pole structure of a mid is what is causing concern since it focuses a lot of strain in the peak area. Personally, I’m not very worried about it and am in process of building a mid from .93 myself.

Apr 11, 2016 at 1:31 pm #3395432Hoosier, please post some pics of the tarp when you’re done. Show close ups of the reinforcements and tieouts.

Nobody has commented on the RSBTR 1.24 oz silnylon. Is it inherently stronger than silpoly? Since it’s 20d I would certainly think so. I see the 1.1 oz Silpoly is 20 d, whereas the .93 oz and PU 4000 Silpolys are 15d. Of the 4 materials, is the silnylon the strongest?

Apr 11, 2016 at 1:41 pm #3395437I can do that for sure. I’m sewing the ridgeline tonight so it will probably be a week or so before I’m done. As far as the Silnylon, yea it will be slightly stronger, but unnecessarily so. I have heard and read a LOT of raving reviews os Silpoly due to it’s lack of sagging when wet. Don’t let anyone tell you it doesn’t stretch though. It is quite stretchy fabric, it just doesn’t absorb water like Silnylon. I think the strength of Silpoly is plenty strong for most plain vanilla applications (I.E. flat/cat tarps) and thereofr Silnylon’s strength would be overkill. The fabric comparison guide for coated fabrics from RSBTR is really handy as well if you haven’t seen it:

Apr 11, 2016 at 6:45 pm #3395504

Apr 11, 2016 at 6:45 pm #3395504Duh! Thanks Hoosier, I can’t believe I havn’t seen that chart before.

I’m going to go with the 1.24 oz Silnylon. It might sag, stretch and hold more water than the Silpoly, but tear strength is the most important thing to me. I want something I don’t have to worry about in a major blow.

Apr 11, 2016 at 6:48 pm #3395506Given the long history of silnylon shelters, I think it’s the safest bet. I’ll report back if I have any catastrophic failures with my tarp in case you ever want to use membrane for a future project. :)

Apr 11, 2016 at 9:34 pm #3395539Speaking of tear strength, I can speak highly of the 1.24oz silpoly when it comes to winds. I spent some very windy nights in a ‘mid with that material in December and it held up just fine. It wasn’t raining, we just set it up to get out of the wind.

Apr 12, 2016 at 9:38 am #3395617Got my ridgeline sewn up last night. Aside from being slick, this .93 membrane is really easy to work with. Worlds easier than even 1.1 oz ripstop nylon despite it being lighter. Pretty happy with it so far but I’ll definitely post some photos for you when I’m done. Should just be a few more days.

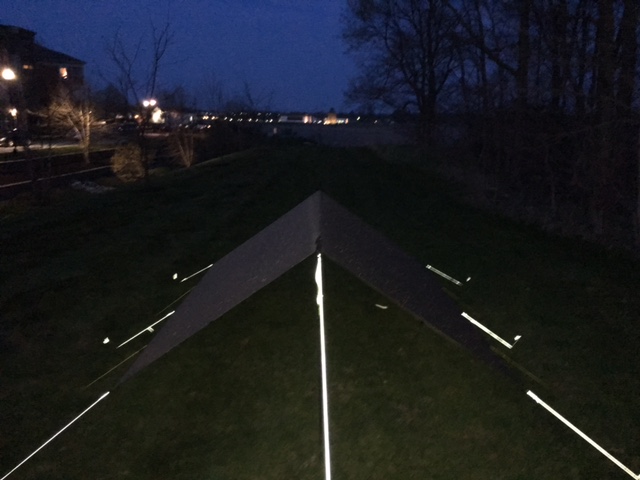

Apr 18, 2016 at 7:28 am #3396577The tarp is done and I’m really happy with the Membrane Silpoly. The tarp is 9×10 and the finished weight (tarp only, no guyline) is 12.2 oz. I will get a close up of the reinforcements later on and post them, per your request. I just used triangle reinforcements with the tie out sewn to the 1/2″ seam with an XBOX stitch. First time ever pitching a tarp so please don’t hate. I definitely need some practice. However, I tugged and tugged on the tie outs, mostly the ridgeline, trying to see if anything would tear and nothing even budged. Very happy with the results. I do need to tweak the lines for the Echo net as they’re too short so that’s the reason for the poor structure.

Apr 18, 2016 at 8:11 am #3396587

Apr 18, 2016 at 8:11 am #3396587It must have been windy?

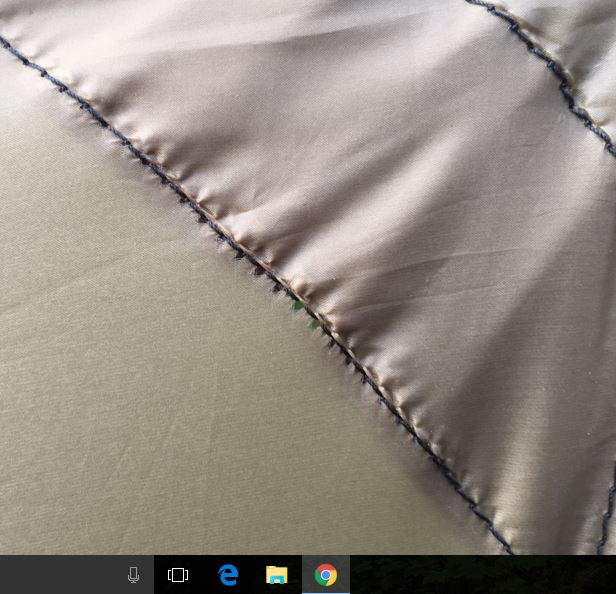

Yeah, closeup of reinforcement

Apr 18, 2016 at 8:19 am #3396591Yea there was a steady wind. I will post close ups tonight.

Apr 18, 2016 at 8:40 am #3396595with generic 1.4 oz silnylon you don’t have to worry much about reinforcements. Like just sew webbing to a seam or hem.

I suspect with these lighter weights and poly, reinforcements are more important.

Apr 18, 2016 at 8:45 am #3396598In regards to strength, given an equivalent coating of around .35oz we have a fabric weight of .58 and .89oz for each. (within a few hundredths of an ounce.) Given that nylon66 is roughly 40% stronger to start with, we have a relative strength based on the weight of around .58 for Poly and 1.25 for Nylon…or roughly twice as strong. If your membrane tarp works, then strength only means how long it will last, generally speaking.

Apr 18, 2016 at 1:51 pm #3396663Looks good Hoosier, but I’d personally go with more tieouts on a 9′ X 10′ tarp….16 to be exact. I think you’d be surprised how much tighter of a pitch you’d get . Of course you would use 12 tieouts with the A frame setup.

I’d be afraid to go with just 8 tieouts on a tarp that size in big weather, you might suffer shipwreck in a powerful thunderstorm.

Apr 18, 2016 at 1:52 pm #3396664 There 16 tie outs, you just may not be able to see them all. I will also be adding two panel tie outs on each side and three ridgeline tie outs.Apr 18, 2016 at 1:56 pm #3396665

There 16 tie outs, you just may not be able to see them all. I will also be adding two panel tie outs on each side and three ridgeline tie outs.Apr 18, 2016 at 1:56 pm #3396665Oh, ok, sorry. didn’t see them. Yea I’d like to see pics with the other 4 side tieouts put into use.

Apr 18, 2016 at 1:56 pm #3396666They are kind of tough to see as I used smaller reinforcements on the mids. 6×6 squares cut in half vs 8×8 squares for the main tie outs.

Apr 18, 2016 at 1:58 pm #3396667Yea I’ve been waiting for my Zing it to come in as that’s wat I’m going to use for the extra tie outs. I’m using Lawson’s 2mm glowire for all the others. I’ll try to pitch it tonight and get some photos as well as some close ups of the tie out construction.

Apr 18, 2016 at 7:33 pm #3396735Well it got dark on me but I took some pics anyways. Good call on using the extra side tie outs. With those, it was drum tight. Better than I even expected I would get with a flat tarp. I also took some pictures of my tie outs. For the smaller side tie outs I used a Z stitch instead of the XBOX as I felt it was plenty for low stress points.

Mids:

Ridgeline:

Corner:

Pitched:

Apr 19, 2016 at 5:33 pm #3396876

Apr 19, 2016 at 5:33 pm #3396876So after a third pitch I have some concerning findings. This is my first tarp so maybe I’m paranoid but this looks to me like it could rip out any minute. It looks this way at both ridgeline tie outs. Thoughts? I would say hold off on using the Membrane for now :) Maybe I’m just biased since I just potentially wasted $60 and hours of work. I sent an email to Kyle at RSBTR to get his thoughts as well.

-

AuthorPosts

- You must be logged in to reply to this topic.

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

Our Community Posts are Moderated

Backpacking Light community posts are moderated and here to foster helpful and positive discussions about lightweight backpacking. Please be mindful of our values and boundaries and review our Community Guidelines prior to posting.

Get the Newsletter

Gear Research & Discovery Tools

- Browse our curated Gear Shop

- See the latest Gear Deals and Sales

- Our Recommendations

- Search for Gear on Sale with the Gear Finder

- Used Gear Swap

- Member Gear Reviews and BPL Gear Review Articles

- Browse by Gear Type or Brand.

There 16 tie outs, you just may not be able to see them all. I will also be adding two panel tie outs on each side and three ridgeline tie outs.

There 16 tie outs, you just may not be able to see them all. I will also be adding two panel tie outs on each side and three ridgeline tie outs.