Topic

Standardised Benchmarking for Insulated Jackets (beyond R-Value)

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

Home › Forums › Gear Forums › Gear (General) › Standardised Benchmarking for Insulated Jackets (beyond R-Value)

- This topic has 62 replies, 11 voices, and was last updated 4 years ago by

Rex Sanders.

Rex Sanders.

-

AuthorPosts

-

Apr 2, 2020 at 2:47 pm #3639367

I am not sure that either of you guys are being fair to the R-value measurement. It is a measurement of the insulation value of a single layer of material. It is NOT a measurement of of an entire floor/wall/ceiling assembly, and attempts to make it so are silly. It’s a bit like trying to use the cubic capacity of an engine to indicate the horsepower.

The use of R-value as a measure of an air mat or foam sheet is not perfect, but it IS a starting point. It will let you compare a down air mat to a 1/4″ layer of foam, and it will let you see what effect the level of inflation has on an air mat. Without some sort of measurement you would be left in the wilderness.

The use of R-value on clothing is obviously a lot more tricky. We can measure the R-value of the back of the jacket and be able to make some predictions about how the jacket might perform: that is reasonable. It’s when someone tries to make that R-value measurement as the sole means of comparison between two jackets that the whole thing breaks down a bit.

I suggest that the real problem is not with the concept of ‘R-value’, but rather with the gap between what a single measurement means and what the consumer is able to comprehend. Imagine trying to say that car A is better than car B because it has more horsepower -while ignoring the fact that car A steers like a pig and has pathetic brakes.

That’s the problem: consumer perception. It is not helped by marketing spin, which sadly often comes from a source of ignorance. Sadly, I don’t have a solution to that!

Cheers

Apr 2, 2020 at 3:46 pm #3639371What is it that we really want to know, from a pragmatic stand-point?

Take the climber / belaying issue. Working hard (generating heat), you stop and your climbing partner takes over. You put on your belay jacket.

Question: How long before you’re freezing your something off?

It’s all about time. How long can I slow down nature’s unrelenting quest for equilibrium. That’s why the more I read about it the more I like the mannequin model and Scramble’s time suggestion : a measure that says in X (fixed) conditions Jacket Y lasted Z minutes before Mr Mannequin dropped a pre-defined unit of temperature.

You’re testing the whole jacket and everyone can relate to getting colder over time.

If you have a jacket with 10 g/sm of insulation on the back and 200 g/sm of insulation at the front. Such a test would expose that.

We’re asking these jackets to perform an endurance test against the cold. How long can they stem the tide? That’s the question. And I don’t think the R-Value as a single measure really gets that temporal aspect across to the average consumer (i.e. me).

Andy

Apr 2, 2020 at 5:02 pm #3639379R value / Clo value on its own is meaningless without knowing how much of your body the garment covers, what the fit is and how transparent to weather that same garment is.

But the old standby of simply looking at the two easiest factors still should work, how big is it and how thick is it.

Nobody would be so stupid to make a jacket with 10GSM on the back and 200GSM on the front but they do often use different weights on the sleeves and hoods and that I would like to see evaluated.

If the discussion is about belay jackets in particular then fit becomes much more important as does seasonal and situational importance. An Alpine or winter belay jacket needs to provide both more insulation and greater coverage than one used for mild weather rock-climbing and also needs to be more weather proof and more robust than the usual UL gear talked about in this forum.

The time factor is easy enough to guestimate; for belay jackets it’s about an hour or so, which is about how long it might take to climb a pitch, belay and bring up the second on the rope and exchange leads and swap the jacket over as you might be sharing the belay jacket.

No single factor rules here but wind resistance is a high priority

Apr 2, 2020 at 8:20 pm #3639416I think that either R or clo would be a good starting point. Just to have some idea of what you can expect. Then the marketing would be for the features not the warmth.

it would still be up to the individual to determine if they wanted one face fabric over another, or a wpb membrane.

customer reviews would take care of ‘arms too short for climbing, or boxy cut, or wind cuts right through.’ If the user didn’t look into it that much then whatever they get is what they get, but they would have some sort of Starting point for the overall warmth.sleeping bag ratings used to be Up to the companies and it sucked, then EU ratings came out. It isn’t perfect but it gives a baseline until the next best way to rate them gets ‘invented’

Apr 3, 2020 at 7:47 am #3639442you need that chart that Richard posted

clo required vs temperature

with lines for different MET – vigorous exercise, camping, sleeping,…

that gives you a particular clo required (or you can use R or the metric equivalent – just different units, you can use whatever you’re familiar with)

that’s the average over your entire body. If you’re using a sleeping bag, that’s straightforward, if you’re wearing a coat/pants/hat it’s more complicated

clo or R value for a jacket is a good starting point

at least you can use it to compare different jackets. If your current jacket is too cold or warm you can get idea what new jacket to get

Apr 3, 2020 at 10:31 am #3639474“It is a measurement of the insulation value of a single layer of material. It is NOT a measurement of of an entire floor/wall/ceiling assembly, and attempts to make it so are silly.”

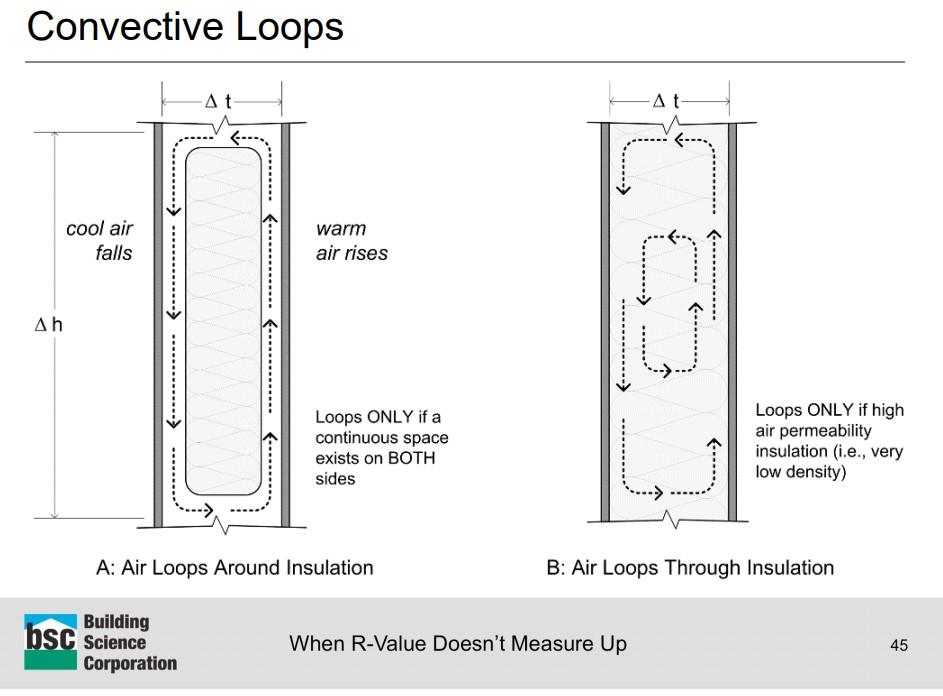

Roger, that’s precisely the issue: For ages, builders have been led to believe that R(assembly) equals the sum of all the R values which it does… sort of, (I was taught this in architecture school 30 years ago). But it’s 2020 now, and it’s pretty clear that the overall performance of an assembly requires a different kind of analysis. Although the more recent International building codes have finally created prescriptive solutions to reconcile both air infiltration requirements in conjunction with the use of materials with R values within assemblies, there is still miss-perception going on, both in the building industry and consumers alike.

(Slideshow from a ten year old presentation at NSEA : When R-Value Doesn’t Measure Up)

And regarding single materials? Sure, R value is a good starting point for measuring a single homogeneous material at a specific temperature (since temperature has now been proven to affect the R values of even what we define as a homogeneous materials), but it seems the biggest issues arise when examining non-homogeneous materials.

In my opinion, down jackets, air mattresses and any other “assembly” of materials should not be measured by a R value alone. There are too many variables involved which can greatly skew the R value testing results. And when the marketing departments are involved, it’s obvious which way they will skew their numbers.

(fwiw, ASTM F3340 does take non-homogeneous mattresses into consideration. Sadly, it’s way of doing this is by only by changing the test location on the pad and averaging the results. The testing ambient temperature and pressure applied on the pad are not changed in the analysis, which field experience has proven will greatly affect the results.)

Apr 3, 2020 at 10:56 am #3639476another complication is convection

if it’s windy and you don’t have a wind blocking outer layer, the insulation will be less effective

with a wind blocking outer layer, the wind will reduce the skin effect so the over-all system effectiveness will be less

still, if all jackets used the same R value measuring standard, you could compare different jackets. If you are just a little cold or very cold in your current jacket, you could get an idea which jacket to replace it.

Apr 3, 2020 at 3:01 pm #3639512Convection is probably one of the biggest issues to consider with insulated jackets. With wall assemblies, wind pressure combined with interior convection due to tiny air gaps can reduce the assembly’s R value by over 50%! So how might “interior convection” affect the R value performance of a down jacket, or an air mattress?

Apr 3, 2020 at 4:28 pm #3639521

Apr 3, 2020 at 4:28 pm #3639521builders have been led to believe that R(assembly) equals the sum of all the R values

I have to plead complete ignorance here about the US building trade. What is written here could be (mis)interpreted to mean the builders add the R-value of the wall to that of the floor and ceiling – which is clearly totally false. Or is the problem more to do with air leaks?This latter (air leaks) is obviously relevant to clothing as well. The R-value of a flat bit in the middle of the back of the jacket is obviously not a full measure of the warmth of the jacket when worn. Again, marketing spin plus consumer ignorance – for which there is no solution.

Cheers

Apr 4, 2020 at 8:36 am #3639604Hi Matt:

I believe the objective of the Power Point you reference is that material properties or construction/design errors can result in unexpected performance that may deviate from expectations.

Many of the design/construction issues cited in the Power Point are well understood, and have led to changes in construction practices. I know from personal experience that many of the design/construction issues raised in the Power Point were discovered through testing and have resulted in the implementation of government mandated testing to ensure these errors don’t end up in newly constructed buildings. Here is an early discussion of some of these issues:

Stephen Seeber, “Use Of Infrared Thermography For The Identification Of Design And Construction Faults In Buildings”, Proc. SPIE 0446, Thermosense VI: Thermal Infrared Sensing for Diagnostics and Control, (27 March 1984)

This is not to say that the issues identified in the Power Point have been eliminated. But, diligent developers can and do employ testing as a quality control tool to help ensure that building thermal performance meets expectations.

We all know that actual comfort of a garment in use is a complex combination of user physiology, garment performance characteristics and environmental conditions. However, measurements made through testing can shed light on the complexity and where design or construction methods fall short. These measurements can help inform consumers of where their expectations may not be met.

The fact that manufacturers may not make or publicize the results of tests means that 3rd party testers should be relied upon more heavily to fill that gap. Measurements of R value, moisture vapor transmission, air permeability, wicking and others may not be perfect, but they can provide substantial insight into performance that consumers can expect in the garments that they purchase.

Apr 4, 2020 at 5:51 pm #3639667In the short term if only makers would list both fill weight/ fill power AND average loft

Apr 4, 2020 at 5:59 pm #3639673@ed

That information might not be what they want you to think about.Cheers

Apr 4, 2020 at 7:27 pm #3639711<rant>

I sincerely hope the backpacking industry doesn’t repeat the many head-slapping mistakes made by California building code authors, particularly around “energy savings.” What looked great on computer screens has turned into costly and health-threatening disasters in real life.

</rant>

Back to topic: R-values have many other problems that I won’t repeat here. https://backpackinglight.com/sleeping-pad-r-value-not-that-useful/

— Rex, a disgruntled and much poorer home owner

-

AuthorPosts

- You must be logged in to reply to this topic.

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

Our Community Posts are Moderated

Backpacking Light community posts are moderated and here to foster helpful and positive discussions about lightweight backpacking. Please be mindful of our values and boundaries and review our Community Guidelines prior to posting.

Get the Newsletter

Gear Research & Discovery Tools

- Browse our curated Gear Shop

- See the latest Gear Deals and Sales

- Our Recommendations

- Search for Gear on Sale with the Gear Finder

- Used Gear Swap

- Member Gear Reviews and BPL Gear Review Articles

- Browse by Gear Type or Brand.