Topic

Evaluation of North Face Futurelight

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

Home › Forums › Gear Forums › Gear (General) › Evaluation of North Face Futurelight

- This topic has 32 replies, 3 voices, and was last updated 2 years, 6 months ago by

Christopher S.

Christopher S.

-

AuthorPosts

-

Oct 25, 2019 at 2:53 am #3615617

North Face has introduced their latest technology, Futurelight, with lots of marketing fanfare. After reading a number of reviews, I decided to take a look at a Futurelight garment to see if it lives up to the fanfare.

You can read about it here: https://www.dropbox.com/s/emgxodiuxotssih/

Oct 25, 2019 at 7:01 am #3615629The above tests are good performance indicators for DWR based air permeable rain gear used for typical front country use with no rain or light to moderate rain. The very expensive Gore-Tex Pro rain (>$1,000 for a top/bottom) used during the podcast trip (link below in next paragraph) also tests similarly using these methods.

This is what frequently happens and how the user explains it when they don’t understand the related physics differences between different WPB technologies: Podcast

Those who understand the related physics, commonly use windshirts for optimal air permeability and only non-porous (aka non air permeable) rain gear for backcountry environments subject to heavy rain events.

Related Physics

The vast majority of the methods that are currently used to test rain gear, do not consider the effects of rain. Since waterproof breathable fabrics are intended for use under conditions of rain, such methods do not fully assess the transport properties of waterproof breathable fabrics.

When it is raining, the removal of perspiration through venting becomes less effective. This is because firstly, the ambient air, which usually mixes with and dilutes the air within the clothing microclimate has itself got a very high water vapour concentration. Secondly, the garment apertures through which venting occurs, are usually closed to prevent rain ingress. This means that the removal of water vapour through the fabrics themselves becomes more critical when it is raining.

Experimental Method

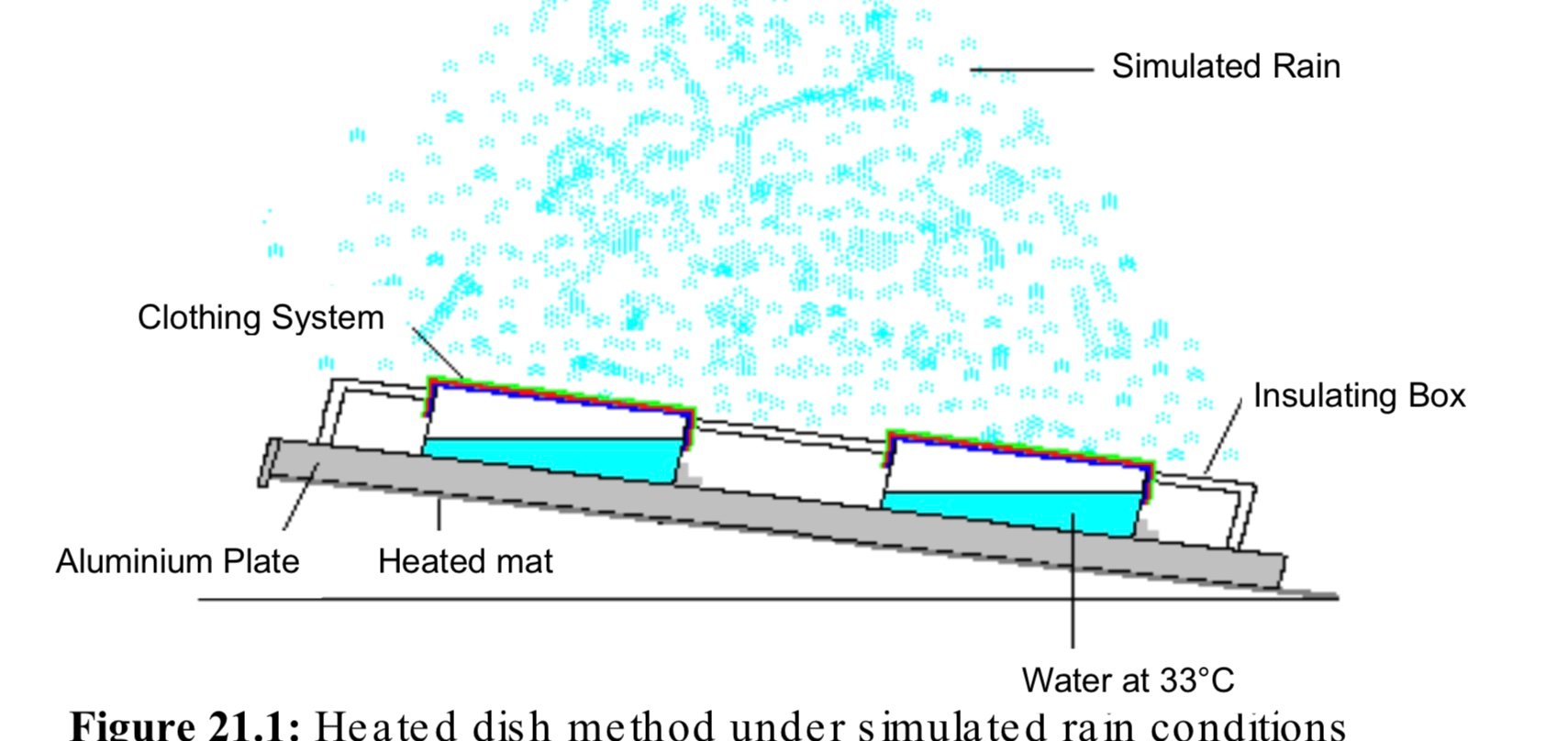

To undertake this work a heated evaporative dish method was developed. This method allowed waterproof breathable fabrics to be assessed with a simulated clothing system under realistic conditions in terms of temperature, relative humidity and rain conditions.

Ten glass dishes were placed onto an aluminium plate heated by a carbon mat (Figure 21.1). This heated mat maintained water in the glass dishes to stimulate skin temperature. Waterproof breathable fabrics in conjunction with a standard clothing system were sealed over the mouths of the dishes. An insulating guard ring was used to ensure that heat was only lost through the clothing systems. The heated mat assembly was tilted at an an angle of 10 degrees to prevent an excessive accumulation of rain on the samples.

An atomising water jet was adopted to create realistic rainfall. The jet was mounted 150 cm above the base of the heated mat. This jet was connected to a metered water pump and a compressed air line. The water pump and air pressure were set to create rainfall that corresponded to that of actual heavy rain in terms of intensity and drops size.

The whole apparatus was housed inside an environmental chamber, and hence any desired temperature and relative humidity could be adopted. For this series of tests a temperature of 5°C was adopted with an RH of 65%, to simulate winter conditions in the UK.

A selection of two layer waterproof breathable laminates were assessed. These included microporous PU samples, hydrophilic PU samples and bicomponent samples which

contained a microporous PTFE element and hydrophilic PU element. All of the films were laminated to polyamide Taslan face fabrics. Assessed with the waterproof breathable samples to simulate actual wear was a polyester lining fabric, a polyester fleece fabric and a cotton jersey T-shirt fabric.The clothing systems were assessed for three hours under both dry and rain conditions. The assessment of the clothing systems were based on the moisture vapour transmission rates, which were determined by the weight of water lost from the dish assembly, and the amount of condensation that accumulated within each clothing system.

To confirm the validity of the laboratory assessments, a series of controlled wearer trials were undertaken in a rain chamber. The rain chamber also simulated heavy rain. The fabrics assessed in the laboratory tests were manufactured into standard clothing systems for use in the wearer trials. Objective results were obtained through the use of temperature and relative humidity sensors that were located within the clothing ensemble.

Results

Under dry conditions, the bicomponent samples and the hydrophilic samples transmitted similar amounts of water vapour. The microporous samples transmitted slightly less water vapour (Figure 21.2). All of the clothing systems accumulated a small amount of condensation. Under conditions of rain, the moisture vapour transmission rates of all the samples declined when compared to the dry rates (Figure 21.2). Correspondingly, the amount of condensation that accumulated within the clothing systems increased. The extent to which the moisture vapour transmission rates fell was not uniform for all of the samples. The microporous samples ceased to transmit water vapour under rain conditions and accumulated the largest amount of condensation (Figure 21.3). The moisture vapour transmission rates of the hydrophilic samples fell by 57%. These samples accumulated less condensation than the microporous samples. The moisture vapour transmission rates of the bicomponent samples fell by 27%. When compared to the other types of waterproof breathable fabrics, the bicomponent samples transmitted the greatest amounts of water vapour under rain conditions and accumulated the least amount of condensation.

The violet bars are for dry conditions and burgundy are for hard rain after 3 hours.

Oct 25, 2019 at 11:19 am #3615635Richard:

Please check your post. It did not reproduce properly so I cannot follow your discussion.

Steve

Oct 25, 2019 at 1:23 pm #3615643Richard,

Without seeing the rest of your post due to some weird corruption or something: Is there any reason to expect permanent beading surface (Outdry Ex, GoreTex Shakedry) fabrics to perform differently under the conditions experienced by the hunter, or perspective backpacker?

Oct 25, 2019 at 1:54 pm #3615645Cool report, thanks for posting.

Oct 25, 2019 at 3:31 pm #3615658Hi Stephen,

Thanks so much for this. I have some questions which I am curious about regarding your analysis:

- Regarding Futurelight as a material, I thought I read somewhere that one of the reasons why TNF has created this is because they can create fabrics with different levels of permeability. Are you aware that this is to be the case? (If so, perhaps we might end up with different “Futurelight” materials which all behave differently, creating confusion.)

- Air Permeability vs Breathability: I understand the use of the term air permeability. I’m curious as to why you used “Breathability” instead of vapor permeability. Has the term “breathability” become “commonly accepted” to only refer to vapor transport now? If so, I’d be concerned that more consumer confusion would occur, since people still use a “breath test” to evaluate cmf movement through a fabric (aka air permeability).

- Speaking of air permeability, do any of the jackets tested have any mechanical ventilation? While I understand that they are all considered to be “windproof”, it may be important to note if a jacket does contain such a feature (like pit vents), it will perform very differently as a whole. If so, it may be important to note this because a “less breathable” jacket with mechanical ventilation will ultimately “perform” better than it’s material tests might otherwise indicate.

Also, have you see this?

Thanks again for doing this.

Oct 25, 2019 at 10:38 pm #3615759Hi Richard:

I will take some time to read this. I think it will be an interesting discussion. However, this general issue for measuring performance with any WPB garment is pretty off topic for the review I have written. The point of my review is to consider whether this product moves the needle on performance of WPB garments. One can read the data that I have gathered and make their decision. If you believe WPB fail under certain circumstances, then you have probably made your decision. I have actually contacted Tyler Freel to get more details on his experience and will share the information as it arrives. However, I think you might simply start a discussion of these issues on a separate thread and see if we can get members with similar experiences to describe the situations where they think their WPB garments failed. I think we should get plenty. I think this would be useful so that members can become realistic about what to expect from their expensive WPB garments.

Oct 25, 2019 at 11:13 pm #3615774Hi Matt:

Before I moved out to Colorado, I lived pretty close to you and I used to shop at HTO when it was Hudson Bay Outfitters. They had a great store in Kensington back then.

Let me try to respond to the points you raised:

- TNF does say they can adapt their membrane technologies to many uses. In fact, if you look at their lineup of garments using Futurelight, they do the change the fabric construction. I can’t tell much, but they change the face and liner deniers. Don’t know if they change the membrane properties. However, I suspect that if they improve breathability they may loose HH performance. As described in the report, Neoshell had somewhat better breathability than Futurelight but HH performance of Neoshell was not as good as Futurelight. I selected the lightest fabric they presently offer expecting that it would provide the best breathability that could be achieved, particularly since it was aimed at the running market. So, it is possible they will evolve the products and get better performance. But, can it improve enough to matter, or just enough to justify additional sales as a “new and improved” product like the latest laundry detergent? Time will tell. I would like to get my hands on one of their “Alpine” models and see how the performance compares.

- I share your frustration on the terminology. Vapor permeability seems more descriptive to me, but breathability seems to have become the popular term. As you point out, a breath test measures air permeability, not vapor permeability. It is kind of confusing. When I read product reviews or people’s comments, it is not always clear which they are talking about.

- Mechanical ventilation, as you are clearly aware, is critically important and typically will remove more water vapor than breathability. I really did not address the features of this jacket because I wanted to concentrate on what the fabric brought to the table, not features that can be easily changed. In fact, this jacket lacks pit zips and positive closures for the sleeves, both of which I think are necessary on any jacket that I will use. This jacket does not have the feature set I would want for my activities. However, it is designed as a running jacket, and runners might be happy with the feature set. Their other jackets have additional features that are more suitable for backpacking and winter activities. I do agree with you that mechanical ventilation will always enhance jacket performance. It will add a bit of weight and some cost and bulk, but done right, I will want those trade-offs. I own the other two jackets included in this study and they have gotten a lot of use. They both have excellent ventilation features and controls.

- Also, have you seen this? Read it. Sounds strangely like the way I do my breathability tests. I have similar USB humidity/temp sensors (theirs are not USB) and a Labview control program to run the kettles. I can control on various temps at different process locations. I can also control on vapor pressure differential over a fairly wide range. As noted in the paper, I tested at three vapor pressure differential setpoints, .2, .3 and .4. This was probably unnecessary since these are all microporous membranes in this study, so, as found, the response to vapor pressure differential was pretty linear. The use of alternate VPD setpoints is useful when testing PU membranes, which are hydrophillic or combination PU/PTFE membranes such as Goretex Pro Shell. Windstopper, tested here, lacks the PU layer. When I first looked at the paper, I thought perhaps they were going to embed sensors within test garments on actual people. This would be an interesting approach but, I think it would be difficult to pull off for a variety of reasons. Hence, the reliance on labs better funded then mine on active mannequins that heat, sweat and walk. Of course, these present their own analytical issues and have their own ISO standard. Finally, ASTM F2298 describes a testing procedure using the Dynamic Permeation Cell that was developed Phillip Gibson of NATICK, allows control over a broad range of parameters that covers, it seems, everything that matters. It is a very flexible test that permits lots of issues to be investigated. Sadly, building one of these is also beyond my budget.

Steve

Oct 26, 2019 at 1:11 am #3615793Hi Richard:

I took a quick look at what you posted. Who did this study, I would like to read it?

There are lots of studies on this issue.

ASTM F2298 describes a testing procedure using the Dynamic Permeation Cell that was developed Phillip Gibson of NATICK, allows control over a broad range of parameters that covers, it seems, everything that matters. It is a very flexible test that permits lots of issues to be investigated. It has been used to look at precisely the issues raised in the report that you have reproduced. I am sure you have access to the many papers he has published on this topic. The simplest should be found by doing a google search for “Breathability Comparison of Commercial Outerwear Shell Layers”. If you cannot find it PM me and I can send you that and others. This little report is great because it summarizes the issues raised in the report that you cited. Of course, in other papers, he deals with this issue at length.

My kettles can also look at this kind of issue. Since I can run my kettles to meet a vapor pressure differential, all that needs to be done is to calculate the VPD that corresponds to the condition of the test that you cited. You can get a little flavor for this in the data I included in my report. I looked at three different VPDs to see how linear the response would be. I do not have the range of control of a Dynamic permeation cell, but I am not limited to a single static test condition.

I now have two responses from Tyler describing his experience in detail. I agree with you that this failure is interesting. I have not done any calculations yet, but I do not see why water could penetrate the membrane just from wind. He is a very experienced outdoor person and his email is pretty interesting.

As I stated above, I suggest you post this story as its own thread. Perhaps the members have their own similar experiences or can shed light on this. I will do some vapor pressure calculations based on the information he has given me. If you can start the thread, I will participate. I have already asked Tyler if I can reproduce his email describing the journey and the conditions to which he was subjected and am awaiting his reply. This would be an interesting project, I think, for the community.

Oct 26, 2019 at 5:01 pm #3615869“I used to shop at HTO when it was Hudson Bay Outfitters. They had a great store in Kensington back then.”

That was a wonderful store! My first “real job” at 16 was working at the HTO in Tenley Circle (30+ years ago.) Because REI didn’t have brick & mortar stories east of the Mississippi back then, HTO was the place to be.

I hope I’m not causing too much thread drift on this next question, but something has been vexing me for all these years: the claims that wetted out jackets aren’t actually leaking, but simply condensing from a user’s perspiration. One thing I’ve noticed as an architect over the last decade is an increased awareness and understanding of vapor drive through wall assemblies.

And then the following article came out a few years ago which made me think about wetted out jackets:

https://www.buildingscience.com/documents/building-science-insights/bsi-099-its-all-relative

Working in outdoor retail for a lot of my early adulthood, I’ve been around a lot of unhappy folks trying to explain to them that their “jacket doesn’t leak”. I’ve also personally experienced a high quality jacket “wet out” while casually wearing it, and it genuinely feels like bulk water infiltration, especially since I was not exerting any high level of heat and perspiration. And it’s <b>not</b> the same sensation as sweating under a silnylon jacket. And I don’t believe the sensory difference can be explained as a “temperature gradient phenomenon.” (Or whatever it’s been called.)

So… I’m genuinely starting to wonder if the so called “4th state of water” in the BSC article above may have to do with vapor permeable jackets “short circuiting” due, to the miss-understood physics of capillary condensation, especially when the temperature differential on the two sides of a material is high. I’m wondering if may only take a tiny bit of vapor drive in this scenario to “construct” water on both sides of a porous membrane surface.

And on that note, when calculating for the vtmr, is the material itself being weighed before and after the testing? Theoretically it’s kind of like a sponge, right?

Oct 26, 2019 at 5:49 pm #3615877Hi Stephen,

In the gearjunkie article by Regenold, he repeats the 75,000 MVTR , 1.5 CFM claimed by TNF. But when he asked a TNF rep to compare Futurelight to Ascentshell and Neoshell, “He had no comment. Mellin said TNF would release more test data this fall, at which point some of the lab-generated specs can be compared for anyone interested in the membrane wars.”

Have TNF released any further test data on Futurelight? I have also seen test numbers mentioned in some reviews of the Interstellar (15 k HH, 30 k MVTR), but haven’t found any official numbers for Ascentshell on the OR website. Rab does have HH (10k) and MVTR (35+k) numbers for Proflex on their site, though they do not specify the specific MVTR test standard.

I know that Gore does not use these numbers and understand their reasoning (their testing better simulates real world conditions and uses). I have, however, seen some manufacturers publish test numbers. I had a Mammut Gore Tex Active/C-Knit (Meron Light HS) that they stated as 28k HH, RET <3.5 m2 Pa/W.

Oct 26, 2019 at 6:39 pm #3615880Hi Matt:

I can answer the last question easily. At the end of the test, if I see evidence of condensation on the bottom of the garment, I will weigh it and compare it with the dry garment. In my test configuration, for the types of garments that I test, this almost never happens. However, it will happen with garments with low breathability. The review I did here: https://backpackinglight.com/forums/topic/performance-evaluation-of-12-99-rockbros-jacket/ was a great example of this. It had an MVTR of 480. The lowest of any fabric I have tested and it had lots of condensation. Since I am recording humidity and humidity was extremely high, this is most likely condensation rather than adsorption, to which you refer.

That is a pretty complicated article you reference and worthy of more than the brief look I gave it. I would not be surprised if adsorption energy levels of nylon and polyester are much lower than those of brick, mortar and other construction materials. Especially when fabrics are coated with DWR, which will lower the surface energy of the fabrics to prevent bonding of with water. Your article discusses the relatively narrow coating of water that occurs, 5 molecules thick, depending on surface energy. Such a thin coating my support mold growth, but can it lead to enough water accumulation to wet out a layer of fabric? I think we need a chemist to weigh in on this issue.

Oct 26, 2019 at 7:15 pm #3615884Hi Michael:

Well, fall is here and I have not seen any new numbers on the TNF website. That does not mean they have not been released but I am not sure they will rush to release HH numbers.

It is great when manufacturer’s publish their performance numbers. It is unfortunate when they don’t indicate what test standards were used or how the application was modified for the particular test. I will repeat here what I wrote on another thread yesterday.

There are numerous breathability test methodologies, and, as discussed in my paper, they utilize different vapor pressure differences and different treatments of still or moving air layers. All of these things can dramatically impact the results. Higher vapor pressure differentials, faster moving or eliminated air layers will all increase the numbers and increase them substantially. A garment that produces 800 under ASTM E96 can produce 30000 under JIS L1099. Most of the really high numbers probably result from the JIS L1099 test. There are four versions of this test. The upright cup version uses a vapor pressure difference of .92 psi, which is huge. It also uses a pretty high velocity air flow over the cup. The B2 version completely eliminates air layers. So, even within the JIS L1099 standard, large variations in test results are present. This, of course, does not include RET ratings produced by guarded hot plates or Dynamic Permeation Cells. Manufacturers are free to use whatever standard shows their product in the best light.

Oct 26, 2019 at 9:06 pm #3615900Jeff,

You said, “Is there any reason to expect permanent beading surface (Outdry Ex, GoreTex Shakedry) fabrics to perform differently under the conditions experienced by the hunter, or perspective backpacker?”

The short answer is “yes” because DWR failure is always the predicate event for microporous aka air permeable WPB types (eVent, Futurelight, and Gore-Tex Pro) leakage to occur.

The long answer is as follows: Scientific observations during prolonged severe artificial rain based experiments show that for several hours after starting a test, water droplets formed mercury shapes and rolled down along the fabric surfaces. There was no wetting of the porous fabric surface until the formation of mercury shapes ceased. Then, as water drops fell successively into the same pore, a water film formed between the fibres. As a result, the contact angle decreased and water was not withdrawn completely from the pore. Succeeding drops falling into the same pore then forced the water surface into it and the water was withdrawn to a lesser extent because the contact angle had decreased. This process of penetration of the fabric by rain continued until the kinetic energy of falling rain was sufficient to force the water column deeper into the pore and then inside the porous WPB garment.

Each different WPB technology type has a different use case. Stephen’s test garments were all the same one of many specific types: microporous/fluorocarbon DWR. All published peer reviewed scientific literature, that I am aware of, has conclusively shown that the same “use case” for this type: it provides the best water vapor transfer in dry to moderate conditions and no vapor transfer after as little as three hours of hard rain. Subsequent to the stopping of vapor transfer, leakage can begin into the garment.

It is important to note that Gore-tex has multiple membrane types. The only type relevant to my analysis is the Gore-Tex Pro version (microporous aka optometric aka air permeable); this is the same version used in the podcast

Source: Gore-Tex

Oct 27, 2019 at 1:58 am #3615940

Oct 27, 2019 at 1:58 am #3615940Stephen,

Thanks, yeah, haven’t heard much from TNF on Futurelight numbers since those early reviews. Outside Magazine’s review in June stated, ” the North Face won’t release technical performance specs like vapor transmission rates until the fall, when Futurelight products go on sale, and it has requested that journalists don’t yet use third-party testing.” But based on reviews and your analysis it seems like it’s really not much different from Ascentshell and Neoshell in terms of vapor transmission and HH.

Yes, read your paper and understand there are different MVTR standards and that variables can be manipulated to get different results. RET would appear to be a better method for determining vapor transmission, but I rarely see RET numbers mentioned by manufacturers. Had to look up RET when I was considering that Mammut Gore Tex Active.

Curious what you think about Gore’s argument for not using HH. Basically their testing methods are better real world tests and waterproof is waterproof.

https://www.gore-tex.co.uk/blog/when-is-a-garment-waterproof

Oct 27, 2019 at 3:09 am #3615966Hi Richard:

I would appreciate it if you can provide some citations for the academic literature to which you refer. I am trying to understand the process you describe.

This is my interpretation of what your post is claiming:

During heavy rain, the adhesion reduction provided by DWR is lost. When they are lost, a water film develops that eventually seeps through the pores of the face fabric.

At this point, the kinetic energy of the rain drops can force their way through the microporous membrane.

Here is my concern about this:

The HH test measures the amount of pressure to penetrate the microporous membrane. In the case of Goretex Pro, the falling rain kinetic energy converted to pressure upon impact must exceed the HH of the membrane.

In order to determine if this can happen, we can calculate the Potential Energy that must be exceeded for the membrane to be penetrated by a raindrop. The calculation and data sources are below:

The force to penetrate the membrane is .0823 joules.

The force of a typical raindrop is .001 joules

The pressure to penetrate the membrane is 83 times the pressure in a raindrop.

So, I am having trouble with the explanation you have provided and would appreciate it if you can clarify this.

Steve

Oct 27, 2019 at 3:54 am #3615980Your analysis is far too simplistic. There is only a limited amount of published research on the impact of raindrops, and a lot of that is more concerned with the energy needed to start soil erosion when a raindrop hits lose soil. ($$ are involved there.)

One paper I read went into some detail about the dynamics of a raindrop hitting a hard steel plate. The surprising thing from that paper was that the peak pressure at the middle of the impact face is predicted to be appallingly high for microseconds. This is because when the drop hits a hard steel plate it has to spatter sideways, and the water at the edge of the drop has accelerate to a high speed in very little time. This is achieved by a sudden peak in the pressure at the middle of the impact face.

A secondary insight from this paper is that you cannot assume that the pressure in a drop is the same everywhere in that drop. It is not, because of the microsecond dynamics involved. To be sure, ‘water is incompressable’ – in static terms. This rule does not apply to pressure waves inside the drop though.

But my tent fly is not a hard steel plate. I believe, on one very brief mention in another paper, that the impact of a raindrop on a taut bit of fabric can and does cause a micro-indentation (ie a tiny bulge) as the fabric absorbs the energy of the impact. Nylon is good at absorbing such forces; other plastics are not so good.

I have not been able to get any further than this in my publications searches. One reason is that the experimental problem of testing such theory is ‘hard’ to the point of being almost impossible. You would need to be able to monitor significant microsecond pressure peaks over an area of 0.1 x 0.1 mm. Um. (Well, I can’t see how to do it myself.)

HTH

CheersOct 27, 2019 at 3:58 am #3615983Hi Michael:

I have seen that explanation from Goretex and they make some good points. There are a number of spray tests for water resistance: ISO 22954 Textiles — Water resistance — Rain tests: exposure to a horizontal water spray, ISO 9865 Bundesmann Rain Shower Test and AATCC TM35 and TM42. All pour water on fabrics, like the Goretex spray room. They may be right for some circumstances, such as rain, but not necessarily right for circumstances that produce direct, often localized pressure, such as water under backpack straps, sliding on snow or kneeling on wet ground. That is why I said in the paper that the HH ratings for Futurelight, just like with Neoshell, may make the garments unsuitable for certain applications. For me, the Neoshell garments were not suited for certain aspects of my winter activities.

Oct 27, 2019 at 4:26 am #3615996Hi Roger:

I agree with everything that you say. I did a very simple analysis that provides an order of magnitude feel for the issue. I also found the erosion literature. It does give you a whole new appreciation for the power of some raindrops. What I would really like is for Richard to provide some sources so I can understand the tests behind the issues he is raising. I would like to understand the circumstances where Gore Pro will simply let rain penetrate as may be the case of the podcast posted by Richard and the study result also posted by Richard. I have not found any useful studies about this. When I have gotten wet with Goretex, like everyone else, it is from sweat or, when it is rainy and windy, from water getting in at garment openings such as sleeves or hood openings. So, perhaps he, you or someone else, can shed some light on possible causes or relate their own similar experiences.

Oct 27, 2019 at 6:21 am #3616012I did get wet around the shoulders once while wearing an expensive GTX jacket. I took it to the local Gore offices where they tested the fabric for me. Fountains of water! Turns out the prickly scrub (eg holly) had put hundreds of tiny holes through the membrane around the shoulders. The $$$ jacket was essentially useless thereafter.

Cheers

Oct 27, 2019 at 6:46 am #3616014Hi Stephen,

Yeah, although they don’t really accept HH as a useful measure for those applications either:

“However, this method of testing the waterproofness of a garment is not relevant to real-life situations. For example, when you wear a jacket, any pressure that is exerted is not static. Even when you put on waterproof trousers and kneel in a puddle, the pressure exerted is not particularly high. Your knee will quite simply push aside the water in the puddle.”

I take the material testing data as just one potentially useful factor when trying to evaluate suitability of a garment for a particular purpose. If I’m looking for a wind shell, I want to know the CFM of the material. Too often manufacturers fail to provide this kind of testing info.

Oct 27, 2019 at 8:07 am #3616015Your knee will quite simply push aside the water in the puddle.

Warning: whoever wrote that does not know what he is talking about – seriously. If you put your knee in the puddle, it will push the water aside: that is true. But once you kneel on the ground and put pressure on the fabric, it is a different matter.I was told unofficially by one vendor that companies just keep trying different ratings systems – and there is a horde of them out there, until they find one that puts their stuff near the top. My experience above with GTX and holly leaves is a classic example of ‘what can go wrong’.

Expect to get wet: you will anyhow. Treat all vendor claims as just so much marketing spin.

Cheers

Oct 27, 2019 at 2:21 pm #3616028Hi Roger,

That knee quote is from the same article I mentioned earlier where a Gore Tex “product specialist” explains why they don’t consider HH measurements useful. The main argument is that HH does not simulate rain so you need to use a different testing method. They use their rain room and Stephen pointed out similar spray/shower test methods available, but that his HH testing indicates that Futurelight might not be great under certain conditions (e.g., sliding, kneeling) where pressure is being applied to the fabric. But the Gore specialist wants to argue that HH is totally useless and hence the knee comment.

https://www.gore-tex.co.uk/blog/when-is-a-garment-waterproof

You mentioned your “prickly scrub” experience with GTX. From the same article:

“Nevertheless, in the retail trade water column test methods and ratings are the generally accepted way of determining the degree of “waterproofness”. “The higher, the better” is a common misconception. However, a garment cannot be “a bit waterproof” or “a bit more waterproof”. Waterproofness is an absolute measure: a fabric is either waterproof, which means that it does not let water through, or it isn’t. Even a tiny hole in the fabric, measuring no more than 10 μm (0.01 mm), would result in a water column rating of 0 mm and amount to a leak.”

Yes, there is really no expectation that holes in the fabric will be waterproof.

Oct 27, 2019 at 8:36 pm #3616082The main argument is that HH does not simulate rain so you need to use a different testing method.

I can see his point that HH does not simulate rain – but then neither does anything else in a reasonably measurable way. On the other hand, HH does provide a fairly simple, direct and understandable measurement which does, in most cases, work well and is used across the industry.From my own experience I know that kneeling on a groundsheet does raise the pressure and can let water through. When new my blue tent groundsheet did not let water through; when aged by 5 – 6 years it did let water through when kneeling; when recoated with a very thin layer of silicone sealant (in the field) it was again waterproof.

For the rest of it, I suspect Gore marketing spin.

Cheers

Oct 27, 2019 at 11:10 pm #3616092Hi Roger:

A value used to determine kinetic energy of a falling raindrop in yesterday’s post was incorrect. In redoing this calculation today, I have found that the experience described in Tyler Freel’s podcast is credible with the presence of a strong enough wind. I will take you through the calculation step-by-step.

If Gore added wind to the shower room test (which might require a shower room built in a wind tunnel), this could be proved. However, using the shower room test only, the Gore Pro will always be waterproof in the lab but not necessarily in severe weather conditions.

Our numbers would change if you relax our conservation of energy assumption, as would be required for comprehensive analysis. However, Tyler Freel’s experience suggests our conclusion is possible in the face of enough wind.

Steve

-

AuthorPosts

- You must be logged in to reply to this topic.

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

Our Community Posts are Moderated

Backpacking Light community posts are moderated and here to foster helpful and positive discussions about lightweight backpacking. Please be mindful of our values and boundaries and review our Community Guidelines prior to posting.

Get the Newsletter

Gear Research & Discovery Tools

- Browse our curated Gear Shop

- See the latest Gear Deals and Sales

- Our Recommendations

- Search for Gear on Sale with the Gear Finder

- Used Gear Swap

- Member Gear Reviews and BPL Gear Review Articles

- Browse by Gear Type or Brand.