Topic

Engineering the V4 Winter Stove

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

Home › Forums › Gear Forums › Make Your Own Gear › Engineering the V4 Winter Stove

- This topic has 76 replies, 11 voices, and was last updated 4 years, 5 months ago by

Roger Caffin.

Roger Caffin.

-

AuthorPosts

-

Jul 16, 2020 at 7:18 pm #3664735

I had a second thought about the cost accounting. Your estimate of +$100 per posting might not be that far off, but that cost has to be amortised across about 25 stoves each time. I am (fortunately) not so silly as to try making these stoves in singles: I am making them in batches.

Other benefits of making them in batches include: I can’t afford to waste all that effort making 25 defective units (so I have to get it right before I start), and there is much greater consistency when working in batches.

The hobby side of it – yeah, true. But I have spent my professional life in science research; switching to production manufacturing has been a real eye-opener. I had not idea it was this hard!

Cheers

Jul 16, 2020 at 8:12 pm #3664838IMO, production is easy. Verification of performance, now that is where all of the work takes place. There is a big difference between making 1 prototype work. It is a whole different story to make 25 behave consistently. My 2 cents.

Jul 16, 2020 at 8:54 pm #3664841I think we are talking about different levels of complexity here, as well as very different types of stoves. The design exhibited here is the outcome of a lot of work. It only resulted after a full development cycle, where I had many set-backs and failures. Hey: I don’t mention ALL my mistakes!

Now when I make a dozen stoves on the CNC, I only need to test one of them to be able to predict how they will all perform. But that is because they are copies made on a CNC. My machining is not that good.

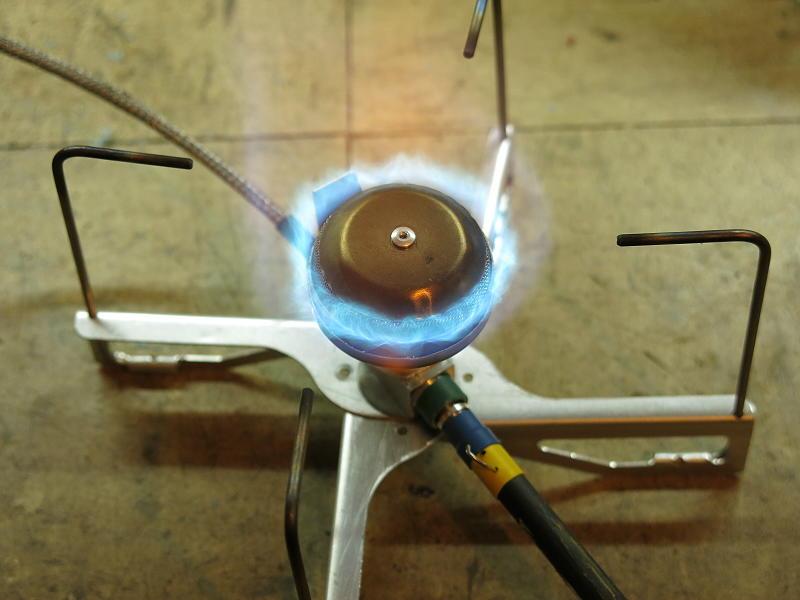

That said, I do burn-test every single stove I have made, just to make sure. And yes, they do all perform the same. That gives me some confidence, which I still need.

Is production easy? That depends on what is being produced, and how many parts and materials are needed. The Bill Of Materials for my V4 stove has about 44 items in it, and getting some of them has taken some work. It has been a new experience for me.

Cheers

Jul 17, 2020 at 4:16 am #3664863Hose bits

On the 20th of June I gave some details about making the hoses for the stoves. Having just spent a really exciting day making some more bits for hoses, I thought I would bore you with the details.

This photo shows the bits which get fitted to the end of each hose. The flat plates are the Retaining Plates, the round bits of tube are the crimp rings which clamp the braid to the end fittings, the two end fittings on the right are for the canister connector and for the stove connection. So far, so good. The collection of tiny tubes in the middle are the ‘Lock Tubes’ which go inside the hose, forcing it outwards against the holes in the fittings.

You see, you cannot get a length of hose up a tight hole in the end fitting: there has to be clearance. That clearance is a problem: even if there is only 10 microns of clearance between the hose and the fitting, that makes a leak area of about 1/3 of the jet size. Fuel would pour out there.

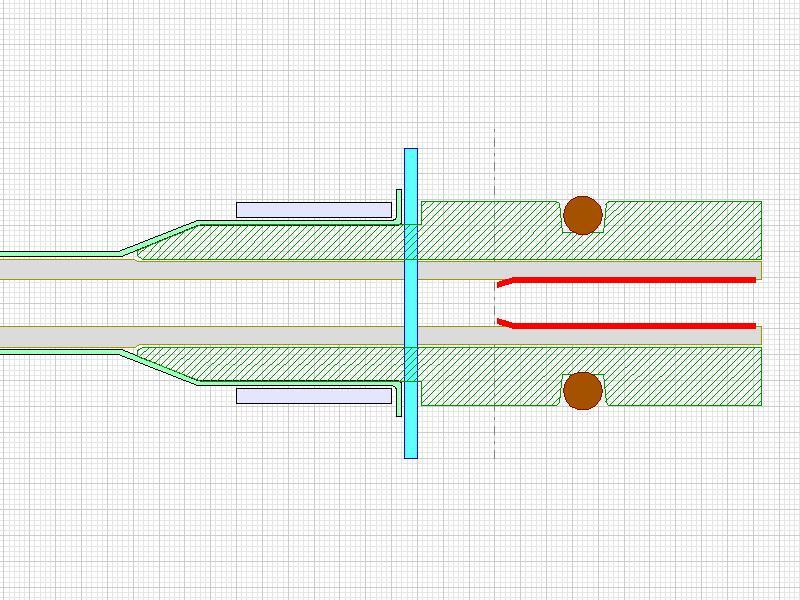

The hose is the grey part, the fitting is the green part, and you can see where the gas would leak out between the two. So a small ‘lock tube’ (red) is forced into the hose to expand it out and prevent any leaks. Ah, but I have to make this lock tube.

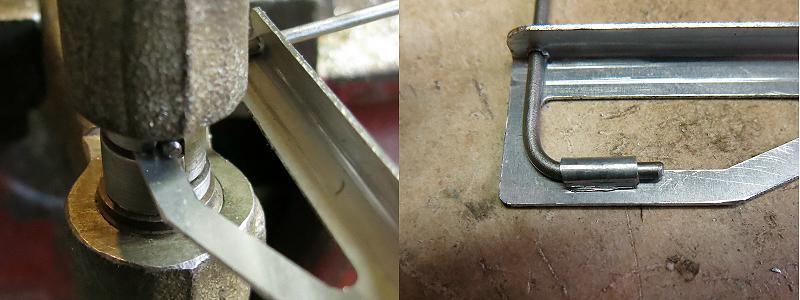

I start with some SS hypodermic tubing and cut off short lengths. That sounds simple. However, one end of the tube has to be tapered so it will push the hose outwards when it is inserted. This is done by careful design of the parting tool. You can see the tapers at the left hand end of each bit of tube.

Of course, if I just parted those bits off over a lathe bed covered in swarf, I would never find them. So I threaded a bit of 1 mm Ti wire through the hole and collected them as they came off.

Even though the tip of the lathe tool was sharp, there was still a burr formed on the inside of each end of the bits. This had to be cleaned out before the tube could be forced into the hose. This was done, one bit at a time, with a 1.35 mm drill bit. I had to hold the tube itself with pliers while the drill bit was used.

There is another reason why I had to clean out the inside of the tube. Look at the diagram above of the hose and connector. It looks as though the lock tube (in red) can just slide into the hose, but that is not so. Despite the tapered end going in first, some of the PFA plastic is forced out ahead of the tube, a bit like dirt in front of a bulldozer. After all, the plastic is not very compressible. When I started I found that a blunt end on the hose could pile enough plastic at the inside end of the tube that the hose could be nearly blocked – so cleaning the plowed-up plastic out of the way was done with the same 1.35 mm drill bit.

Provided all these little steps are done carefully, the hose passes both liquid fuel and gas very nicely, is solidly anchored into the end fittings, and does not leak gas. But doing it all manually is a shade tedious. Oh well.

I did try to get these lock tubes made by a small parts manufacturer. They declined. Smoothed ends they could do, but a tapered end they could not.

Jul 20, 2020 at 12:43 am #3665583I’m a simple man but love complex subjects. The pictures along with the dialog make the visual thinking part of me understand what I may not gather in otherwise. I hike stoveless and I want this stove:) well done

Jul 20, 2020 at 2:02 am #3665584That said, I do burn-test every single stove I have made, just to make sure. And yes, they do all perform the same. That gives me some confidence, which I still need.

Sometimes a manufacturer is at the mercy of a vendor/supplier. For example a company may buy automotive hose in bulk that is supposed to have been tested to meet SAE (Society of Automotive Engineers) specifications, but it doesn’t and problems creep up after a product is in use for a couple of years.

I like how you tested your fuel line. Then you rejected the hose sheathing, which might have delayed production. So a good quality control process can help ensure there is almost never any variability in the finished product. Not always guaranteed, but usually reliable. You know, 5S, Six Sigma, and all that stuff large companies do. Also good that you test every stove before shipping it.

Jul 20, 2020 at 2:10 am #3665585Also good that you test every stove before shipping it.

Can you imagine just how embarrassing it would be if I sent someone a stove and it did not work properly on arrival? I am just not going there.

Cheers

Jul 20, 2020 at 10:04 am #3665606Can you imagine just how embarrassing it would be if I sent someone a stove and it did not work properly on arrival?

or if the pot supports deformed when when the stove is operated :-)

Jul 20, 2020 at 12:00 pm #3665616Right now I don’t have a need for a winter stove of any kind, but I’ve become so vested in this story that I want one…Are all 100 units pre-sold or will you have some available?

Jul 20, 2020 at 5:12 pm #3665661or if the pot supports deformed when when the stove is operated :-)

The standard pot supports on the V2 stove were fine, but I did supply a smaller version on request. That was a mistake because when the stove was operated flat out (that is probably >3 kW) for a while with a big load on them, the middle of the pot supports could bend a bit. The stove was not meant to be run this way, but it was possible. If anyone has this problem, please contact me. I will support the stove.Kevin

I have sold all the ones I have made so far, and I have outstanding orders I am working to fulfill (soon), but there should be some more available in some (unspecified) weeks. I am in the workshop every day on this. Anyhow, contact me at [email protected] for more info.Cheers

Jul 20, 2020 at 8:12 pm #3665691Stove Body

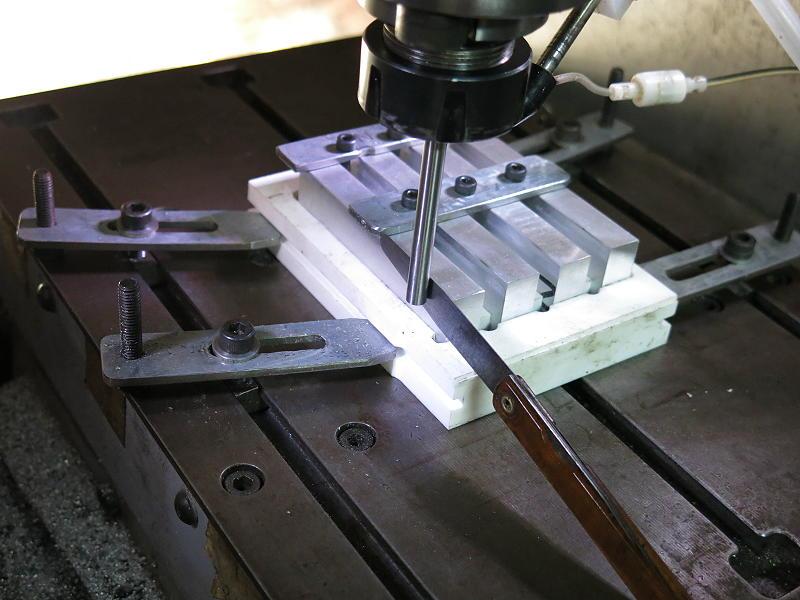

Fortunately the design of the stove body was fairly stable from the start, and the CNC programs for making it were checked out with the first batch of V4 stoves which I made. So it is just a simple matter of preparing the aluminium blanks, mounting them in the jigs, and running the programs. Simple, yes?

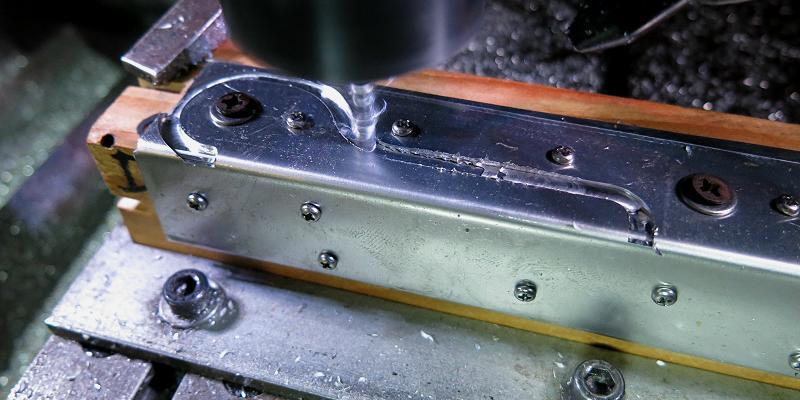

Well, almost. A precison jig is needed to hold the blanks in exactly the right place. That is the white base you can see below. Each aluminium bar will become two stove bases. I had to remake this base as the last one died. Well, it was sort-of an interim stand-in at the time.

Here I am setting the reference point for the machining. Typically I do this to about 0.01 mm (10 microns). The feeler guage is 0.25 mm and the ground steel rod is 6.00 mm. Then I machine down the top of the blanks to leave the burner head boss.

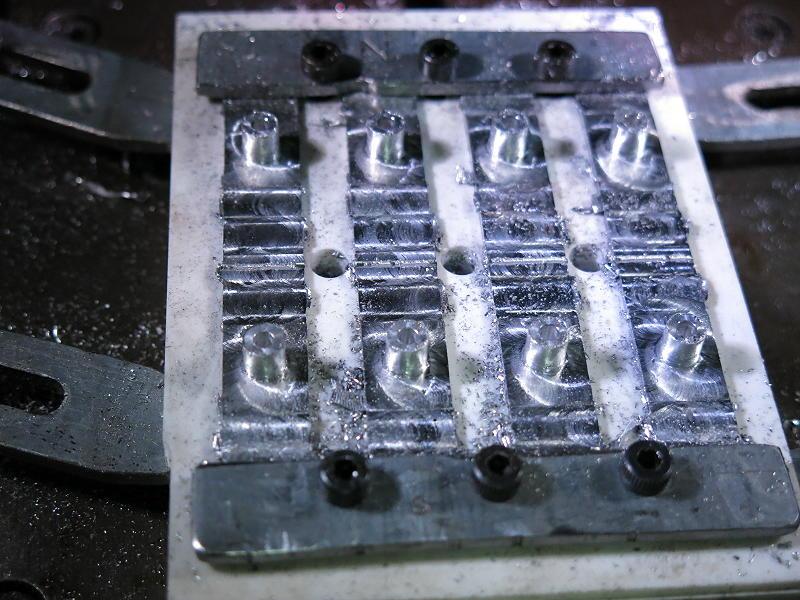

Here I have machined the boss which holds the burner head (two per blank) and now the thread needed (M12x1) to hold the burner head is being cut with a thread milling cutter. These are fragile things, and far more expensive than the mass produced ordinary end mills. On the other hand, there is no worry about getting a die onto the aluminium boss dead square. Thread mills do a more reliable job.

After all the bosses have been threaded on the outside, a second thread is machined on the inside of the hole in the boss for the jet to screw into. This is not shown: it is just more chips of aluminium flying around.

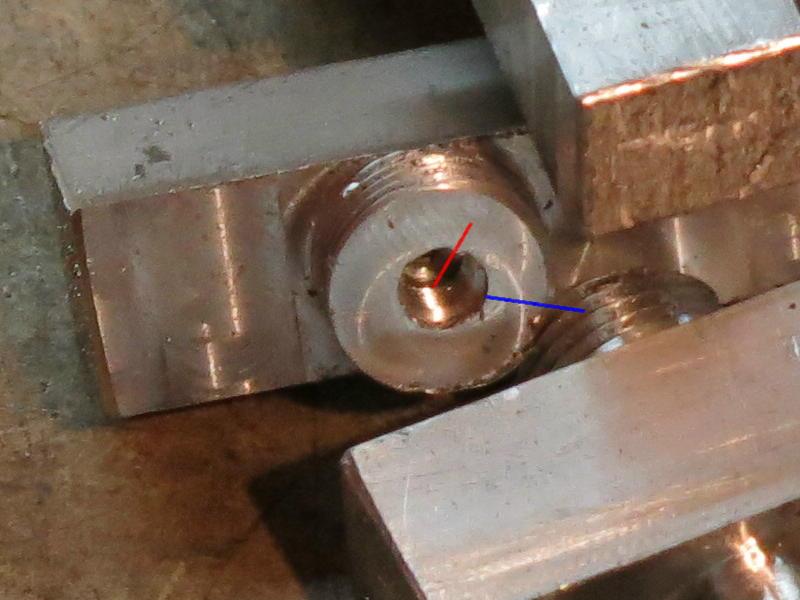

While it may not matter too much, I like to have the jet seal against the stove body properly, You can’t rely on a thread to do this: there would be leaks. Instead I designed the jet socket to provide an explicit seal. The thread is 4 mm diameter and indicated by the red line. Above the thread there is a recess some 4.8 mm diameter with a sharp rim, shown by the blue line. This rim seals against the tapered underside of the jet. Some clean up of the jet socket is needed of course to remove machining swarf.

With the top side machined, it is time to flip every blank upside down to mill out the 6 mm pivot for the stove legs. Once that is done a hole is drilled in the middle of the pivot to take an M3 thread. The threading is done with a thread-forming tap rather than being cut with a conventional tap. The thread forming taps are more expensive, but they do a better job here. A stainless steel M3 stud goes in this hole for the nut which holds the legs onto the stove body. We will get to that later.

Jul 22, 2020 at 5:16 pm #3665886

One ends up with a heap of half-machined stove bodies, as shown here. What they are missing so far is the machining at the ends.

First the stove bodies are mounted in a different clamp: a vertical one. This jig allows me to machine up to 10 units at a time. This saves a huge amount of time as there is only one set of tool changes per 10 units, rather than 1 set per each unit. It’s not just changing the collet and the cutter which takes time. but the new cutter has to be ‘zeroed’ so it is cutting in the right place. That has to be done slowly as the zeroing is done to a tolerance of 5 microns.

A hazard with machining aluminium is that tiny chips can stick to the cutter and build up there. This is called ‘Built Up Edge’ (BUE), and usually destroys both the cutter and the job. In the old days they used to pour ‘flood coolant’ over the work piece to prevent this, but that stuff is expensive, very messy, prone to developing bacteria in the tank, damaging to the skin and extremely expensive to dispose of later. Smart machining shops (eg big aerospace companies) now use air blast plus a pulsed lubricant. The black nozzle is the air jet: it blows all the chips away so they don’t get in the way. The visible stuff coming out of the nozzle is the Minimum Quantity Lubricant (MQL) I use: 3 parts kero and 1 part olive oil. The pulses are about 0.5 seconds long repeated once every 10+ seconds. The stuff keeps the cutter surface wet and prevents BUE. Given the very small amount used and the blast of air, parts come out almost dry and a small jam bottle of the mix lasts for many weeks.

Here the machine is cutting the thread for the hose nut. I covered the hose some days ago. The nut will lock against the stove body, leaving the metal core free to rotate to accommodate any curve in the hose.

And we end up with a finished connector end. The drops on the surface are not MQL; they are water from the air compressor. Sydney is very humid.

That’s it for the hose connector end. The valve end is machined in the same way, except that the thread is on the inside, as shown here. The smooth area left of the internal thread is where the needle valve O-ring seals. You don’t want leaks.

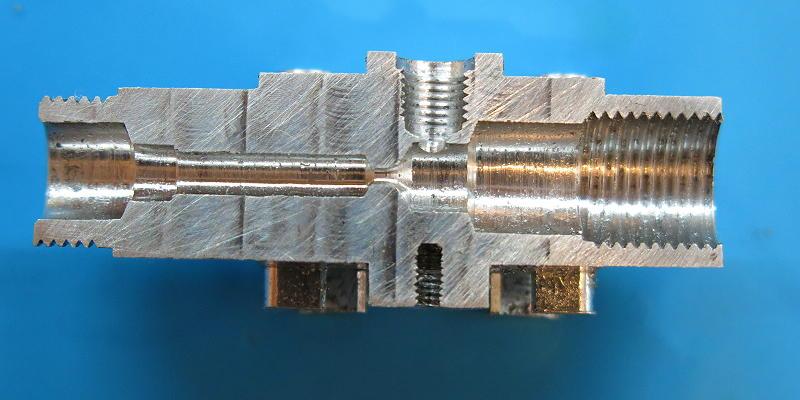

The most tricky bit of the valve end machining is creating the valve seat and orifice. The cross-section above shows what it looks like (in the middle). To get this very small hole with a smooth shoulder I use a special long thin carbide centre drill. It is not a stock item: I had to get a couple made up for me by an ebay vendor in China. He had access to the factory where cutters are made, and they did a nice job of it. The cost was probably 1/10 of what a custom centre drill from USA would have cost me. The factory in China could do it so cheaply (and well) because these days they are using precision CNC diamond grinding machines for this work. I think the machines come from Europe. All the factory had to do was tweak a few parameters in a generic program for centre drills and load some blank stock. It took maybe a week or two from request to supply.

Finally some stainless steel M3 grub screws were inserted into the pivots and tightened into place with an Allen key.

Jul 25, 2020 at 3:58 am #3666207Stove Legs and Pot Supports

I have shown this photo before. Now look at the stove legs and pot supports. The stove legs are machined bits of sheet aluminium; the pot supports are titanium wire. The two components have different requirements. Also, note the good clearance between the burner head and the pot: the flames will not be prematurely quenched so the CO levels will be very low.

The titanium wire pot supports are fairly simple: each one is crimped to the bottom of the stove leg, rises up and bends in to support the pot. Since the vertical parts of the Ti wire do not get hot, they remain strong and stiff. Only the innermost tips of the Ti wire get hot in practice. The photo here makes that obvious.

The pot supports support the pot (duh!); it is the aluminium legs which support the stove. These legs are made from 0.83 mm thick aluminium alloy sheet: they are good and don’t flex too much, but they could not safely support a pot. However, they don’t have to: all they do is support the stove body, and this they do easily. Also they collapse into a bundle nicely by pivoting around: that makes setting the stove up much easier than having to connect the legs to the stove body. Treat it as an exercise in laziness.

There is a problem with how to make the legs. I wanted them to ‘stack’, so they could pivot together under the stove. But that means the pivot hole has to be in a slightly different position in each of the four legs on the stove, offset by the thickness of the aluminium. The solution is fortunately simple: put all 4 leg blanks together and then machine them in one go.

I take a strip of aluminium, fold it lengthwise, cut it into 4 matching strips, and stack them all on a fairly precise machining jig (yes, that is the wood block underneath). Holes are drilled through and self-tapper screws inserted to keep the four bits in place and then the shape is machined. This shows the start of machining the top surface.

Then the machining jig is rolled over and repositioned in exactly the same place so the side can be machined. Part of the magic here is the precise nature of the jigs (wooden blocks) and how they are positioned on the mill table: against the steel strip you see in front in both photos.

Finally, one ends up with two sets of aluminium legs from one set of blanks (plus a certain amount of scrap aluminium).

The photo above shows the legs with a weight-reducing hole in the vertical face. Sticking up from the bottom edge is a ‘tab’ (red line). This tab is crucial to the pot supports.

Jul 29, 2020 at 11:41 pm #3667581

First however a little (2.4 mm) hole is drilled right on the edge of the fold, using (of course) yet another jig. This is more difficult than it sounds: the hole is entering the aluminium where it is curved. With a normal long High Speed Steel (HSS) jobber drill bit the tip would simply skate off onto the timber. Things are improved by the use of a short ‘stub’ drill bit, but not enough. The edge of the hole has to be lined up with the surface of the aluminium, and there is still too much sideways movement of the tip. So, enter a stub (short) carbide drill bit of the right size. Carbide is much harder and stiffer than ordinary HSS, and this works fine. Just not common, and not cheap.

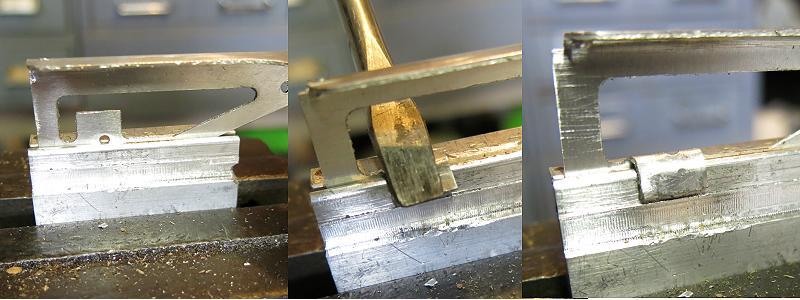

The leg is then placed in a custom jig (left) and the tab is bent over (middle) and flattened against the jig (right). That middle bit is hard aluminum some 2.5 mm thick: the Ti wire used for the pot supports is 2.4 mm thick.

We divert now to the Ti wire pot supports.

Straight Ti rod or wire is cut to the desired length, the ends cleaned up (a bit ragged from the bolt cutter), and placed one at a time in my custom bender. The lever arm at the top has a ball race on it, and this ‘rolls’ the wire around an 8 mm post. A bend is made at each end. The wire has to be clamped before this to stop it from moving, hence the centre clamp with the Allen key in it. The two pots in front show ‘work in progress’.

Now we get to the assembly part. The Ti wire is poked through the drilled hole and one bent end is snugged into the folded-over tab. The tab is gently crimped over with pliers to keep it in place, and then a hard crimp is done.

On the left is my Roper-Whitney lever punch, with a custom die set in it. The die is designed to very tightly crimp the tab around the Ti wire, with the result at the right. Now, what is the point of all this you might ask.

Here we have an assembled stove. The legs pivot from under the stove body and the Ti wire pot supports stick up. The problem is to keep those Ti wire pot supports firmly attached to the aluminium legs and pointed upwards. The little hole I had drill retains the Ti wire nicely – at one point on top of the stove leg. By very firmly crimping the bottom of the wire to the leg, as described here, the whole assembly become stable in the long term. To be sure, beat it up too much and bad things might happen, but I will assume that anyone using one of my stoves will take care of it.

Could one get the same effect without the bend at the bottom of the wire? No. Sooner or later the pot supports would twist and loosen the crimp. It is only when the wire at the bottom is bent in a right angle that such twisting becomes impossible. I have to admit here that I have never even tried a vertical crimp: it was not, to my mind, even worth trying.

Finally, just to show you what a large number of stove legs looks like, we have this. There is a reason for stacking them like this: they come in sets of 4 legs, so the pivot holes line up, and I have kept them in sets.

Aug 3, 2020 at 6:27 pm #3668690Stove Leg Assembly on Stove

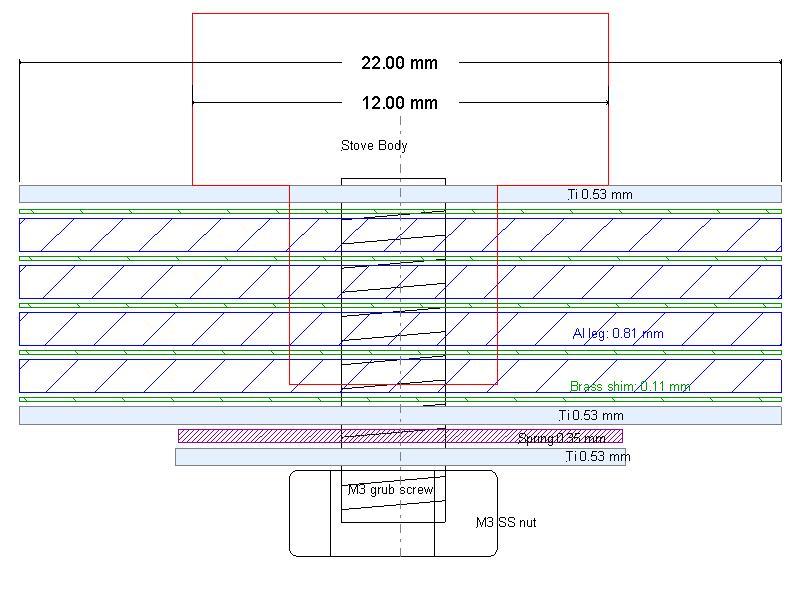

The last bit described how the individual legs are made. This bit describes how the 4 legs are added to the stove. There are a few complications – surprise! This below is an ‘exploded’ diagram of how the legs work.

First of all, the top face of the aluminium leg (blue) might be expected to bear on the underside of the (red) stove body, but a little experiment showed that the result was not good enough. The bearing face, the bottom face of the stove body, was just too small, and the aluminium leg flexed rather easily. A bigger bearing face was needed. This was provided by a 22 mm diameter Ti washer (grey) – the top one in the exploded engineering drawing above.

Would not the Ti washer rock as much as the aluminium? Well, the aluminium was not rocking; it was flexing. The Ti washer does not flex, and it is held hard against the stove body too. It provides a large-area bearing face.

The next complication was the problem of galling, which would happen when the aluminium legs rubbed (rotated) against each other. That would were the legs out. So a very thin hard shim brass washer (green) is inserted between every aluminium leg: brass is a good non-galling bearing material.

Unless the legs and the washers are pressed hard against each other,they will rock around all over the place. So, for the same reason as above, another 22 mm Ti washer is added at the bottom of the stack, and a spring (purple) is provided to add pressure. The spring is held by a smaller Ti washer, and compressed by the M3 nut. When not ‘exploded’, the stack matches in height the pivot column (red) once the spring is accommodated, so the nut and the small Ti washer are done up tight against the end of the pivot column. The spring has to be fairly stiff and yet very short: a slotted disk spring is used here.

And why does the spring have to be ‘hard’? Because you don’t want the legs flailing around in the breeze. You want them able to rotate, but inclined to stay where you put them. A bit of spring pressure is needed to get that. The secret to all this is getting the height of the pivot column ‘just right’, to within 0.1 mm, so the spring is correctly compressed.

A small mumble: I was able to buy a quantity of these springs locally – once. Since then I have not found a supplier with stock on the shelf. Various AliBaba vendors expressed great enthusiasm to supply me – provided I bought 1,000 units and paid for the dies to make them. Their advertisements had promised off-the-shelf availability. So much for AliBaba: I have never had any joy from any of them. An American company was willing to supply samples of something similar, at $50 per unit. A better price was promised for orders of 500 – 1,000.

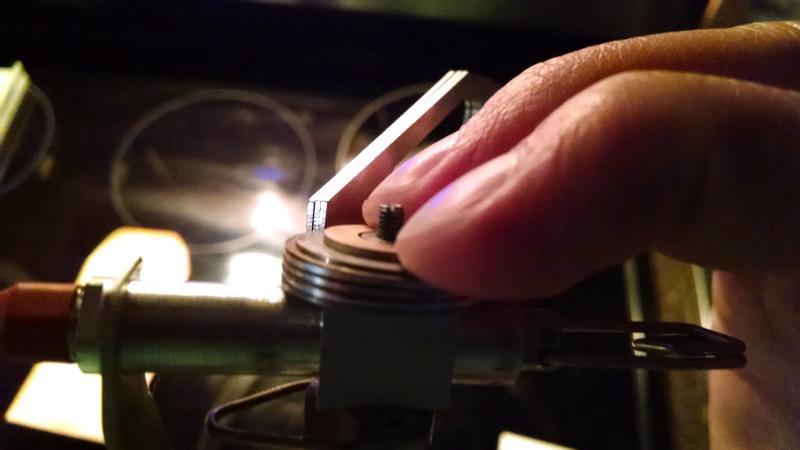

Now this stack looks simple, doesn’t it? It is, until it comes to putting all the bits together. It would be different if the M3 grub screw was 20 mm longer! Some dexterity is required to keep all the bits on the pivot column while trying to juggle the M3 nut in place. Practice … Just don’t disassemble the leg stack! My thanks to James K for this photo, by the way: I had not been able to take one myself.

Aug 4, 2020 at 8:38 am #3668780Neat. Is the spring a wire coil, wavy washer or a Belleville washer?

https://en.wikipedia.org/wiki/Belleville_washer

Link supplied as that’s exactly the sort of thing that would have a different name in different countries.

Aug 4, 2020 at 3:46 pm #3668885None of the above. It is a slotted disk spring.

Like a Belleville washer but with slots for more control over the stress/strain characteristics. They have a flat region in the middle of the curve.

Cheers

Aug 8, 2020 at 4:20 am #3669847Heat Shunt and Heat Exchanger

The Heat Shunt is just a simple bit of sheet aluminium with a big hole (12 mm) at one end, matching the spigot which holds the burner head. However, while I could just cut out rectangles and punch holes, that would look a little unfinished. So I machine them out in stacks, with nice curves. The complexity is that they are rather small, the sheet aluminium is a bit soft, the hole at one end is large, so how do you hold all of them down safely? Some long self-tapper screws and a locating pin, as you can see here.

The locating pin is essential for the machining, but it also serves as a marker for where to make the bend later on.

The base I am using looks like wood – yeah, it is, but it is very old (100 years?) Australian red gum, and that stuff is HARD. You machine this stuff with carbide-tipped tools. Pine wood it is not.

The Heat Exchanger rods which go inside the stove body are small rods of aluminium with a known diameter to fit suitably in the hole in the stove body and with an angle at one end to prevent them from blocking the gas flow. Being a fairly close fit, that means the liquid fuel flows over them in a very thin film. And that means there is very good heat transfer from the stove body to the fuel, to vaporise it. Sounds good.

Well, reality is that they are short bits of 2.4 mm aluminium welding wire cut off (carefully, with the right cutters) to have one angled end and one square end. I do clean them up a little with a file (a couple of strokes at each end) so they fit easily in the hole.

Suffice to say that they work just fine at what they do. I will add that if you remove the hose from the stove body for any reason, you may very well lose this HX rod, and then your stove will never stop sputtering. It happens: I have posted replacements out once or twice. Leave the hose connected.

Aug 8, 2020 at 3:05 pm #3669932The Brunton stove legs have a good sized support pad extension on the bottom of the leg to prevent sinking into the soil.

Your stove legs do not have any such extension, is that why your stove support legs have to be fastened to a piece of plywood?

Aug 8, 2020 at 4:42 pm #3670005

Aug 8, 2020 at 4:42 pm #3670005However, the Brunton pads are not large enough in the snow, and my stoves are designed as winter stoves. So I supply a base and micro-pegs with all my stoves, all versions.

You don’t have to use my baseboard of course, and many don’t.

(Thank you Simone.)Cheers

Aug 8, 2020 at 5:32 pm #3670020I would think the plywood base would always be used to be certain the stove support would be stable under all conditions.

How well do the 4 holdown pegs work in snow/frozen ground?

Aug 8, 2020 at 6:14 pm #3670030

Aug 8, 2020 at 6:14 pm #3670030How well do the 4 holdown pegs work in snow/frozen ground?

Medium to reasonable.We start with well-stomped snow for the tent base. After stomping it tends to harden – that’s called firnification. I never try to put the base on soft fluffy stuff.

Next, there are holes in the base (see photo) which provide a huge constraint on any movement, and the hook tops hold the legs.

The micro-pegs are thin, that is true, but they are long enough. To seriously move one sideways at the top means the tip, well below the surface, has to move a lot. That is not so easy.

One might wonder whether the pegs might get warm from radiation and melt the snow, but in practice they don’t. To be sure, there is some downwards radiation, but the very thin cross section means they do not intercept much energy. Also, Ti wire that thin is a very poor conductor of heat, so little energy travels down the wires.

Mind you, I don’t always use the pegs, sometimes just the base. With some care, which is very reasonable inside a tent in a storm, there is no problem. As the surface of the 3-ply has been coated with linseed oil for water-proofing, it is not slippery. Others have used stiff foam as a base: same story.

Cheers

Aug 9, 2020 at 10:08 am #3670086You don’t have to use my baseboard of course, and many don’t.

Ok, it’s just extra baggage for many users.

I think I’ve seen you say that most of the time in winter months you use your stove in your tent so the board and pegs are not needed, correct?

I’m putting together a winter stove kit for a friend(an me) that’s why all the questions. Thanks

Cheers

Aug 9, 2020 at 3:47 pm #3670154Not quite right.

I would say the base board is ALWAYS needed, for safety against the snow melting if nothing else.The pegs not so much, provided the base is not slippery. In my current red winter tent I have a mini-groundsheet in the vestibule so I can cook there without getting snow on everything. Obviously, I don’t use the pegs there.

Hum, yes, well there was a bit of snow ‘everywhere’ that night anyhow.Cheers

Aug 9, 2020 at 6:23 pm #3670172As you have shown in a photo, a snow shovel can be used instead of the plywood. 4 min. to heat 2 cups water won’t melt much snow under various materials.

Thanks for your insight. Lots of good info here.

What prevents the adjusting rod from comming off the valve end…what’s under the blue material seen in the photo? Does the rod need to be propped up to prevent slippage?

-

AuthorPosts

- You must be logged in to reply to this topic.

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

HAPPENING RIGHT NOW (February 11-21, 2025) - Shop Hyperlite Mountain Gear's Biggest Sale of the Year:

Our Community Posts are Moderated

Backpacking Light community posts are moderated and here to foster helpful and positive discussions about lightweight backpacking. Please be mindful of our values and boundaries and review our Community Guidelines prior to posting.

Get the Newsletter

Gear Research & Discovery Tools

- Browse our curated Gear Shop

- See the latest Gear Deals and Sales

- Our Recommendations

- Search for Gear on Sale with the Gear Finder

- Used Gear Swap

- Member Gear Reviews and BPL Gear Review Articles

- Browse by Gear Type or Brand.