Topic

DIMENSION-POLYANT Technical Fabrics: Properties and Development

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

Home › Forums › Gear Forums › Make Your Own Gear › DIMENSION-POLYANT Technical Fabrics: Properties and Development

- This topic has 83 replies, 17 voices, and was last updated 5 years, 9 months ago by

Roger Caffin.

Roger Caffin.

-

AuthorPosts

-

Feb 11, 2018 at 4:10 am #3517733

Lester,

I haven’t experimented with mylar tape on Xpac – the only tape I’ve used is 3M transfer tape (9485PC and a couple other variants) bonded to cuben fiber.

Feb 11, 2018 at 6:22 am #3517749Thanks Nick – I’ll look up that 3M tape. You’re right Roger – didn’t think about the needle holes in the sides!

Feb 11, 2018 at 7:02 am #3517752Hi Lester

Ah well – I found out the hard way (but at home). A lot of mfrs ‘close’ the selvedge with some tape sewn over the top, but the seam still leaks. So I filled a bag with water and hung it up, then looked closely to see where all the water was leaking. Light-bulb moment.

Cheers

Feb 12, 2018 at 4:18 am #3517943Great thread thanks very much Taylor.

I’m also a little concerned about the resin exterior make up, As Dan noted if the exterior resin is broken down the fabric (LS07 & LS42) will lose all water resistance.

I’ve managed to cut through the resin on LS42 with #70 thread running at too higher tension, I believe this fabric behaves this way due to the slightly spongy 420D backing.

Cheers, Dan.

Feb 12, 2018 at 5:40 am #3517955Hi WT

When you say ‘cut through the resin’, was this with the resin side uppermost? I can understand if ‘yes’: it’s the top thread which has the movement.

Did cutting the resin gum up the needle or thread at all (like with adhesive tape)?Cheers

Feb 12, 2018 at 6:25 am #3517959Hi Roger,

Sorry I didn’t explain very well.

Yes, when top stitching with the resin face up, I feel like it’s a little less forgiving than say VX21 in terms of machine set up for general DIY. No needle gum up.

Also let me know if anyone is interested how LS07 performs in the field, I built a 70L test pack to look at fabric performance and potential failure points. The pack has been used for over a 6 month period with aggressive off track work hauling big loads of climbing gear and the like.

Cheers, Dan. …….Sorry for the poor image.

Feb 12, 2018 at 6:40 am #3517960

Feb 12, 2018 at 6:40 am #3517960Hey, no fair! I was planning on doing that! Oh well …

I must say, it’s a very clean-looking pack, good for going through scrub and up cliff faces.Any seam sealing?

What sort of seams?

Any chance of some very close-up photos of the seams and the sewing holes?

How did you anchor the webbing in the seams, and how is it fairing?

What sort of frame is on the other side?Geek out, geek out …

CheersFeb 12, 2018 at 7:17 am #3517962That. Is. A. Beautiful. Simple. Pack!

Like Roger said, no crap to snag on brush.

I’m so excited to promote the eradication of side pocket mesh!

Love it!

Feb 12, 2018 at 8:55 am #3517966Thanks Roger & Ryan for the kind words,

The Blackburn pack is definitely built to have minimal bits & bobs on it to get caught up, primarily for packrafting missions and the like.

Unfortunately I haven’t come across a sufficient seam sealing solution that is time efficient for manufacturing, but I’m always exploring options.

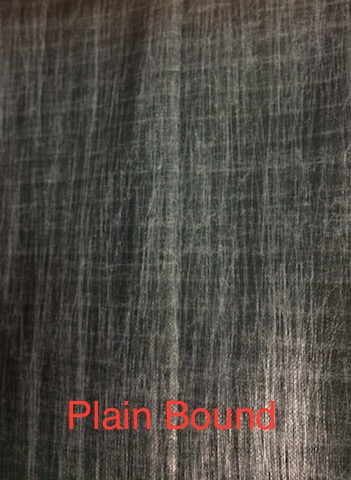

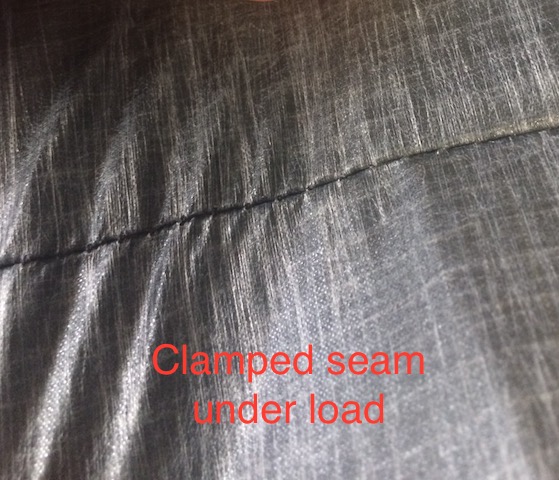

I used plain bound seams to test the LS07 with fair results but it really behaves best with french seams. perhaps not so critical on small volume packs but definitely french for high load & maximum seal.

I have attached some pics which may only help a little as I’m a terrible photographer! Tacked webbing shot is actually on my personal pack built from LS42, I have had no failures using this method on all packs I build. Frame is 1.5mm HDPE frame sheet with centred 20mm wide 6061 stay. Pic attached of the back panel layout shows up better on the D40 fabric.

Cheers, Dan.

Feb 12, 2018 at 9:00 am #3517968

Feb 12, 2018 at 9:00 am #3517968Whoops, and this one Roger…..

Feb 12, 2018 at 9:07 am #3517969

Feb 12, 2018 at 9:07 am #3517969Nice pack. Does it have any sort of frame? Rods, anything?

Cheers

Feb 12, 2018 at 9:42 am #3517971Thanks Roger,

Only the 1.5mm HDPE frame sheet which is full back panel width & runs from bottom to load lifters. webbing sleeve sewn to frame sheet with centred 20mm wide 6061 stay to allow for some shaping & extra rigidity. I have found the frame sheet to really spread a nice even load to the hips. Always looking to get the frame lighter but still maintain a relatively simple construction.

Cheers, Dan.

Feb 12, 2018 at 9:49 am #3517972Sorry Roger,

Also 10mm foam sized the same as frame sheet, against back.

Cheers, Dan.

Feb 12, 2018 at 10:48 am #3517978Planning on selling them?

Cheers

Feb 12, 2018 at 11:32 am #3517979Echo that your packs are gorgeous Dan! Where in Aus are you?

Roger: Any of these do you think would work as lightweight Gaiter fabrics?

Feb 12, 2018 at 8:44 pm #3518032Hi Adam

I would not recommend any of them for gaiters. You would sweat like a pig inside them. You need something which can breathe, imho.

Cheers

Feb 12, 2018 at 9:14 pm #3518038Hi Roger,

I started the design for the Blackburn pack in 2013 and have built many for customers over the past 5 years. Of late I’ve been building this pack in an 85Li version for packrafters throughout Australasia. This type of pack in the larger volume may trend in the up coming year I suspect.

Sorry Roger, I know these details should be discussed else where and not in this particular thread, apologies.

Cheers, Dan

Feb 12, 2018 at 9:17 pm #3518040Hi Adam,

Thanks for the kind words, I’m glad you like it! I’m based on the Sunshine Coast in Queensland.

Cheers, Dan.

Feb 12, 2018 at 9:18 pm #3518041Hi Dan

I know these details should be discussed else where and not in this particular thread, apologies.

I am not complaining. It’s all good MYOG stuff.cheers

Mar 11, 2018 at 9:02 pm #3523797Hi Taylor, Do you have contact info. for someone in Europe (Switzerland would be even better) that I can talk to about purchasing XPac & Dyneema (formerly Cuben) at wholesale? I’ve had difficulty contacting the company directly. Thanks in advance.

FYI – I use the products to make custom bikepacking bags.

Mar 15, 2018 at 3:21 pm #3524761I am on the hunt for a glue that would work well with x-pac (v21). The aim here is to glue some Velcro to the interior of a camera bag that in it’s turn will hold a padded insert in place, so only minor forces at play.

Any ideas to what type of glue that would work well on the interior coating? I am primarily looking for something I could source here in Europe.

Mar 15, 2018 at 9:15 pm #3524841That Q is best sent to Taylor from DP I think. I know a lot of X-Pac fabrics have a DWR on the outside surface, but maybe not on the inside surface. I was able to use 3M9485 transfer tape very successfully on VX07 and VX02.

Cheers

Mar 16, 2018 at 1:06 pm #3524947Hi Aron,

We are working on a heat activated glue system for X-PAC. Perhaps I could send you a sample to try. DM or email me you address and I’ll arrange for you to try some. Taylor.North at dimension-polyant.com

Cheers,

Taylor

Mar 16, 2018 at 8:30 pm #3525024Very, very nice!

We want a full report!Taylor – any chance of a tech doc?

Cheers

Mar 16, 2018 at 9:41 pm #3525044Taylor, You have mail! This sounds super interesting :)

-

AuthorPosts

- You must be logged in to reply to this topic.

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

Our Community Posts are Moderated

Backpacking Light community posts are moderated and here to foster helpful and positive discussions about lightweight backpacking. Please be mindful of our values and boundaries and review our Community Guidelines prior to posting.

Get the Newsletter

Gear Research & Discovery Tools

- Browse our curated Gear Shop

- See the latest Gear Deals and Sales

- Our Recommendations

- Search for Gear on Sale with the Gear Finder

- Used Gear Swap

- Member Gear Reviews and BPL Gear Review Articles

- Browse by Gear Type or Brand.