Topic

3 Pack Fabric's HH Tests

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

Home › Forums › Gear Forums › Make Your Own Gear › 3 Pack Fabric's HH Tests

- This topic has 45 replies, 10 voices, and was last updated 6 years, 7 months ago by

Roger Caffin.

Roger Caffin.

-

AuthorPosts

-

Apr 6, 2018 at 12:40 am #3528934

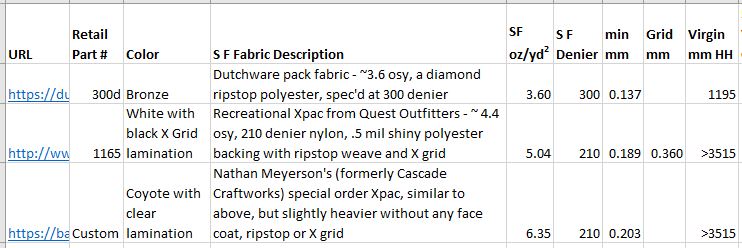

Sam Farrington sent me three different pack fabrics to test for water resistance when new and when wet flex aged. One of the three fabrics failed its virgin HH test at 1195 mm HH and the other two tested >3515 mm HH. In order to get separation between the two remaining contenders I will begin an extended wet-flex test and post the results to this thread when there is a clear winner. A summary of the initial characteristics are as follows:

The label that same attached to each fabric and their respective micrographs are as follows:

Dutchware pack fabric – ~3.6 osy, a diamond ripstop polyester, spec’d at 300 denier

20 mm FOV

5mm FOV

1.4mm FOV

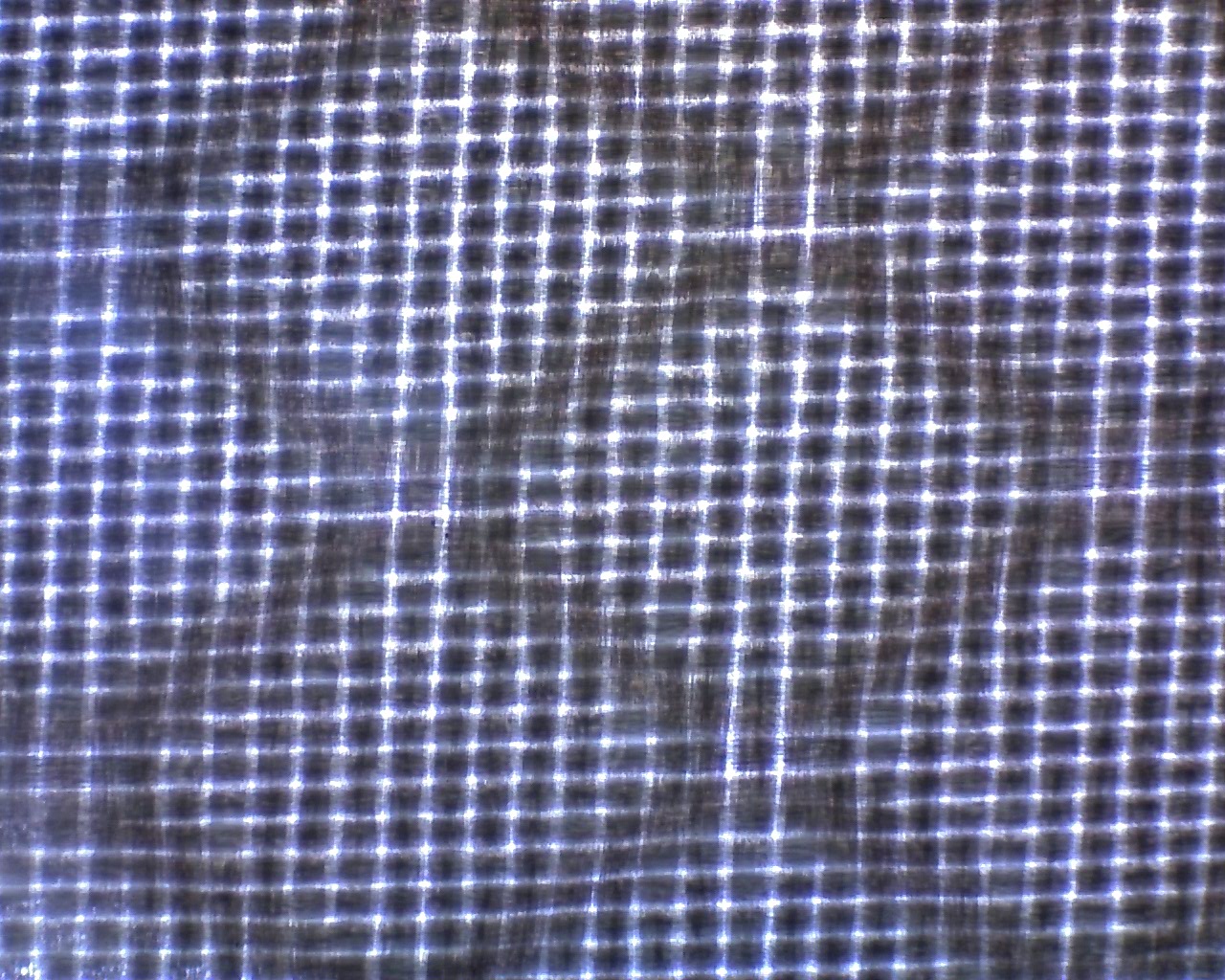

Recreational Xpac from Quest Outfitters – ~ 4.4 osy, 210 denier nylon, .5 mil shiny polyester backing with ripstop weave and X grid

20 mm FOV

5mm FOV

1.4mm FOV

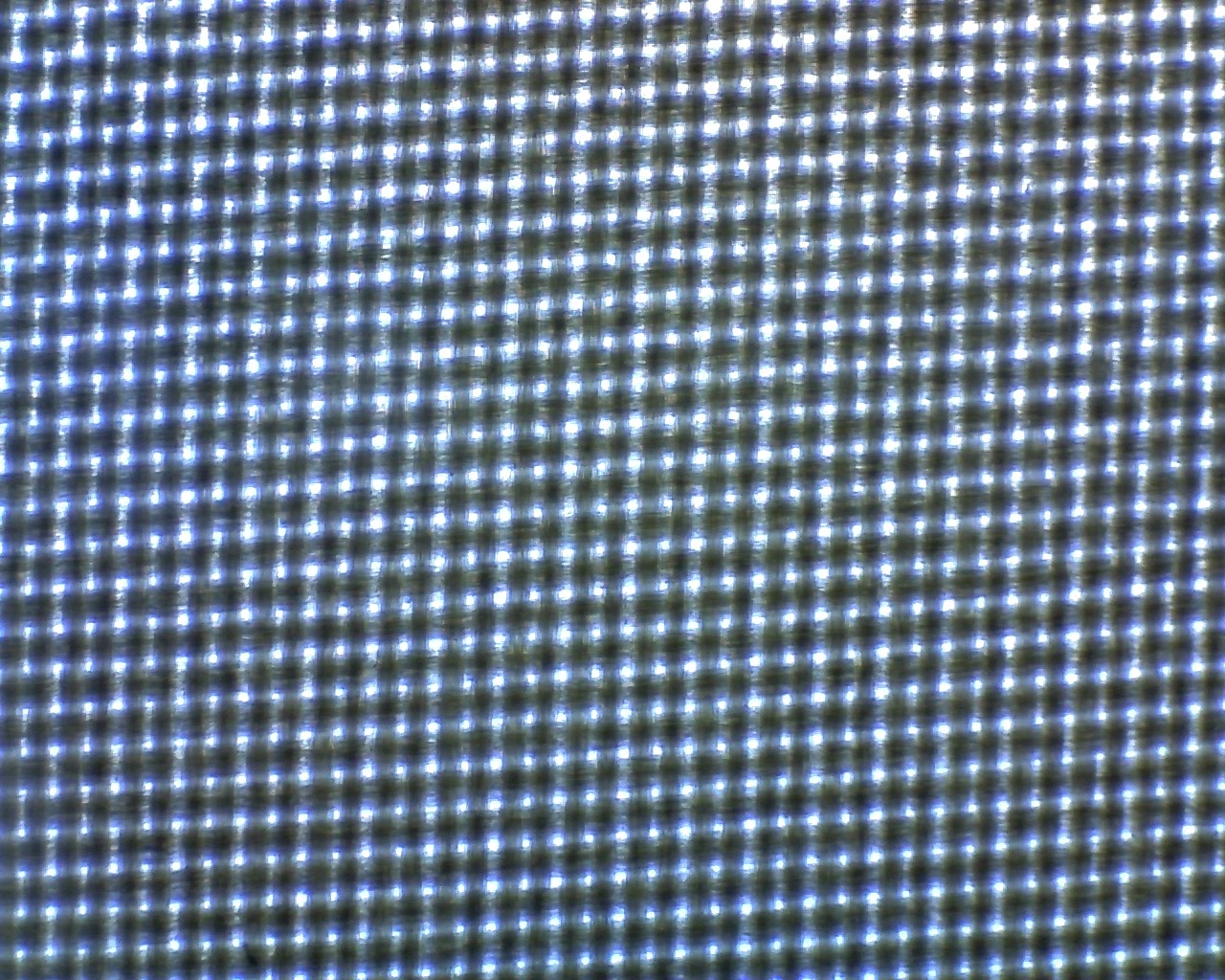

Nathan Meyerson’s (formerly Cascade Craftworks) special order Xpac, similar to above, but slightly heavier without any face coat, ripstop or X grid

20mm FOV

5mm FOV

1.4mm FOV

20mm FOVApr 6, 2018 at 4:26 am #3528974The oz/yd2 for the Coyote colored fabric in the prior post is wrong but since it was the first post of the thread, I can’t correct it. I highlighted the corrected value in red for this post.

After 5,400 wet flex samples, and the test head centered on the 1′ square sample, the Coyote color XPac had 1 leak point at 633 mm HH. The applicable standard calls for 3 leak points within the test head area to qualify as a HH limit. I moved the test head around the perimeter of the fabric and couldn’t find any additional leak points.

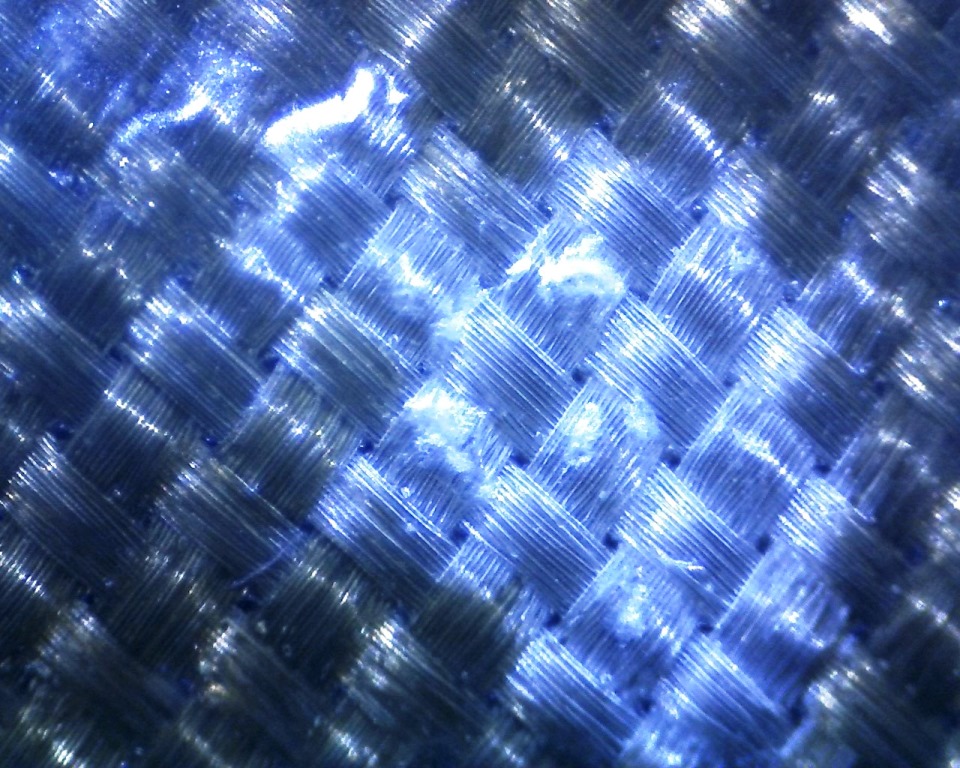

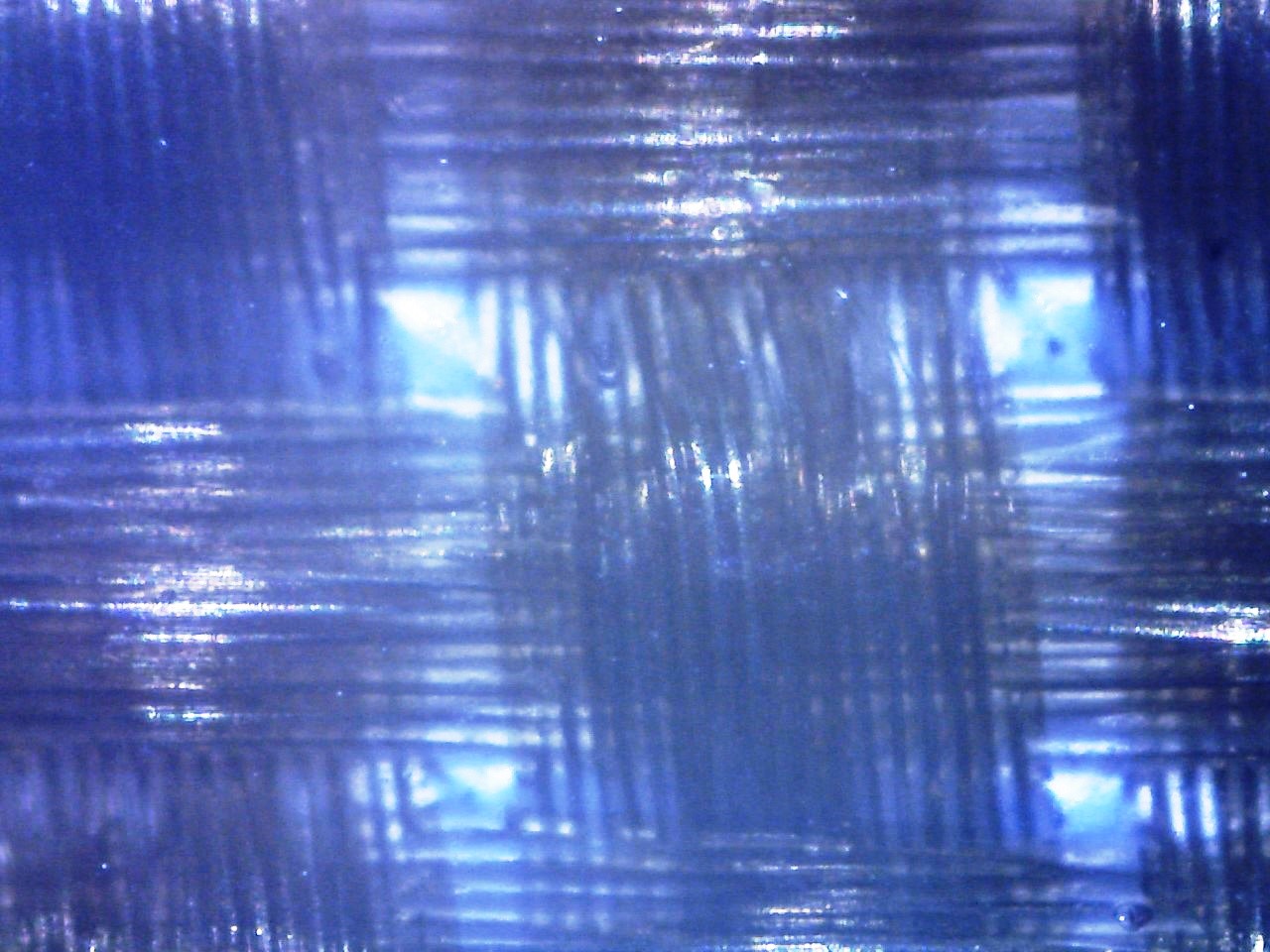

Note the contrast in the coyote XPac construction versus the white XPac construction. The white XPac appears to have had more liquid adhesive applied to the clear lamination and this adhesive both filled the fabric voids and created anchor points by spreading out on the opposite side of the fabric that the clear lamination is on. Does anyone know if this was just manufacturing variance or different lamination processes are used for different fabric combinations?

Apr 6, 2018 at 5:47 pm #3529058

Apr 6, 2018 at 5:47 pm #3529058The coyote XPac’s lamination and PET membrane deteriorated markedly after 10.800 wet-flex cycles. The entire fabric sample has random gusher points, not just seepages; this is indicative of the membrane having relatively large perforations. I won’t do additional wet-flex tests on the remaining white XPac fabric.

Apr 6, 2018 at 6:09 pm #3529064

Apr 6, 2018 at 6:09 pm #3529064You don’t need a microscope to see the clear PET membrane failure. I took this picture with my iPhone.

I have three theories as to why this happens. It could be one or some or none (smile).

- Insufficient glue was applied between the clear PET membrane and the fabric

- The rigidity of the characteristic raised X (omitted on this fabric) distributes the flex load over the large area under each X and hence, prevents the clear PET membrane’s perforations

- The adhesive injector nozzles are not center aligned with the major fabric interstices.

Apr 6, 2018 at 6:29 pm #3529071Thanks Richard for the data. The Coyote V-21 results are interesting. This fabric is noticeably less stiff and roles much easier than three different bolts of the standard X-21 RC materials, which is consistent with your # 2 observation above. The Coyote V-21 is also significantly lighter at 3.6 oz/sqyd (similar to the value you got) as opposed to 5.0 – 5.2 oz/sqyd for various X-21 RC materials.

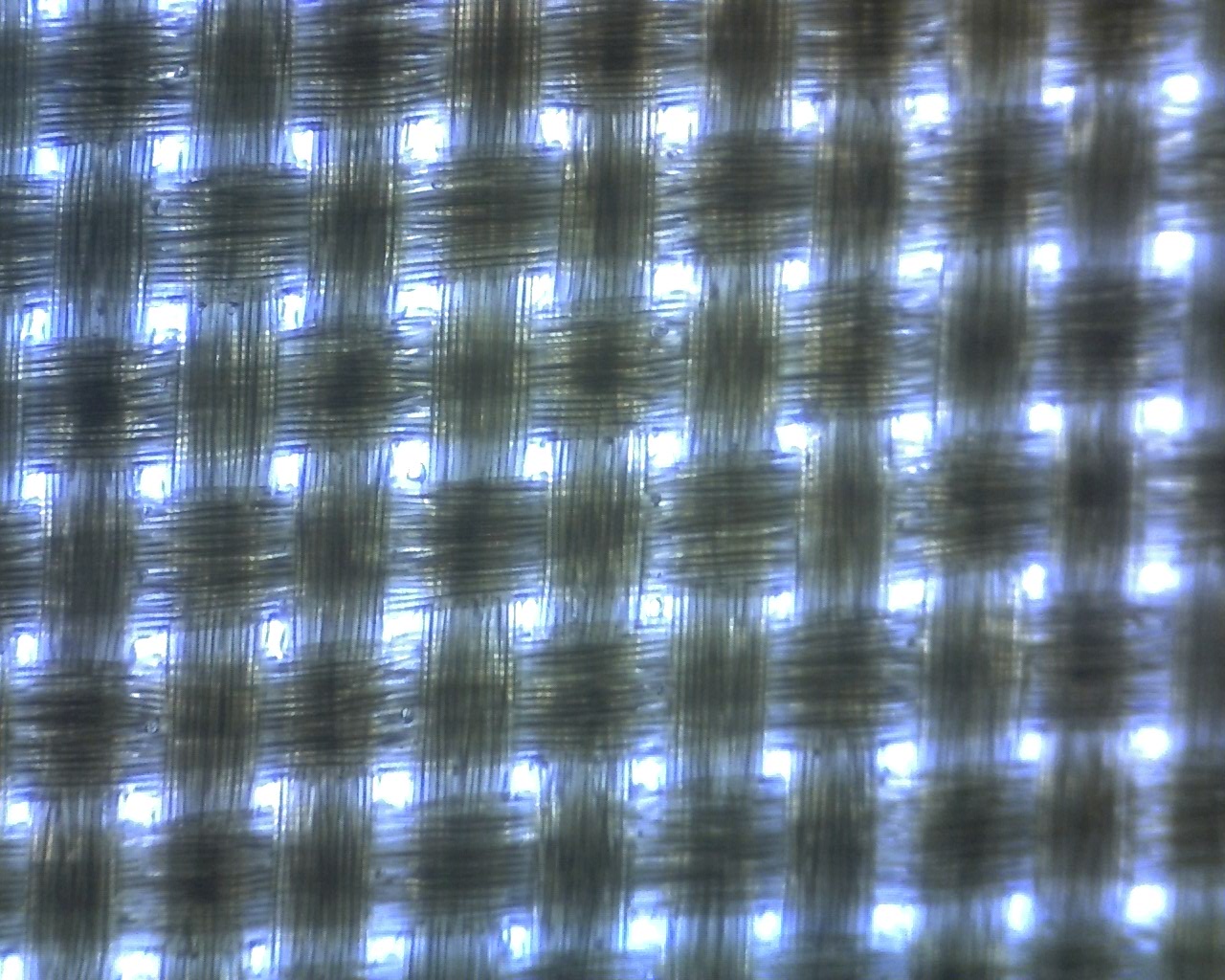

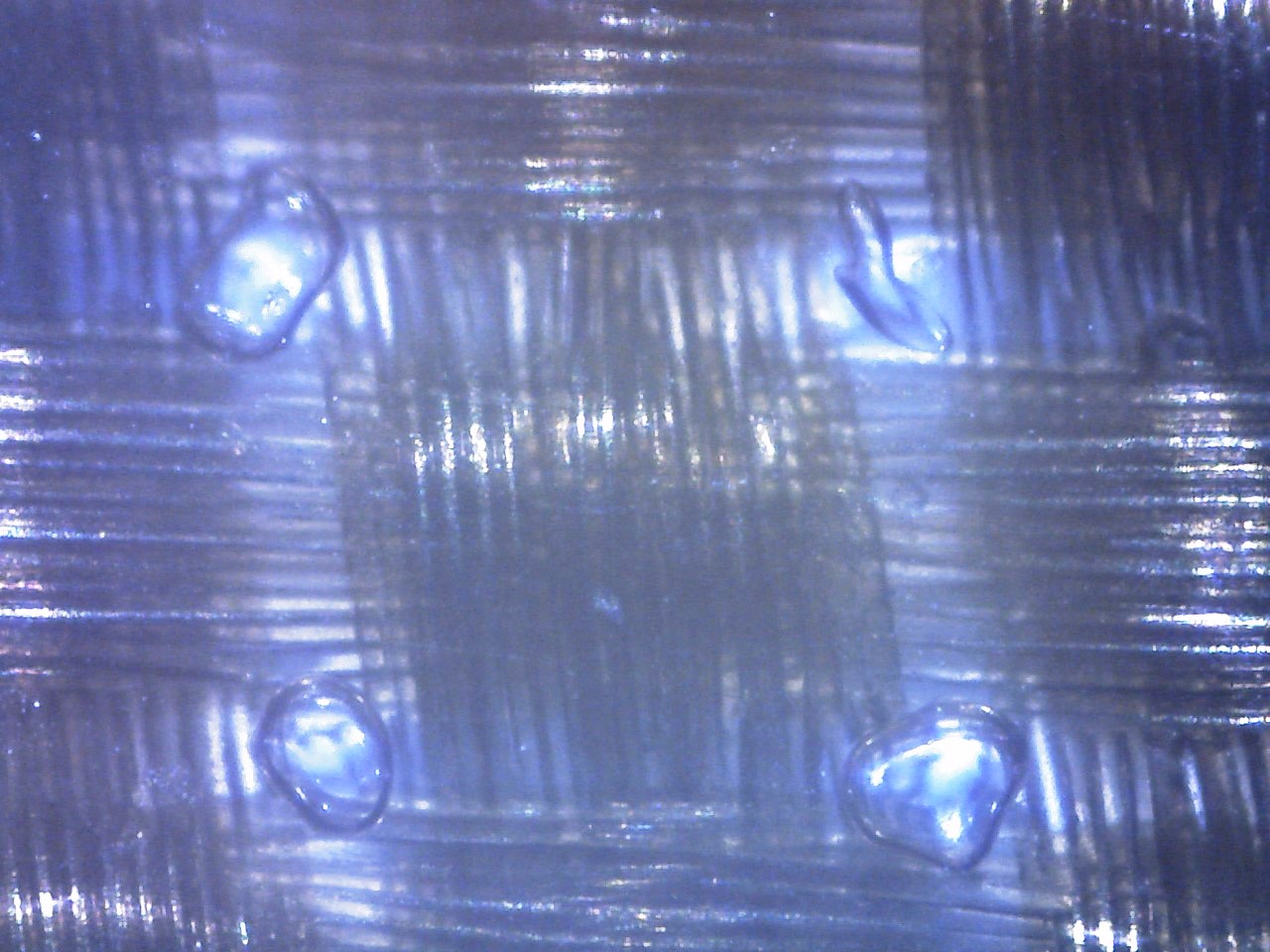

Apr 6, 2018 at 6:38 pm #35290735mm FOV showing one of the failure points. It indicates both delamination and membrane perforation.

Apr 6, 2018 at 7:41 pm #3529084

Apr 6, 2018 at 7:41 pm #3529084Richard, are these stereoscope images? What are you using?

I’ve been thinking about upgrading my stereoscope to something that is digital so I can capture water movement in textiles with video.

Apr 6, 2018 at 10:26 pm #3529124Ryan,

I am using an old USB microscope with no software. I combined this with some custom software on Windows 10 Professional for a “kludge solution” which doesn’t support video.

If you find something that does what you want, please post that information to this thread. I would like to find a supported product.

Apr 6, 2018 at 10:38 pm #3529128Interesting findings, Richard, thanks for the information!

I’m happy to send out swatches of other Xpac fabrics as well if you’d like to increase sample size.

My question is how consistent DP lamination process is between batches of fabric or even within singular rolls.

Apr 7, 2018 at 12:22 am #3529146Nathan,

I think the fastest way to solve this is for the DP engineers to get involved as the next step. Only they can modify their manufacturing process, their QA process, or make the determination that nothing needs to be done.

Apr 8, 2018 at 12:54 am #3529353As always, thanks Richard. Can you remind us what amount of use 10,800 wet flex cycles translates to in the real world?

P.S. – Have you tested hybrid cuben to 10,800 cycles? If so, do you recall the results?

RyanApr 8, 2018 at 2:45 am #3529362Ryan,

10.800 wet-flex cycles correlates to the approximate weathering from 4 weeks of heavy wind and rain.

I haven’t tested any WP pack fabric’s before. I last tested a Cuben fabric (aluminized version 3) in 2014. That 2014 work was done in cooperation with Nathan Myerson. It is described in detail Here. The Cuben was still >3515 mm HH after I stopped testing at 16,200 Cubex wet-flex cycles.

Apr 8, 2018 at 6:22 pm #3529413Ryan,

I purchased an HMG Porter 4400 (hybrid Cuben) 1/30/14. I have used it for an average of 3 weeks per year during the past 4 years. When backpacking, I normally have a packraft cinched on top of the collar. When in WW, it is lashed to the bow of my boat. Four weeks of those trips involved heavy bushwhacking in AK with near constant rain.

It has experienced approximately 32,400 wet-flex cycles from field use. I just HH tested the collar material (most flexing) @ >3515 mm HH.

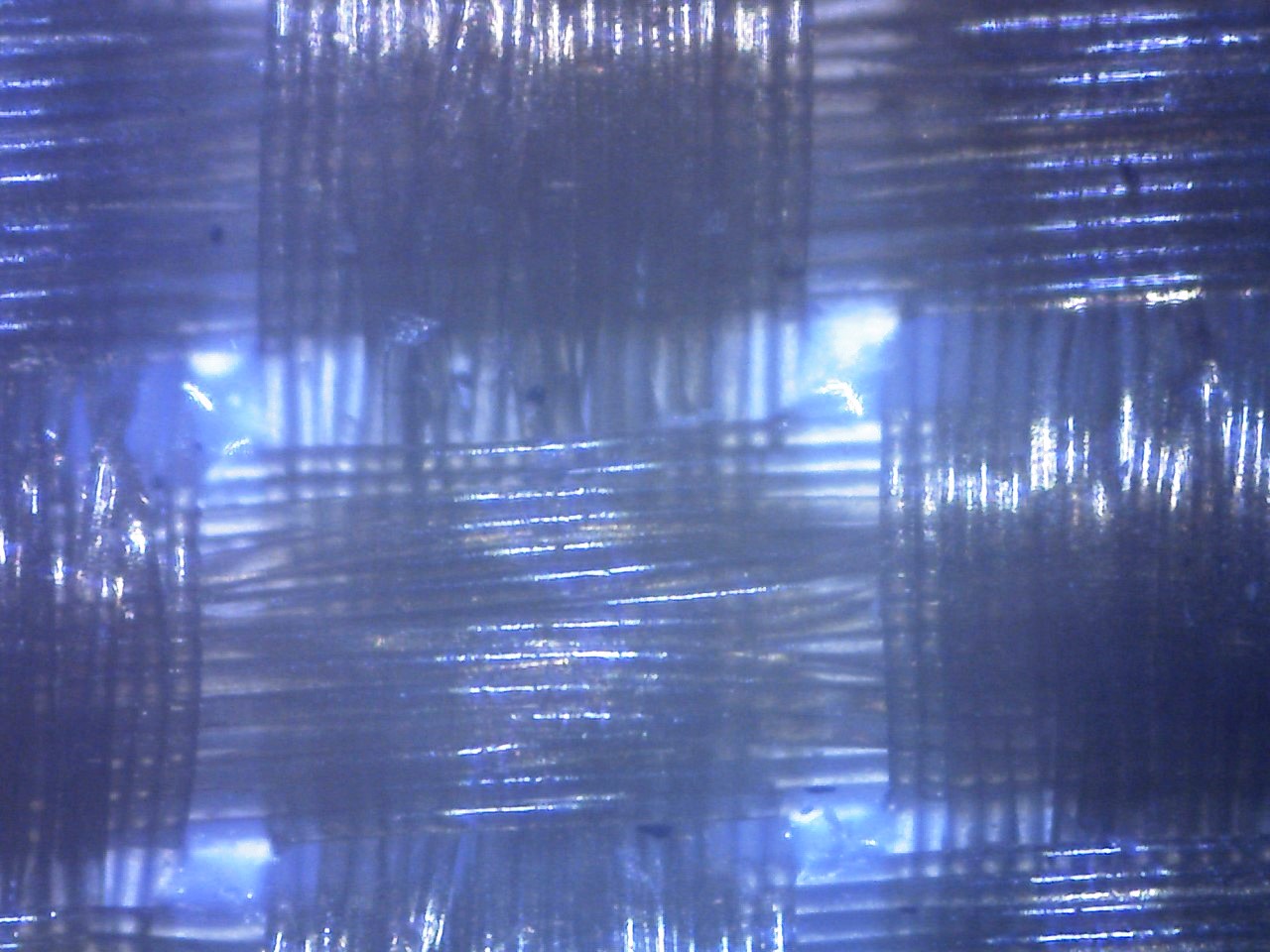

Apr 9, 2018 at 12:11 am #3529513Two additional 1.4mm FOV micrographs with the microscope facing the PET layer and looking through it to the fabric.

White composite

Coyote composite

Two additional 1.4mm FOV micrographs with the microscope facing the fabric layer and looking through it to the PET layer. If they are doing a fine nozzle adhesive injection into the fabric side’s major interstice pattern, it’s possible that the adhesive injector is not center aligned and/or not injecting enough adhesive into the Coyote version.

White composite

Coyote Fabric

I tried to use different lighting to create easier to interpret micrographs in this post. My objective was to assist the DP engineers in an expedited problem analysis.

There are areas of the Coyote lamination where the amount of adhesive looks adequate and other areas where the amount looks inadequate. This seems to reinforce the hypothesis that the missing X grid is the more likely cause of the delamination areas and perforations.

A 1.4mm FOV micrograph taken with the microscope facing the PET layer. Some areas of the composite seem to have the normal amount and placement of adhesive.

5mm FOV of the Coyote fabric looking at it from the PET side. Although there are areas where the adhesive is not centered on the major fabric interstice, most of the areas appear to have ample adhesive. This makes me suspect even more that the missing X-grid is what caused this fabric to delaminate. The X-grid normally provides both bias stability and added tear strength. The lack of bias stability is probably what resulted in delamination.

Apr 13, 2018 at 2:52 pm #3530280

Apr 13, 2018 at 2:52 pm #3530280Hi All,

Sorry for the delay in replying to this thread. I’ve been travelling this week.

The microscope pictures are very interesting! We keep very detailed records of every step of the manufacturing process and test each lot of cloth we produce. We likely have samples in are archives from these lots. Richard, do you happen to have roll/lot numbers from the fabrics you tested?

The process, or recipe, for laminating outdoor fabrics is the same and standardized across the X-PAC line, in terms of the film, adhesive and amount of adhesive used.

Nathan, in absolute terms the DP lamination process is extremely consistent from lot to lot, roll to roll, or manufacturing order to manufacturing order. We monitor the amount of adhesive across the width in real time. Zooming in to the micro level, there may be slight variations in adhesive from the beginning to the end of the roll. As in any manufacturing process there is an opportunity for defects and we try to minimize those events. Happy to take a deeper look at these lots to see if there is a quality issue.

If any of you are interested to see how we make fabric and passing through Connecticut. I’d be happy to show you how we make X-PAC fabrics.

Cheers,

Taylor

Apr 13, 2018 at 5:26 pm #3530300Taylor,

Thank you for your interest in solving this problem.

The DP coyote colored laminate was from Nathan Meyerson’s custom order (no x-grid pattern). Nathan can provide the roll/lot numbers; I wasn’t given that information.

Has DP ever experienced a similar lamination failure before, with the x- grid layer as part of the laminate, and if so, what was the cause(s)?

Has DP ever experienced a similar lamination failure before, with the x- grid layer not part of the laminate, and if so, what was the cause(s)?

Apr 13, 2018 at 5:57 pm #3530311Hi Richard,

Any chance, you send me a piece of both fabrics you tested?

DIMENSION-POLYANT

Attn: Taylor North

78 Highland Drive

Putnam, CT 06260

Cheers,

TaylorApr 13, 2018 at 7:38 pm #3530321Taylor,

I will do better than just sending you a piece of each DP fabric. I will send you both complete 1′ square DP samples, that I reported on in this forum thread.

Did you get the roll/lot number information from Nathan Meyerson for the Coyote colored DP fabric?

Apr 13, 2018 at 8:13 pm #3530336Richard, thanks! No, I have not heard from Nathan.

Apr 13, 2018 at 9:14 pm #3530346Taylor,

I put the two DP samples in a large white plastic mailer and sent them to you via first-class USPS from CA. They should arrive at your CT facility next Friday. The tracking number is: 9500 1154 6779 8103 2214 76.

Thanks again for trying to solve this problem

Apr 13, 2018 at 9:37 pm #3530357Hi Taylor, Lot # for the V21 Coyote in question is

61084-103-00

Fingers crossed it’s just a fluke, had my hopes up for the V21 Material!

Apr 14, 2018 at 1:32 am #3530398“It has experienced approximately 32,400 wet-flex cycles from field use. I just HH tested the collar material (most flexing) @ >3515 mm HH.”

Thanks for going above and beyond, Richard. I anticipated the cuben hybrid not doing very well at that level of usage. Pleasantly suprised!

Hope D-P figures it out. On paper, V21 should be an excellent fabric.

Ryan

Apr 16, 2018 at 2:24 pm #3530683Richard, Nathan,

Thanks! We’ll take a close look at the samples and the lot of V21.

Cheers,

Taylor

Apr 16, 2018 at 6:53 pm #3530744Taylor,

After DP determines what caused the failure, please post the analysis summary to this thread.

Apr 17, 2018 at 12:28 am #3530815My hunch is that issue is due to combination of the soft-hand of the coyote fabric and lack of X-grid. Other folks have used V21 in other colors, but it was expressed to me before purchase that the coyote material(also used in VX21 -Soft) hasn’t been used before for V21.

Heres to hoping my investment and color choice doesn’t turn out to be all for naught.

Though I’d rather have informed consumers than hype a material that doesn’t deliver.

Cheers

-

AuthorPosts

- You must be logged in to reply to this topic.

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

LAST CALL (Sale Ends Feb 24) - Hyperlite Mountain Gear's Biggest Sale of the Year.

All DCF shelters, packs, premium quilts, and accessories are on sale.

Our Community Posts are Moderated

Backpacking Light community posts are moderated and here to foster helpful and positive discussions about lightweight backpacking. Please be mindful of our values and boundaries and review our Community Guidelines prior to posting.

Get the Newsletter

Gear Research & Discovery Tools

- Browse our curated Gear Shop

- See the latest Gear Deals and Sales

- Our Recommendations

- Search for Gear on Sale with the Gear Finder

- Used Gear Swap

- Member Gear Reviews and BPL Gear Review Articles

- Browse by Gear Type or Brand.