Background

I worked in the 3D printing industry for many years: actual jetting of material (not dispensing molten material through a single nozzle). We were using a 300 dot per inch printhead to generate solid objects and the printhead contained 1200 nozzles. Building a single 8” tall object was equivalent to printing 5000 pages.

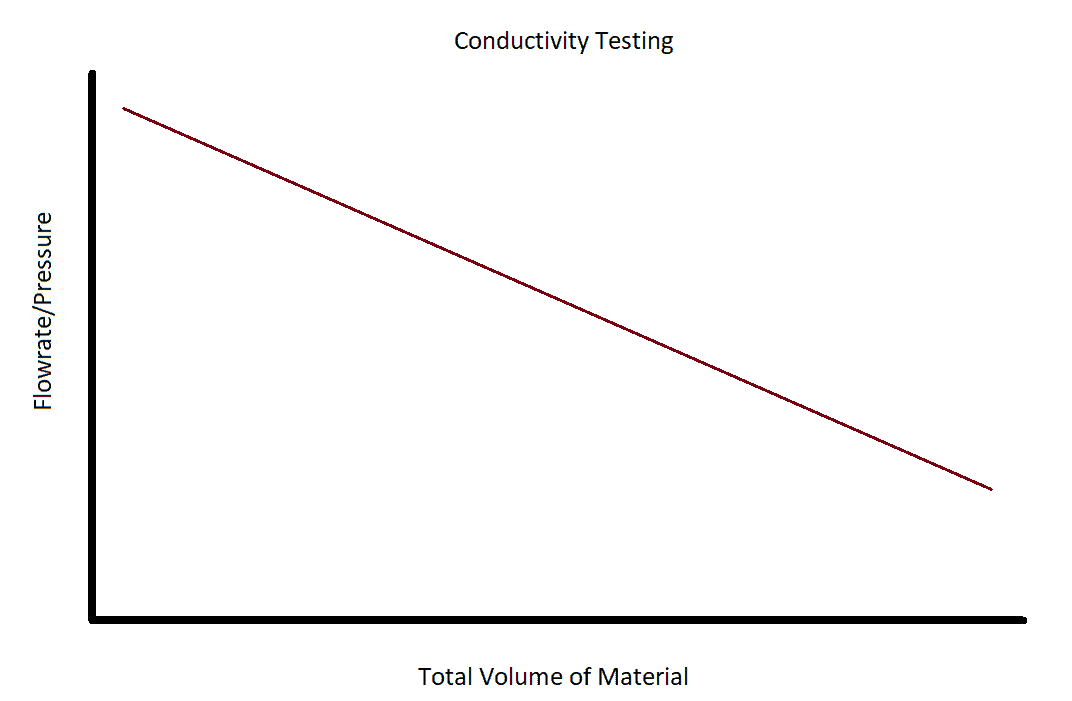

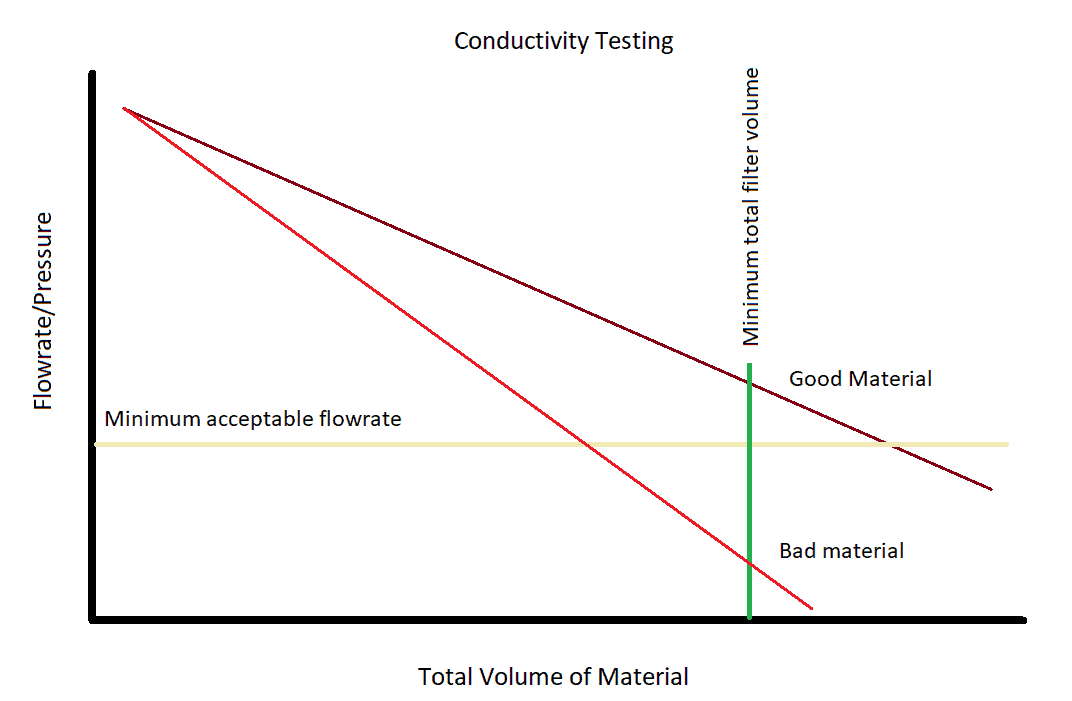

Supplying the printhead with clean material was paramount to printing reliability as well as longevity. To assess this issue, a metric was developed to evaluate jetted material for cleanliness. This is called Conductivity Testing. To conduct the test, liquid was placed into the test apparatus and the fluid level was held at a constant level - this would provide a uniform fluid pressure. Downstream from the vessel was a standardized filter material. The liquid was allowed to flow through the filter and the data was collected. To generate a Conductivity Chart, you plot the real-time flowrate of the liquid through the filter material (Y-axis) against the total amount of fluid that had passed through the filter (X-axis). The chart would look like a straight line with a negative slope: high on the left side and diminishing on the right.

The slope of the line would give us the rate at which the filter clogged or in other words, a measure of the material cleanliness. The minimum flowrate is defined by performance requirements needed to jet material correctly. The total volume of material jetted is defined by marketing requirements. From this chart you can determine how many cubic feet (or pounds) of material could be jetted before the flowrate drops below acceptable levels.

The test metric is excellent for verifying material cleanliness, so we can apply this to estimate backcountry water filter performance.

However, we have no control over water quality in the backcountry. Modifying the test methodology to estimate effective filter area does add a lot more value to help characterize the performance state of the water filter.

It would be easy to replicate this type of test for water filters and the results would be highly repeatable. That being said, the system we used for evaluating 3D printing material quality, described above, is bulky and requires additional equipment that would make it difficult for most backpackers to emulate.

Thus, in this article, I am proposing a faster and easier-to-use test that, while not as accurate, the would be easy to replicate and is user friendly enough for most backpackers.

The goal of this test is to determine the effective age of your backpacking water filter based on comparing its current flowrate to its flowrate when new.

Word Count: 2000+Member Exclusive

A Premium or Unlimited Membership* is required to view the rest of this article.

* A Basic Membership is required to view Member Q&A events

Home › Forums › Estimating the Age (Lifespan) of Your Backcountry Water Filter