Introduction

I have measured thermal resistance of a lot of garments. I have often found that the measured resistance of the garment didn’t seem to relate very well to the insulating performance claimed by the insulating manufacturer. How much of this was the result of the garment construction and how much might be related to misleading claims by the insulation manufacturer?

So, I decided to measure the thermal performance of bare, brand new insulation.

It is clear that garment construction can be responsible for the loss of significant insulating value. However, in this study I found that manufacturer’s claims of insulating performance may be dubious. I also found what appear to be surprising lapses in quality control and/or achievable manufacturing tolerances.

Oh, of course, you probably want to know: what is warmer—Climashield Apex or Primaloft Gold? The answer is, as sold by weight per square yard, they seem to be pretty identical. Which lasts better over the long term? Which is warmer when wet? Those questions will have to wait on upcoming articles in this series.

One of the challenges in studying insulation is that I can only study products that are available for purchase. The insulations that are available for sale online are a small portion of what you see advertised by clothing manufacturers. Many of the proprietary insulations are made by third-party manufacturers and are rebranded by the garment manufacturer. I don’t expect any of the users of proprietary insulations will be willing to provide samples for testing, so you won’t see them here.

I must warn the readers, this is a long article. There are a lot of basics to cover here. There will be additional articles to come that examine more of the issues of concern for synthetic insulation. I promise these will be shorter.

Here is what will be discussed in this article:

- Synthetic insulation categories and types with a brief discussion of advantages and disadvantages.

- What is a Clo? Clo is a measurement of resistance to heat loss. It is a simple concept that creates a lot of confusion. The confusion is warranted. The meaning of clo has multiple definitions and you typically don’t know which is being applied and what test method or variations were used – thus, the confusion.

- The guarded hot plate is one of the methods available for measuring the thermal performance of insulation. We will briefly discuss the guarded hot plate and link you to a more detailed discussion of how a hot plate works and a discussion of the guarded hot plate I built for this study.

- Thermal performance measurements of several market-leading insulations will be presented along with four performance metrics to help judge their performance. Performance results for specific insulations will be considered.

Editor’s Note: While we of course recommend that you read the entire article in order to have a complete understanding of Stephen’s results, we also recognize that not everybody wants the kind of detail we are about to jump into here. If you want to skip straight to the results, scroll down until you see the section titled “Results of the Thermal Resistance Measurements of Selected Insulations.”

Synthetic Insulation Categories and Types

The synthetic insulations we’ll discuss in this article fall into two primary categories: Non-woven and knit.

Non-Woven Insulations

The majority of synthetic insulations fall in the non-woven category. Non-woven fabrics constitute a huge worldwide industry that spans numerous applications. Non-woven fabrics are created by depositing fibers, composed of a wide range of materials, both synthetic and natural, into a continuous web. The material that goes into 3M N95 masks is non-woven. Geotechnical fabrics that prevent soil erosion can be non-wovens. Filter media used to purify your drinking water are non-woven fabrics. Non-woven fabrics can have an extraordinary array of properties based on the materials, manufacturing processes, and chemical or mechanical treatments utilized in their production.

There are a variety of manufacturing processes for non-wovens. The actual fibers may be produced as part of the manufacturing process (Spunlaid, Meltblown, Submicron Spinning) or incorporated into the process as bales of material (Drylaid-Carded, Short Fiber Airlaid, or Wetlaid). If you want to know more about any of these processes, this is a good source.

After the fibers are formed into a web or mat, the resulting web strength is minimal. Web bonding must be undertaken to stabilize the web to achieve adequate structural integrity for its intended application. This is accomplished by bonding the fibers through applications of heat, adhesives, or mechanical processing such as needle punching and compression. During this processing, additional chemicals may be added to reduce friction between fibers, improve moisture resistance, or control the build-up of static electricity.

When selecting the type of non-woven to utilize, designers must consider a number of issues:

- The garment design, appearance, and manufacturing costs. Thick, inflexible blankets of insulation will not lend themselves to sleek, athletic-looking garments. Insulation physical space requirements, pliability, and ease of assembly will impact the materials selection process.

- Quilting Requirements. Structural integrity will vary greatly among insulation types. Insulation rigidity can be achieved during the manufacturing of the web or during garment production through the use of quilting. The use of quilting may be desirable from an aesthetic or marketing perspective, but it reduces thermal efficiency. A quilted seam produces a localized area where the insulation is compressed and provides little or no thermal resistance for the garment. Some insulations are self-supporting so that quilting requirements are minimized or eliminated. Support considerations will have a direct impact on fabrication costs, insulation efficiency, and garment weight.

- Fiber characteristics. The shape, length, and diameter of fibers that comprise the web will influence insulation warmth, resilience, and longevity. Smaller fiber diameters can reduce radiant heat transfer in the insulation but at the cost of the structural integrity of the web. Some insulations are created with a range of fiber diameters and shapes to provide the desired balance of thermal efficiency and loft maintenance.

The three major categories of non-woven insulation include cluster fiber, short-staple, and continuous filament.

Cluster Fiber insulation consists of tiny tufts of fibers. The North Face Thermoball (made by Primaloft) or Rab Cirrus (3M Featherless Down) are examples. These fibers can readily substitute for down in the manufacturing process and lend themselves to garment designs associated with the use of down. These types of insulations require extensive quilting to provide stabilization. None of these products are included in the present study.

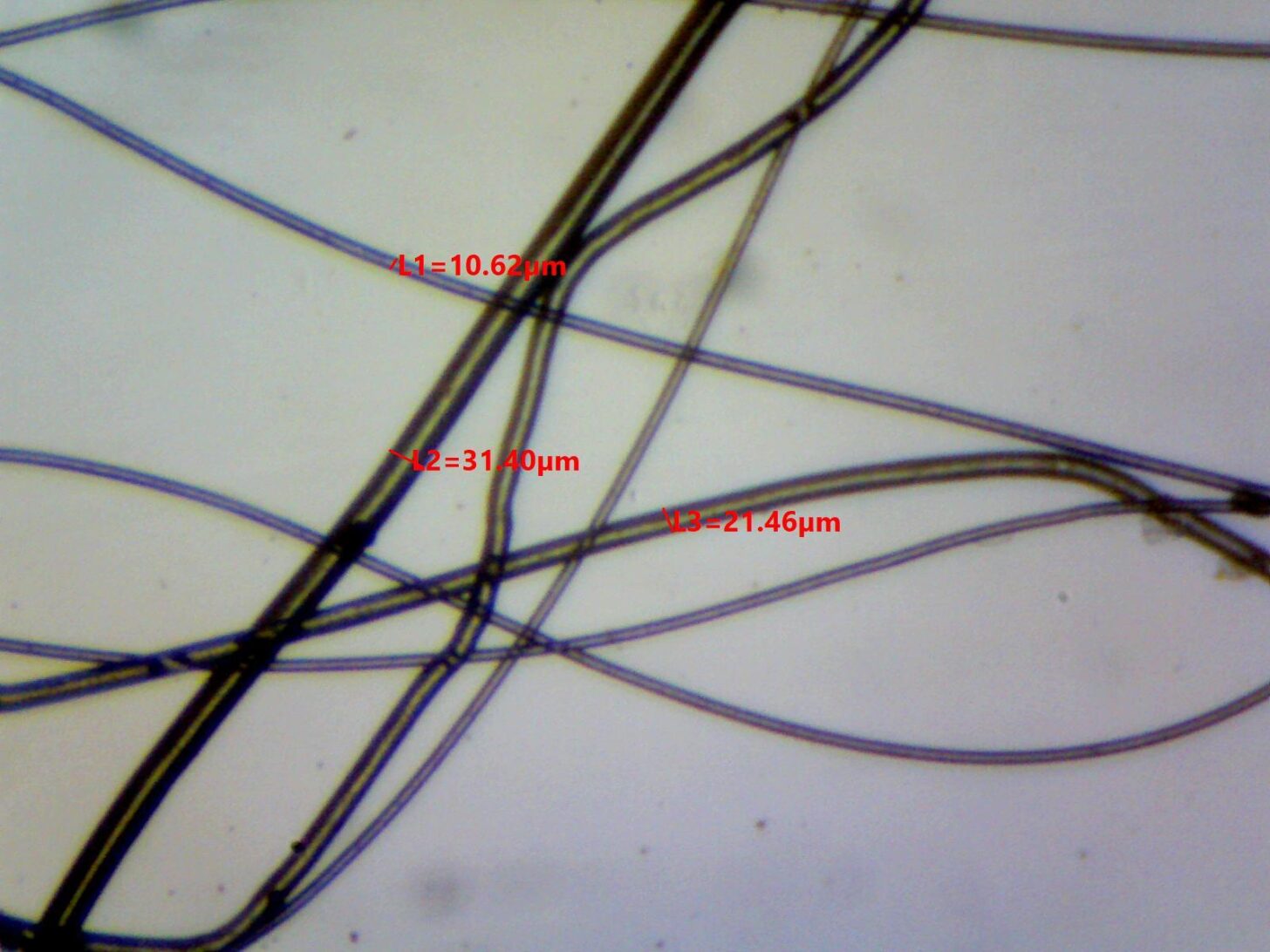

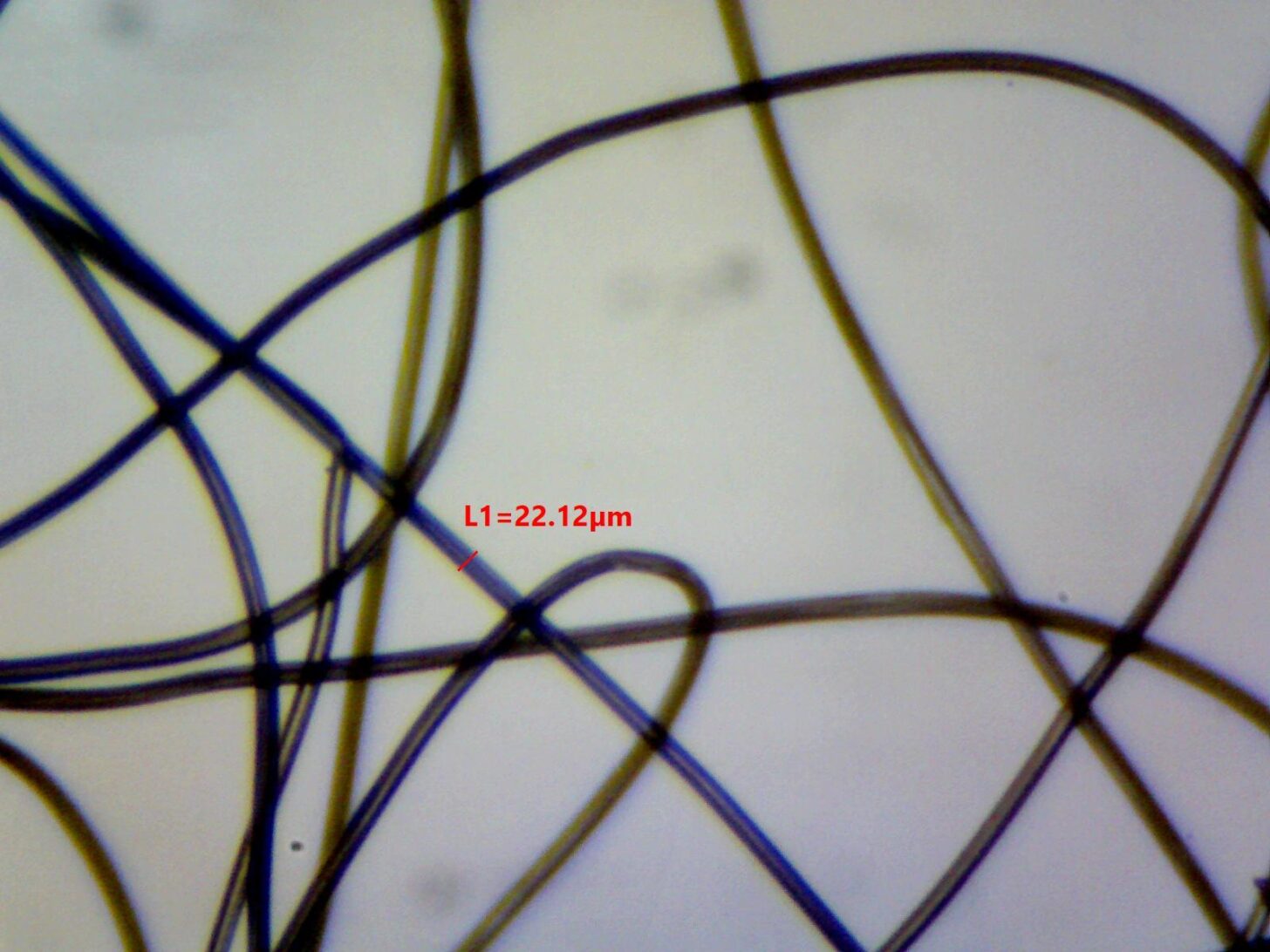

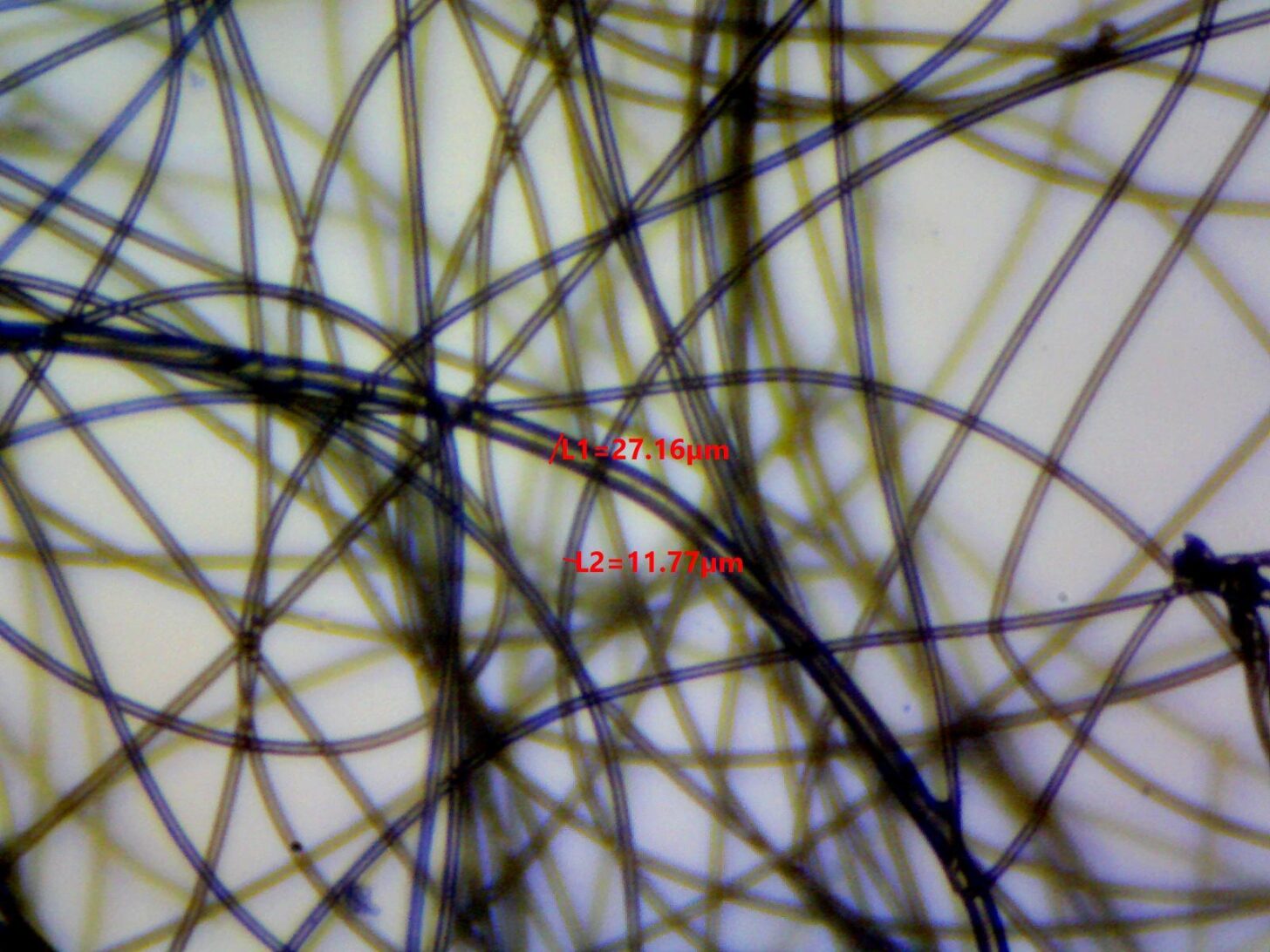

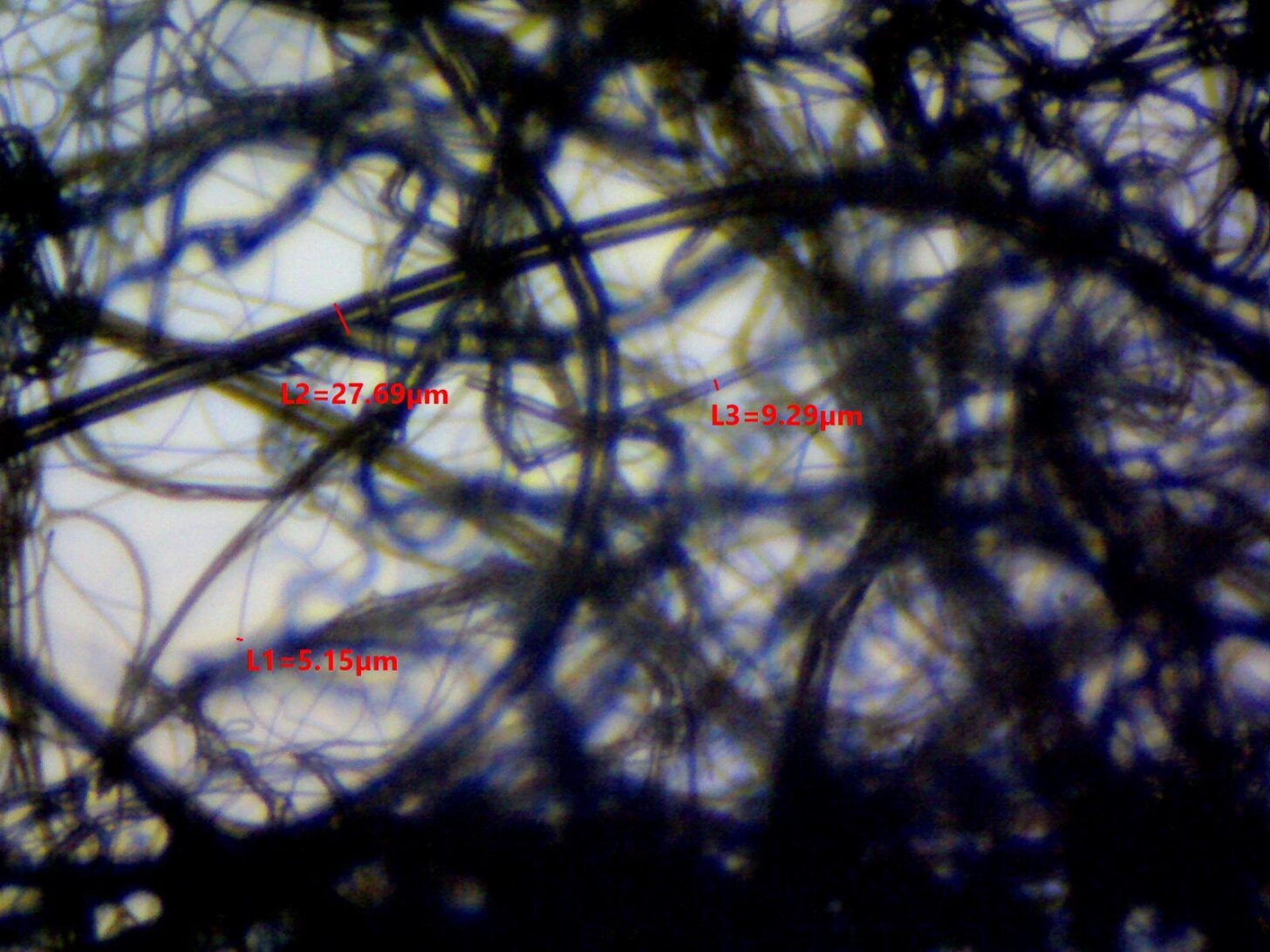

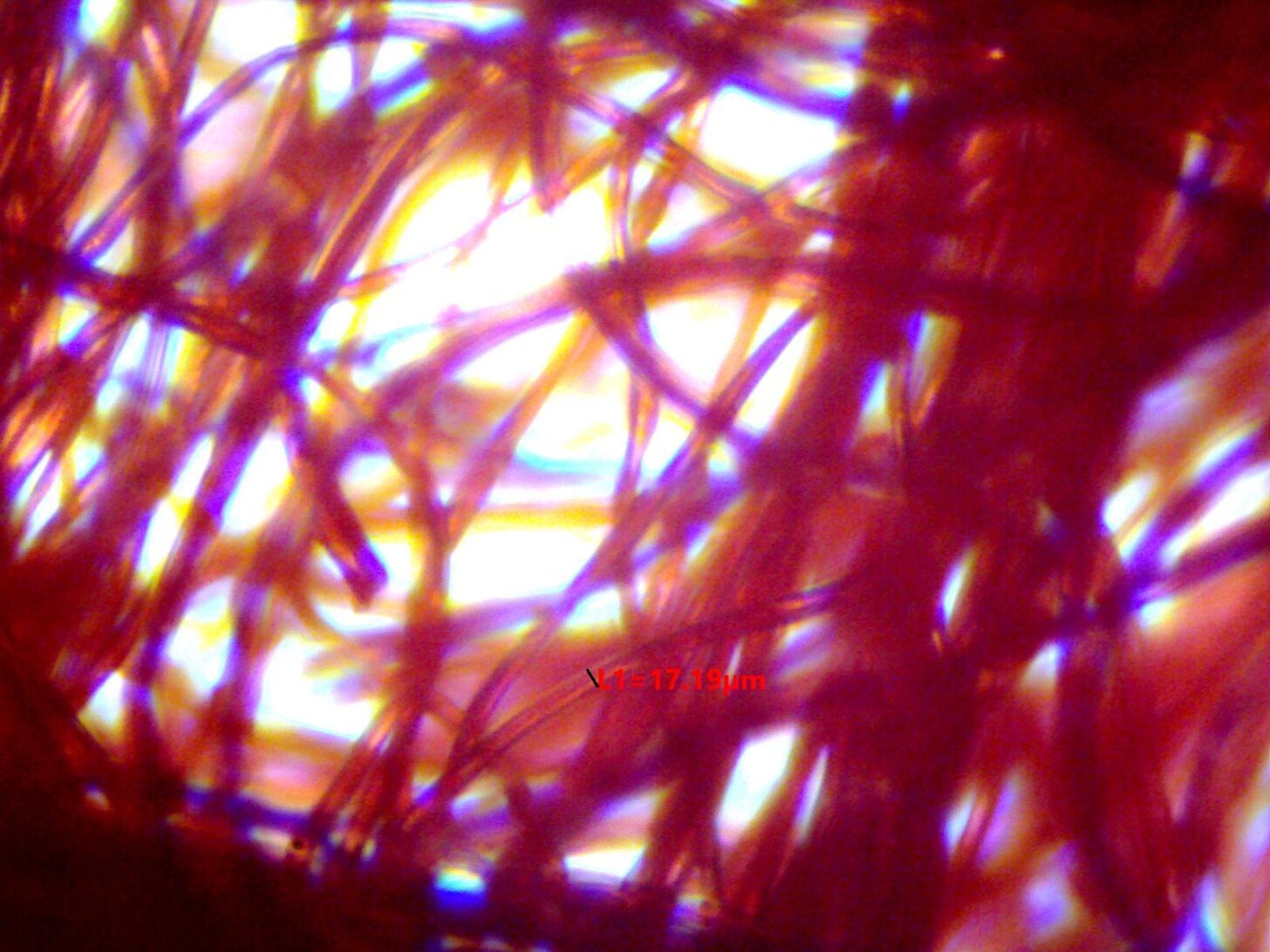

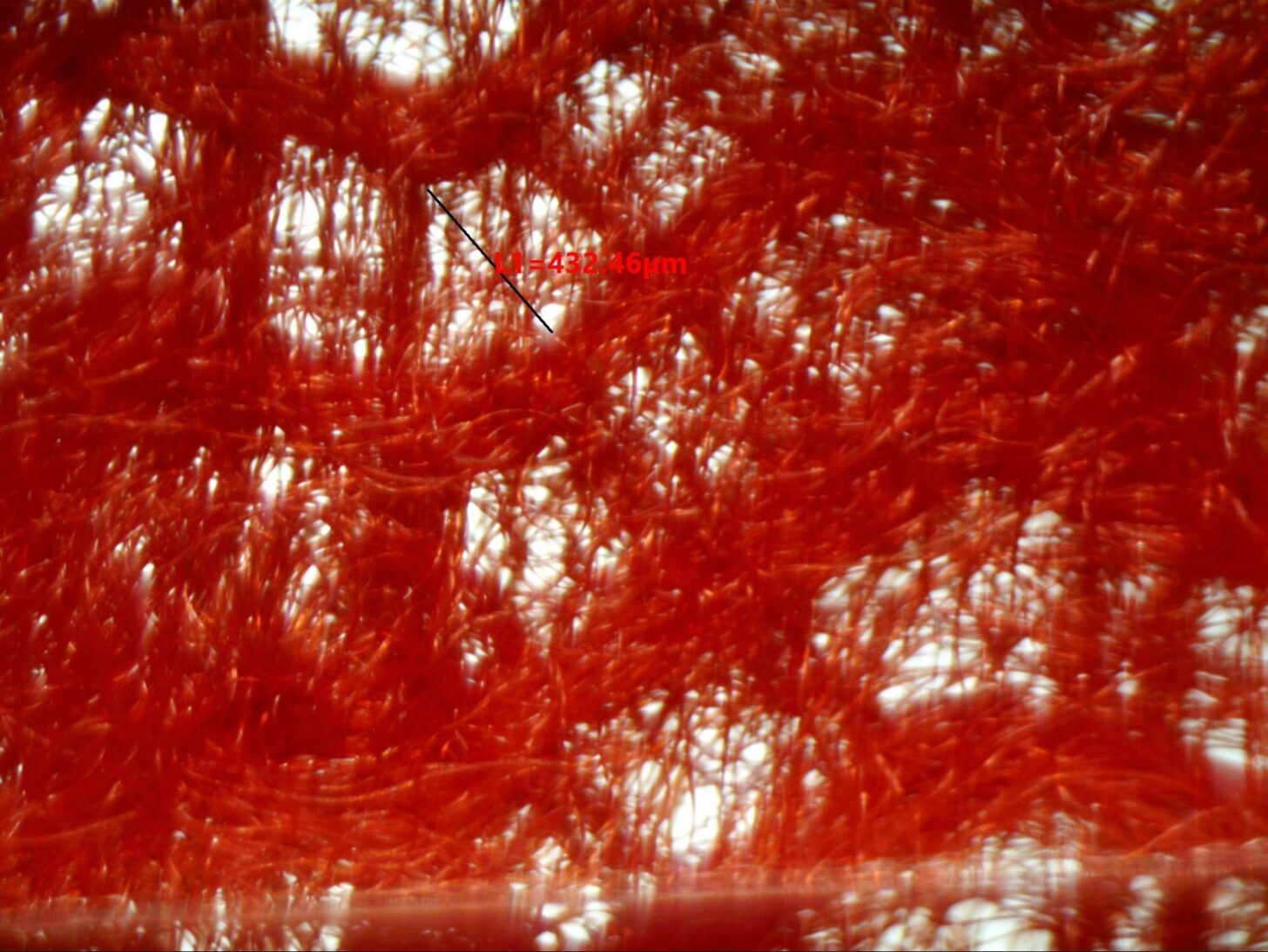

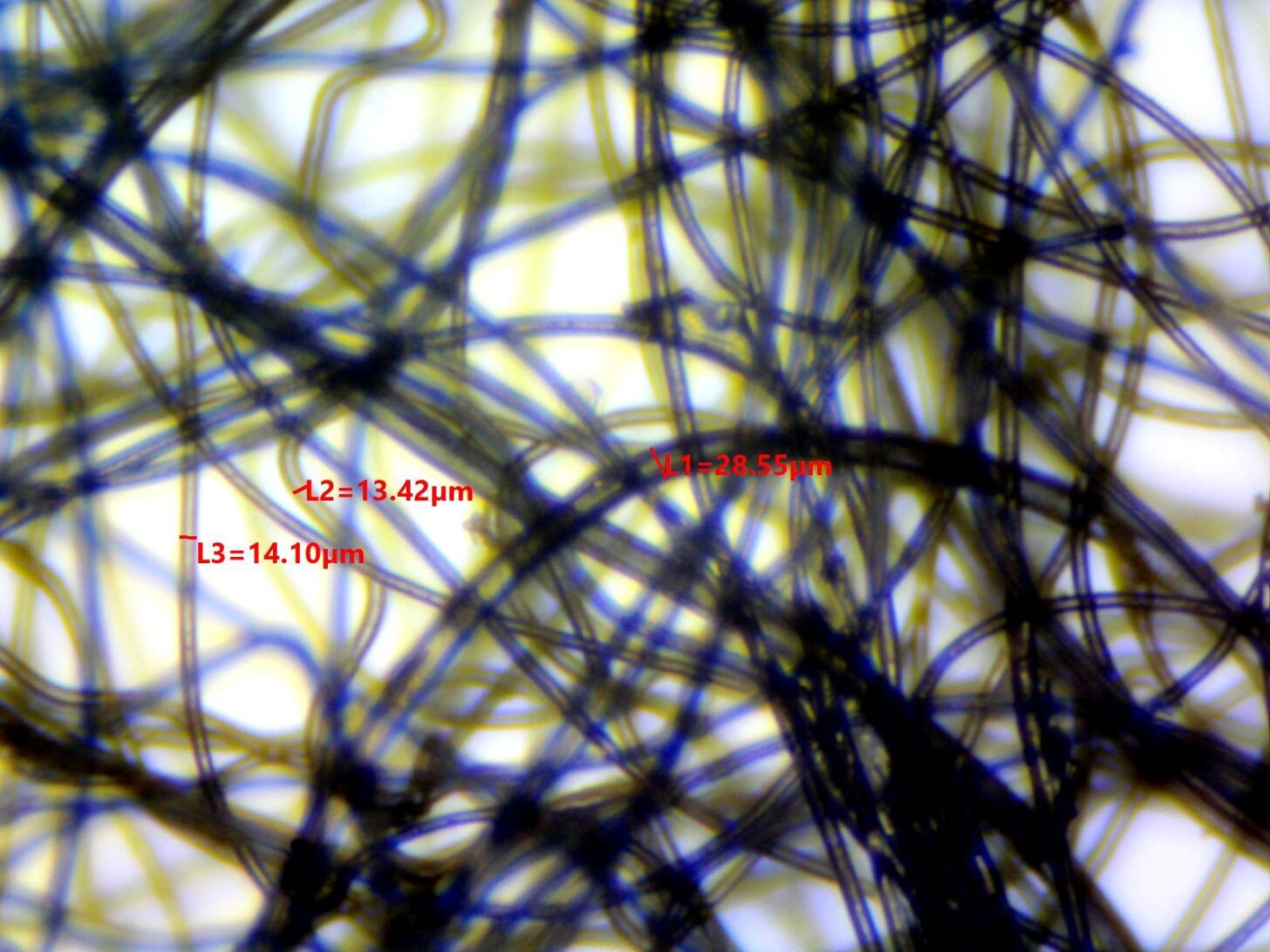

Short-Staple insulation consists of short fibers, typically less than 2 to 3 in (5 to 8 cm) in length. Primaloft Gold is a market-leading example of short-staple insulation, of which two weights are tested in this study. Short staple insulation can have a very soft feel, excellent conformability to complex shapes, and very good warmth-to-weight performance. As is the case with a number of short-staple insulations, several diameters of fibers are incorporated into Primaloft Gold. These range in diameter from approximately 10 microns to 30 microns.

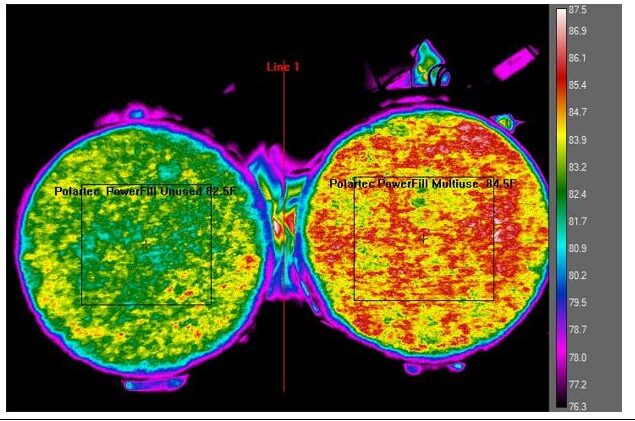

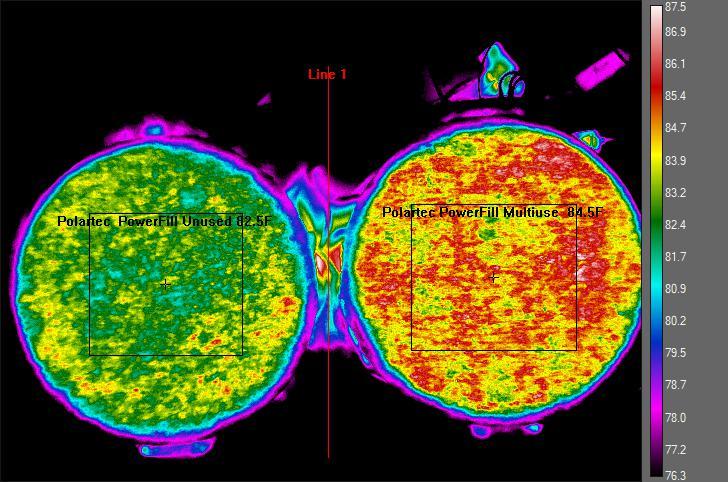

The thin fibers allow for the greatest entrapment of air (trapped air provides the insulation in any of these products) but have little strength to resist compression. The thicker fibers provide resistance to compression and allow the web to restore loft after compression. The short fiber insulations have little strength in any direction and can be easily pulled apart by movement, washing, or compression. As a result, quilting is essential for garments that use short-staple insulation. Short staple insulation suffers from loss of insulating ability from use. Depending on the insulation, loss of insulating ability can be rapid and significant. Figure 1 below shows an infrared image that compares surface temperatures of two samples of Polartec Power Fill short-staple insulation.

As re-testing on this insulation proceeded, I noticed that the surface temperature increased by 1 °F, showing reduced insulating ability. I took the sample and ran it in a dryer with no heat for an hour and tested it again. As shown in the sample on the right of Figure 1, the surface temperature increased to 2 °F above unused insulation (left sample). These thermal images demonstrate significant insulating degradation with very minimal use. Another short fiber insulation included in this study is 3M Thinsulate.

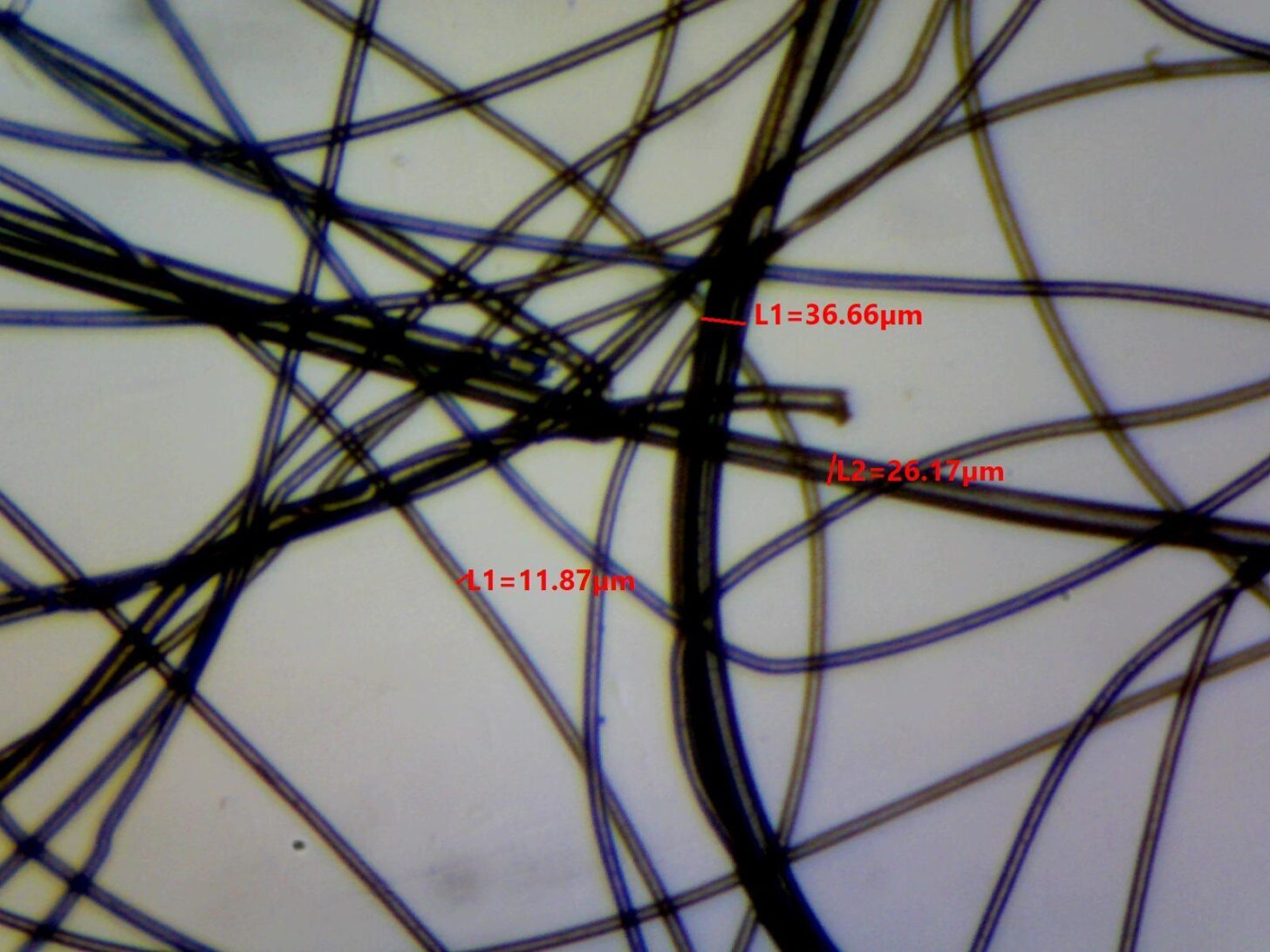

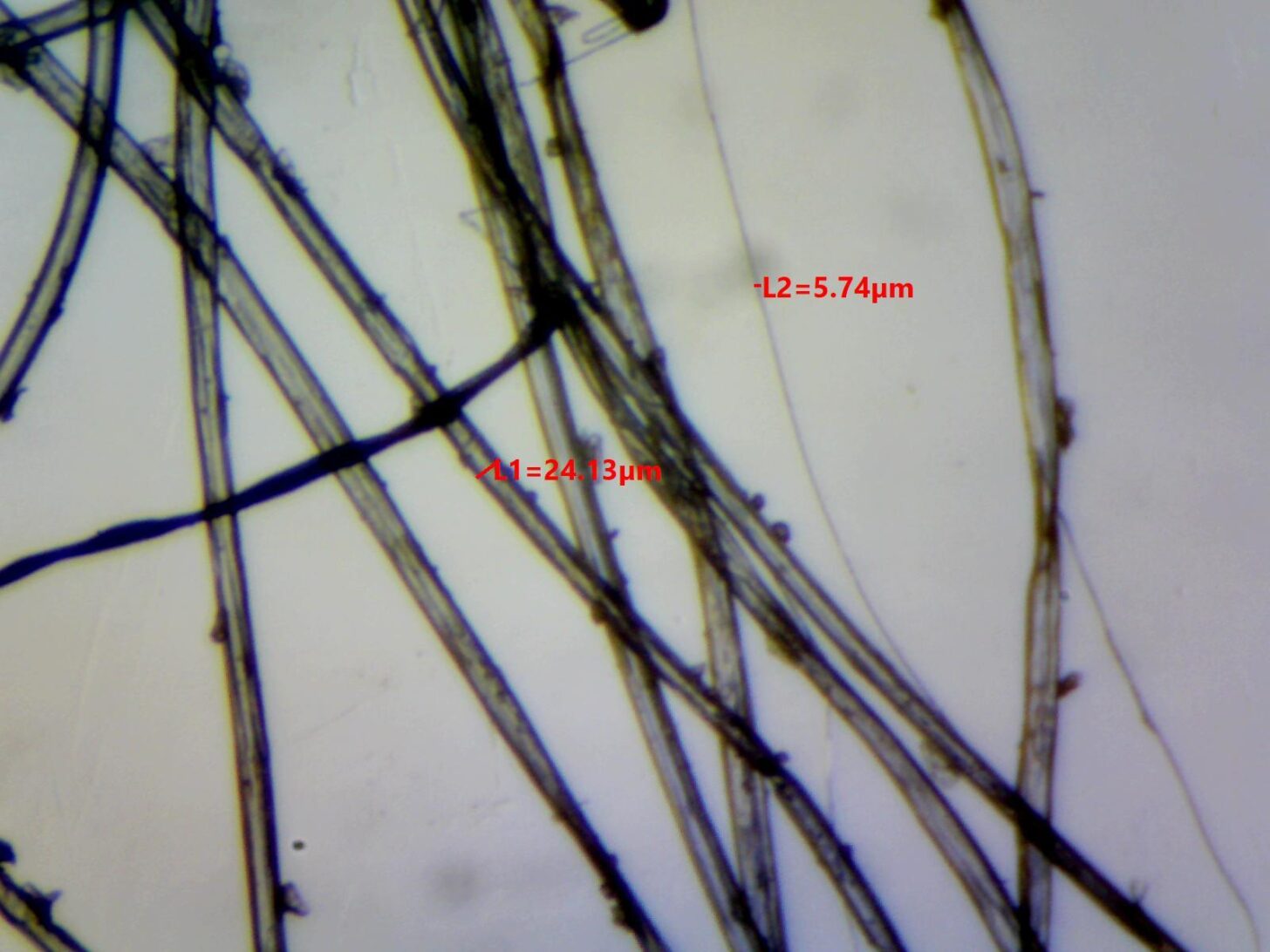

Continuous Filament Insulation is constructed from continuous fibers that run across the width of the web. As a result of the continuous fibers, the insulation web can have substantial strength. For example, Primaloft Gold, with short fiber running in all directions, can be easily ripped apart in any direction. By comparison, Climashield Apex, made with continuous filaments, has substantial strength across the roll. Strength in the direction of the roll (the direction in which the web is pulled through the production machinery) is substantially less, as evidenced by the manual force required to pull the fabric apart in both directions. Climashield, owned by Harvest Consumer Insulation appears to be the market leader in this type of insulation. The corporate predecessor of Climashield produced Polarguard, which is no longer marketed.

Climashield is produced with relatively large diameter fibers—approximately 22 microns. Thanks to the larger fibers and continuous filaments, this type of insulation reportedly has better long-term loft retention than short-staple insulations. (This is a subject we will follow up on in a forthcoming article.) Continuous filament insulation can be installed in garments or sleeping bags without quilting. In assembled garments or sleeping bags, this should provide an advantage in thermal efficiency over short-staple insulations. In theory, the warmth to weight ratio may be better in new short-staple insulation with small diameter fibers than with continuous filament insulation. However, this possible advantage for short-staple insulation may well disappear due to faster loft degradation than may be the case for continuous filament insulation.

At this point, the potential warmth to weight advantage of short-staple insulation is not supported by our tests. We find that for 6 osy (oz/yd2) insulation, Climashield Apex has a small warmth advantage over Primaloft Gold. However, for the 6 osy insulations, Apex is about 0.25 in (1 cm) thicker than Primaloft Gold. So, when using Apex, expect a similar initial insulating performance per ounce of insulation compared to Primaloft Gold but in a thicker garment or bag. Our Primaloft samples had softer hand, better pliability, and greater thickness uniformity than our Climashield Apex samples. For this article, we include three weights of Climashield Apex. We also include a German continuous filament insulation: Freudenberg KHT-60.

Knit Insulations

Two types of knit insulations will be considered in this study. Both are made by Polartec and made from polyester.

The first type includes Polartec Alpha and Alpha Direct. The second is Polartec Fleece. Fleece will be covered in detail in a follow-up article.

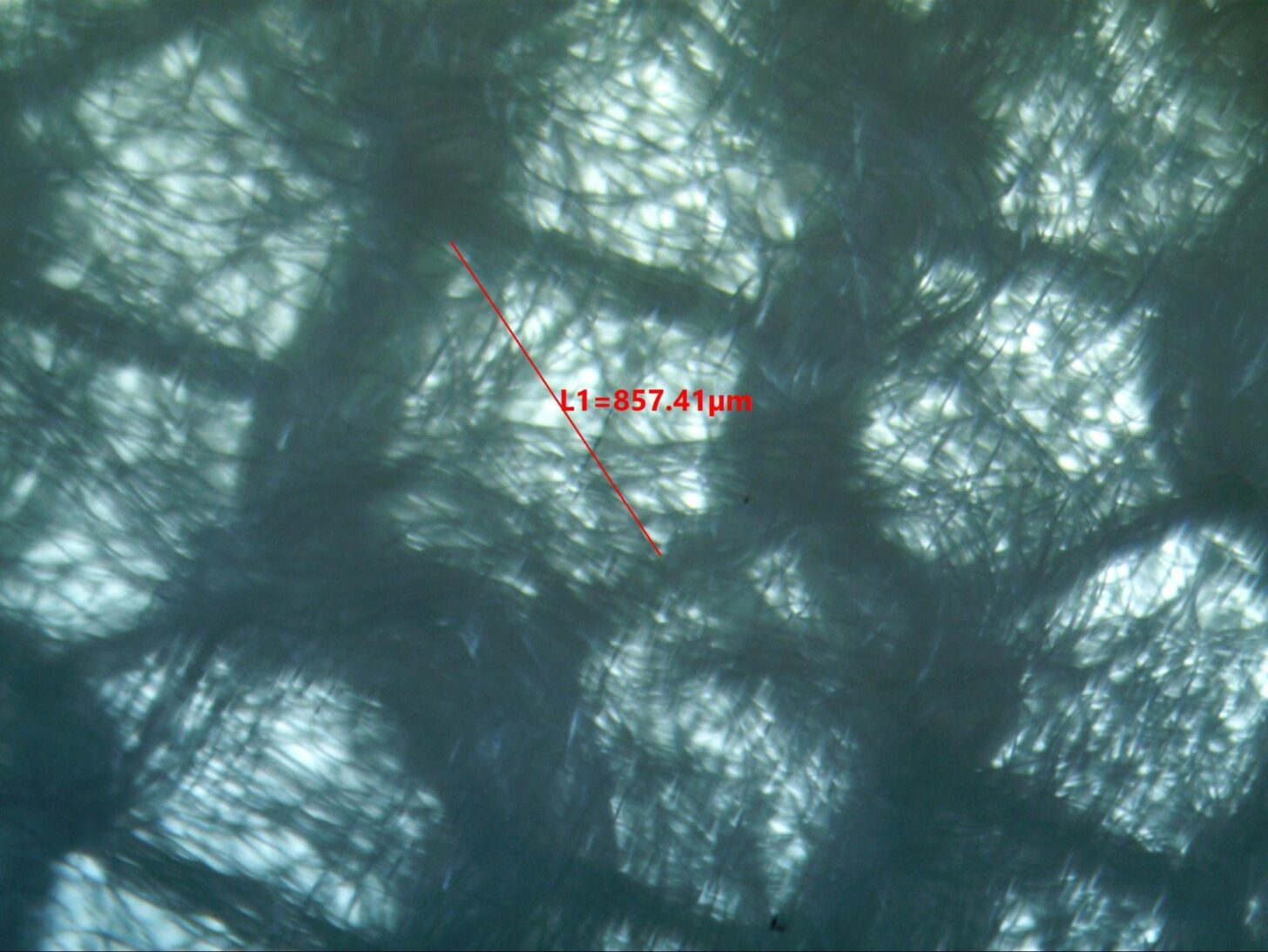

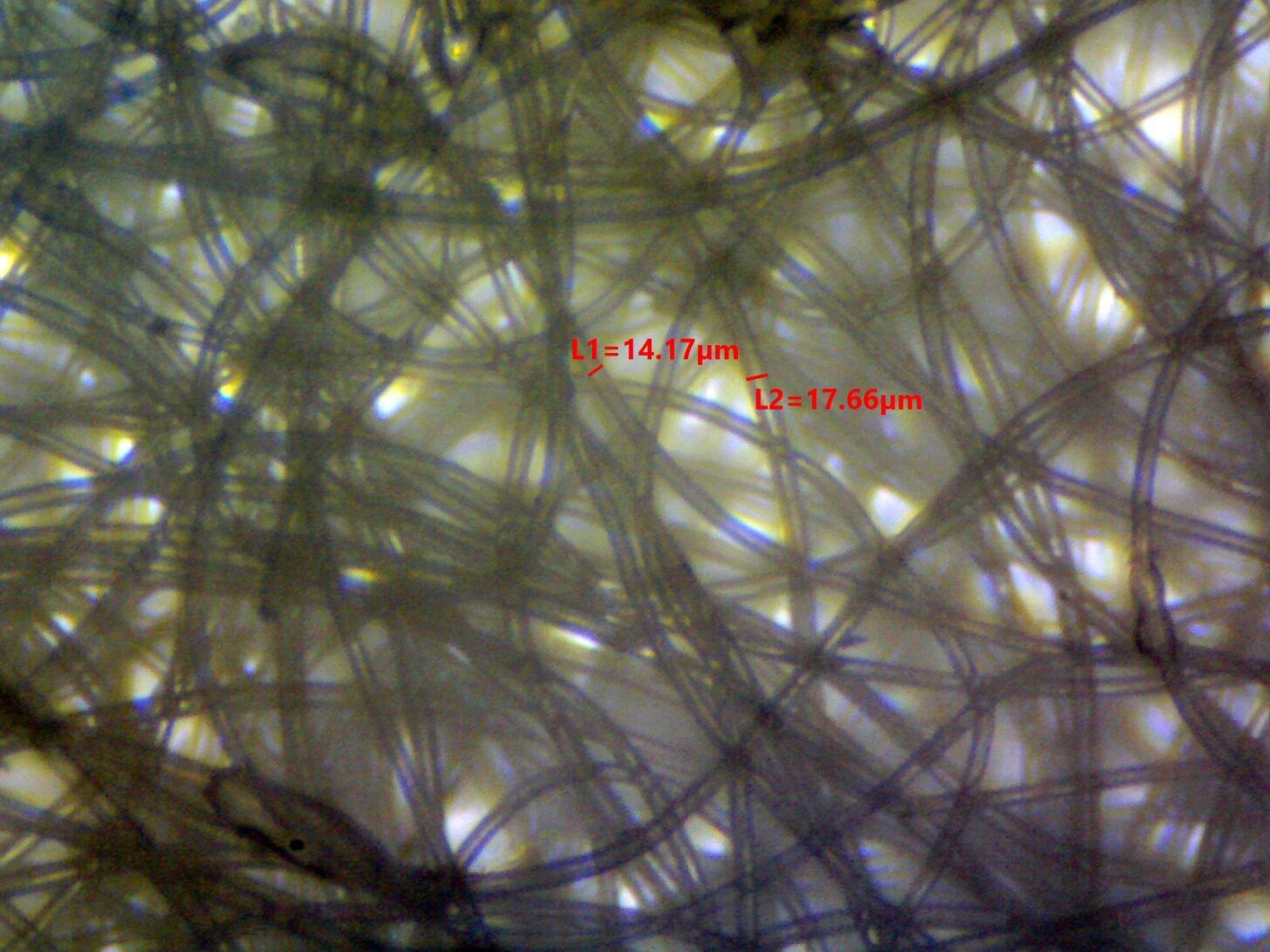

Construction is somewhat similar for both: A grid support structure is knit using polyester fibers. The fibers are then knapped to provide loft and sheared to produce a uniform surface.

Alpha offers several unique capabilities. The fabric is self-supporting so that quilting is not required for assembly in a garment. The Alpha knit matrix allows for substantial airflow to support the elimination of excess heat and promote rapid drying. Any face fabrics or liner fabrics used in Alpha garments can also support substantial air permeability because they do not require high-density fabrics to contain the insulation as in the case of down and some synthetics.

One feature not offered by this insulation is high warmth. The insulation is created for high exertion activities and so is not expected to provide high insulation values. It provides the lowest value of any insulation in this study except fleece. The Alpha insulation we tested is about 3 osy but has less than half the thermal resistance of other 3 osy non-woven insulations we tested.

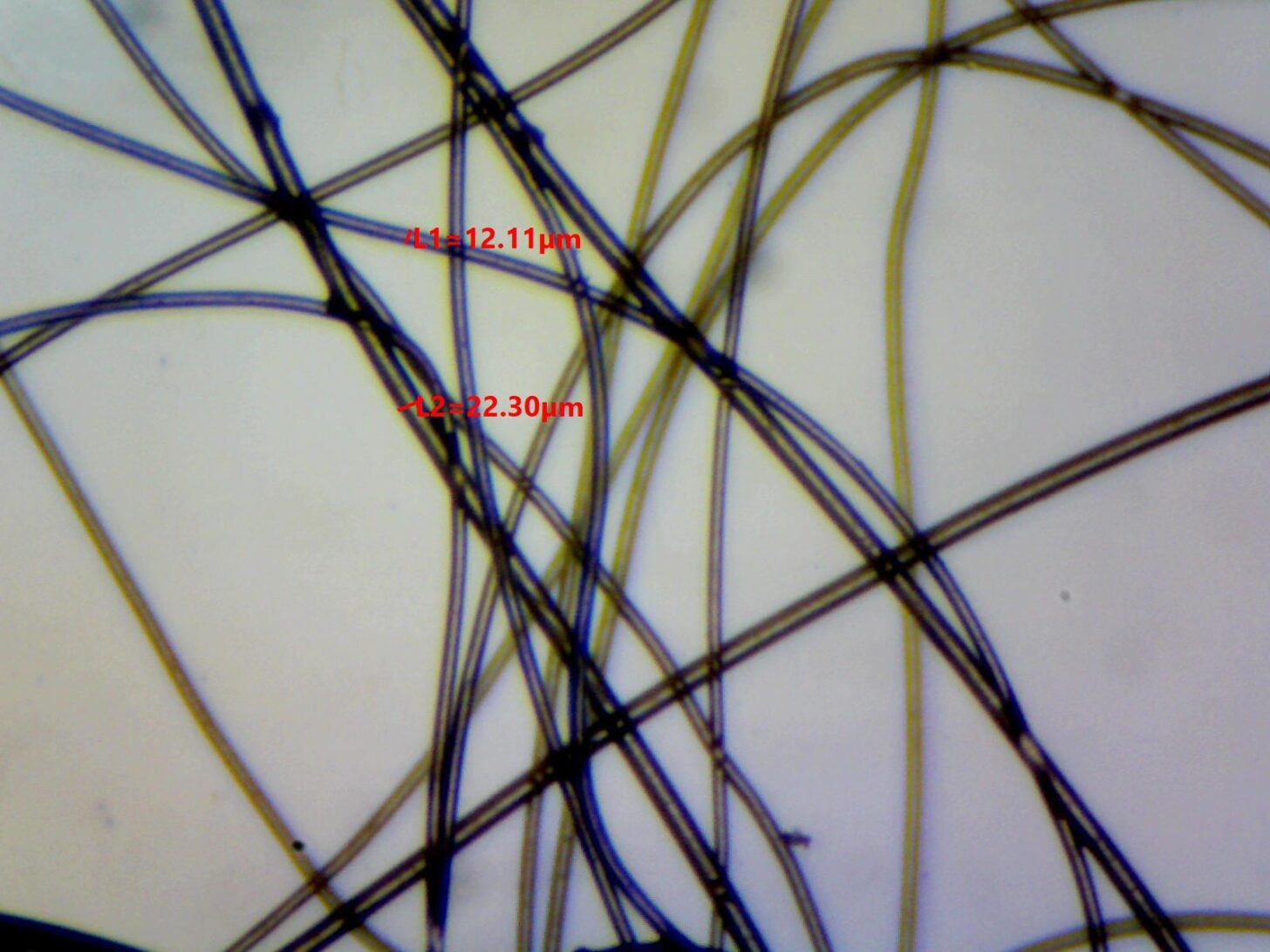

Synthetic Insulations Under the Microscope

Photomicrographs of various insulations are presented below. These were produced so I could determine the fiber diameters used in each type of insulation. The diameters used can help highlight expected warmth and expected resilience. The diameters of fibers are measured and displayed for each insulation.

What is a Clo?

Clo seems to be a source of confusion for many. So, what is a clo? It is a unit of thermal resistance applied to clothing. Thermal resistance refers to a material’s ability to prevent the transfer of heat from hot areas to cold areas.

In metric units, RSI refers to thermal resistance. In Imperial or English units, R refers to thermal resistance. As R gets bigger, less heat transfer will take place.

1 clo equals the thermal resistance of a clothing ensemble that will keep a person at thermal equilibrium in room with an air temperature of 70 °F. This is typically a lightweight business suit.

There is a simple mathematical conversion from any RSI or R-value to clo:

- Metric: 1 clo = 0.1548 K⋅m2/W or 1 clo = 0.1548 RSI

- Imperial: 1 clo = 0.879 °F⋅ft2⋅hr/BTU or 1 clo = 0.879 R

Simple (ish).

Now, it gets less simple. There are three main standards for measuring the thermal resistance of insulation or clothing using a guarded hot plate. None calculate clo directly. They calculate RSI. Then, the standards may or may not define how to convert RSI to clo.

The basic steps are the same for the three standards:

- Measure Rct (total thermal resistance of the fabric sample and air film) by placing the sample on the hot plate and measuring the power required to keep the hot plate temperature at 35 °C.

- Measure Rcpb (air film resistance of the hot plate by repeating the Rct measurement but with no sample on the hot plate).

Calculate Rcf (intrinsic resistance of the fabric sample alone) by subtracting Rcpb (air film thermal resistance) from Rct (total thermal resistance).

The nomenclature can vary a bit for each standard. The process is similar. The calculation of clo for each is not.

ASTM D1518-11a: Standard Test Method for Thermal Resistance of Batting Systems using a Hot Plate

Convert Rct (total thermal resistance) or Rcf (intrinsic resistance) to clo units:

- It = Rct × 6.458

- If = Rcf × 6.458

We have two different clo values – It and If. One (It) with the air film resistance and one (If) without. Below, we will discuss why this is important.

Now, if we continue in the standard, the standard specifies that you can state clo/unit weight/unit area (clo/oz/yd2) or clo/unit thickness (clo/in). The standard specifies that for these metrics, intrinsic insulation value must be used, which eliminates the air film resistance confusion.

Of the three hot plate standards, this is the only one that specifies using intrinsic insulation (no air film resistance) value when reporting clo/unit weight or clo/unit thickness.

ASTM F 1868-02 Standard Test Method of Thermal and Evaporative Resistance of Clothing Materials Using a Sweating Hot Plate

Convert Rct to clo units:

- It = Rct × 6.458

In this standard, the only guidance on calculating clo units includes the air film resistance. It does not include guidance on calculating clo/unit weight or clo/unit thickness.

ISO 11092 Textiles-Physiological effects-Measurement of thermal and water vapor resistance under steady-state conditions (sweating guarded-hot plate test)

There is no mention of clo units at all in this standard. Nor is there any mention of calculating thermal resistance/unit of weight or thermal resistance per unit of thickness.

This standard is often cited by manufacturers as being used to calculate listed clo values. Without further clarification, this is a misleading statement since the standard does not include the clo metric.

There is yet another way to calculate clothing thermal resistance and that is with a heated, sweating manikin. This method produces an intrinsic value by subtracting out the air film resistance but then adjusts the intrinsic value to reflect the portion of the manikin covered by the garment. So, this clo value will differ from those calculated under guarded hot plate standards.

We can see there are different treatments of clo calculation and different definitions of intrinsic clo or intrinsic insulation. No wonder people find this topic confusing!

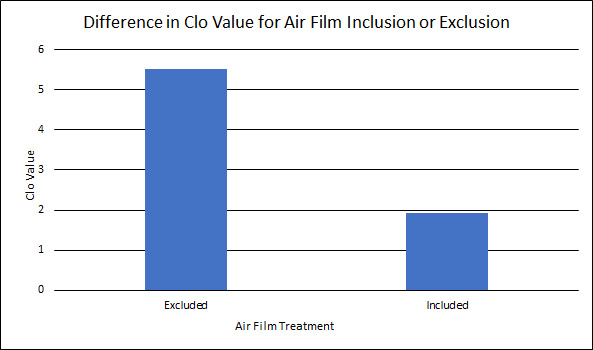

Why does this matter? The short answer is the potential for double-counting the air film resistance. Double counting will inflate the expected performance of the insulation for multiple ounces of insulation.

Primaloft Gold claims the clo/oz/yd2 is 0.92. We don’t know if this includes or excludes the air film. Figure 2, below shows the difference this makes in intrinsic value for 6 osy insulation:

In summary, if a clothing or insulation specification does not describe how the thermal performance test was converted from thermal resistance to clo, then we cannot readily assess its expected performance.

Development of a Guarded Hot Plate

As part of this project, a thorough review was undertaken of the methodology I have been using to measure thermal resistance in prior studies.

Modifications to the process included an improved calibration procedure for all thermocouples that are used. Additional thermocouples were installed to provide improved ambient temperature measurements. Modifications were made to the convection loss calculations. Partitions were added around the kettles to minimize the influence of convection currents on sample surface temperatures. These changes improved the repeatability and accuracy of the measurements.

One of the standard methods of measuring thermal resistance uses a guarded hot plate. I decided to build one of these so I could compare the results of the two measurement methods. In fact, I ended up building three versions of the guarded hot plate, obtaining improved results with each version.

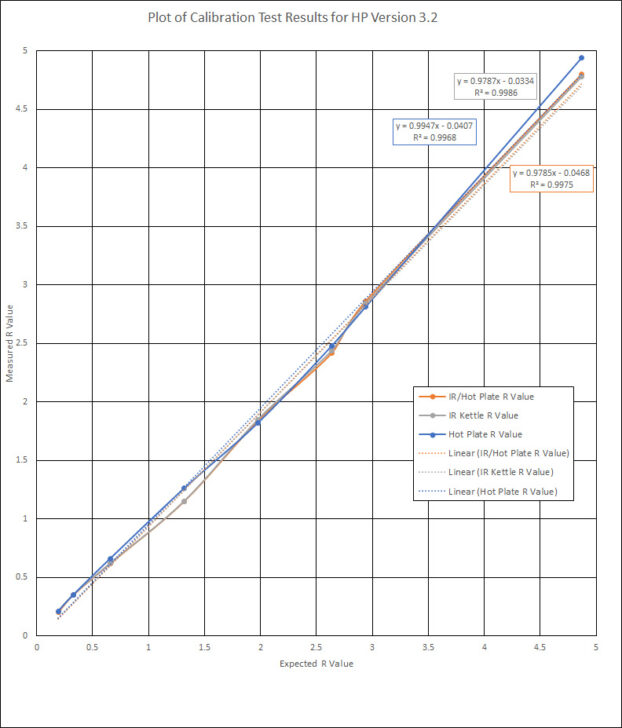

A detailed discussion of the hot plate and its operation may be found here. The hot plate discussion starts on page 14. Calibration data for the IR/Kettle method I have traditionally used and the new guarded hot plate is reproduced in the table below.

Calibration was accomplished using cork sheets and extruded polystyrene (XPS) sheets with published thermal performance data. Version 3 of the hot plate produced acceptable test results. Simultaneous measurements were made for the IR/kettle method and the hot plate method. The IR method was also used to calculate thermal resistance and watts used for the hot plate sample. For each calibration sample, thermal resistance was measured and then compared with the expected thermal resistance value. The data is shown in the table below.

Table 1: Calibration Data

| Sample | Expected R Value | Measured Hot Plate R Value | Measured IR/Hot Plate R Value | Measured IR Kettle R Value | Variance From Expected Hot Plate (%) | Variance From Expected IR Hot Plate | Variance From Expected IR Kettle | Hot Plate Watts Measured | IR Hot Plate Watts Calculated |

|---|---|---|---|---|---|---|---|---|---|

| .065 Cork | 0.195 | 0.21 | 0.2 | 0.21 | 7.70% | 2.60% | 7.70% | 15.25 | 15.4 |

| .11 Cork | 0.33 | 0.35 | 0.35 | 0.35 | 6.10% | 6.10% | 6.10% | 13.15 | 13.1 |

| .22 Cork | 0.66 | 0.66 | 0.62 | 0.62 | 0.00% | -6.10% | -6.10% | 8.95 | 9.8 |

| .44 Cork | 1.32 | 1.26 | 1.15 | 1.15 | -4.50% | -12.90% | -12.90% | 6.59 | 6.7 |

| .66 Cork | 1.98 | 1.82 | 1.84 | 1.85 | -8.10% | -7.10% | -6.60% | 5.38 | 4.8 |

| .88 Cork | 2.64 | 2.48 | 2.42 | 2.44 | -6.10% | -8.30% | -7.60% | 4.1 | 4.16 |

| .5 XPS | 2.94 | 2.81 | 2.86 | 2.84 | -4.40% | -2.70% | -3.40% | 3.45 | 3.5 |

| 1 XPS | 4.87 | 4.94 | 4.8 | 4.78 | 1.40% | -1.40% | -1.80% | 2.38 | 1.94 |

| Average | 4.80% | 5.90% | 6.50% |

The data show good agreement between the IR and hot plate methods and with the expected sample R values.

Figure 3 compares measured and expected R values for each test sample.

Perfect agreement between a test method and expected results will result in straight lines with a slope of 1.

The slopes of all lines are within 3% of perfect agreement, further verifying that good accuracy is achieved by both the measurement methods, with slightly better accuracy achieved by the hot plate method.

After completion of calibration, I began to test batt insulation samples using the IR/Kettle and Hot plate methods. Despite excellent agreement between methods in the calibration process, the hot plate tests revealed substantial disagreement with the IR/kettle tests. The hot plate thermal resistance measurements ranged from 52% to 83% higher than the IR tests. Thinsulate showed the best agreement with a discrepancy of only 11%. Thinsulate has a relatively robust scrim on each side, so the thermal imager is not actually seeing the insulation surface directly.

Further study of this issue revealed the cause for this discrepancy.

Member Exclusive

A Premium or Unlimited Membership* is required to view the rest of this article.

* A Basic Membership is required to view Member Q&A events

Home › Forums › By the Numbers: Thermal Performance Measurements of Synthetic Insulations