Topic

Which of these three materials for a SUL backpack?

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

Home › Forums › Gear Forums › Make Your Own Gear › Which of these three materials for a SUL backpack?

- This topic has 30 replies, 19 voices, and was last updated 6 years ago by

Anonymous.

-

AuthorPosts

-

Mar 31, 2018 at 11:02 am #3527927

Lester,

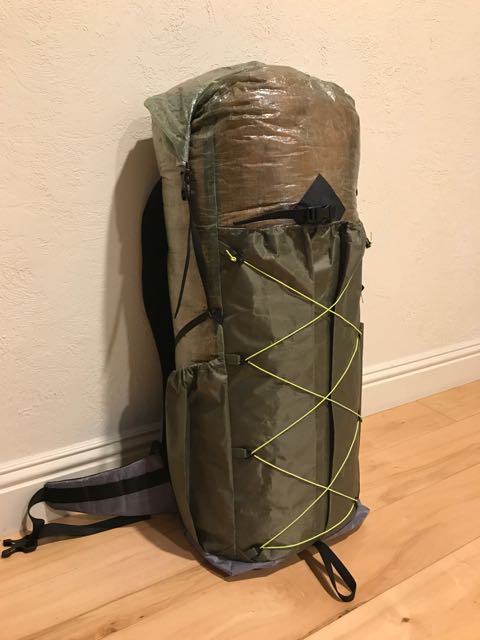

I’ve made four or five packs predominantly with 1.43 reinforced with 2.9. The lightest pack I made was about 8 ounces and that was with padding in the shoulder straps and a waist belt with padding. Most of my packs have been 30-35 liters with a dry bag closure and webbing to tighten down. If you made it 22 liters with 3d mesh shoulder straps without additional padding, and used a simple dry bag closure with two mesh, or even better, 2.9 DCF, you could get close to that number. I might even try. The 1.43 is fine in my opinion if you treat your gear well. I like the 2.9 for the side pockets because you can fold pleats into the fabric that stay and it makes it lighter and doesn’t snag on bushes. Just be sure to put a drain hole in like you did with your last pack.Mar 31, 2018 at 11:24 am #3527928Attached are some of the packs I’ve made with a combination of 1.4 and 2.9 DCF. The green and black pack is smaller and is made for day ski tours. With the ski straps on the side, it weighs about 10 ounces. I use grosgrain to attach the shoulder straps and haven’t had a problem so far. I would suggest not putting a front pocket on the pack to keep the weight down. I also use 3/8″ foam in the back of all of my packs and sew .7 inside to form a pocket. I really don’t like not having foam against my back.

Mar 31, 2018 at 2:02 pm #3527934

Mar 31, 2018 at 2:02 pm #3527934Nice looking packs, Andrew. But, at around 10oz they are not what the OP was looking for. 4-5oz is what he wanted. Just getting to that weight in any pack is difficult.

it starts with the lightest materials that are reasonably used. Thank the stars that the old spinnaker is gone. Anyway, at around 6x10x21 with a 10 inch extension collar, two pad keepers for adding a CCF pad as padding/dual use as sleeping, and a largish front pouch, you should come up with something like a Murmur without the bells and whistles.

At one ounce/yd:

ROBIC, for light weight containment is about the lightest, strongest, most puncture resistant fabric out there.

Poly is simply not strong enough at about 1/3 less than nylon ROBIC.

DCF at around the same weight is simply not puncture resistant enough, or, abrasion resistant enough.

It will take about 1.5 yards of fabric depending on your exact sizes. About a half yard of mesh at around 1.75oz/yd. (You could simply use regular fabric for this too, but I prefer some stretch.)

Cording/stiffeners/buckles and strapping can be 3/4″ poly, simply because the corse texture works better in buckles…about 1.5oz.

1/8″ ccf is light and fairly inexpensive…adds about a half ounce.

Buckles adds some but get the heaviest duty you can find. Broken buckles are painful. About 1/2oz.

Wrap a 3/4″ strap completely around the shoulder harness and down the back panel about 2″. This will add a lot of strength.

The pad keepers can be stretchy mesh, folded and sewn with three layers on the edges. Ribbon’s come loose. About a half ounce.

Total is around 5.5oz assuming a 40L pack capable of carrying about 25pounds relatively comfortably. Not quite SUL, but large enough for week to two week outings. If you elect to go smaller, say around 30L you can get this down to around 4.5oz in a relatively durable package. It will carry what you need for a few days at around 20lbs.

SUL packs are never as durable as UL packs. Adding a few more ounces WILL beef up the pack, say by adding some laminate/XPack to the bottom. But you will also add weight. A couple strips of sewn in 3/4″ straps along the bottom will help a LOT with durability. Pay attention to the seams. A good folded seam (four layer/double stitched) will hold up well. PLAN it out before starting to sew. Remove stresses on a seam and apply them to the panels, instead for greater durability. Pockets should be rolled in to the seams, and stitched/hemmed to the panel for example. Shoulder harness fabric should be long, folded and stitched/hemmed to the panel and into the seam for another. A difficult job of sewing, but a fairly durable at the end. You should get all the stress to distribute from a simple seam to an area of about 1/2″ of the panel being sewn adding 50-75% to the strength, overall. Basically, when the panel tears instead of fails at the seam, you did a good job.Mar 31, 2018 at 2:29 pm #3527935yeah, nice looking pack Andrew

Mar 31, 2018 at 5:36 pm #3527949Clean, simple and functional pack Andrew. It’s good to see designs like yours to counteract my feature creep engineering tendencies.

Good points James – after making a sub-4 oz pack that should hold up to a few seasons of use, my next SUL pack will likely have some beefier fabric for the bottom, back and side pockets, even if it adds a few ounces (maybe 6.X ounces total). It’s a subjective and personal choice, but 6.X seems like a good compromize for a SUL pack. For SUL, a workable definition might be “a small, simple pack with enough toughness to last a few years of gentle use on short trips on relatively groomed trails in good weather”. Definitely a niche within a niche.

Apr 9, 2018 at 4:22 pm #3529604Anonymous

InactiveI think composites/blends are probably the best bet to get lightest for most durability (unless you’re talking pure, woven Dyneema or Spectra fabric). If I had plenty of spending money and was interested in such a project (trying to save as much weight as possible for semi-reasonable durability), I would go with something like RSBR’s Mountain Silnylon for the outer, .34 ounce DCF for the middle, and .74 Robic or .66 nylon taffeta for the inner. Sew all fabrics together around the perimeter, then an X (or maybe also straight through the center of the X as well) and plug up the thread holes with silicone.

The outer provides some abrasion and puncture resistance and waterproofness, the middle provides tensile strength and reduces sag and further increases waterproofness, and the inner protects the middle from abrasion some. You’re looking at around 2.3 to 2.38 oz/yd2. Damage to one layer of the system shouldn’t affect the overall usability and function of the whole.

Personally though, I wouldn’t go that light for a pack fabric unless it was pure, woven Dyneema or Spectra fabric. I value durability over a small weight savings nowadays.

Probably would do one layer of Mountain Silnylon for outer, .7 DCF for middle and Mountain silnylon for inner, with a light coat of silicone between all layers and sewed perimeter and X together. But can’t afford such a project. You would have to gently and carefully rough up the mylar surface a bit on the DCF to get a good bond with the silcone though.

-

AuthorPosts

- You must be logged in to reply to this topic.

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

Our Community Posts are Moderated

Backpacking Light community posts are moderated and here to foster helpful and positive discussions about lightweight backpacking. Please be mindful of our values and boundaries and review our Community Guidelines prior to posting.

Get the Newsletter

Gear Research & Discovery Tools

- Browse our curated Gear Shop

- See the latest Gear Deals and Sales

- Our Recommendations

- Search for Gear on Sale with the Gear Finder

- Used Gear Swap

- Member Gear Reviews and BPL Gear Review Articles

- Browse by Gear Type or Brand.