Topic

Tarptent StratoSpire Li vs Zpacks Duplex

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

Home › Forums › Gear Forums › Gear (General) › Tarptent StratoSpire Li vs Zpacks Duplex

- This topic has 55 replies, 11 voices, and was last updated 2 years, 9 months ago by

Peter C.

Peter C.

-

AuthorPosts

-

Dec 4, 2018 at 7:17 pm #3567394

From what I can gather the Tarptent StratoSpire Li is about 5 ounces heavier when including stakes, $79 more expensive, but has a full double wall system and larger vestibules, and overall more wind/snow worthy. Anything I am missing in the comparison? I am having trouble finding information/reviews other than Ryan’s detailed review of the Notch Li (though thats just initial impressions – not long term usage). thanks in advance for your replies!

Dec 5, 2018 at 4:49 am #3567486That’s some tent! Seems well thought out, might be generation ahead of everybody else. the ‘box’ ends for extra volume are really well done. The vestibules are big.

The set-up video looks a bit busy. I’m sure you know how you’d do it the 10th time: Instead of walking around it twice, adjusting and adjusting… you do one side kind of tight, the whole thing’ll look lopsided, then you do the other side, make any adjustments there. Then only if you have to, shift the poles, and only go back around to the other side if there might be some flapping in the wind. (I’ve done set-ups where I think, ‘When I go pee, I’ll do it on that side and adjust it then.’ )

I don’t know enough to speak about the benefits of a double wall. My basic concept of a tent is: it’s a ventilated rain cover and wind break, with a bug screen. My Big Agnes is all screen on top under the rainfly, so that’s no double wall at all. Tents have to be well ventilated or they’ll just condense breath inside.

Dec 5, 2018 at 5:59 am #3567498A few more differences/points:

– SS Li has vents, Duplex has none

– SS Li has nice water resistant zips, Duplex has clips which many folks report being hard to use

– SS Li is more complex to set up.

– SS Li likely has better construction quality

– Neither is going to be great at shedding snow.

– The SS Li fly has more coverage so better at blocking windsPersonally I’d take the SS Li. I much prefer double wall tents for the additional condensation protection and modular capabilities.

Dec 5, 2018 at 6:31 am #3567501Double wall tents still get condensation on the outside wall/fly, but you are much less likely to make contact while inside, keeping you and your equipment dryer.

Other Stratospire vs Duplex features:

- J-door vs half-moon inner door. I prefer J-doors because the mesh doesn’t fall on the floor to get caught, tangled, or damaged; and I can flop in faster than most of the mosquitos.

- Struts vs no struts. In practice, not a big deal, unless you need to pack your tent into an unusual space.

- Stratospire option for “solid” (1/3 mesh) inner tent for better wind and snowdrift protection.

- New(ish) product from a company relatively new to DCF fabric vs many happy Duplex customers from a company that pioneered DCF/Cuben fabrics. Working with DCF is quite a bit different from traditional tent fabrics, but Henry generally does something really well or not at all.

— Rex

Dec 5, 2018 at 6:49 am #3567503I wouldn’t give ZPacks too much credit for pioneering DCF. The Duplex is a similar design to the DCF SMD Refuge X that preceded it, and Zpacks was just sewing DCF with regular sewing techniques for the longest time. Even now I think they still do that and just slap some tape over top (I could be wrong). Whereas TarpTent is actually bonding the seams and then sewing afterwards to make sure the bonding doesn’t slip.

Dec 5, 2018 at 7:03 am #3567505A few more Stratospire vs Duplex features:

- Trekking pole tip up vs handle up. Some people accidentally poke holes in tents while installing with the tip up. And with the tip down, your pole is solidly in the ground.

- Duplex optional pole set for free-standing setup

- Stratospire PitchLoc corners are a bit fiddly to set up correctly, beyond just adjusting line tension. On my TT Moment, I haven’t found the magic formula to get them just right on the first, second, or even third try.

Nice to have choices.

— Rex

Dec 5, 2018 at 8:24 am #3567508“Whereas TarpTent is actually bonding the seams and then sewing afterwards to make sure the bonding doesn’t slip.”

Hi Dan, where did this information come from? I haven’t come across this on the website. Presumably they then tape as well since the website says it is taped and doesn’t need seam sealing. If so, this would be bomber production – and very time consuming manufacturing.

For a tent like the Duplex, sewn and then taped is fine, IMO. It’s not a design for extreme conditions anyway, and the cases of failure that I’ve come across on the web haven’t involved the seams. With ,.51oz cuben, the seams are probably the strongest part, anyway.

Dec 5, 2018 at 10:09 pm #3567666” On my TT Moment, I haven’t found the magic formula to get them just right on the first, second, or even third try’

I’ll shoot a video in the next few days to show how it’s done.

It is rather simple to do, once you know.

Dec 6, 2018 at 3:35 am #3567731“Hi Dan, where did this information come from?”

The BPL review of the Notch Li says: “The Tarptent Notch Li applies a bonded-then-sewn approach to adjoining DCF seams”I agree that the sewn seams of the Duplex aren’t going to fail when the tent is used reasonably. They’re fine. My point was just that Zpacks construction methods don’t really provide a reason to choose their product over someone else’s. Their methods are good enough, but not anything special.

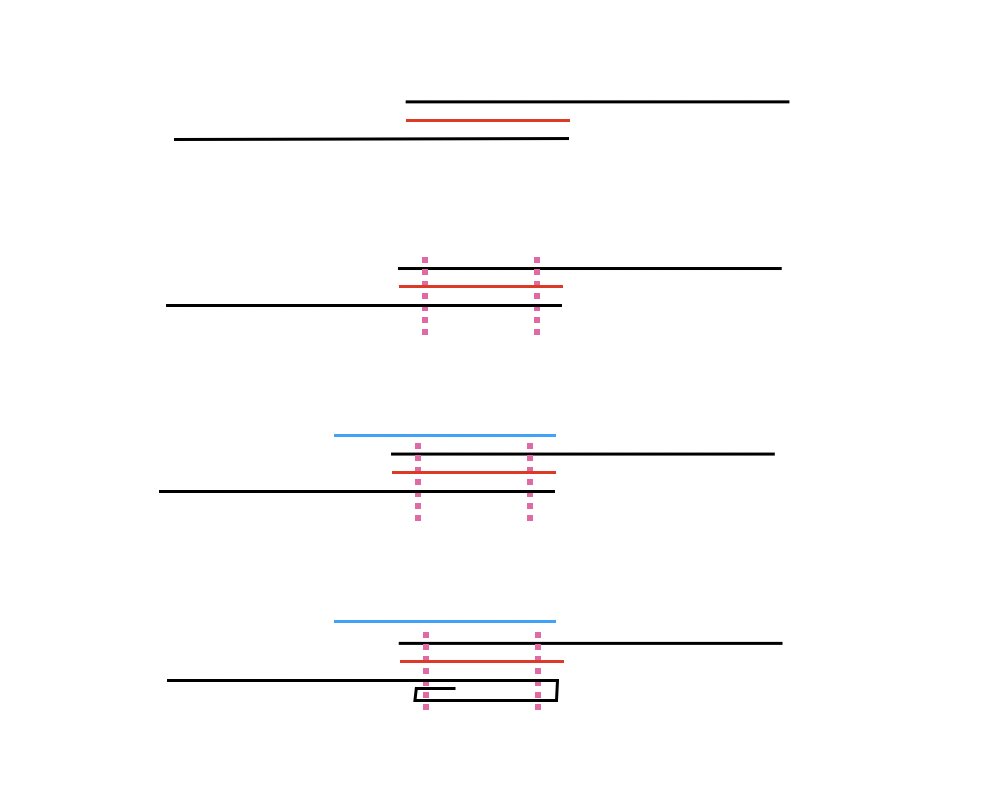

If you start by taping, then you’re probably using 1″ double sided tape in sheer (first diagram below. This gives a really strong seam because the force is distributed so widely. It’s much stronger than stitching but tape can slip/creep in really hot or cold conditions. So then you can add sewing to stop the slip (2nd diagram below) and you get a bomber seam but it leaks.

So then you add more tape on the outside like the 3rd diagram. Now it’s bomber and leakproof. But you also want to hide the raw edges of the DCF so they don’t fray, so then you’re left with something like the last diagram. I think this is close to what HMG is doing, who seam to have the nicest DCF seams, but I’m not certain.Whereas if you start by stitching, you get a mediocre seam strength because the stress is concentrated on the stitches and DCF has poor puncture resistance so the stitch holes grow. Adding tape on the outside seals the stitching and also improves the strength a lot if the tape overlaps the panels (like the blue line above) so it’s pretty good but not as strong as having the tape right in the seam (red tape) where there is more contact area with the bonding.

So perhaps it’s semantics since if something is good enough then why worry about it further, but still like things to be as good as they can be unless there is a cost to doing that. And there would be a weight cost to the full method in my diagrams since it’s effectively double taped which probably adds 1/2 – 1oz to the tent.

Dec 6, 2018 at 6:03 am #3567747Thanks for the reply, Dan. So what method will the DCF X-mid use ;)

Dec 6, 2018 at 8:04 am #3567754Still experimenting. Factory is going to be the same one that’s making the Big Agnes DCF tents because they have more experience with DCF. The first proto will hopefully be ready in a month or so and it’ll use a combo of methods – some seams how I want them (basically that last diagram) and other seams how they think is best. And then we’ll work from there.

Dec 6, 2018 at 4:23 pm #3567788As always, I prefer durability/ruggedness over extreme light weight. A normal flat seam, rolled together with glue, provides this. With DCF, you would simply use a narrower tape, like 1/4″-3/8″ wide in three layers in the seam itself with a wider 3/4″ to 1″ single sided tape over that, just to make sure there are no leaks.

Like this:

I don’t think the additional “top” layer is really required for waterproofness, because stitching through the glue will pretty much seal the actual sewn seams. Maybe you could use a regular flat seam (no glue) with tape over it? Don’t know…anyway, covering the seam holes may be overkill. But again, durability, reliability, ruggedness are my focal points. Of course, cleaning the needle with a alcohol or acetone rag will be required periodically.

The actual mechanics of glue creep and “Strength Of the Joint” (SOJ) seem to indicate a combination joint. Glue & Stitch is a fairly standard technique. Glue creeps in hot (softens slightly) or cold (gets brittle and cracks.) As it creeps, the first stitch picks up picks up pressure (depending on your viewpoint) transferring it to the second stitch. And, yes, it will also elongate the holes somewhat. This really happens simultaneously from both sides of each panel. Between the combination of glue and the two stitches, the SOJ will actually make up about 90-99% of the fabric strength. Generally, any shredding or tears will NOT happen at the join, but rather in the panel where scratches or other abrasion weakens it. The SOJ will hold up even under a LOT of abrasion, which is what you want. It may leak a bit through the over-tape from seam abrasion, but this is about a year of use down the road. The SOJ is mostly in shear so all the glue lines/stitches act in concert, reinforcing each other. The two lines of stitches through the glue will distribute any load away from the glue, and, pick up more fibers in the DCF than a single stitch. Standard stuff while sewing. Only the glue between them is different, preventing the join from unrolling.

The overall weight of the joins in a two person tent will be about two ounces heavier. But, the overall join durability is increased about 2 to 4 times. Maybe that is overkill, but it sure feels good to know you have a rugged tent in less than sunshine and calm conditions.

Is this clear? My writing is terrible sometimes…

Dec 6, 2018 at 11:24 pm #3567857James,

I think there is an issue with that seam design, which is that a lot of the tape is designed in peel.

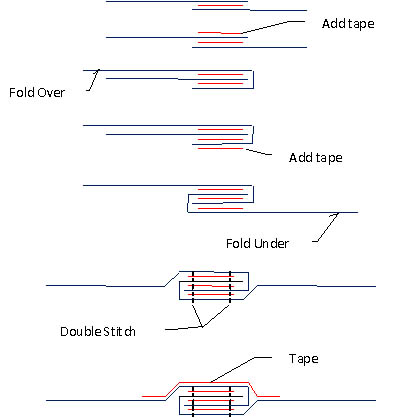

In the diagram below I’ve drawn your seam, but omitted the stitching and top piece of tape to just focus on the tape in the rolled seam itself (I’ll discuss those other parts after). What happens is that as you pull on the seam it twists (and this would be particularly pronounced here because the seam is to thick) so it would start to peel the outer layers of tape (middle diagram) and if that was all there was to the seam, these would peel apart until you are left with only the middle bit of tape that is in “sheer” so it won’t peel:

So in the diagram above the outer tape will peel apart until you are left with the stronger bit of tape in the center. That would hold, but ugly to have a seam do this.But you’ve got stitching and that top piece of tape. That top piece of tape is going to prevent the peeling on one side (the bottom as you’ve drawn it) because it takes the load, but then the bottom tape isn’t really doing anything. The only thing it could do would be subject to peel forces, so but it’s an inefficient use of tape. But more importantly, the top (or left) side will still start to peel. This will peel back to the stitching, and then all the force will be on that line of stitching and it becomes the weak point of the seam. If that single line of stitching fails then the seam peels to unravel back to the middle piece of tape. So ultimately the seam is very strong because of the tape in sheer in the middle, but this load isn’t transferred to here until several other components have failed. So it’s a lot more complex and heavier that what I’ve drawn, but I don’t think it would function as well.

Dec 7, 2018 at 2:45 am #3567886Yeah, you are likely correct. In a quick test I was getting something greater than a 2x SOJ vs a unstitched glued joint, but, I was just testing to destruction. Just a thought…

Dec 7, 2018 at 6:49 am #3567901Rex,

I have started a thread with a short video clip to show how I set up those Pitchloc corners.

let me know if that does not do it for you.

Dec 7, 2018 at 7:27 am #3567902James: What’s SOJ? Strength of joint?

Dec 7, 2018 at 11:49 am #3567915Dan, yes. But this was being tested to destruction. I think it would have leaked long before it actually pulled apart…again, you might be right: that the flat joint actually doesn’t leak under greater pressure than a rolled joint. The stitched rolled joint simply supported more weight in total.

Dec 7, 2018 at 2:21 pm #3567920The most immaculately constructed DCF shelter I have ever seen was an MLD Grace Duo Tarp and it didn’t have a single stitch in it’s construction. I studied the ridge line seam in particular, and never could quite be certain how it was put together. From what I have read, it is generally considered as bomber as any DCF shelter out there, and MLD has claimed to have not received any reports of failure in the field.

Any one know what seam construction MLD uses, or is it a proprietary secret?

Dec 8, 2018 at 1:05 am #3568022I’m not sure what MLD uses but obviously it would be some type of tape (rather than a liquid adhesive). I think MLD normally does sew too (my DCF DuoMid had stitching). Locus Gear’s bonding is highly regarded.

I’m hesitant of a bonded only approach because I’ve seen bonded DCF seams creeping over time. Even if it doesn’t there was a good thread here on BPL where folks (Lawson Kline mostly) showed that the available adhesives are problematic in temperature extremes. Ahh here it is. Tape loses a lot of performance such that sudden failure can happen in cold temps. Perhaps tape only is fine as a fairweather shelter. Or perhaps there are better adhesives that the UL community isn’t familiar with. Lawson’s done a lot of testing and he’s pretty convinced you have to sew and bond.

Dec 8, 2018 at 6:36 am #3568042Outdoor Gear Lab compares the SS Li and Duplex (and several others), and found some interesting differences. Be sure to read through the Overview text.

https://www.outdoorgearlab.com/topics/camping-and-hiking/best-ultralight-tent

Individual reviews:

https://www.outdoorgearlab.com/reviews/camping-and-hiking/ultralight-tent/zpacks-duplex-flex-upgrade

https://www.outdoorgearlab.com/reviews/camping-and-hiking/ultralight-tent/tarptent-stratospire-li

We are very impressed with the performance of the Stratospire in crummy weather, its ease of setup, and spacious design. Only the Zpacks Duplex scores higher due to its lightweight, but the StratoSpire holds up better in poor weather.

— Rex

Dec 9, 2018 at 6:54 pm #3568181“The most immaculately constructed DCF shelter I have ever seen was an MLD Grace Duo Tarp and it didn’t have a single stitch in it’s construction. I studied the ridge line seam in particular, and never could quite be certain how it was put together. From what I have read, it is generally considered as bomber as any DCF shelter out there, and MLD has claimed to have not received any reports of failure in the field.

Any one know what seam construction MLD uses, or is it a proprietary secret?”

I just received a .51 DCF Grace Duo from MLD a few weeks ago. Mine does have a stitched hemmed edge finishing the perimeter of the tarp.

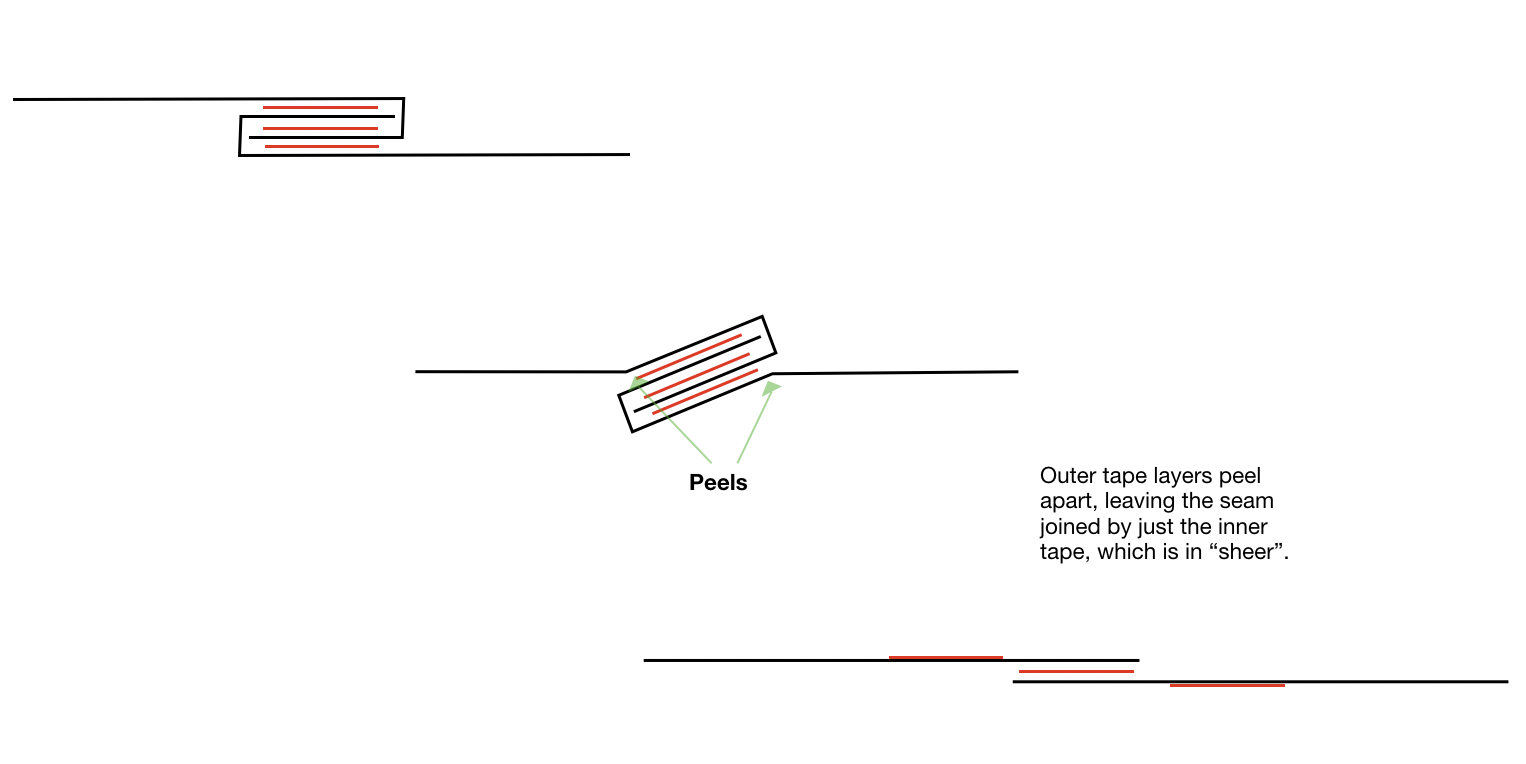

The ridgeline is bonded with a simple overlapped seam without any stitching. I have looked closely and cannot discern whether they use tape or a liquid adhesive. The seam looks like this (image stolen from Dan):

The reinforcements at guyout points are bonded without any stitching.

Dec 10, 2018 at 5:17 am #3568267Hi Matthew,

So how do the edges of the DCF not fray if it’s just a simply overlap like that? Are they tucked under somehow?

It’s pretty common to stitch the bottom hem and I think this is a good idea because it is measurably lighter and you don’t need a bonded seam here.

Dec 10, 2018 at 7:52 am #3568284I seem to remember an ancient thread that came to the conclusion that the simple bonding solution shown above in matthew k’s post was as strong as anything else so why make things more complicated and heavier. The dcf doesn’t fray (very much) because of the laminate, similar to the sil coating limiting the fray on sil-nylon. Both do fray a little after a lot of use but a damn sight less than uncoated fabrics.

Agree about stitching the hem.

Dec 10, 2018 at 11:56 am #3568290Dan, the honest answer is I don’t know about fraying. Isn’t this how ZPacks finishes the seams on their tents? The seam looks more or less like what I remember on my Duplex, just two pieces glued/taped together.

Dec 12, 2018 at 5:49 am #3568598I think Zpacks does a normal rolled (flat felled) seam and then slaps tape on the outside, but it’s been a while since I really looked at one.

-

AuthorPosts

- You must be logged in to reply to this topic.

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

LAST CALL (Sale Ends Feb 24) - Hyperlite Mountain Gear's Biggest Sale of the Year.

All DCF shelters, packs, premium quilts, and accessories are on sale.

Our Community Posts are Moderated

Backpacking Light community posts are moderated and here to foster helpful and positive discussions about lightweight backpacking. Please be mindful of our values and boundaries and review our Community Guidelines prior to posting.

Get the Newsletter

Gear Research & Discovery Tools

- Browse our curated Gear Shop

- See the latest Gear Deals and Sales

- Our Recommendations

- Search for Gear on Sale with the Gear Finder

- Used Gear Swap

- Member Gear Reviews and BPL Gear Review Articles

- Browse by Gear Type or Brand.