Topic

Storm-proofing the Side Panel on a lightweight A Frame Design

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

Home › Forums › Gear Forums › Make Your Own Gear › Storm-proofing the Side Panel on a lightweight A Frame Design

- This topic has 129 replies, 1 voice, and was last updated 1 month, 2 weeks ago by

Ross Mellows.

Ross Mellows.

-

AuthorPosts

-

Oct 14, 2016 at 5:54 pm #3431210

More thoughts:

- Poles. Trekking poles aren’t designed for side load / bending. This is what sleeves apply. They’ll withstand a greater compressive load if they’re not also subject to a side load. Pending how stiff the poles used are, you may actually have to put a curve in the sleeve and intentionally flex the pole to apply tension to the middle of the attached panels.

- Curves. I’m curious to see how deep you make the ridge curve. The Beta Lite and Tuolomne use a deep curve to apply more tension to the side panels. They both have fairly tall poles to accommodate this. This is acceptable because the added sail area is very well supported – at the tip of the pole – and relatively low drag – a pointy protrusion.

- Foot print. The Beta Lite is nearly twice as wide in the middle as at the ends. I don’t think this is just to increase floor space. Making the big side convex reduces wind loading and I think placing adjacent panels at an angle to each other (as opposed to making them co-planar) reduces flapping. The Trail Star also exhibits this trait.

- Side anchors. Do you want to be able to do a fair weather pitch with out side anchors (and not end up with completely slack side walls) or are you ok requiring side anchors? If it’s the latter, you can take the above convex notion a step further. This photo makes it clear just how far the sides of the Tuolomne redux protrude:

Also notice how high up the pull flap is.

Here’s my suggestion:

Not proportional, but conveys the idea (didn’t bother drawing vestibules/etc). A pyramidal side is convex and more aero, produces smaller panels, more seams to support the load, more interior space, and more angles between adjacent panels.

Inspired by:

http://mountainsmith.com/products/all-tents/mountain-shelter-lt.html

Also, take a look at the orange Douglas Adams design towards the bottom of the OP here:

https://backpackinglight.com/forums/topic/29220/

Oct 14, 2016 at 6:14 pm #3431212Interesting, but some of those designs were not tested very well. The Missing Link was a nostalgic throwback to the 50s but with no redeeming features in anything other than very still weather. The Douglas Adams design is not something you would want to use if there was any chance of a snow fall, and it might well leak a bit in heavy rain.

Rene’s pyramidal side looks a lot more interesting imho. Could you put a very light carbon fibre pole under the guy line?

Cheers

Oct 14, 2016 at 6:51 pm #3431218Regarding side guys and skirts – there is a balancing act between height of guy attachment point and length of guyline. For a given sidewall angle and guyline attachment point, there is a minimum distance out away from the tent at which you must place the stake in order to have tension on the fabric both above and below the attachment point. If you put the attachment point higher, you have to put the stake further away from the tent to get the proper angle on the guyline to achieve that balanced tension. This is the root of the comment about fabric flapping below a guyline attached too high – it’s not so much that the attachment point is too high, but the guyline is not at the required angle. The problem comes when you have limited area in which to place your stakes, or a downslope away from the tent on that side, and thus can’t get the angle you need. This leads also to Roger’s comment on the strut below the guyline attachment point; that can alleviate the issue since with the strut in place you can now have compression below the attachment point instead of tension, which changes the angle you can have on the guyline (among other things). Personally I’ve long felt, ever since making a-frame tents back in the 70’s, that relying on side guylines for added interior volume is asking for a poor pitch most of the time. The simpler geometry is easier to get tight. Having the side guys there simply as extra beef to relieve some of the wind load on the panel works better. If you look at tents with side guys (other than those attached to poles or pole sleeves), how often do you see a really taut pitch with no wrinkles while the side guys are in use?

Oct 15, 2016 at 8:29 am #3431267Hi guys – more useful input. Seems like a thread that refuses to die!

Guys and stakes

I guess the key is to eliminate the need for guys and stakes as much as possible, but not to skimp where they’re needed. As Roger says, a bit of dyneema and ti doesn’t weigh much, and light becomes stupid-light if your tent shreds around you…

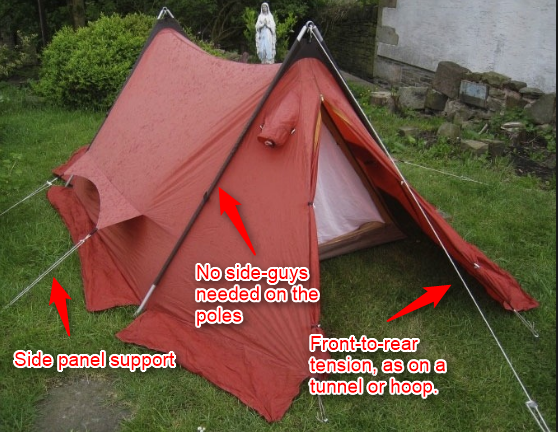

In bendy pole designs, you need guys to support the poles. With an A-frame the priorities are different – the poles are rigid and braced, so the main issue is to tension the ridge and stabalise the side-panels.

As Paul says, guys can’t always be placed ideally, so a key design goal must be to transmit as much of the force as possible directly to the stakes holding down the fly.

I know I keep banging on about my TrailStar, but it really is striking how it shrugs off 80mph winds without any side-guys at all. The only guy holds up the door, and in a major hoolie you eliminate that and peg it down all round like a limpet. This is a huge expanse of fabric supported only at the apex and the edges, but it doesn’t flap or fail. Some owners hurricane-chase to test out their TrailStars, but no-one has found the limit. And that’s what cat-cut triangular panels can do for you.

For the ridge tension, a generous, well-pegged porch front and back can transmit much of the load directly to the ground, so the fore and aft guys become a bad-weather supplement. And the panels are naturally pretty much triangular and aero.

With the side panels, I do think a triangulated design reduces the need for side guys, to the point that the MSR Twin Sisters doesn’t have them at all and still seems to perform quite well in the wind. Guyed out like the Locus in nasty weather, I think this geometry would do well, based on the evidence of the TrailStar, the Twin Sisters, the Shangri-La and the Beta-Lite. Though as Rene says, I’d probably have to make the floor wider in the center to get the full benefit. Locus call their design a double pyramid rather than a ridge tent, which is probably the right way to think about it.

Rene – many thanks for the idea of the pyramidal side – this is new to me. As you say, it does produce smaller and more supported panels. The downside, as you also say, is that it relies much more on a side guy compared with the Beta-Lite approach. As Roger says, a light carbon pole from the top to bottom of the side guy might make this even stronger, especially in a sleeve. Sewing that 5-seam join looks a bit of a headache – a patch of Dyneema, I guess, would be the way to go. Looking at videos of the MountainSmith I’m not so convinced it would be as easy to tension the seams compared to the Beta-Lite. Goodness knows which approach would perform better – I’m thinking I might knock up a couple of scale prototypes in a 10D fabric and get them out in a Dartmoor storm.

A simple slab-sided wall relies much more on the guys for stability – it would be flappy without them. Perhaps one reason the classic designs kept them low is that the guys don’t have to be so long for them to work efficiently, and footprint is reduced. It’s the simple approach, but one of the triangulated approaches would make for a more interesting project…

The Douglas Adams

That looks like a “homage” to the Ultimate Hobo. This was a wildly popular 3-season tent that proved it’s weather-worthiness all over the UK and the Alps. There’s still a lively market for useable survivals on UK forums. Why Roger would think it can’t handle rain or unseasonal snow escapes me. Vango are a Scottish company – do you think they’d have lasted 50 years if they sold tents that leak??

For me, the interesting design feature is the severe slope on the ridge to reduce the size of the side panels without compromising headroom at the door end. The way they handled the poles and porch is pretty much as good as it gets IMHO and is what I’m planning to go with. I just want a stronger treatment for the sides.

Oct 15, 2016 at 2:16 pm #3431320

Oct 15, 2016 at 2:16 pm #3431320Hi Geoff

In bendy pole designs, you need guys to support the poles. With an A-frame the priorities are different – the poles are rigid and braced,

‘Bendy poles’ is not quite how I would described the carbon fibre poles in one of my tunnels. Straight poles are not ‘pre-tensioned’, but curved poles in a tunnel certainly are. On my tunnels the straight CF tubing is bent to a radius of ~1800 mm: that makes them far more rigid. They resist a lot of side-wind when they have no guys at all. Been there, tested that.

The other half of the equation is that the carbon fibre poles are 7.5 mm OD: they weigh MUCH less than the big stiff straight Al poles or a pair of trekking poles. More complexity, yes, but more performance.Why Roger would think it can’t handle rain or unseasonal snow escapes me.

It has a flat top that will collect rain and snow under still conditions. I have some photos from other people showing flattened tents (not mine) due to that.

Ah, but does Scotland ever have rain or snow under still conditions? Not very often is my memory! So it all depends …Cheers

Oct 15, 2016 at 5:07 pm #3431363Done a bit of Googling on the Mountainsmith. Reviewers praise its performance in the wind, but the way they have implemented the side-guy so high, it seems to create a flat area on the ridge and a couple of users say it accumulates snow. Personally I’d have thought this idea might work better with the guy-out a bit lower. It never seems to pitch as taut as a Trailstar which suggests that there’s something sub-optimal with the cut.

Oct 15, 2016 at 6:06 pm #3431369

Oct 15, 2016 at 6:06 pm #3431369Here’s a different angle of the Mountainsmith Mountain Shelter LT. Looks like it would collect a lot of snow in some conditions. Nice little stove, though.

Oct 16, 2016 at 5:37 am #3431393

Oct 16, 2016 at 5:37 am #3431393Roger

‘Bendy poles’ is not quite how I would described the carbon fibre poles in one of my tunnels.

As we discussed above, I’m a great admirer of your design and the way it adds strength to lightweight poles. But sadly for the rest of us, it seems that it’s too complex to manufacture commercially, so I was talking about every other bendy pole design on the planet :-)

A-frames, tunnels and hoops all share a need for fore and aft guys, but the side guying is different. In tunnels and hoops (even on your tunnels), the side guys are primarily aimed at supporting the poles. While on an A-frame there is no need for the side guys to support the poles – they are plenty strong enough – so the side guys are aimed at supporting the fabric panel. That’s all I was trying to say, and I can’t see that it’s contentious?

Oct 16, 2016 at 5:42 am #3431394

Oct 16, 2016 at 5:42 am #3431394An interesting take on side-guying from a Black Diamond Bibler.

Oct 16, 2016 at 2:48 pm #3431448

Oct 16, 2016 at 2:48 pm #3431448Hi Geoff

A similar design to mine, the Olympus, is manufactured by Macpac in New Zealand, and yes, it is expensive. But it sells very well and is revered by alpine walkers. I lived in one for a few years too.

Several Hilleberg models are similar, and they are widely respected in Europe, even though they too are expensive. And there are other brands of tunnels on the market too.

The Product Manager for tents at Easton was going to manufacture my tents, but he was sabotaged by the Sales Dept who were only interested in selling to Walmart. Internal political battles, and he lost.

So I don’t think either tunnels in general, or my designs in particular, are too expensive to make. To be sure, they are NOT in the Walmart class. But they do require a bit of a commitment up front by the mfr.As for the side guys – they are NOT essential. A tunnel will stay up without them. If you read our article When Things Go WRong, you will see that I noticed that my tent was wobbling slightly early in the morning in a howling storm (winds to 100 kph), due to a loss of all the guy ropes (abrasion on the stakes). Wobbling slightly, not being flattened. Yes, I do include side guys on the design and I use them in the field – so I am paranoid … and the guys weigh next to nothing. But having installed all the guys, I then sleep very well.

I must measure the forces on the guys one day, or measure the deflection of the poles. It would be nice to have some numbers.

Cheers

Oct 16, 2016 at 3:02 pm #3431451Roger – I remember reading that article – Heck of a trip! Do you have threads detailing your current tent designs? I know you’re a man of constant thought & improvement, and I’d like to see how those impressive tents stand today.

Oct 16, 2016 at 3:21 pm #3431454Geoff,

the two lower guyout points in that Bibler Fitzroy have corresponding pole loops on the inside.Oct 16, 2016 at 3:22 pm #3431455Hi HiLight

Sorry, but I have not published the details (yet). I do have patterns. The red one is still my current winter tent. The blue summer tent is still in use, although it is looking a bit ‘worn’ by now. There could be some minor tweaks to the design, but not many.

Part of the design process was developing a generalised mathematical model for tunnel tents. Yeah, seriously. That let me build a spreadsheet for the patterns, so I could play around with small tweaks on the screen, with the visual model adjusting as I went. Infinite fun for the gear freak.

The thing is, both of those designs have several antecedents which were built and tested in the field. The blue tent must be V10 I think (with at least 5 versions built), and the red tent is V7 (with 3 versions built), but the winter version was building also on the blue tents and the Macpac Olympus. I started tent design about 2000 I think.

Cheers

Oct 16, 2016 at 3:37 pm #3431457Roger – Your designs are pushing the limits of the materials, so being able to fine tune before cutting fabric and revisiting exact parameters while reviewing improvements makes perfect sense. I look forward to more articles on the Caffin Cabins. Maybe they’ll be posted by the time I’m ready to tackle my own MYOG tent from the thread up.

Oct 16, 2016 at 3:44 pm #3431459Hi HiLight

Pushing the limits of design maybe, but not pushing the limits of the materials themselves. I have tried to keep the materials well within their limits, so they can handle extremes. Probably a semantic quibble, but I thought I should mention it.Cheers

Oct 16, 2016 at 3:58 pm #3431464Sure. I was thinking more about how designs & materials have changed, and how important it is to incorporate those advances into modern designs. An elegantly designed tent of 30 years ago would be heavy by today’s standards because the available materials are stronger & lighter. I’ve always been interested in how designs have been refined as materials, manufacturing, and the market have allowed.

Jun 14, 2017 at 5:51 pm #3473365Hi folks

Well – life got in the way and I’ve only just managed to revive the project.

Just as a reminder, I’m designing a tapered solo A-Frame with trekking-pole support that I’m trying to bring in for under 800 grams. I camp in exposed spots and run the risk of unseasonal snow, so the US A-Frame offerings from the likes of TarpTent and Yama don’t really give the the storm-worthiness I’m looking for. The closest to my needs is the TrekkerTent Stealth 1, which is well liked by users and built for European conditions:

But I feel the vestibules could be improved to provide better shelter and through-draft, and the side-panels could be strengthened without adding significant weight.

Now, I’ve recently heard that TrekkerTent have had the 40 gsm version of the Stealth 1 in 60 mph winds and say it behaves pretty well, so I don’t need to do anything too radical. But I will be supporting the front seam of the side panels with A-Poles (the Stealth uses a single central pole), and need to finalise my approach to supporting the side panel itself.

We discussed the options ad-nauseam above, and the most proven solution is still the type of wing-guying that was popular in the 1970s.

But I’ve spotted a new option that has the virtues of elegance and simplicity, and would appreciate your feedback.

This is a Mountain Hardwear expedition tent, and they’ve braced the side panel with strips of stronger fabric that transmit force from the frame to the guy, adding support to the panel. This is a clip from a video where the panel is rock-solid in a strong side-wind.

You can see the design more clearly below. It’s rated a Top Pick by OutdoorGearLab and users are impressed by its performance in wind.

This clip of a Stealth 1 in a 50 kph wind would suggest that reinforcing along the red lines would transmit the force from the poles to the guy with less panel distortion, and might improve the potentially flappy unbraced area under the single side guy.

I’m quite attracted to this option. It’s simple, saves a peg per side compared to the winged guying arrangement, and would weigh very little. I’d probably sew the reinforcements at each end, but simply bond them along most of their length. With the added reinforcement, I’d be more confident using a 20d fabric for the fly, especially after spotting a video of a 20d Nordisk tent surviving 90 mph in a wind tunnel!. So I’d actually end up with something lighter than a 40d fly without the reinforcement.

What do people think? It works well in the EV2, but why hasn’t this idea been more widely used? Has it got any potential drawbacks?

Jun 14, 2017 at 10:33 pm #3473395Caution: very biased opinion follows.

It won’t work. Tension in the fabric along those red lines is zero substitute for a 3rd pole in the middle. Yes, I have tried it, and no, it did not work. The fabric flaps, possibly worse when the wind is at 45 degrees, and no amount of tension will stop that.

You mention saving the weight of one peg (per side). That is, imho, a very strong example of ‘foolish light’. You are trying to save a few grams on what is probably the single most critical part of your gear, and that is beyond foolish.

Yes, I am being harsh – but I have spent too much time in the high alps under extreme conditions.

Cheers

Jun 15, 2017 at 4:47 pm #3473552Second reason why this won’t work:

your reinforcing fabric would have different stretch characteristics from the main fabric, like less stretchy – and thus it will take the tension but the fabric around it will not get taut enough and htus will flap – perhaps even more than without it. Managing stretch is critical to maintaining a taut pitch. That EV2 is a different beast since it’s fabric is heavier and a laminate – very different stuff than light silnylon in terms of how it stretches. So things that work with one fabric may not work with the other. Mid-panel guylines are maddeningly difficult to get right, so much so that they rarely are done well. I have been looking carefuly at tents since the 70’s – and started making my own in that era – and I have seen very, very few tents with mid-panel guylines that work well and allow a tight pitch without wrinkles – and none that I can think of that can achieve a tight pitch both with and without the mid-panel guylines. I would not use mid-panel guylines on any design of mine. Guylines belong on poles or on corners in my opinion. If a panel needs a mid-panel guyline then it is too big.

Jun 15, 2017 at 4:59 pm #3473555Paul is absolutely right about the problems with fabric stretch. You have to match fabrics carefully. Too much reinforcing can even (sometimes) be worse than not enough. And laminate fabrics are a whole different ballgame as well.

Cheers

Jun 15, 2017 at 7:21 pm #3473579Thanks for the responses – your arguments are convincing so I’ll drop the reinforcement idea. ‘Twas merely a passing fancy…

Of the options that remain, I’m going to go for the wing guying approach, despite Paul’s reservations.

We did discuss ways of breaking up the side panels earlier in the thread. But the Beta Lite “double pyramid” approach doesn’t really work for a solo tent – you can’t get the poles far enough apart without compromising the geometry. All the 2-man commercial implementations have the poles inside the living space with the users sleeping on either side. Rene’s pyramidal side idea looks interesting, especially with Roger’s suggestion of using short poles to support the side-apex. But it’s unproven, and achieving a taut cut for the panels looks decidedly challenging – especially with a tapered ridge line making it asymmetrical. I may experiment with this, but not for my first project – I think it would need a number of iterations to get it working.

That leaves me with the wing-guy approach. This is what designers went with for expedition tents for decades till the advent of bendy poles, so it clearly works when properly executed. Essentially, I’ll be doing a tapered version of the Phoenix Phortress – in my view (and more to the point, in Chris Townshend’s view) the high water mark of A-Frame design and one of the most stable tents ever made. It’s the conservative choice, but I should surely end up with something usable.

A problem is that the wings won’t be needed in clement weather. So I think I’ll have pockets under the wing to stow the guys, and velcro tabs to keep the wings flat against the side panel when not in use.

So now I need to sort out the detail. I’ve decided to go for a floorless tarp. It will be easier to build and very flexible – I can use it with everything from a simple groundsheet to a solid-walled inner. I can bring the tarp home for 450 grams to 550 grams depending on whether I go for 20d or 40d silpoly. I guess the extra 100g isn’t a lot to pay for greater peace of mind. A net inner with bathtub would add around 250g. So I’m getting something pretty bomber at 800g, (ex pegs). Realistically, I doubt you can build something storm-worthy for less.. The other challenges are figuring out a way to attach the A poles to the fly, and designing a rear porch that optimises weight, ventilation and stability. But that’s all doable.

So – time to stop talking and build the thing. Thanks for all the input, and watch this space…

Jun 15, 2017 at 8:08 pm #3473587achieving a taut cut for the panels looks decidedly challenging – especially with a tapered ridge line making it asymmetrical.

Add in a catenary cut on the ridge line … :-)what designers went with for expedition tents for decades till the advent of bendy poles,

Maybe so, but with much heavier and less stretchy fabric!A problem is that the wings won’t be needed in clement weather.

So what? Adding bits of velcro etc just adds weight. If you use the wings in fine weather you are losing nothing, gaining interior space (quite a lot in practice), and will be set for the occasional midnight change in the weather. One time we had lovely fine sunny weather for dinner – and several cm of snow in the morning.figuring out a way to attach the A poles to the fly

There is only ONE way to do this properly if you want a Phortress-style tent. Sleeves at the seam for the poles to go into. Hooks and straps cannot match the performance of tubular sleeves, and probably weigh more anyhow.

When you have built the tent, stand back and compare it with a tunnel. In reality, there will not be a lot of difference! This was my 1st MYOG tent, back in 2004. Is it an A-frame or a tunnel? Please note: it even has little wings!Cheers

PS: the log was for sitting on while I cooked dinner.Jun 15, 2017 at 11:06 pm #3473605How much weight do you save in a tapered tent when using modern fabrics?

I know reducing fabric yardages used was important when all we had to work with was stuff that weighed 120GSM but does it really make such a large percentage difference with 20GSM fabrics?

Also having had to use such a monkey coffin in storms a few times I was happy to pay the weight penalty when I got my Eureka Firelite for more comfort. Actually the Firelite weighed less than my Vango F10 Solo, was more stable in the wind and quicker to put up, my daughter still has it

My point being is comfort worth saving a couple of hundred grams if really foul weather is a given?

Roger in your first tent what angle joiner did you use for the Gothic arch?

Jun 16, 2017 at 12:38 am #3473610How much weight do you save in a tapered tent when using modern fabrics?

Compared to a parallel tent? Very little savings, less than ‘a few hundred grams’ for sure. I stopped bothering shortly afterwards.what angle joiner did you use for the Gothic arch?

In the V1 tent shown: front end included angle is 105 degrees; rear end included angle is 79 degrees. Radius of curvature is 2,000 mm at both ends.Non-tapered means the front and rear poles are interchangeable, which can be a real benefit.

Cheers

Jun 16, 2017 at 5:01 am #3473616Well, we’re in danger of rehashing our earlier discussions.

Roger – this is a tent for thru-hiking and exhausting high level routes. Weight is a priority. There’s no way that I could bring a tunnel home for 800 g – the poles would be too heavy, and I’m carrying my trekking poles anyway which is why I want to use them. Plus we’ve agreed that the tunnel isn’t particularly efficient for a solo shelter. I haven’t seen that version before, but with the twin arch design I can’t see that it offers any particular advantage over the A-frame, apart from a little more internal space which isn’t a priority for me. The unsupported panels would be bigger, if anything. Plus I don’t have the skills or workshop access to begin to match the quality of your construction, while the A-frame is much lower tech and doable.

I do agree about the sleeves though – they would be the strongest option . It pretty much restricts me to twist-lock poles, but I can live with that. It also means that I don’t need to guy the poles. I’d need 6 guys – two bomber pegs fore and aft to stretch the ridge, and four smaller pegs for the side guys. After that it’s just a question of pegging down the edges – I could get away with ti-crooks in most conditions.as the poles and guys will take most of the strain. It’s a lot of pegs compared to some of the TarpTent designs – but can you really build a stormworthy design with just 4 or 6 pegs? I rather doubt it…

As for the taper, you’re both right – the fabric savings are modest at around 150 grams in fabric for the outer, and 50 or so for the inner.

But the issue is poles. I only carry two and they are both used in the front A frame. With a fairly severe taper, I can use a short, light DAC pole for the rear. In a symmetrical A-frame tent, I’d have to carry two more heavy rigid poles for no great additional advantage – it wouldn’t make any sense at all. For a workable symmetrical design I’d have to sacrifice the A at the front and use a single pole at each end like a pup tent. This would significantly reduce the strength as the long side-seams would be unsupported, and you have a sodding great pole in the middle of the entrance.

Plus the taper reduces the panel size and wind resistance, especially if I can pitch with the back into the wind.

I’m planning fairly generous space at the front, and just enough to keep my quilt off the walls at the rear. It’s nice to have a little space around the head and shoulders – space for the feet I can live without. Comfort is personal and subjective, and I know that this is the best series of tradeoffs for my personal needs.

-

AuthorPosts

- You must be logged in to reply to this topic.

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

Our Community Posts are Moderated

Backpacking Light community posts are moderated and here to foster helpful and positive discussions about lightweight backpacking. Please be mindful of our values and boundaries and review our Community Guidelines prior to posting.

Get the Newsletter

Gear Research & Discovery Tools

- Browse our curated Gear Shop

- See the latest Gear Deals and Sales

- Our Recommendations

- Search for Gear on Sale with the Gear Finder

- Used Gear Swap

- Member Gear Reviews and BPL Gear Review Articles

- Browse by Gear Type or Brand.