Topic

Storm-proofing the Side Panel on a lightweight A Frame Design

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

Home › Forums › Gear Forums › Make Your Own Gear › Storm-proofing the Side Panel on a lightweight A Frame Design

- This topic has 129 replies, 1 voice, and was last updated 1 month, 2 weeks ago by

Ross Mellows.

Ross Mellows.

-

AuthorPosts

-

Oct 3, 2016 at 9:38 am #3429095

It must be remembered that in the Fitzroy pic you’re only showing half the tent and not the tent with the rainfly. The fly changes everything and even offers a minimal awning like in some many other A-frame tents. It looks big enough to almost be the start of a vestibule.

Fitzroy in back. This pic from—

http://www.supertopo.com/climbing/thread.php?topic_id=1060647&tn=20

Oct 3, 2016 at 10:11 am #3429100Back in the day (at least in the US) many tents did not come with the flysheet, they had to be purchased separately (just like some heavy tent makers today sell a separate footprint). Marketing brochures usually showed the tent without the fly, so the reader could see more detail. Tipi is correct, the Fitzroy also used a flysheet and was a double wall tent.

The Fitzroy was made by Trailwise, a company made famous by Colin Fletcher in his first Complete Walker book. Of course everyone knows the epicenter of modern day backpacking (and now the high tech industry in Silicone Valley) was the area around Berkley and San Francisco, California, so you Brits and Aussies might not be familiar with some of these leading edge companies :-)

The founders of Sierra Designs were two former Trailwise employees, David Buschman and Bob Swanson who were the most creative of all the early backpacking companies. There is also an intertwined history between The North Face and Sierra Designs, not to mention Kelty. Here’s some background on Sierra Designs and the industry.

Anyway, the Fitzroy also had an optional ridge line pole. It was marketed as a free standing tent only requiring stakes at the four corners and no guys. Of course, the instructions were different, recommending guys for windy conditions. But the 4 poles by themselves created a lot of tension on the fabric (and not super easy to get all 4 poles in place) and it was a rather tall “2 man” tent. With guys, stakes, ridge pole, and flysheet it was a 9 pound beast. It was a very storm worthy tent. The floor was 102″ X 57″ with tapers forward of the poles. However, the poles were heavy — which again is going to be Geoff’s challenge: a light weight A-frame that can handle poor weather.

Oct 3, 2016 at 3:01 pm #3429157Nick—I just discovered your linked website recently and somehow located many videos on the site like this—

http://www.outinunder.com/content/oval-intention-walkthrough-lp-version

Oct 3, 2016 at 3:22 pm #3429164Rivendell

The Green and Gold version (Aussie colours…) is the Bombshelter Super, a later version of the Bombshelter.

Oct 4, 2016 at 1:43 am #3429248Tipi & Nick

Thanks for the explanation about the Fitzroy rainfly – as you say, that would have locked everything down a bit. In storms I’d still be wanting the end guys whatever the marketing said…

Yes – I’m prepared to concede that you guys in California were ahead of the UK in those days! Though we had our entrepreneurs too. In the early 70s I knew a bloke called Rab Carrington who made me a sleeping bag on his kitchen table. I’ve heard rumours that he went on to be quite successful :-)

Interestingly, George Marks in the article makes it clear that Sierra were reluctant to abandon their straight pole designs. He says that their flagship was the Glacier A-frame and that many Glacier customers “wrote to tell us that they were safe in their tents in spite of horrendous conditions”.

But then the market was swept by dome-mania. He says the bottom fell out of the A-frame market so suddenly that they were left with a huge stock of poles they had to scrap, even though the domes at the time weren’t very storm-worthy. The way he tells it, there was a strong element of fashion in the shift, which is my own memory of that period too.

In passing, there’s an interesting interview on tent design on that OutInUnder site: http://www.outinunder.com/content/martin-zemitis-tent-design-essentials-and-trade-offs

Oct 4, 2016 at 6:57 am #3429264“there was a strong element of fashion in the shift”

there’s a strong element of fashion (or fad) in everything we humans buy, including SUL

not that there’s anything wrong with that

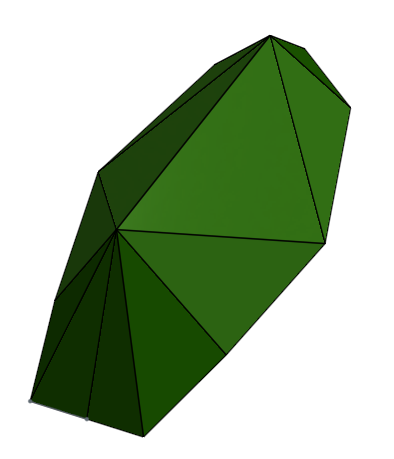

Oct 8, 2016 at 5:34 pm #3430102Spotted another take on the triangulated panel design – this time from Locus. It’s a big tent, but I can’t see why the ideas wouldn’t scale down:

This combines Nick Gatel’s idea that a seam in the centre of the side panel would add strength, with the triangular panel idea from the Black Diamond Beta Lite et al. A cat-cut ridge adds support to the central seam..

Locus have used the side seams to provide a rugged and structurally logical location for side-guys. (In many lightweight tarps and A-frames the side guys seem to be placed rather arbitrarily in the middle of the panels.) And you could add another side guy to the central seam. In anything short of the apocalypse they could all be attached to a single strong peg, as in the photo, keeping peg weight down.

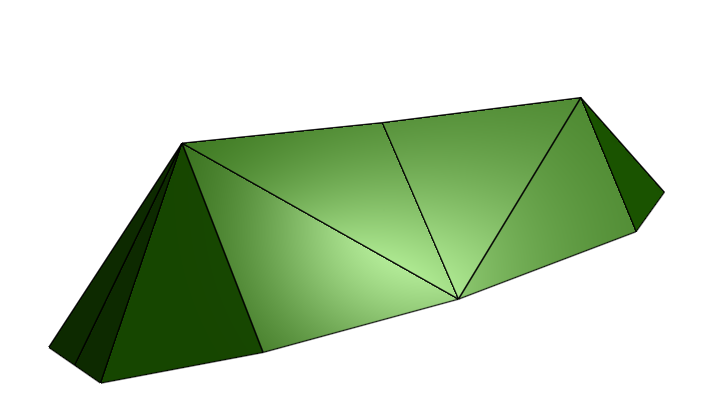

Here’s a quick and dirty visualisation of a smaller tapered version:

Lots of seams, but if I use the RSBTR silpoly PU they will be easy to seal with thermal tape. And according to experienced designer Mike Cecot-Scherer, a tape-sealed silpoly PU seam is the strongest and most waterproof part of a lightweight tent. I’m also thinking I could reduce stretch in the seams by sewing a strip of cuben into the flat fell, with very little weight penalty.

As I’ve said before, my experience with Ron’s TrailStar has impressed me with the performance of triangular panels in high winds – the seams are very effective in transmitting wind loads to the pegs without flapping. This approach turns the whole tent into a series of small triangular panels. I suspect it would work well, and I’m tempted to prototype it.

I’d need a tensioning system for the sleeved poles to ensure the panels are stretched, but that’s not rocket science, and with a poly fly sagging is less of an issue.

In a winter version, this could be executed in 40D with DAC A poles in sleeves up the central seam. Should be pretty bombproof. And with a tapered solo design it would come in at a few grams over a kilo, which is pretty good for a genuine 4-season tent.

Oct 8, 2016 at 6:09 pm #3430112“But then the market was swept by dome-mania”

Yes, I recall dome-mania. I had an REI Crestline with the Expedition rain-fly (could safely cook under the vestibule, especially if you built a snow-wall around that side of the tent). Stable but pretty heavy and you needed lots of stakes, and snow stakes are pretty heavy. I purchased a Sierra Designs dome tent (the original, still use it) mainly because it was larger inside (fit 3 more easily) and NO STAKES.

Of course you had to tie it down somehow if it was windy, I heard of people helplessly watching their dome roll across a field or lake. We usually just threw our packs in once it was set up. But one really windy evening in the Enchantments my wife got in and it still seemed like it was going to take off. That night I tied it down to every rock I could find. And we couldn’t cook due to the wind, either.

But we were in the Enchantments, so we didn’t care!

Oct 8, 2016 at 10:56 pm #3430136The Trailwise Fitzroy was indeed a stout-looking beast. Saw one in the Ski Hut back in ’72 or ’73. Steep walls to shed snow; and with the poles inboard of the ends you got shortened ridgeline and smaller unsupported panels. Also, at the peak of the A-frame poles, they had a nice machined aluminum fitting that connected the two poles, and incorporated a short rod over which passed 1″ nylon webbing that you could tighten with a tabler buckle (grandaddy of the LadderLoc). This allowed for extra tension – and plenty of it. In mild weather just staking the ends would hold it up, but clearly you’d have end guys for real weather.

The Bombshelter was almost a custom tent – they were only made when one was ordered is how I understand it.

The demise of the A-frame is an interesting subject. It ‘s worth remembering that before the 70’s there were almost no backpacking tents. There were camping tents and mountaineering tents, with the vast majority of the mountaineering tents being A-frames, plus a few anomalies like the Eureka Draw-Tite (for which, picture an industrial strength Big Agnes Copper Spur). A couple companies made backpacking tents of a sort (Gerry for one) but hardly any. So for most high mountain backpacking, if you took a tent it was a mountaineering tent. Now mountaineers have always had different ideas about shelter. For one, rain was not their main concern; snow was. For another, they have always been wiling to trade interior room for stormworthiness (as in the Bombshelter). Only in the 70’s, with the original backpacking boom, did the market for backpacking tents really emerge. And backpackers in general, who have always tended to stick to the trees for the most part when choosing campsites, did not need as much weather capability as the mountaineers. But, being less hardcore, they wanted more comfort, meaning more interior space. Domes and tunnels give you that increased space for the same footprint, but if they are flexible pole structures, they give up stormworthiness. This is a tradeoff most people have been willing to accept, and is, I think, why domes quickly became popular. Of course, a tunnel with more rigid poles (e.g., Warmlite) can handle some serious stuff, as can a flexy-poled tunnel with plenty of guylines, or a geodesic design with plenty of poles. But a tunnel with more rigid poles is much harder to design, cut and sew than a flexy poled one, and the poles are far more expensive to make, since they have to be custom bent for each model of tent.. Which is likely why so few manufacturers ever went the rigid pole tunnel route. I can think of only one or two other than Warmilte from the past (and can’t recall the names). Also, the self-supporting nature of a dome has always been popular. I spent a few years working in various shops selling gear, and people always loved the idea. In fact I recall that when I worked at REI in the early 80’s, our best selling tent was actually not a dome, it was an A-frame – but a freestanding A-frame – the Eureka Timberline that had a ridge pole. Inexpensive, easy to set up, handled rain just fine, handled a fair amount of weather if you staked it out well. they flew out the door. But other than that, domes and more domes is what moved.

Oct 9, 2016 at 2:40 pm #3430218Nothing new under the sun dept…

Just in passing, it’s not easy to dream up anything new in tent design…

Here’s a vintage side-entry A-frame:

And here’s Zerogram’s current side-entry A-frame:

Oct 9, 2016 at 3:24 pm #3430230

Oct 9, 2016 at 3:24 pm #3430230Paul – thanks for the lucid survey. Pretty much chimes with my own experience of the period.

In Scotland in the ’60s everything was canvas or Ventile. As a schoolkid the lightest tent I could afford was a cheap car-camping A-frame. It performed remarkably well in the hills and I have happy memories. But the weight was crippling, especially when wet. The Vango Force Ten appeared in the late ’60s – bomber but still heavy. And the lightweight revolution didn’t get going till Bob Saunders ramped up production in the early ’70s with a blizzard of innovation (not everything came from California, you know!).

As I’ve said above, I think the main reason we all ditched our A-frames was that we didn’t have to carry those sodding rigid poles any more. With competition from bendy-pole designs Eureka developed a lighter weight pole system that makes the A-frame more portable and it seems to have been a runaway success for them – they claim over 1 million sold and it’s still very much in production: http://store.eurekatent.com/timberline-series. So hardly a dead design!

But in the lightweight world, the revival can surely be traced to the increasing popularity of trekking poles. For solo use especially the A-frame is an efficient and reasonably liveable way to make use of the poles, with a number of advantages over solo-sized mids in my experience. So we have seen offerings from TarpTent, GoLite, Black Diamond, Yama, MSR, HMG, Bear Paw, TrekkerTent and others. TrekkerTent have just closed their order book, they’re so overwhelmed with demand. So all you A-frame haters watch out – we’re loud and we’re proud and we’re coming for you :-)

On a more practical note, any feedback on the Locus triangulated side panel? They’re one of the more respected cottage designers, and I feel it has potential…

Oct 12, 2016 at 7:25 pm #3430867Geoff – Now I see why you’re not interested in a “Bibler” style tent. : )

I can’t say that I agree about it being too cramped, but this has been an interesting read.

Oct 13, 2016 at 1:05 pm #3430971Re. the Locus design.

That center seam is most likely a necessity of size and roll width. The tent is 6m long, the poles are 3m apart. Unless you intent to add contour to the center panel by joining curved edges at a center seam, I wouldn’t put a seam there. You can’t add strength across the seam because there’s weaker fabric on both sides – a strong link in the middle of a chain doesn’t improve the end to end strength. It might help you pull the ridge line down in the middle, but that defeats the purpose of a catenary ridge line – providing even tension to the panels. If you’re not adding contour but still want lengthwise strength where that seam is, go with tape.

Before adding Cuben to your seams, ask yourself how strong do they really need to be. Felled seams already have 3 – 4 layers of fabric, and its easy to add further strength by going wider or adding more layers. The important distinction is that Cuben stretches differently than the other fabric. If you use it, it will likely end up carrying the full lengthwise load, in which case you need to ensure you have enough of it. Again, a chain is only as strong as its weakest link, and I don’t think many people do an end to end evaluation of their full load/anchor system.

You’ve mentioned using RSBTR’s PU coated silpoly. It has a higher HH rating than the silicon coated fabric, but a lower tear strength. Just wanted to remind you of that.

Looking forward to seeing the finished product.

Oct 13, 2016 at 3:14 pm #3430996I have to agree with Rene:

* I cannot see any benefit from that middle seam at all. It is due to the fabric width being inadequate.

* The middle seam will upset the benefits of the cat cut.

* Adding Cuban to the ridge line is probably counter-productive as it has really different stretch properties from the rest of the fabric, and thin strips of Cuban are not going to be all that strong anyhow. It may snap easily.

* More attention may be needed to the end anchors.Cheers

Oct 13, 2016 at 5:25 pm #3431014Hi guys

Useful input.

Reinforcing the seams

I think you’re right about reinforcing the seams – there’s probably a reason why no-one does it. The idea was that reducing stretch would reduce flapping, but I suspect it might not work out that way. One of the benefits of a poly tent over a cuben is that the flex helps achieve an optimal pitch and distribute wind load over the panels. Making the seams too rigid might well compromise this. I’m not aware of any serious expedition tent made in cuben, so it seems that the designers don’t think that such a rigid fabric is suitable for high wind loads. The TrailStar flat out doesn’t work in cuben and Ron tries to talk customers out of it. Flex seems to be integral to performance. So I’ll simply sew conventional flat felled seams.

Breaking up the side panels

And you’re probably right about the central seam, though I feel it’s more of an open question. Rene – the idea isn’t to reinforce the fabric against damage – as you say, that would be futile. It came from observing how the triangular seams in the TrailStar seem to break up the large unsupported walls so that force gets transmitted to the anchors rather than flapping the fabric. It really is quite striking – my TrailStar flexes but it simply doesn’t flap.

Then I realised that a couple of US makers have used this triangulation idea on their A-frame trekking pole tarps (see posts above). There are a few videos of those tarps under wind-load and the triangular panels are behaving the same way as the TrailStar. And reviewers consistently comment on how well they perform in the wind, even though the guying seems far from optimal to my eye. (I think that Locus really nailed the guying, and I’ll copy their approach.)

So then the question is how to triangulate the walls: three side panels, as on the Black Diamond and MSR, or 4 panels and a central seam as on the Locus?

The advantage of the 3 panel design is that all 3 corners have solid support on the A poles or the peg. And it’s simpler. The potential advantage of the central seam is that it breaks up the large central panel, and provides a solid location for a central guy. But as you say, the only support at the top of the seam is the cat ridge, so perhaps it wouldn’t be very effective. And it does look as if the Locus seam is there because of fabric constraints – they’re not using it for guying. So yes, maybe the central seam would be overkill… The safest route would be to copy the MSR and Black Diamond – I’m sure those guys did a lot of prototyping. Any additional comments to help with this decision?

The alternative is the tried-and-tested winged guy, as on the Ultimate, the Phoenix and the Saunders. Their stability was legendary, but it would be more fun to try something different. And I do love my TrailStar in the wind. I guess that the answer is prototyping with old fabric, as Roger says.

Fabric strength

As for the silpoly PU, I’ve been assured by one of the most experienced designers in the business that fabric strength won’t be an issue – he uses 20D silpoly PU in his own designs and has wind-tunnel tested it to destruction, so I have reason to believe him.

Oct 13, 2016 at 5:37 pm #3431017Hi Geoff

I don’t used winged guys at all on my tunnels, obviously, but the idea does attract me for an A-frame. However, I would NOT guy the corners of the wing as shown in your last photo: I would run the guys out straight to 2 separate stakes.

I would also tension the pole sleeves down to the ends of the poles. In the same photo the sleeves look crinkled – bad imho.

I would also make the end bells (vestibules) a little longer to get a better tension support for the poles. I might also add guy rope anchors to the pole sleeves and move to slightly lighter poles. Yes, I believe in guy ropes! The windward end pole guys would go out at 45 degrees to help counter end-on wind when needed.

Cheers

Oct 13, 2016 at 5:55 pm #3431022Hi Roger – it’s a sloppy pitch, so please don’t judge the design my it. It was at a stove-collectors’ convention, which is a thing, apparently! The vestibule is fully open. With a more serious pitch it looks like this:

Note how the poles extend beyond the fabric – there’s a strap from the apex which is used to tension the sleeves. The Fitzroy used this too.

I was thinking of end guys at 45 degrees as you suggest, but looking at the pic I suspect the single guys fore and aft would do the job – rigid A poles are pretty much self-supporting when it comes to side loading.

Oct 13, 2016 at 6:17 pm #3431025Hi Geoff

Ah so, fair enough.

Hum … I wonder whether that guy wing could be 40 mm higher? Dunno.We need photos of YOUR tent next!

Cheers

Oct 14, 2016 at 3:56 am #3431104Hi Roger

According to Franco there’s a reason for placing these wing guys quite low – if you place them higher the fabric below them will tend to flap. If I go this way, I’ll copy the classic tents – they all used this approach and I think they had their reasons.

Yes, we’ve probably flogged this one to death – next step is some prototyping. , it’s going to be a relaxed project though – my current schedule is crazy and I’m giving myself the winter to get this done…

Oct 14, 2016 at 4:25 am #3431105Hi Geoff

As I said: ‘I wonder …’ and ‘Dunno’. I still dunno. And I still wonder.As for the idea that the fabric below might flap: that would not worry me at all. I would tension the hem and insert a middle stake. For bad weather – and the tent has snow flaps after all, stakes halfway along the hem seems like a good idea. Hey – I have a middle anchor at the end bell of my tunnels, and that is a shorter stretch of fabric – and it has been needed at times.

Oct 14, 2016 at 9:55 am #3431141

Oct 14, 2016 at 9:55 am #3431141And you’re probably right about the central seam, though I feel it’s more of an open question. Rene – the idea isn’t to reinforce the fabric against damage – as you say, that would be futile. It came from observing how the triangular seams in the TrailStar seem to break up the large unsupported walls so that force gets transmitted to the anchors rather than flapping the fabric. It really is quite striking – my TrailStar flexes but it simply doesn’t flap.

Agree.

Regarding the side tie going to one stake vs. two. More tie outs and more stakes work better, but people want fewer stakes to reduce weight and setup time. As you recall, my Super Flash has 20 stakes for full blown Antarctic weather mode and all tie outs used. Given that at 6 pounds it really is a light shelter for those kinds of conditions, the extra stakes and tie outs should be given serious consideration.

Oct 14, 2016 at 2:06 pm #3431175but people want fewer stakes to reduce weight and setup time.

The thought which popped into my mind here was of the transition from ‘ultra-light’ to ‘stupid light’.

I am going to be spending 8 – 10 hours in this tent each night. I need rest and warmth and relaxation. A Ti wire stake weighs 6.1 g.

My 2c.Cheers

Oct 14, 2016 at 2:17 pm #3431178Not really my thing, but some grams could be freed up by tailoring the amount of support to the expected conditions. For an ultra weight trimmer, some guy & stake points could be optional. Winged guy points could be designed to use one or two stakes, and maybe a similar economy could be used elsewhere. Stake everything in winter mountain conditions, but remove some line & stakes from the kit for calmer trips.

Oct 14, 2016 at 2:26 pm #3431181Ti wire stake: 6.1 g

Spectra guy rope: 0.5 gThe sweat on my shirt weighs more than that.

Cheers

Oct 14, 2016 at 3:23 pm #3431187Dude, that’s like 6.6 grams right there. Multiply that a few times and we’re talking major weight, more than an ounce!

Like I said, it’s not my thing, but some people care about it. If someone removes zip pulls to save weight, they’d probably lose some Spectra to save weight, too. I’ll admit to thinking about replacing my Triptease guys with something lighter. : )

-

AuthorPosts

- You must be logged in to reply to this topic.

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

Our Community Posts are Moderated

Backpacking Light community posts are moderated and here to foster helpful and positive discussions about lightweight backpacking. Please be mindful of our values and boundaries and review our Community Guidelines prior to posting.

Get the Newsletter

Gear Research & Discovery Tools

- Browse our curated Gear Shop

- See the latest Gear Deals and Sales

- Our Recommendations

- Search for Gear on Sale with the Gear Finder

- Used Gear Swap

- Member Gear Reviews and BPL Gear Review Articles

- Browse by Gear Type or Brand.