Topic

Standardised Benchmarking for Insulated Jackets (beyond R-Value)

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

Home › Forums › Gear Forums › Gear (General) › Standardised Benchmarking for Insulated Jackets (beyond R-Value)

- This topic has 62 replies, 11 voices, and was last updated 4 years, 9 months ago by

Rex Sanders.

Rex Sanders.

-

AuthorPosts

-

Nov 13, 2019 at 1:40 am #3618411

Hi all,

Firstly, I’ve read through these threads here

https://backpackinglight.com/forums/topic/scientific-way-to-compare-r-value-to-down-insulation/

https://backpackinglight.com/forums/topic/73153/… and plenty elsewhere. Let’s just say, this issue has been bothering me for some time.

So, here’s an interesting sentence:

“Every construction / design architect / engineer (A/E) knows a material’s R-value is an important factor when specifying insulation products, with many regulations requiring minimum values for wall, ceiling, and roof assemblies.”

(Source: https://www.greenbuildingsolutions.org/blog/structural-insulated-panels-sips-r-values/ )Let’s hear that again: “a material’s R-value is an important factor when specifying insulation products“. Unless of course you’re selling jackets to people who rely on them for their survival. Then, it would appear, it’s not so important.

By way of illustration, let’s take 3 similar weight synthetic insulation jackets:

Mountain Equipment’s old Compressor:

Item Weight = 380g (L) / 60 g/sqm Primaloft Gold InsulationMountain Equipment’s Rampart:

Item Weight = 395g (L) / 80 g/sqm of POLARLOFT Micro InsulationMontane Icarus Lite Jacket

Item Weight 430g (size unstated) / 160 g (M) of PrimaLoft Silver ThermoPlume (blown into baffles like down) InsulationLet’s for the sake of simplicity assume they all have the same face fabric.

Which will be warmer? I’m guessing, like me, no one here will have a clue (perhaps I’m wrong).

And I’m also guessing the manufacturers like it this way.For example, it allows Rab to drop (the presumably expensive) 60 g/sqm of Primaloft Gold for their own 60 g/sqm Stratus recycled insulation in their new Xenon Jacket and claim, that even though the jacket (326g L) is 16% lighter than its previous incarnation (Rab Xenon X Hoodie, 390g) it’s just as warm. They offer no proof, they just state it, so it must be so.

If I buy an integrated amplifier, I’m not expected to wait until I get home to find out whether it can power my speakers. We have a specification which will tell me exactly the max load into x ohm speakers. Yet, when it comes to outdoor insulated clothing, I have to wait until I’m dying from exposure until I know that the jacket was not up to the task. Hmmm.

I realise that R-Values for clothing items are tricky in the sense that with down, you’ve got fill power (quality) versus total fill weight (quantity) over a certain area etc … but this is the 21st century and surely there has to be a way to come up with a standardised benchmark so customers can make informed decisions when buying insulated clothing across formats (down / synthetic).

What is wrong with this:

- Crash-test dummy with a 40″ chest and a heated core (say 20°C (68°F).

- Sat in a room that is say -20°C (-4°F). [ + wind (20mph) machine if we would want that as part of the standard ]

- The manufacturer provides the correct jacket for the standardised dummy.

- How long does it take for the dummy’s core to drop to 0°C (32°F)?

- That time is your benchmark.

This method helps get away from the age old problem of isolating the insulation, which leads to: “yes, but what about the face fabric, what about the stitch-through baffles, elasticated wrists, storm flaps on the zips etc..”

Yes, we’re still left with, “well what about the relative humidity and the compression of the down”. But in my mind these are things that people can factor in themselves. Everyone know that compressing down reduces its effectiveness and likewise soaking wet clumps of down suck at keeping you warm. But this is like saying, “the amplifier is not loud enough when I turn my speaker to face the wall”.What we need is a standardised benchmarking system for insulated jackets. The time to zero may not be a wonderful real-world test. But it would provide a like for like measure at how well warm air is trapped in a real-world product.

I’d love to hear some thoughts as to why this approach may or may not work. And why the industry seems so reluctant to offer a meaningful measure of their insulated products.

Cheers,

AndyNov 13, 2019 at 3:47 am #3618429some thoughts as to why this approach may or may not work.

Marketing Depts would hate it, just as politicians hate the idea of science-based legislation.Introduce measurement and you remove the marketing dept’s ability to spin madly. A bit like fact-checking on politicians.

We have had the same problems with sleeping bags. There is now a European Standard for assessing them. American bags seem to be claiming around 16 C better performance than the measurements show. Mind you, they are not the only ones, just the most extreme.

Cheers

Nov 13, 2019 at 4:22 am #3618430Well I’m sure you’re sadly correct. But I would argue it like this:

Carabiners, crampons, ice axes all have certified safety standards:

“Almost all climbing hardware is categorised under

the European Personal Protective Equipment

(PPE) Directive.This applies to all equipment

carried on the person to be used for protecting

against falls from a height (ie. harnesses, ropes,

nuts, karabiners etc.), or to protect against

slippage (crampons & ice axe) or head protection

(helmets).To be allowed to sell an item of PPE

in Europe, a manufacturer must go to an

independent ‘notified body’ and have their

equipment tested against an appropriate standard

and their quality control procedures verified.

Once approval is given, the equipment can carry

the CE mark and go on sale.”So if you fall, slip or slide that’s regarded as a real safety issue and we don’t rely on the word of marketing departments to reassure us (“it’s really strong, honest”) . I would suggest that freezing to death be added to the list of genuine safety concerns (that trump marketing departments’ desire to deceive) since insulation is just as essential (and deserving of genuine measure) as breaking strength etc …

It would also serve as a useful reminder to many outdoor brands that they’re in the outdoor (“safety”) industry and not the fashion industry (for which no such accreditation would be necessary).

Andy.

Nov 13, 2019 at 5:27 am #3618440It would also serve as a useful reminder to many outdoor brands that they’re in the outdoor (“safety”) industry and not the fashion industry

Well, yeah, but where do you think they make all their profit? It’s NOT from the outdoors industry per se, but from the fashion customers. Problem.Cheers

Nov 13, 2019 at 6:29 am #3618443Even for the products where we do have insulation standards (sleeping bags and sleeping pads), the standards have problems and the marketing around “standard” values created new problems. Try making sense of REI Magma sleeping bag names vs EN ratings, for example.

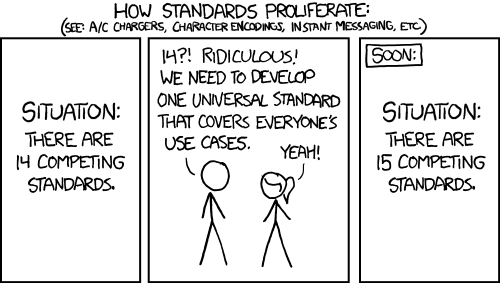

While I agree that having a repeatable and rational standardized method for measuring jacket insulation would be an improvement, it will create new problems without solving all the old ones. And depending on how the standards committee members (often packed with reps from large companies) game the standards (don’t look shocked), expect the biggest manufacturers and most conventional (boring) designs to come out ahead. Same as it ever was.

Standards are always double-edged swords.

— Rex

Nov 13, 2019 at 8:01 am #3618455Could be worse:

I worked in IT for over 40 years and had friends on various standards committees. Serving on a standards committee is like being Sisyphus in stuffy meeting rooms, only they usually fly you to nice places.

— Rex

Nov 13, 2019 at 1:13 pm #3618469@ Roger. Yes indeed they make their money from the high-street and not the mountain. But at least in Europe the sleeping bag EN rating system is a hell of lot better than what we have with jackets where you’re literally shopping blind. May be it’s just me, but frauds, especially where they’re obvious (and have real, non-trivial implications) bother me.

Can anyone see any real issues with the kind of test sketched out above?

Any refinements that would make it better? (easier to replicate, stuff like that?)I mean essentially what we are talking about is 1) warmed trapped air, b) simulated cold conditions and c) a thermometer and a stopwatch.

Andy

Nov 13, 2019 at 1:14 pm #3618471When it comes to down, all I know is loft is king. And loft is dependent on fill weight, down quality, and the garment’s cut (sewn through, differential cut, box construction, double offset construction, etc). Obviously shell material goes to warmth too. Warm garments weigh something! One reason the much lauded MH Ghost Whisperer barely qualifies as a summer jacket here in Montana.

I think a good place to start would be for all mfg’s to give all the garments salient specifics… down quality, fill weight, garment cut, loft, shell material.

Nov 13, 2019 at 1:43 pm #3618473What @bradmacmt said.

Unfortunately, the only way to evaluate what “down quality, fill weight, garment cut, loft, shell material” is right for *you* is with experience, and so evaluating those specifics, assuming they are accurately published by the manufacturer, only make sense if you have experience with other products for which you have those specifications.

At this point I like/trust the Montbell product line to deliver the performance and fit I am looking for. I’d be happy to try some of the other brands, but when I plop down over $300 on a puffy, I’m not terribly inclined to take risks.

Nov 13, 2019 at 2:07 pm #3618476At this point I like/trust the Montbell product line to deliver the performance and fit I am looking for.

JCH, funny you bring up Montbell… I almost mentioned them as one of the sandout’s in terms of information. All things considered, they make my favorite down jackets.

Nov 13, 2019 at 2:47 pm #3618481Yeah, I don’t think down is so much of an issue. But for example if I ask an “experienced person” (like those that inhabit these forums), how warm are those 3 synthetic jackets (mentioned in the OP) compared with say this jacket by Mountain Equipment, which uses an identical face fabric:

Weight = 375g: down specs: 116g (Size L) of water resistant duck down with a minimum content of 90/10 700 fill power:

https://www.mountain-equipment.co.uk/arete-hooded-jacketIt weighs almost the same as ME’s old Compressor jacket (380g size large, 60g/sm of Primaloft Gold).

The test I’ve mentioned would tell you the answer, or at least indicate a pretty reliable standardised answer. Can you tell me? Because I haven’t a clue (well I do – my guess is that the down jacket would be a little warmer in dry conditions — but how much warmer I haven’t a clue).

And that, at least to my mind, is somewhat pathetic.

Andy

Nov 13, 2019 at 8:42 pm #3618533A Standard would be nice, but agreement on its content from what is mainly a fashion industry would be near impossible. Preventing massive gaming of the Standard, and outright fraud as well, would be a labour of Hercules. Standards and marketing spin are polar opposites.

Cheers

Nov 13, 2019 at 9:04 pm #3618541“If I buy an integrated amplifier, I’m not expected to wait until I get home to find out whether it can power my speakers.”

Funny you mention this. I remember Bose would refuse to publish sensitivity ratings on their speakers, in order to compel users to simply listen to them and “not judge a speaker by it’s specs”. Well for myself, that was a major turn off since I wasn’t about to mix a 80-85db pair of Bose into a home theater setup with speakers that were literally ten times louder. Don’t know if Bose has changed their ways since then, but I certainly haven’t.

But standardizing insulated jackets? I dunno. While your method appears quite rational, it also seems pretty labor intensive. And just what companies would be “required” to test their jackets, because there are so many “non-outdoor” companies also sell insulated jackets. Would the Costco Kirkland down coat need to be tested right along side the ArcTeryx Fission SV?

As Roger said, it’s all about whether a test like this would actually help them sell more of them, and not actually ever be about safety. (And while you mentioned that Europe DOES require CE/UIAA labels on all climbing equipment, keep in mind its still completely voluntary in most other countries.)

Since the late 90’s sleeping pad manufacturers have been marketing “R values” on their products, to try to sell them a little better to consumers. It took 20 years and significant support from the major pad companies to create the ASTM F3340 standard. And as far as I can tell, it will mostly benefit the big companies first and foremost. “Requiring” Tim Marshal at EE to start testing his jackets would significantly affect the cost of his merchandise, while TNF or Patagonia wouldn’t miss a beat.

If something like this were ever to happen with jackets, it would take a long time for it to take shape, and would most likely be guided by the big companies who would make sure it would benefit their bottom line, first and foremost.

But it does appear Land’s End is doing something about it for their own jackets!

Nov 13, 2019 at 9:20 pm #3618544To get temperature rating you also have to consider what else is worn – pants, hat,…

With sleeping bags the one bag is responsible for all warmth so it’s easier

Yeah, it ought to be standardized.

I appreciate Rex’s observation

Nov 13, 2019 at 10:19 pm #3618554Andy,

The ME down jacket is 2.63 Iclo and the thermo- neutral camp chores temp, with 1 clo of other clothing, is 31F.

The ME compressor is .89 Iclo and the equivalent thermo- neutral temp is 48F.

The down jacket will maintain its insulation value indefinitely. The PL1 will rapidly decrease its insulation value from stuffing or sleeping in it.

Nov 15, 2019 at 12:12 am #3618774Richard, can you explain for a simpleton, what this means:”the equivalent thermo-neutral temp is 48F”, and how did you get those figures?

Thanks,

AndyNov 15, 2019 at 1:22 am #3618794…funny you bring up Montbell… I almost mentioned them as one of the standout’s in terms of information.

IMO, this graphic (from the montbell.us website) is how down jackets are properly marketed. All you need is experience with one of thier jackets and you can accurately predict the performance of the others.

Nov 15, 2019 at 1:58 am #3618802

Nov 15, 2019 at 1:58 am #3618802Andy,

An average mix of camp chores results in an metabolic rate (METs) of 1.75 The ambient temperature, in no wind, at which the heat generated by the individual exactly matches the heat lost from 1 clo of a UL backpacking clothing ensemble (1 Clo) + the garment being tested (Iclo factored by the body surface area it covers) is the thermo-neutral temperature.

In laymen’s terms, the forecast low temp for a UL backpacking trip should be greater than or equal to the thermo-neutral temperature for your hiking ensemble plus your puffy.

I calculated the thermo-neutral temperatures for both jackets you referenced in your post that most closely preceded my response.

To understand the details on how I derive camp chores thermo-neutral temperatures, please review my relevant BPL forum posts for the last 10 years.

The rare vendors who provide temperature ratings for their garments base their analysis on brisk walking on a level ground MET rate which always results in less insulation than is required for camp chores.

Nov 15, 2019 at 5:40 am #3618896Richard,

Interesting …

I guess the problem I’m having is I don’t really have any reference, in the sense that I don’t know the clo of anything.

I’ve been doing some work with Scramble in the UK (of the tarp kind). They reviewed the ME Compressor a while back. So I asked what this guy was wearing (under the jacket) when the pic below was taken:

This was the (upper body) ensemble, i.e. what that guy is wearing under the ME Compressor (2014)

….

[ BASELAYER ] : Bergans of Norway: Akeleie Half Zip (Merino / Polyester hybrid) baselayer (250g)

[ 2 x “LIGHTWEIGHT” NON-INSULATED SOFTSHELLS ] : The combination of Softshells (#1, left panel) below:

….

What the clo of that combination is I have no idea – but perhaps you do …

The temperature when that picture was taken was around -8°C (17.6°F).

So does that all tally / kind of make sense with your calculations?

Thanks for the info.

AndyNov 15, 2019 at 6:18 am #3618906Andy,

The short answer is yes.

The long answer is that 1 clo is representative of the average ensemble (not including the addition of a puffy while not actually backpacking).

Nov 15, 2019 at 6:27 am #3618909My understanding of ‘clo’ is that it is a particularly British measurement, whereby 1 clo is meant to represent the typical business attire worn in an office.

Cheers

Nov 15, 2019 at 8:11 am #3618923From Wikipedia;

1 clo = 0.155 K·m²·W⁻¹ ≈ 0.88 R

This is the amount of insulation that allows a person at rest to maintain thermal equilibrium in an environment at 21°C (70°F) in a normally ventilated room (0.1 m/s air movement).

0.1 m/s = 0.22 mph

The rest of that Wikipedia article might be worth reading in the context of this discussion. Togs anyone?

— Rex

Nov 15, 2019 at 10:08 am #3618927Hi Rex

1 clo = 0.155 K·m²·W⁻¹ ≈ 0.88 R

Why on earth would anyone pick that amount of insulation for a definition? How totally weird!You need just a bit more of that definition to understand. It goes

Clo = 1 – corresponds to the insulating value of clothing needed to maintain a person in comfort sitting at rest in a room at 21 ℃ (70 ℉) with air movement of 0.1 m/s and humidity less than 50% – typically a person wearing a business suit

https://www.engineeringtoolbox.com/clo-clothing-thermal-insulation-d_732.htmlThen it all makes sense. A business man in an air-conditioned office: how useful. The metric version or units came later, possibly because no-one ever agreed exactly as to what 1 clo meant!

Cheers

Nov 15, 2019 at 2:43 pm #3618941@ Roger

“Why on earth would anyone pick that amount of insulation for a definition? How totally weird!”

Yes indeed, and I’m familiar with all the stuff above (read the wiki stuff etc …) , clo, tog and all that … my understanding is that Tog is more the measure in the UK. But I’m still left with zero appreciation of how I do on a mountain in 50mph winds in a damp business suit. Perhaps it’s just me. I also have no intuitive sense of how many suit jackets = 1 x 400g OR Ferrosi. Again, perhaps I’m just dumb.

Every time I read up on clo and tog, I come to the same conclusion – just use r-value. Imagine someone said, “I know grams and ounces are fine for measuring building materials, but we need a different way of stating the weight of clothing. Let’s use gogs and cloz”.

@ Richard — I’m still lost because if the short and long answer is yes, I can’t get my brain to where = 48°F = 17.6°F.

I suppose what has been handy about this little exercise is that it shows that the insulation metric field for clothing is confusing as hell and all this would be remedied by the simple test I laid out in the first post.

Crash test dummy in merino baselayer and beanie + jacket X = 180 mins to freezing his arse off vs ME Arete Hooded Jacket = 360 mins to freezing arse off. Oh, the ME down jacket is twice as warm. Good to know.

No one here in the UK seems to use tog or clo. I may be wrong but my impression is that people base their insulation assessment on weight of insulation and hope for the best (or have experience) as to whether that insulation is any good. Again – when it comes to down you certainly have more to go on because down is down to a large degree and you’ve got the 3 meaningful metrics of Fill Power, Fill Weight and Down/Feather ratio.

Andy

Nov 15, 2019 at 7:59 pm #3618983Andy,

17.6F = marketing

48.0F = physiology / physics modeling

Choose your religion (smile).

You said, “Every time I read up on clo and tog, I come to the same conclusion – just use r-value. Imagine someone said, “I know grams and ounces are fine for measuring building materials, but we need a different way of stating the weight of clothing. Let’s use gogs and cloz”.”

Thermal resistance is a measure of both an insulation’s property and either it’s thickness or density. R-Value, m2K/W, Clo, and TOG are all easily convertible thermal resistance units. What’s hard is determining the Value, not the representation.

Marketing, trial and error, or physiology/physics modeling can be used to determine a base line guidance for a minimum temperature VALUE based on any combination of physical activity and a clothing ensemble’s thermal resistance.

The Natick Laboratory scientists use physiology/physics modeling for the US Special Forces. The US Special Forces operators are then given a table listing Active or Non-Active use and a minimum temperature for each combination of their clothing. That is similar to what I provided for you.

-

AuthorPosts

- You must be logged in to reply to this topic.

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

Our Community Posts are Moderated

Backpacking Light community posts are moderated and here to foster helpful and positive discussions about lightweight backpacking. Please be mindful of our values and boundaries and review our Community Guidelines prior to posting.

Get the Newsletter

Gear Research & Discovery Tools

- Browse our curated Gear Shop

- See the latest Gear Deals and Sales

- Our Recommendations

- Search for Gear on Sale with the Gear Finder

- Used Gear Swap

- Member Gear Reviews and BPL Gear Review Articles

- Browse by Gear Type or Brand.