Topic

Shelters and Tarps in 10D silnylon?

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

Home › Forums › Gear Forums › Gear (General) › Shelters and Tarps in 10D silnylon?

- This topic has 77 replies, 11 voices, and was last updated 1 year, 9 months ago by

Sam Farrington.

Sam Farrington.

-

AuthorPosts

-

Feb 16, 2023 at 7:29 am #3773332

I was thinking that I should define “mediocre” a bit more. We’re talking about the category of high performance fabrics that are considered very lightweight.

The 20D sil/pu silpolys and 10D sil/pu silnylons being discussed here are undoubtedly adequate for the applications being contemplated and tested in the field. In that sense, they are not mediocre at all. It is only relative to fabrics that take the performance up a notch or two that they look a little less attractive. Those fabrics, however, are far and few between and generally hard to impossible to get a hold of.

I started this thread to really focus on 10D sil/sil fabric, not sil/pu, but it’s all good.

Feb 16, 2023 at 11:18 pm #3773360Re: “The tear strength of the 10D silnylon that I have is much higher than that of the 20D sil/PU silpolys …”

Thank you Jon for your helpful replies about sil/sil. See your point, and I’ll do some hunting and hopefully come up with something helpful soon.

Feb 21, 2023 at 2:48 pm #3773805Jon, Mountain Hardware makes 15D silnylon tents that are “sil/sil,” but only one for 1P, and it seems on the heavy side. It is also similar to the Big Agnes ‘Fly Creek’ design which is not free standing and cramped. Ordinarily, a 15D fabric would excite me, but this tent is close to 2 lbs. I’ll keep looking.

Feb 21, 2023 at 3:02 pm #3773807Hey Sam, thanks, I hadn’t noticed that one. Mountain Hardwear isn’t available in Europe so it kind of fell off my radar.

I see that you must be talking about the Nimbus UL1, which is made in 15D sil/sil. The fabric sounds nice (MHW doesn’t tell much about it) but the design of that tent is not attractive at all to me.

The giveaway in terms of storm resistance is the mention of “passing showers” in the product description. I wouldn’t want to face anything more severe than that in the Nimbus. The foot area will definitely suffer major deflection in strong wind and I’d wager that the whole tent will deflect massively. It doesn’t look like there are any guyout points that connect the fly to the poles. [Edit: it looks on closer inspection like there are two guyout points that are connected to the poles]. And the number of guyouts is minimal. [Edit: from the photos, it looks like those two guyouts are the only ones on the whole tent]. Yikes. Given what you’ve said you’re looking for, this is definitely not a suitable shelter for your needs, even if it were a bit lighter. This is just a fair weather tent for the occasional mountain tourist.

It is cool that the fabric is undyed, though.

Feb 21, 2023 at 5:16 pm #3773821Jon, no arguments here. There was a poor review on the site. So I’ve ordered a Sling Fin tarp that seems to be what you have in mind: 10D, sil/sil. It should be here shortly. Did read in my internet travels that it is a bit crinkly. No matter, want to test it against the Yama and the Dutchware Xenon .1 sil for shape holding and water resistance. Then I’ll post.

P.S. Also read somewhere that a thin sil coat over a Porcher paraglider fabric can boost the water resistance without weakening the fabric; so might check that out. Might include Icarex, sold by Metropolis Drachen, a kite fabric that is polyester, and PU, but is not as strong as Porcher Skytex 32 T2 with a mini-ripstop. Progress has been slow, though, especially the long articles. When I got back as far as 2012 and there were posts on a thread related to this subject, found some posts by Dan D that surprised me. In any event, crinkly could be a problem what with noise in high winds, not to mention the bias stretch that I’m looking for, and is one of the reasons I’m not keen on DCF. Hasta la vista.

Feb 22, 2023 at 1:04 am #3773851Don’t dismiss the Slingfin fabrics. I’ve seen the tear strength and UV data and have been using the new tarp for a few months now. Crinkly and stiff, sure. But it pitches tight, stays tight, and is really strong (minimal flapping in high winds).

Feb 22, 2023 at 5:24 am #3773857Don’t dismiss the Slingfin fabrics. I’ve seen the tear strength and UV data and have been using the new tarp for a few months now. Crinkly and stiff, sure. But it pitches tight, stays tight, and is really strong (minimal flapping in high winds).

Wow, that is great news. As I mentioned at the start of this thread, I sold my TT Aeon Li as a consequence of deciding that shelters made of DCF CTE1.08 aren’t for me. To replace it, I picked up a Slingfin Splitwing and Vestibule on sale to use with a bivy for when I want the lightest possible shelter with full protection. (It was a lot easier for me in France to get the Splitwing than, say, a Yama Gear Cirriform Min).

As for “crinkly” silnylon, yes, I noticed that right away on the Splitwing. I’m very interested about that. I have a couple of things made with heavier denier silnylons (a bathtub groundsheet and a door for the MLD Cricket) that have the same “crinkly” hand and much less of the elasticity normally associated with silnylons. I don’t have any idea where that fabric is manufactured and what, if any, differences there are with the “normal” supple/elastic kind of silnylon. I’m very curious to know more, as in, does it affect tear strength and/or longevity? Obviously, the 10D sil/sil nylon that Slingfin is using tested very well in their in house testing.

Feb 22, 2023 at 7:58 am #3773861A note to not over focus on the Denier of the fabric. I know most folks here are fairly well informed on the range of differences in strength and stretch for any set size of Denier in that one 10D SilNylon/Poly/ PU one side , etc. may be great and another one that looks on paper to be about the same not so much. I recall the first time looking at a swatch + spec list of 40+ 10d-20d light fabrics from a single manufacturer listing denier, tear strength, weave density, weights, coating, + even the twist and filament count of each thread, etc. and it was baffling the lack of predictable consistency between the 40+ listed. Some 10ds were more than 2X as strong as other 10d’s that weighed the same. Some 20d’s were weaker than some 10d and 15d’s that weighed less. Some stretched like a rubber band and others not. It makes it hard for a consumer to figure out apples to apples from specs and descriptions but it’s not the mfgrs are trying to make it hard – it’s just hard, even for them. Most all tent mfgrs are doing a pretty good job at getting the best fabrics at a given weight and coating for thier tent goals. Some favor more strength over lighterweight / lighter coating and that may be about the only metric that ends up mattering for most consumers.

Feb 22, 2023 at 10:53 am #3773876A note to not over focus on the Denier of the fabric.

What should end users focus on, then?

Most all tent mfgrs are doing a pretty good job at getting the best fabrics at a given weight and coating for thier tent goals.

No doubt that’s true and for that reason most of us trust the choices mfgrs make. However, it’s not always clear what their goals really are.

Feb 22, 2023 at 1:44 pm #3773898Re denier, or ‘D’: Looked up the definitions on Google some time ago. My impression was that it is a measure of the weight of the yarn or thread that is woven into the fabric. If I got that wrong, please correct. But if I have it right, it means that it is NOT a measure of the coating weight, or tightness of weave; meaning that with the same yarn, a tighter weave would be heavier. Hence, fabric weight can vary substantially with the same denier. Years ago, I protested when one of the BPL gurus posted to the contrary by stating the denier is a good measure of the fabric weight.

All this makes me wonder why the Yama fabric, which is spec’d at 20D, weighs only 1.08 oz/sq/yd on my scales (have two scales for double checking), while fabric from retail merchants runs around 1.2-1.3 oz/sq/yd for 20D silpoly. It could mean that the coating weighs less, or heaven forbid, that the weave is not as tight, or that other things added during the weaving change the fabric weight. Go ponder.

Those are some of the factors that vary fabric weight; but there are even more factors. When Stephen Seeber posted about a plain weave silpoly at my request, he found some large variations in the strength of the fabric when purchased at a different time by a different buyer; suggesting that ‘QC’ (quality control) is a big factor in fabric variations. So is aging.

So with all these variables, what is a customer to do in selecting fabric, or a shelter based on the fabric used by the manufacturer? For DIY/MYOG, it is a matter of testing and using fabric from the same roll, and if from a different roll, retesting again. For others, it is not possible to test in the store, and very inconvenient or impossible to order a shelter, test it, and return it unused when quality is an issue. So as a practical matter we are left to the fabric manufacturer, as distinguished from the retail seller, to perform QC. And we must rely on the tent makers, as distinguished from the fabric makers who are unknown to us, to perform QC. Fortunately, we can develop a good idea from BPL posts by experienced hikers about quality; and it is evident from forum posting that this is a good way to choose sellers. Complicated of course by posts that reflect fads or inexperience. Since we face the same dilemma with all our shopping, we get plenty of practice.

Feb 23, 2023 at 12:07 am #3773938Hi Sam

So with all these variables, what is a customer to do in selecting fabric, or a shelter based on the fabric used by the manufacturer?

You could take a good magnifier plus a back-lightlight, or even a small microscope, to the shop, and actually count the threads/inch. The higher the count, the better the fabric and, probably, the better the HH.Cheers

Feb 23, 2023 at 3:09 am #3773943Roger writes:

You could take a good magnifier plus a back-lightlight, or even a small microscope, to the shop, and actually count the threads/inch. The higher the count, the better the fabric and, probably, the better the HH.

Ron writes:

I recall the first time looking at a swatch + spec list of 40+ 10d-20d light fabrics from a single manufacturer listing denier, tear strength, weave density, weights, coating, + even the twist and filament count of each thread, etc. and it was baffling the lack of predictable consistency between the 40+ listed.

Ummm, there’s a contradiction here…

Feb 23, 2023 at 3:10 am #3773944Sam

Dutchware has a silpoly with a claimed finished weight of 1.1 oz.

All best,

JonFeb 23, 2023 at 4:32 am #3773945All this makes me wonder why the Yama fabric, which is spec’d at 20D, weighs only 1.08 oz/sq/yd on my scales (have two scales for double checking), while fabric from retail merchants runs around 1.2-1.3 oz/sq/yd for 20D silpoly.

Sam,

Dutchware has a 20D silpoly that has a claimed finished weight of 1.1 oz.

Sincerely,

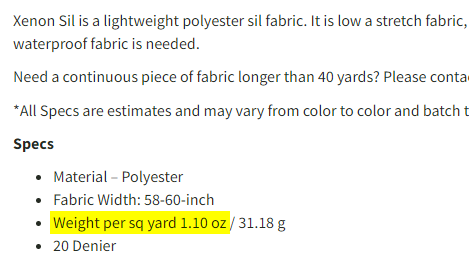

JonFeb 23, 2023 at 12:56 pm #3773979Jon: You may be referring to Xenon sil 1.1 from Dutchware, which is a polyester fabric. Over the years the fabric weight has changed, from 1.17 oz/sq/yd to 1.12 oz/sq/yd currently. The Yama silpoly, at 1.08 oz/sq/yd, as noted earlier, is very waterproof, but currently comes only in dark colors, and I’m keen on a lighter colors for a tent canopy. But found an older roll of the Xenon 1.1 fabric bought several years ago that is sufficient for a tent and is “moss” green, a lighter color that has been discontinued, and will check the weight. And there is the Sling Fin silnylon noted in your OP that I’ve ordered in a tarp and will also test. One way or another, I plan to get going with a MYOG tent project, but it has been a long slog getting there. (Roger, please do not roll your eyes, and thanks for the post about thread count.) Jon, thanks again for this thread, which has been very helpful. Hope you find what you are looking for in the 10D. When a fabric has been chosen, I’ll post on this thread with the trade-offs and reasons for the choice.

Feb 23, 2023 at 2:01 pm #3773985Hey Sam, where or when did you see that it was 1.12 osy? I haven’t been watching Dutch’s website closely but the current specs for Xenon Sil 1.1 list a weight of 1.10 . But none of the current colors are light. Good luck on your search. I’ll definitely be interested in what you end up with.

Feb 23, 2023 at 2:08 pm #3773986On a journey of a hundred miles, ninety is but half way.

-Chinese Proverb(Which is clearly a fib, because the ancient Chinese did not use ‘miles’.)

Feb 23, 2023 at 2:17 pm #3773987The Xenon 1.1 I got from Dutch weighs 1.25 oz per sq yd on a very accurate scale. The Xenon Wide weighs 1.18 oz and is a different material than the Xenon 1.1. Dutch claim’s it’s better and supposedly has an HH of 4000 mm, but I’ve only tested it in the field. I made a 70″ X 108″ flat tarp out of the Xenon Wide.

Feb 23, 2023 at 2:23 pm #3773991The Xenon 1.1 I got from Dutch weighs 1.25 oz per sq yd on a very accurate scale.

Whoa. That’s more than just a margin of error.

Here’s a screen cap from Dutch’s site:

Feb 23, 2023 at 2:28 pm #3773993

Feb 23, 2023 at 2:28 pm #3773993Yea I love Dutch and I buy a lot of supplies from him but he is a smooth talker. The Xenon .9 weighs .93 oz as stated.

Feb 23, 2023 at 2:35 pm #37739941.25 osy is about 42 gsm. The 30D silpoly from ExtremTextil weighs 45gsm. I don’t have the actual weight right at my fingertips but from memory I’m pretty sure that it is very close to the stated weight. And it blows Xenon Sil 1.1 outta the water on every point but cost.

I confess that I have a thing for awesome fabrics.

Feb 25, 2023 at 11:15 pm #3774254Jon; The Dutchware Xenon 1.1 that I bought several years ago weighs 1.12 oz/sq/yd finished in the moss green color. That is using My Weigh scales. I think there are a variety of factors that result in weight variations, including color, coating process etc. So the weights can vary from roll to toll. However, my notes indicate that there was some leakage at high pressure; so I’ll have to retest any of the fabric being used.

As for the colors, I called Dutchware this month and was advised that they have discontinued the moss green color.

On a related note, I received the Sling Fin tarp, and it is indeed crinkly. There is little or no flex in the fabric in any direction. This is not consistent with a silicone coating; so the first thing I’ll do is see how dabs of silicone and PU sealants adhere to it. Even if it is silcoated, the crinkling is barely acceptable to me; but more importantly, my tent design requires some elasticity in the bias stretch in order to enable the sides of the tent to form a convex shape over the pole framework, as distinguished from a slightly concave shape in an A-frame, for example.

I looked at the TarpTent site, and their 20D silpoly is spec’d at 1.4 oz/sq/yd, and that is heavier than the spec’d weight of either the Extrem Textil 30D silpoly or the RBTR 20D silpoly. The differences of a few tenths of an ounce per sq. yard may be acceptable for many; however I’m trying to shave weight wherever possible to keep the design competitive with DCF weights. This includes the weights of everything that goes into the tent, including poles, shockcord, elbows, stakes, zippers, buckles, inners, floor, fittings, bug netting, etc., all with materials that will withstand severe weather.

Speaking of DCF, TarpTent, which produces tents using both DCF and woven tent materials, has some helpful comments in its site about the merits of DCF.

Feb 26, 2023 at 7:38 am #3774267Is the Dutch Xenon sil/sil?

Feb 26, 2023 at 7:59 am #3774268I looked at the TarpTent site, and their 20D silpoly is spec’d at 1.4 oz/sq/yd, and that is heavier than the spec’d weight of either the Extrem Textil 30D silpoly or the RBTR 20D silpoly.

Well, I checked. The measured weight of the 30D silpoly from ET is 1.42 osy, so not any different, actually.

In terms of the 10D silnylon fabric used by Slingfin, there’s no surprise there. Everybody tells the same story:

There is little or no flex in the fabric in any direction. This is not consistent with a silicone coating; so the first thing I’ll do is see how dabs of silicone and PU sealants adhere to it. This is not consistent with a silicone coating

As mentioned above, I have other sil/sil coated silnylons that are the same (crinkly and not so elastic). It is impossible that Tim Hunt at Slingfin would lie about the composition of the coatings on this fabric. So, you will have to revise your idea of what a siliconized coating is like, much as Ron Bell suggested earlier in this thread.

In short, your expectations of what you expect to find in terms of fabric are unrealistic, IMHO.

If cost were no object, I think that you should buy one or two Voss 5 ULW tarps from Nordisk in their superlative 10D sil/sil nylon and cannibilize the fabric for your tent. If you look around, you can find them on sale and you won’t have to pay the VAT. But it won’t meet your criteria for color, since it is dark forest green.

Feb 26, 2023 at 4:33 pm #3774315Jon: The Extrem Textil site shows their 30D silpoly weight as 45 gsm (grams per square meter). The multiplier to convert gsm to ounces per square yard is .0295, showing an equivalent weight in ounces per sq. yard of 1.3275.

Thank you for introducing me to the 10D silpoly. A portion of the fabric in the Sling Fin tarp was tightened in an embroidery hoop and placed outside under a deck yesterday, and after 4-5″ of snow was checked today. It was no longer taut in the hoop, much like the nylon paraglider fabric from Porcher was after exposure to an increase in humidity. However, I will retighten it and check again after another increase in humidity.

It does raise a concern, though, that the net effect of the inelasticity, along with the inability to hold its shape, does not bode well for use in a tent canopy in stormy weather. You are welcome to it, and I’ll roll it back up and send it along to you if you like, Just PM me a mailing address.

Sorry that I could not be more helpful.

-

AuthorPosts

- You must be logged in to reply to this topic.

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

Our Community Posts are Moderated

Backpacking Light community posts are moderated and here to foster helpful and positive discussions about lightweight backpacking. Please be mindful of our values and boundaries and review our Community Guidelines prior to posting.

Get the Newsletter

Gear Research & Discovery Tools

- Browse our curated Gear Shop

- See the latest Gear Deals and Sales

- Our Recommendations

- Search for Gear on Sale with the Gear Finder

- Used Gear Swap

- Member Gear Reviews and BPL Gear Review Articles

- Browse by Gear Type or Brand.