Topic

Quilt Baffles – Tapering

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

Home › Forums › Gear Forums › Make Your Own Gear › Quilt Baffles – Tapering

- This topic has 38 replies, 9 voices, and was last updated 3 years, 2 months ago by

Michael B.

Michael B.

-

AuthorPosts

-

Dec 22, 2020 at 2:50 pm #3690281

I’ve been reading up on baffle design since I am keen to add down quilts to my skill set. I am set on doing horizontal baffling and really like the Western Mountaineering NanoLite design, from an aesthetic standpoint mostly, and I figure they know what they’re doing, sizing/design wise.

My question; I was thinking it might be interesting, in an effort to keep the down in the places it is most important, that being mostly on top, that I might taper the baffle height from 3” down to 2” as the baffles extend to the edge of the quilt. It makes sense to me that since heat rises, the down would be more important on top (like attic insulation in a house) and a little thinner on the sides (like the wall insulation on a house) without a degradation of performance/perceivable heat loss. This would allow for less fill needed overall, while the shaping would encourage down to stay where I want it. I searched around but haven’t seen anyone asking about this aspect of baffle design.

If this has been discussed and you know a link, or can think of some pros/cons, I’d appreciate the inputs.

Dec 22, 2020 at 5:37 pm #3690303Makes sense to me. Another option for this kind of thing, particularly if doing vertical baffels, is to do the final baffle sewn through as this is basically underneath you anyway when you are really hunkered down (legit manufacturers like PHD have been doing sewn through bases in their superlight sleeping bags in recent times….for bags down to about freezing).

I made a synthetic 5oz apex quilt a few years ago, and I deliberately, carefully cut off some layers from the 5oz apex for a few inches along the edge. Not sure how much weight I actually saved but the total quilt weight was just over 140z. While the quilt ended up being a couple of inches too short for me (oops), I certainly did not not notice the reduced insulation at those edges. Its a very warm quilt at or just below freezing temps I tried it in.

Dec 22, 2020 at 5:45 pm #3690305You could try it. I dont think anyone has really considered it yet mainly because baffle height and loft gets compressed when tucked around you during use anyway. The idea is to keep as much loft between you and the outside air to retain heat and help prevent drafts. I would think less available loft toward the outside of the quilt would be prone to more draft depending on temperature and when you start the taper.

Keep in mind the baffle will have an accordion effect naturally when sewn to create the outer (vertical) seam. Also as long as your calculations are correct on the down, you won’t have much migration anyway.

If down migration is your biggest concern, and you’re hesitant on your calculations, you may want to consider vertical baffles for your upper body. Just my 2 cents.

Good luck with your project.

Dec 22, 2020 at 6:27 pm #3690312I am not really “concerned” I am just looking to see if my relatively novel solution to lower the weight, increase loft reliably in the most important places, reduce unnecessary fill in places where it is not going to work for me, and reduce my pack volume might have any major drawbacks that anyone encountered.

I potentially see issues if there is an amazing amount of wind blowing through my shelter, that a thinner layer of insulation on the sides might be detrimental from a convection heat transfer standpoint. I’m using Membrane 15 poly on the outside and Membrane 10 taffeta on the inside. A nominal 2” fill in the size I am looking to make yields an estimated finished weight of 12.8oz (8oz fill of 900 FP). I will likely overstuff, but I am thinking a taper will simulate an overstuff in all the correct places without actually having to overstuff.

Dec 22, 2020 at 11:45 pm #3690356I agree it makes sense. I’ve made a few quilts. One with vertical baffles, several with horizontal baffles including one differential cut quilt. I considered a tapered baffle design but didn’t follow through partly because of the added complexity and partly because I don’t need another quilt.

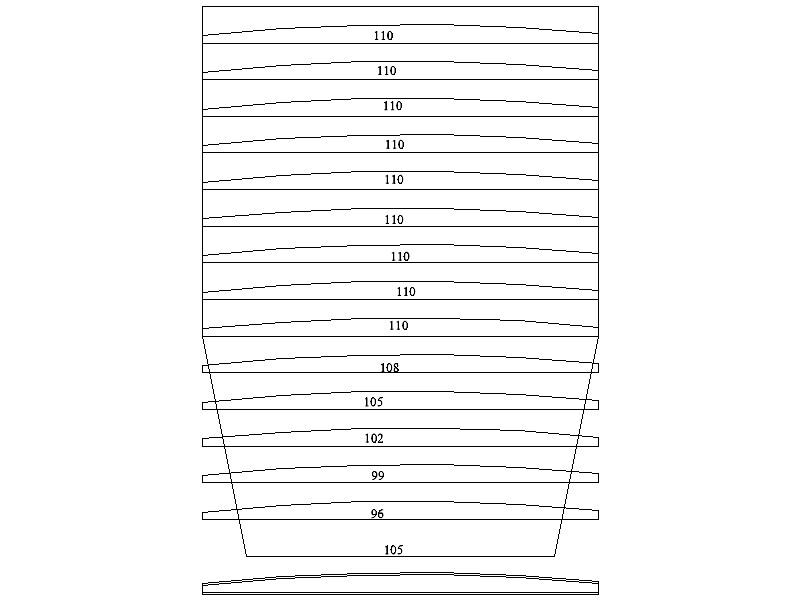

Here is a preliminary sketch of what I was considering:

The baffle heights are 2.5″ tapering down to 1″. A bit extreme compared to your proposal. (The numbers are square inches of baffle for computing volume).

Good luck.

Dec 23, 2020 at 5:01 am #3690361I believe you will have a slight effect, as in VERY SLIGHT. The convectional losses over the approximately 12″ (~30cm) are not that huge. IFF you have a “square” system you can see that it would not help more that peripherally. If you approximate a person sleeping, mostly the side panels resemble a blend between well insulated top and low insulated side. Down is relatively light for it’s insulating value and the material saved would be minimal, so you might save about a half ounce (~14gm) to an ounce in overall weight with a loss of about 2 degreesF (~1C.)

Hmmm, I did that wrong, you actually have to solve for multivariable problem between existing temp, materials and taper to get something close…I forgot the taper and was just figuring the heat loss (a straight baffle.) Anyway, you get the idea.

Dec 23, 2020 at 8:35 am #3690376No, that is exactly what I was thinking, except it looks like you curved the profile, whereas I would just cut it as a strait slope, with a constant thickness across the top. I started doing the volume calculations last night, but didn’t get as far as you did yet.

Dec 23, 2020 at 11:40 pm #3690652Regarding heat loss due to convection, am I right in understanding you don’t believe it (the tapering) will be a big issue?

Is there a big component of heat loss due to conduction in this system? I am guessing no, because once a body touches the liner and conducts that heat into the liner, the air trapped in the down is then the main component responsible for transferring the heat away from the liner via convection, which will then primarily be vertically and not radially away from the body, unless by forced conversion via breezes. Does this seem like sound logic?I am a little less concerned about weight loss than I am about optimizing the use of the materials. I think the line of logic could be applied to thicker heavier quilts/bags as well, and maybe it is not done for manufacturability reasons…

Dec 24, 2020 at 9:10 am #3690690“Regarding heat loss due to convection…” No, it isn’t an issue. Technically, a taper could calculated from 0 to maximum(thickness) that would describe your base system. The idea definitely has merit! But, the weight savings would be slight. Big Agness did something similar with their pad pockets, then tapering the baffles up to a maximum height. But, BA implemented things rather crudely resulting in no weight savings, in fact, a rather heavy bag. Continuing on with a rather difficult setup and the second rate down resulted in a sleeping bag that was not worth the carry. Using good 7D or 10D nylon shells and UL mesh baffles and light zippers with zipper baffle, a shoulder baffle and elastic tie off, hood, etc, you will end up with a nice bag. But, only by using the best materials all around will it be worth the carry. Soo, you can go through a LOT of effort in calculations, design, sewing & stuffing and not gain any advantage, overall … well, except a new bag, of course.

“…Does this seem like sound logic?” YES. What down does inside a baffle is something like a conversion from conduction to convection. Convection is nothing more than conduction, anyway…but usually reserved for gas/liquid energy flows where fluid dynamics can contend with the additional variables, so to speak. There is no such thing as convection except as a convenience/simplification for speaking/calculations.

“I am a little less concerned about weight loss than I am about optimizing the use of the materials.” Perhaps, only with mass production would any material resources be saved. None of the shell materials would be, and only around 5-10% of netting. So, materials would be a wash within 1/2 a buck or so. On a $400 bag, this is like .125%. Down would be about .25%. (As far as weight, I believe it would track about the same in percentage. As above we assume that a 0 fill amount to a max fill amount would define the base taper. Everything else would be the same, roughly speaking…heat transfers are not exactly linear, considering convection.)

OK, some offhand thoughts on utility. 1) I am not sure how to judge the utility of anything we take backpacking without defining a weight. Task accomplishment, weight, multitasking usefulness, redundancy(backup), … Weight is a critical component of all packing else we would all carry a 50lb (~22.5kg) base pack and be done with it. 2) For a quilt, I believe this concept is fairly wasted though I could be wrong. On cold nights, I tuck the edges of the quilt under me and bunch up the baffles over me. This results in a similar effect as a tapered baffle: tight at the bottom, loose at the top. 3) I personally would NOT spend extra dollars on a bag or quilt made with this feature 4) The approximately 3/4% of material savings would not justify the extra complexity of cutting and sewing these for a half to one ounce savings on a 40oz bag. It is much more difficult to cut/sew a curve than a straight line. (Ideally, it should be a doubled half curve.) 5) On the plus side, the design is ultra efficient. The next time I make a bag, I would like to incorporate this, however, I am getting old and somehow I think the equipment I have will likely last longer then me.

Dec 24, 2020 at 9:42 am #3690696Thanks for the thoughts. so I did some math last night.

The textile weight for my quilt will come in at 4.8oz. I’ll likely increase that to 6ish with the addition of a shock cord and a couple doodads. I agree with your assessment of textile weight, it is basically the same regardless of baffle designI looked at the option of constant 2” loft baffles. This resulted in approx. 6900 cuin. of down, and I can pick my flavor of FP to determine down weight- it ends up being around 8oz+/-. I also looked into a taper profile which puts a constant 2.5” loft across the center 24” width of the quilt, then tapering down to .5” at the edges, as you say it seems to be what happens anyway. This baffle design actually increased my volume to about 7300 cuin, so not a weight loss, but a very small weight penalty for a solid increase in loft at the top portion of the quilt. Is it worth the trade? I would say yes, and think it will serve me better than a simple 2” baffle design. Using straight cuts to achieve the taper will not result in a lot of extra work (I think). I am also curious of the compressed volume – I assume the reduced compressed volume using 900FP vs 850FP is minimal and varies directly with the total weight of the down.

my incomplete math failed to account for the additional volume of down needed in the footbox plug, but that will not be tapered, so it will be the same regardless of the baffle design. Just need to remember to add it to my estimates. The textile weight does however account for the weight of the plug material, so that’s good.

If I end up with a 13-14oz quilt with a good thick layer of down at the top and minimal compression effects on the sides, I feel the extra work is worth it.

Dec 24, 2020 at 11:41 am #3690705Yeah, you can fudge the numbers any way you like them. I far prefer a 20F quilt. Ideally for me, it is 56″ wide, 84″ long and 41″ wide at the footbox. A 14oz 20F quilt at my dimensions would really be nice, but I do not think it is possible using today’s materials.

You can make a 35F quilt at 48″x72″/30″ footbox at 14oz. Good luck! It would be too small to use for me.

Dec 24, 2020 at 12:00 pm #3690710The dimensions I have been using for my calcs are 72”L x 56”/40” simple taper, with a sewn footbox (approx 13”diameter plug). This has been more than sufficient sizing for me (6’1”) but realize sizing is very much a personal preference.

How much loft do you associate with your temp ratings? I was comparing with the NanoLight (1.75” loft per side, 38F) and the AstraLite (2.25” loft per side, 26F), figuring they are pretty reasonable. The weights are in the ballpark too. Their quilts are tapered wider at the top (68”), narrower at the bottom (38”), but I am going to use a little heavier fabric, so figure that is a wash.

Dec 24, 2020 at 2:12 pm #3690729What a clever idea!

For another data point, my only down quilt weighs 14 ounces, 9 of which is 850 fill power “Hyperdry” down. It has a 50″ torso width and tapers below the knees to a 39″ footbox circumference with sewn plug. The shell and liner are 0.66oz membrane nylon, and the bottom and end plug of the sewn footbox is 1.1oz silnylon. I used 2″ high karo-style baffles about 12″ on center. Loft is about 3″

It’s marginally wide enough: fine when I’m on my back, just barely enough to tuck under me when I lie on my side (I’m 5′ 8″ and 130lbs). I’ve considered adding fabric draft flaps.

I am not impressed with the down control and added a sewn through longitudinal channel on each side to help prevent the down from settling to the sides. Your tapered baffle height should help prevent that.

I don’t know what temperatures I’ve slept in it, but it was warm enough at 10,000(?) feet on Mt. Rainier in the summer.

If I make another, I would probably use longitudinal baffles and maybe incorporate your idea of different baffle heights on the side channels. I’d also make it maybe 54″ wide.

I look forward to hearing about your progress.

Dec 24, 2020 at 2:31 pm #3690734@Bob

Thanks for sharing your experience.I have read some of the reasons for using horizontal and longitudinal baffles, but honestly, I like the look and simplicity of the horizontal ones, and admit it is more of a factor for me than it probably should be :)

My current synthetic quilt is approx 52” max width at the top and 33” at the bottom, 76” long, with Apex 5.0 filling. Honestly, I don’t NEED to replace it, it has worked fine in all the places I have camped – I am a late summer to late fall California hiker – but it is just a little bulkier than I prefer in the pack, especially since I have to carry a bear can in most of the places I like to go.

I figured this idea would be a low-risk way to scratch my itch to add down quilts to my skill set and try something that, to me at least, seems a little more innovative than just copying a design (which, I admit, I am still taking a lot of cues from bags I’d love to own but am too cheap to just go buy;also my wife would NOT be happy :) ).I am still needing to purchase the down, but will document my build as I get it done, thanks for your interest.

Dec 24, 2020 at 2:32 pm #3690735 Dec 24, 2020 at 7:59 pm #3690767

Dec 24, 2020 at 7:59 pm #3690767Michael, I never bothered to measure it for loft. I would guess about 5″ or so. It is fairly warm down to about 25F, marginal down to about20F (long johns/knee socks only) and needs help down to about 10F.

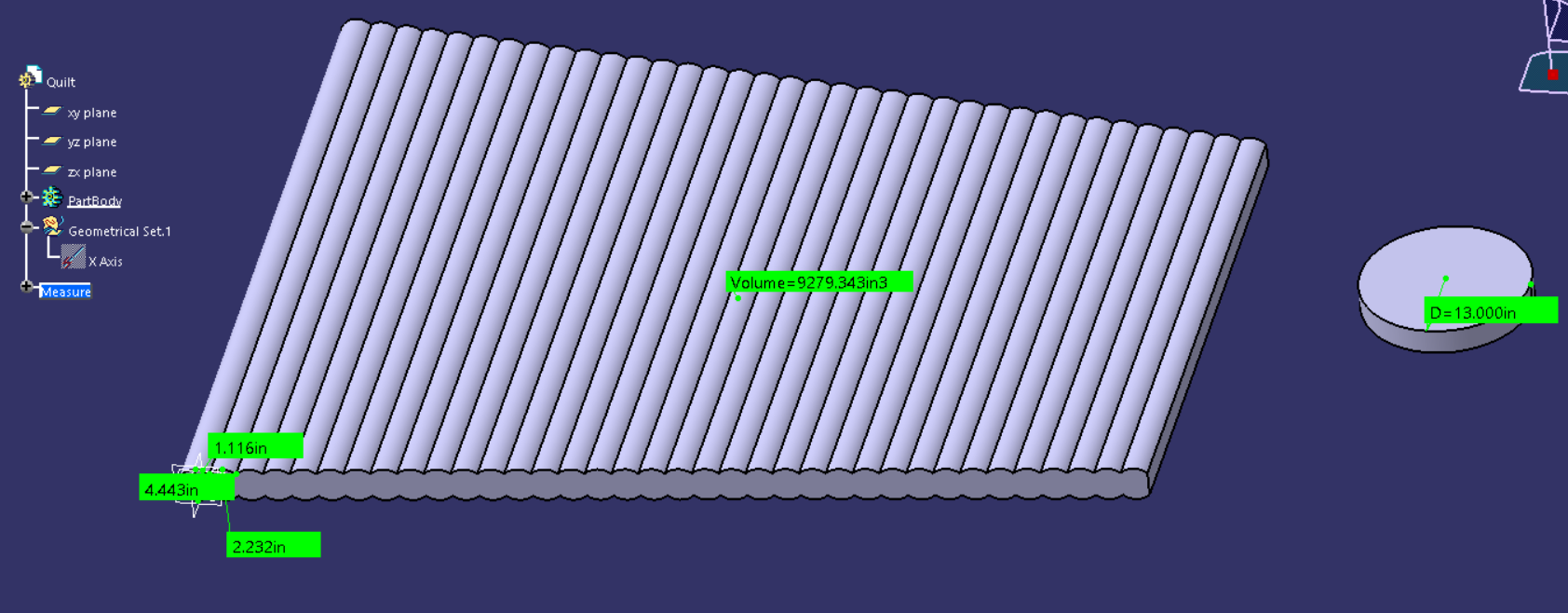

Jan 14, 2021 at 3:05 pm #3693797I just received my down for this project. Looking forward to building it – I am 3D modeling it to get more accurate volumes and material weight estimates. Planning for a nominal 2″ baffle height – tapering to .5″ at the sides. I’ll start the linear taper at about 18″ out from the centerline, so about 10″ of total length of taper on each side. That, combined with a 2″ baffle spacing (36 baffles in total) should keep the down exactly where I want it with minimal shifting.

Customer service from Loose Goose was excellent, just to give them a shout out. Down arrived within a week. I plan about 10-11oz fill total. This should put me in the 2.5-2.8″ loft range depending how well the 850 fills the space. Wish me luck, ha.

Jan 14, 2021 at 5:54 pm #3693824

Jan 14, 2021 at 5:54 pm #3693824Good Luck Michael!

Jan 16, 2021 at 6:43 pm #3694177

Main shell and liner cut. Not the lightest fabrics, Membrane 15 poly shell and Membrane 10 taffeta nylon lining, 4.9oz accounted for so far. Baffles next, and then footbox capping shell and liner. Not sure if I want to do simple circles or a more rounded square or something in between.Jan 17, 2021 at 10:13 am #3694214I have a feeling this will be a lot of effort for marginal if any gains, but I certainly could be wrong. But that’s the great thing about MYOG; you can put in as much effort on one aspect as you want to achieve a design criteria!

I’ve sewn many quilts, and in a lot of ways getting the baffles right has been the hardest part. The baffle material will stretch a lot more than the material you’re sewing it to, and since you MUST sew with the baffle on top to see where the stitch goes it’s made worse by presser foot drag. I’ve got an industrial needle feed machine which helps, so it’s even more difficult on standard feed home machines. So if you pre-cut the baffles to the same length as the material you’re sewing to, when you get to the end of the seam you’re likely to end up with more baffle hanging over the edge.

If you make the baffles two dimensional like you are proposing, you will need to take extra care when sewing that they don’t shift length-wise as you go. I guess what most people do is pin the hell out of them, then sew. That will be VERY time consuming for all those baffles because you’ll probably have to do it on both sides, shell and liner.

One way you might think of doing it is this; Start out with standard-width pre-cut baffle material and sew it to one side, liner or shell. Start out with a longer strip than you need so you don’t have to worry too much about matching the lengths. Once they are attached to one side of your fabric, mark them with the taper you want, then use those marks when sewing to the second side. Or trim them with the taper you want once they are on one side of the fabric before sewing to the second side. And when you do sew to the second side, either pin or make marks along the seam line so you can match up 1/4, 1/2, and 3/4 points in the length of the seam on both shell and liner.

@James Marco:There is no such thing as convection except as a convenience/simplification for speaking/calculations

On the face of it, this statement disagrees with standard thermodynamic principles. Before the physicist in me gets all indignant, care to explain what you mean a little more?

Jan 17, 2021 at 10:20 am #3694215I make the baffles wider/more loft around my torso, less on the foot end of the quilt

That’s easier to construct

There’s less surface area and lower skin temperature on my foot half, so the insulation produces less heat loss. I often pull my legs up towards me which makes it even more so.

Jan 17, 2021 at 10:27 am #3694220Asymmetric sewn through baffles are much easier to construct. Lessens those problems of stretch and dragging on the pressure foot. Provides the same warmth as regular baffles. There’s only one seam per baffle rather than two, no separate strips of fabric for the baffles. After the garment is sewn, if a seam starts to fail, you can just go back and re-sew it. I’ve been doing this for years.

One foot square test piece:

There is a small air gap with no down, but when there’s something facing it, like a jacket, then any internal convection is minimal.

Somebody said they were going to try this. It’s possible it’s just a crazy idea that just works for me : )

Jan 17, 2021 at 2:17 pm #3694258Craig, “convection” is a tern to describe more complicated physics of heat transfer in a media, either liquid or gaseous. Everything about it can be described through normal physical measurements. For example the size of an atom increases with absorption of energy, hence decreasing average density soo, it appears that heat rises. It is just more energetic molecules displacing less energetic molecules in a gravitational field. Without gravity, there would be no convection. You can calculate the equivalencies for the thermodynamics WITHOUT convection by replacing it with various conduction, density, molecular movement, etc calculations. Convection a convenience, only.

Jan 17, 2021 at 2:24 pm #3694260thanks for the suggestions. I am making two quilts, one with and one without taper – as you say, there may be minimal to no gain for the added work. That indeed is the fun of making your own stuff though. It is just time. I indeed cut baffles which are extra length, and will attach them to the one side first, then trim after so the taper is in the correct spot. This is not first rodeo with .5 Noseeum 😁.

if they both turn out awesome, I’ll sell one to recoup my material costs. I am sure there is a market for a nice sub-18oz 30F quilt here – I’ve sold a couple synthetic ones, and this is much nicer material and will be lighter and more compressible. It looks like with the fill I am shooting for, 17-18oz seems reasonable, whether that be a tapered baffle quilt, or one with straight baffles. I was hoping for a little lighter, but you as James convinced me, better to be a little heavier and guarantee the down will perform than to underfill.

Also, I think the point James was making was the relatively minor effect of convection in context of total heat loss. It may be I misunderstood, but that was how I read it.

keeping this round of quilts with the same baffle shape/sizing top to bottom, since I do not have a good handle on my own thermal body mapping preferences yet.

Jan 20, 2021 at 11:32 pm #3694844Doing work. Baffles are tedious, and clear tape is hard to see- starting to use matte tape so I don’t accidentally sew through it. Got 5 baffles done, and learning with each one.

My 3” baffle spacing tool shown. Ensures reasonable straightness.

-

AuthorPosts

- You must be logged in to reply to this topic.

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

Our Community Posts are Moderated

Backpacking Light community posts are moderated and here to foster helpful and positive discussions about lightweight backpacking. Please be mindful of our values and boundaries and review our Community Guidelines prior to posting.

Get the Newsletter

Gear Research & Discovery Tools

- Browse our curated Gear Shop

- See the latest Gear Deals and Sales

- Our Recommendations

- Search for Gear on Sale with the Gear Finder

- Used Gear Swap

- Member Gear Reviews and BPL Gear Review Articles

- Browse by Gear Type or Brand.