Topic

Pots With Heat Exchangers

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

Home › Forums › Gear Forums › Gear (General) › Pots With Heat Exchangers

- This topic has 295 replies, 3 voices, and was last updated 8 months, 2 weeks ago by

DAN-Y.

DAN-Y.

-

AuthorPosts

-

Jan 27, 2018 at 11:55 pm #3514856

Jon, I’m not sure we are talking about the same application. I use a diffuser similar than what you describe earlier (i.e bottom of a tomato can with some holes punched in) on gas canister stoves to spread a narrow flame. For that I would think something with good thermal conductivity is welcome. For a reducer, like the application I showed in my earlier posts you what to reduce the output of an alcohol stove by reducing the opening (less oxigen going in), the added bonus of using a Ti reducer (as opposed to any other metalic reducer) in this application is that it also helps to reduce stove overheating / thermal feedback.

Jan 28, 2018 at 1:06 am #3514874This thread is about heat exchangers. These metal plates you are putting onto the aluminum burner are exchanging heat from thermal feedback onto the burner. The plates are heating up because the flame front is touching the plates. The plates are heating up to high temperatures and transferring it to the burner. Why cant you guys see that! The carbon felt is what you want to use as an insulator/reflector. Make several felt reducers and discard them once the hole shrinks. Use the KISS principle.

Jan 28, 2018 at 1:30 am #3514876Sorry about the thread drift Dan. This things sometimes happen when we get excited to share what we think may be helpful to others, but I agree there are better ways to do that. Heat exchangers… Carry on.

Jan 28, 2018 at 3:09 am #3514893The drift is ok but think about what I said concerning the metal reducer being used. It’s exchanging heat back to your burner causing it to consume fuel faster. The felt has to be underneath it.

One of your Starlytes looks as if carbon felt has been used to snuff it out, causing the blockage. It’s sticking to the hot stainless. In one photo, I can see the discoloration on the edge of the burner caused by the felt decomposing.

Jan 28, 2018 at 12:28 pm #3514925Dan, heat exchangers only help heating by capturing excess heat otherwise wasted. They can cut down boil times a bit, but are not all that efficient. With low heat, they perform no better than a normal grease pot. Around 8-10 years ago I did all the measurements on these and came up with the same numbers as you have. My best was around 3/8oz of SLX fuel to boil two cups water at around 40F to start and an ambient of 68F with or without a heat exchanger. I was actually testing efficiency of heat exchangers, like you were, and found their overall efficiency dropped off quicker with less heat applied than a regular pot. With small amounts of heat (alky stoves) they were indistinguishable from non heat exchanger pots. This was after some 1000 test burns, with 5 burns averaged per test. Time to boil ranged between 4min and 15min. I set my “boil” at 210F because water boils at just under 211F here (altitude.) Heat feedback was never a problem. Typically, the heat shield allowed sufficient air for complete combustion, soo the stove never really got too hot and flared. All alky stoves burn pretty much the same. One tweak that helped a bit was simply to use ethanol picked up from Cornell’s lab where I worked. Ethanol has a higher specific heat than SLX (~12800BTU vs 9800BTU.)

One thing I did find out that pot turbulence along the bottom acts as a type of heat exchanger with no additional weight. A series of 9 concentric rings about 1/4″ deep and about 1/2″ wide was embedded into the grease pot. This accounted for about a 10-15% increase at low heats, but only accounts for about a 3% increase in surface area, unlike a ribbon type heat exchanger. I assumed the increase was from three sources: 1) turbulence (as I mentioned, 2) A Fresnel type lens effect of the IR radiation with respect to heat transfer, and, 3) a slight thinning of the pot bottom material.

Anyway, I added insulation blankets and got truly unbelievable results but it weighed a LOT. Since this was for backpacking, I rejected it. But Aerogel may solve the weight problem. With respect to your stoves suffering from heat feedback, a small disk of this material may solve this problem. It can easily withstand the heat of a propane blowtorch unlike carbon felt.

Jan 29, 2018 at 8:40 pm #3515486James M.

1000 test burns @ 5 burns per test = 200 tests

If you did 10 test burns per day that comes out to 100 days of testing. 20 tests per day = 50 days of testing. You are worse off than me :-)))

Do you have a blog or website where you shared your findings as your testing progressed? Any photos of the grease pot showing “A series of 9 concentric rings about 1/4″ deep and about 1/2″ wide was embedded into the grease pot.”?

I’ve experimented with Aerogel, it smells bad when subjected to flames and is flaky at the cut edges. Good insulation but not something to be handled often.

Jan 29, 2018 at 9:24 pm #3515501Dan, yeah, well I actually took about a year doing this. I was semi-retired at the time and only working half days at the school, when I wasn’t out hiking. I had a web site but I lost it when Road Runner closed it down…a while ago…along with most of the test data. Pissed me off…

I put a couple pics of the pot up on this forum. ‘Corse, this was likely 6 years ago or so. Anyway, I created a form, tapped the bottom into it and smoothed it with a rounded tool (a modified SS spoon.) I have had that pot around for a while, since I did the experiments. I still use it.

Duct tape smells bad! I never worked with aerogel, but the pics were impressive. I realize some form of ti foil was needed to support it.

Jan 30, 2018 at 3:57 am #3515585Well James, it just shows ta go ya, saving online data with printouts is prudent. (Of course I have 20/20 hindsight.)

Jan 30, 2018 at 8:26 am #3515618I had a web site but I lost it when Road Runner closed it down…a while ago…along with most of the test data.

Hopefully the lesson has been learnt.ALL my data and designs and articles are primarily stored on MY system. The BPL web site and My FAQ are strictly secondary.

I run a backup every night and everything is backed up to two different master folders in a physically-separate hard disk. Once a week or so I repeat this backup onto a USB disk drive which is stored OFF-line. I have two of these and alternate. That makes a total of SIX separate backups on three different disk drives. Every now and then I use one of them too.

Cheers

The paranoidJan 30, 2018 at 12:33 pm #3515626Yeah, I lost a lot of stuff, not only the web site. My SCSI drives were up over a gig and backed each other up. Turns out I didn’t allow for the controller. It scrambled all my data in use. Every byte was simply added as random data all over the disks… Since I left it on all the time, well after a month or so, it was pretty bad. Windows never said a word since none of the data was reread, I was using an EIDE for the boot and another as the swap. Even backups are not that great…mostly, it was woodworking data, pics, tables, etc. Anyway, I have a couple 3-terrabyte drives (well 2.3 formatted) I hook up to my laptop. I add them in sequence when I get around to it… Used to cut and paste from word into this site. But, it lost importance. Most tricks for backpacking are well known.

Anyway, holding heat in, heating the water are the most efficient for alky. Alky burns about the same whatever style of stove you use. Heat exchangers only speed heating, but you pay the penalty in loss of efficiency and higher heats needed…around 5/8oz hill get you about a ~4min boil. This is close to canister gas on full open. So for camping I use whatever is best. Short trips: alky, up to 1 8oz can: cannister, long trips: WG with the ability to use car fuel. This hasn’t changed much in many years. Only Roger’s stoves has increased the temp range for canister use spring and fall.

Jan 30, 2018 at 3:49 pm #3515647James Marco wrote: (emphasis added)

Dan, heat exchangers only help heating by capturing excess heat otherwise wasted. They can cut down boil times a bit, but are not all that efficient. With low heat, they perform no better than a normal grease pot.

But James, you come back and contradict what you said by telling us:

One thing I did find out that pot turbulence along the bottom acts as a type of heat exchanger with no additional weight. A series of 9 concentric rings about 1/4″ deep and about 1/2″ wide was embedded into the grease pot. This accounted for about a 10-15% increase at low heats, but only accounts for about a 3% increase in surface area, unlike a ribbon type heat exchanger.

Jan 30, 2018 at 8:38 pm #3515698Dan, like I say, it is mostly the turbulence in the otherwise smooth flow of heat. Some is accounted for by the thinning but this is slight. The Fresnel lens effect may or may not be helping…problematical. Anyway, it did help overall efficiency but, again, with low simmer type heats it converges rapidly with regular grease pans at 12-15min boils. Again, this led me to believe that heat exchangers do nothing for overall fuel efficiency (oz/boil.) Something around 3/8oz per two cups boiled (210F) from 40F ambient was close enough. That is real close to the limit of heating that remains productive. (I realized that Productive Heating depends on heat losses in the system.) So, rather than decreasing the heat and increasing the heat absorption, I switched to working with insulation blankets to hold the heat in. But the added weight for the blankets was around 6-12oz depending…not worth the weight with a 3-1/4oz/1qt pot…but, I never tried aerogel. Of course, the time to boil dropped to around 4min with 3/8oz fuel with fiberglass blankets.

Jan 30, 2018 at 9:02 pm #3515702FWIW, I feel the sides of a pot way down inside of a Caldera Cone are sort of a “heat exchanger” in that they get heat that would otherwise miss the sides.

Even with the fact that a pot on a ti cone (like the Sidewinder or Tri-Ti) sits higher on two ti stake/rods when in wood burning mode it still sits down into the cone at least one inch, thus gaining some extra “side heat”. This is where the Canadian Bush Buddy loses a lot of heat with the pot sitting up on top of the stove.

The never-ending quest for cooking heat efficiency goes on. I still await “de-tuned solid rocket fuel” to replace ESBIT as a solid fuel. :o) Hopefully it will burn cleaner than ESBIT. I think a special ti fuel tab burner will be needed and who knows, maybe it will even be ADJUSTABLE?? Dare we hope?

Jan 30, 2018 at 10:33 pm #3515729Eric, I’ll have modified Ti BGET’s (Brian Green Esbit Tray) modified meaning it will have the bread pan corners to prevent loss of liquefied esbit. For sure you’ll be able to burn “de-tuned solid rocket fuel” when it becomes available. Use it inside a Caldera Cone or any other preferred set-up.

This is what it looks like attached to a Ti pot support:

Jan 30, 2018 at 10:57 pm #3515734

Jan 30, 2018 at 10:57 pm #3515734I still await “de-tuned solid rocket fuel” to replace ESBIT as a solid fuel.

Oooh – caramel candy!

Apologies to those who have never played amateur rocketry.Cheers

Jan 31, 2018 at 1:20 am #3515758Dan,

I “need” that BGET of yours. Hope it’s for sale.

My most recent solution was to wedge a tray into my original Gramcracker holder.

Jan 31, 2018 at 1:43 am #3515761Dan,

I “need” that BGET of yours. Hope it’s for sale.I won’t have access to them till April….unless I can get my daughter to search my garage to find them. I’m off on a holiday :-) I’ll email her a photo of them and see what she says.

Jan 31, 2018 at 1:47 am #3515762Try thermite, guaranteed not to leave any caramel candy in the tray, or any tray for that matter. Just gotta figure out how to slow it down, not burn it hotter.

Jan 31, 2018 at 1:52 am #3515764There are various Ti ESBIT holders around. Could you do your testing with one of those and a separate windshield? BPL had one and I think Vargo had one as well – at one stage. Today – Amazon and eBay have them.

Chuckle – some of the eBay ones are over $30 – with free postage. Others are around $17 plus postage. Caveat emptor.

Cheers

Jan 31, 2018 at 1:59 am #3515766If you are going to play with thermite, why not wrap in alfoil and drop it in the water in the pot? No need for a stove!

Sorry, being silly and excess thread drift. My fault.

Cheers

Jan 31, 2018 at 2:06 am #3515768 Jan 31, 2018 at 3:06 am #3515772

Jan 31, 2018 at 3:06 am #3515772OK, I am not an alky-freak, but that was just so cute! Do you use the container as a pot as well? Thinks: rather small drinks … But as an emergency kit – unreal.

Where did you get that neat ‘lighter”? Yes, I have the mini-Bics as well as full Bics, but … Mind you, I swear I have been using the same full-sized Bic for the last 6 years. It only makes a small flame, but who needs more?

Cheers

Jan 31, 2018 at 5:11 pm #3515860Roger, the lighter I got at a local tobacco/cigarette store. One of the best I’ve had so far. Great for lighting the hard to light esbit cubes.

The container in the video I use for a warmed 1 cup morning drink. I use the 4 gram esbit to heat it. I wait til I hear the bubbles forming on the bottom of the pot and it’s ready. I use the set-up for day hikes and emergency preparedness 72 hour grab-n-run kits.

Mario, there is a thread here at BPL that shows the Starlyte XL4.5 using a carbon felt heat shield/reflector with a metal disc that protects the felt from deteriorating at the edge of the flame front. The shield was needed only because the pot support used with the burner was short, held the burner close to bottom of pot. Lots of infra red radiation going on there. It was a special order request.

At the link there is a photo in the last comment that shows 2 burners with the carbon felt shield.

https://backpackinglight.com/forums/topic/starlytexl-1-year-of-use-review/

https://backpackinglight.com/forums/topic/starlytexl-1-year-of-use-review/

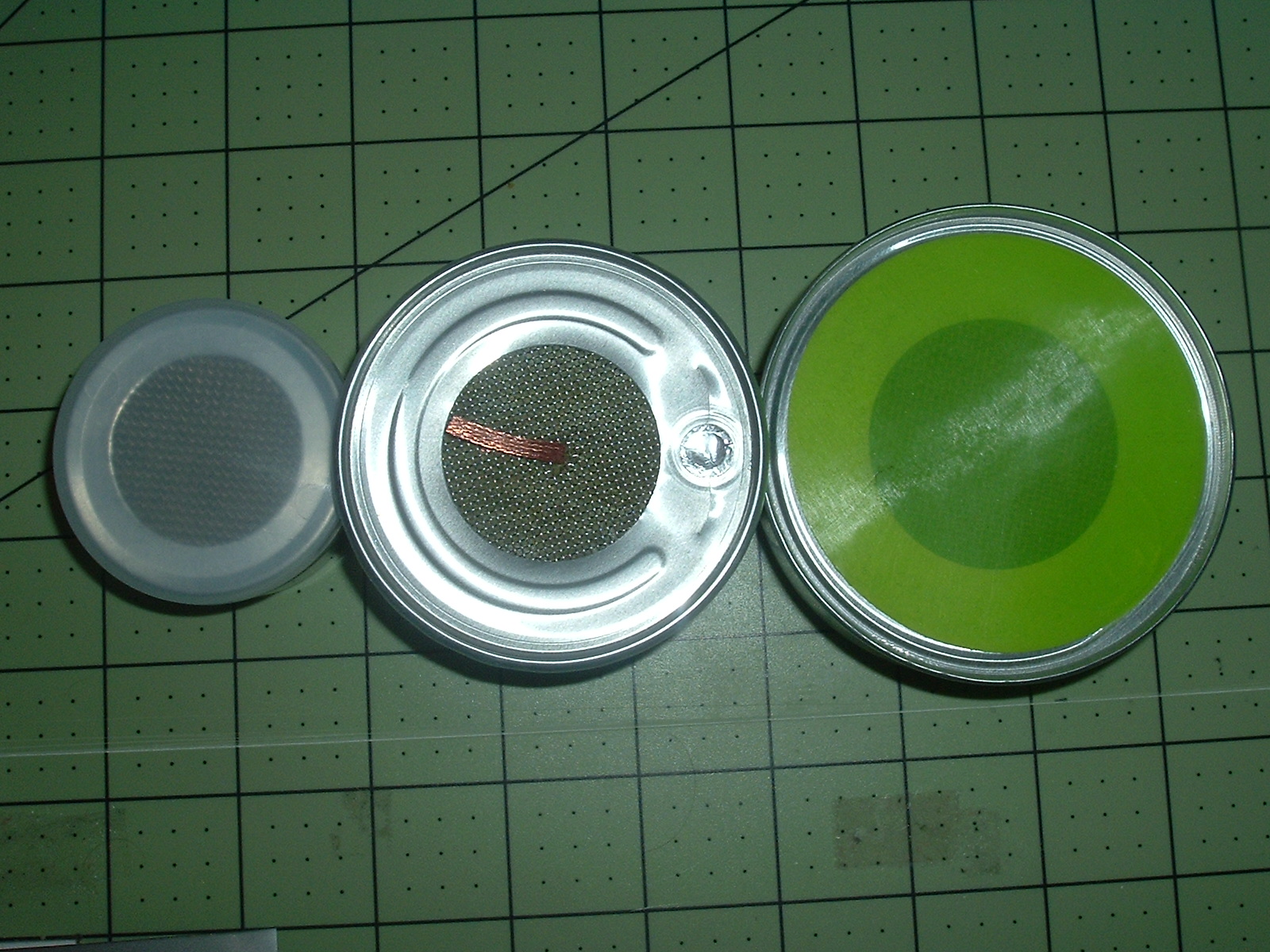

This last photo shows the size difference in the Regular Starlyte and the XL3 and XL4.5

The XL4.5 was difficult to make and collected too much IR so I discontinued it. The XL3 is working out much better, fits easier into pots.

Jan 31, 2018 at 5:57 pm #3515867

Jan 31, 2018 at 5:57 pm #3515867does the lighter have a brand name? model name or number?

Feb 1, 2018 at 1:16 am #3515938Jerry, I don’t have one with me while on vacation. I’ll return home in April and then let you know.

-

AuthorPosts

- You must be logged in to reply to this topic.

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

Trail Days Online! 2025 is this week:

Thursday, February 27 through Saturday, March 1 - Registration is Free.

Our Community Posts are Moderated

Backpacking Light community posts are moderated and here to foster helpful and positive discussions about lightweight backpacking. Please be mindful of our values and boundaries and review our Community Guidelines prior to posting.

Get the Newsletter

Gear Research & Discovery Tools

- Browse our curated Gear Shop

- See the latest Gear Deals and Sales

- Our Recommendations

- Search for Gear on Sale with the Gear Finder

- Used Gear Swap

- Member Gear Reviews and BPL Gear Review Articles

- Browse by Gear Type or Brand.