Topic

Pot … stretching???

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

Home › Forums › Gear Forums › Make Your Own Gear › Pot … stretching???

- This topic has 18 replies, 10 voices, and was last updated 5 years, 1 month ago by

Jack Whiting.

Jack Whiting.

-

AuthorPosts

-

Feb 5, 2019 at 11:35 pm #3576999

I have 2 identical thin walled aluminum pots.

I would like to try and enlarge the diameter of pot#1 so that pot#2 can nest inside.

<p style=”text-align: center;”>Any ideas on how I might go about stretching/enlarging pot#1? I’ve been googling, but I’m not turning up much in the way of ideas or inspiration. (I might not be using proper phraseology.)</p>Feb 6, 2019 at 12:08 am #3577012If the 2 pots are originally the same diameter, it is going to be difficult to stretch one large enough to nest them. Let’s say a pot is 4″ in diameter, you would probably have to stretch it 3%-5% and that is huge. Aluminum can be annealed by heating it in an oven to say 400 for a while, but you would need a series of plugs to expand the diameter in stages with annealing between each stage. It would be far faster and cheaper to find a pot that nest. My 2 cents.

Feb 6, 2019 at 1:09 am #3577031Thanks Jon.

If I had access to a 6 ton shop press, what would make a good plug? Would it require lubrication? Is 400 degrees the target temp, or just a base ballpark?

Feb 6, 2019 at 1:27 am #3577039Look up the annealing temperature for aluminum, it isn’t too hard to find. The problem is that you will need multiple tapered plugs. Let’s say that your ID is 3.95″. You would probably need tapered plugs at 3.985?, 4.015″, 4.040″, 4.075″. Get it? Anneal and stretch a bit, anneal and stretch a bit. That and you need to keep the press force low or the cylinder will buckle. Now, you could go real old school and anneal the pot and then hammer it over a round anvil, thereby stretching it. Then you would have to anneal it and repeat, anneal it and repeat. You will more than likely fracture the aluminum. Fare simpler to find a nesting pot IMO.

Feb 6, 2019 at 3:16 am #3577075Yup, I agree with Jon. It COULD be done, but at VERY great expense for a one-off. Look for a nesting pot set.

Feb 6, 2019 at 4:02 am #3577100Haha. I get it! Buying a nesting set is the obvious way to go! The one embarrassing constant with nearly every piece of gear I have made is that a superior product could have been easily purchased for less money than I spent on the project in the first place. My wife reminds me of this often. That said … the hard and stupid way has to date also been the fun way and I like to tinker in the shed in the winter.

To add detail, I guide large-ish groups in the summer and I have to carry two 4qt pots and a skillet for the programmed meals (I don’t control the meal program.) I’m trying to take three lightweight aluminum Whirly-Pop 6qt containers and stretch/cut them into a three piece nesting set of two pots and one high walled skillet-like thing. I have no doubt I am in for frustration, expense and ultimately likely failure … and I’m okay with that. Haha.

Feb 6, 2019 at 2:39 pm #3577152Whirley-pop and similar alumimum (turkey roasting pans, casseroles, etc.) can be reshaped easily. Just be absolutely sure to keep the bottom covered with liquid when cooking. And don’t overheat the dry sidewall (flame + windscreen).

Have fun out there.

Feb 6, 2019 at 5:48 pm #3577174Fill one with water, freeze and then thaw, repeat as necessary. Bottom will stretch also causing “oil canning” been there done that :-) I can teach you how to fix the oil canned bottom.

Feb 6, 2019 at 6:02 pm #3577176This pot stretcher will fit pots up to 4-1/4″

Find a local truck exhaust repair shop that might be using such a device and ask them to stretch your pot. What diameter pot do you want stretched?

Find a local truck exhaust repair shop that might be using such a device and ask them to stretch your pot. What diameter pot do you want stretched? Feb 6, 2019 at 6:34 pm #3577184

Feb 6, 2019 at 6:34 pm #3577184Hey Dan. How have you been?

Thanks for the ideas.

I looked into exhaust stretchers, but I’m starting from a diameter of about 9.5”. Nothing appears to even approach that size.

The ice idea is interesting and was where my mind originally went when I started thinking about this project. Do you think I would have to “cap” it with some sort of lid to contain the liquid before it expands? What are your “oil canning” remedies?

Thanks again.

Feb 6, 2019 at 8:34 pm #3577217Cut a piece of 3/4″ plywood to a “press fit” diameter of pot. Fill pot with water 3/4″ from top, float plywood on water, place under ram of your 6 ton shop press. Put a 4 foot long cheater pipe over press arm. Now get the press arm at a comfortable position so that you and a buddy can put all your weight onto the bar and compress the water to expand the walls of the pot. or….

Fill the pot half way with water, add dry ice so water level comes up to 3/4″ from top, place plywood piece onto water and then place pot under ram of press. Lower ram so it just barely touches plywood. Dry ice will cause water to freeze while inside your shop area as it sits under you press ram. Drill a few 1/2″ holes in plywood to allow escaping gas given off by dry ice(important ;-)

It might work. If it there is a catastrophic failure of the pot wall, that’s ok, we go to plan C.

Feb 7, 2019 at 12:09 am #3577254

Feb 7, 2019 at 12:09 am #3577254My efforts at using dry ice in water where that it never froze very well. The ice would form a protective layer that inhibited freezing the rest of the water. In the end I had a water shell with a large air gap that used to be dry ice. I don’t think that would work very well to expand a pot.

My thought was to get a nice big chunk of wood and turn it on a lathe, transitioning from your starting diameter to your finish diameter. Hardwood would be better than softwood and I’m not sure what size diameters typical lathes hold. At 9.5″ dia pot maybe a hardwood 2×10… not sure if that is wide enough for your final diameter. Lubricate the walls and make sure you have a plan for pulling it out before you press it in. Some of the expansion will be elastic so your final die will need to be bigger that the dia your looking for.

This is all a thought experiment for me…. I’ve never tried anything like that.

Feb 7, 2019 at 12:37 am #3577260Fill a pot with water, let it freeze. Slather the outside of the pot with white lithium grease. Place on top of other pot while under the ram of your press. Compress slowly :-)

Feb 7, 2019 at 2:34 am #3577273I believe Dan hit on a solution.

However, deforming the metal (ie stretching it permanently) is dependent on the grain size of the metal, exact composition and thickness of the sidewalls. Assuming a stamped pot (could be cast or spun) I would highly recommend that you anneal the pot as plain old aluminum…say 425-500 for an hour. After letting the pot cool, freeze them while full of water. Generally this should expand around 9% (the expansion of water doesn’t really need a lid side to side.) Then thaw them. There will be some “bounce-back” of the metal as the water thaws, though. This is usually around 4% (again depending) but could be a bit higher. Assuming a 4% bounce back, a 5″ diameter pot should end up at 5.2″ to 5.3″, give or take. Note that stretching will also “work harden” the aluminum, so if you wanted to do it a second time, you would likely need to anneal it again or accept the lesser result (around a half what you got the first time…say another 0.1″. You might get the same…depends on the metal.

Feb 7, 2019 at 3:19 am #3577281Man. You guys are awesome. Since I would need to “visit” the shop press across town, I’ll try the annealing + freezing water process first in the comfort of my own home and see what’s what. Thanks for the ideas and the inspiration.

Feb 7, 2019 at 4:08 am #3577285Since we seem to be entertaining fantastical, impractical solutions: have you considered spinning?

https://en.wikipedia.org/wiki/Metal_spinning

Lots of interesting videos out there …

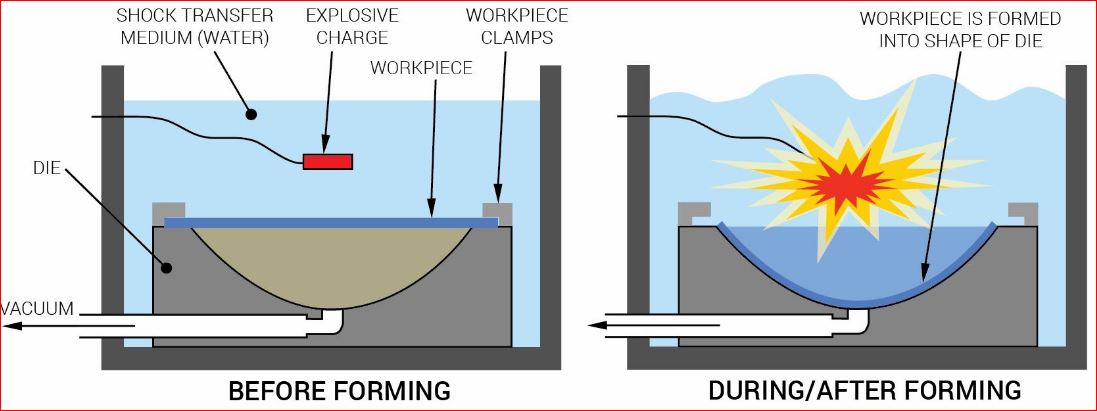

Feb 7, 2019 at 4:33 pm #3577343Adding to the fantastical, impractical solutions… don’t forget the ever popular explosive forming method:

I was a tool designer for 30 years for a tube bending company so spent lots of time with expanding/formiing tubes… but I never got permission to use this method. Dang! We did occasionally resort to expanding with hydraulic fluids under high pressure. I do not now have the formulas to calculate the pressures needed to expand metals but I seriously doubt you will do anything with 6 tons.

If you had the properly sized dies similar the exhaust expander show above you might have a chance as the tapered plug will greatly amplify your power. A solid sizing plug will take a LOT of force to expand it AND you have to extract the plug. Without an outside cage you will most likely just collapse /crush the pot.

Low cost, seat of the pants solution? I’d say beat it thinner to expand. I would guess the ice method will bulge it out… but not evenly.

Does the pot have a curled lip around the edge? More problems.

Feb 7, 2019 at 5:37 pm #3577350Yeah, the lip and bulging could be problems.

Mar 6, 2019 at 1:00 am #3581984Have you considered squashing one of the pots so that it will fit inside the other?

-

AuthorPosts

- You must be logged in to reply to this topic.

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

Our Community Posts are Moderated

Backpacking Light community posts are moderated and here to foster helpful and positive discussions about lightweight backpacking. Please be mindful of our values and boundaries and review our Community Guidelines prior to posting.

Get the Newsletter

Gear Research & Discovery Tools

- Browse our curated Gear Shop

- See the latest Gear Deals and Sales

- Our Recommendations

- Search for Gear on Sale with the Gear Finder

- Used Gear Swap

- Member Gear Reviews and BPL Gear Review Articles

- Browse by Gear Type or Brand.