Topic

MYOG: SUL Remote Inverted Canister Winter Stove Version 7

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

Home › Forums › Campfire › Editor’s Roundtable › MYOG: SUL Remote Inverted Canister Winter Stove Version 7

- This topic has 96 replies, 18 voices, and was last updated 4 months, 1 week ago by

Roger Caffin.

Roger Caffin.

-

AuthorPosts

-

Jun 28, 2024 at 11:59 am #3814176

Companion forum thread to: MYOG: SUL Remote Inverted Canister Winter Stove Version 7

Roger Caffin details the process of designing and constructing the newest version of his SUL Remote Inverted Canister Stoves

Jun 28, 2024 at 1:33 pm #3814179Thank you! I’m looking forward to the future posts!

Jun 28, 2024 at 7:04 pm #3814206Hi Kevin

One thing which may not have been too clear in the article is that as the size has shrunk, the tolerances have had to tighten. Well, that figures of course.

And with the CNC, it is certainly possible.Cheers

Jun 29, 2024 at 6:15 am #3814213Thanks Roger! A nice lookin’ stove and quite light.

Jun 29, 2024 at 8:30 am #3814216Roger,

Excellent article, design and analysis, obviously you spent many hours on this and it shows. I look forward to more details about the development. Incredible amount of engineering and execution went into this design,I am quite impressed.

From a consumer standpoint, there are some things that are extremely attractive about this design. Again, from an SUL viewpoint it’s the weight. But secondarily, it is about the ability to use a cheap, full windscreen to add wind robustness is the killer for me. You take a cheap, simple canister topped stove and transform it into a robust remote stove. What you lose in simplicity, you gain in real world performance.

From an engineering perspective, the pre-heat system is a crazy good design. I suspect that a majority of SUL backpackers do not go out in sub zero temperature. It would be interesting to see how the design would evolve if a pre-heat was not required. If it were stripped down to a bare minimum, it could be a real game changer.

One could take the BRS 3000t along with the MSR Lowdown as a competitor.

BRS 3000t $16 and 26 g

MSR Lowdown $41 and 6.2 oz (176 g)

Total $57 and 202 gYou are probably not interested in going mainstream but IMO a sub $100 system that weighs under 50 g would be an outstanding product.

Some notes on your article

Complete stove -45 g. outstanding!

.01 mm tolerance – As we use to say “ fine, at what temperature?”

Excellent chart on internal canister pressure versus temperature. Did you measure it or reference it? Just curious.

Why make custom jets? What is the advantage?

Exceptional thermal data collectionJun 29, 2024 at 11:44 am #3814224Such a thorough design, Roger. I’ve often thought that a device like an MSR Low-Down (paired with a BRS-3000t) would be great if it weighed less (and had a heat shunt to vaporize the gas). You’ve gone soooo far beyond that. :)

I suspect, but have only partially proven, that a windscreen or heat shield can be designed that out-performs an HX pot at a fraction of the weight. Heating the sides of the pot exposes more surface area than the fins on an HX pot, without adding more than a few grams to make a taller titanium foil windscreen. A remote canister stove makes this easier (maybe safer) to implement, as Jon points out.

Maybe overheating the stove must be considered as well? Similar to protecting the canister on an upright stove.

Jun 29, 2024 at 12:19 pm #3814225Excellent design & information Roger. I assume CO (carbon monoxide) production is very low (?) with this design. :-)

Jun 29, 2024 at 4:19 pm #3814229obviously you spent many hours on this and it shows

Hours?

Months! Many months. Ho hum – about 12 months in fact.interesting to see how the design would evolve if a pre-heat was not required.

As mentioned in the article, I did try without the Heat Exchanger, and that idea failed. I suspect that the lack of a Heat Shunt would be even worse.but IMO a sub $100 system that weighs under 50 g would be an outstanding product.

It would, wouldn’t it? :).01 mm tolerance – As we use to say “ fine, at what temperature?”

Actually, over a fair temperature range. The reason is that the materials are generally carefully matched: aluminium against aluminium and plastic against plastic. There is one place where aluminium is inside plastic, but clearance was allowed for that. The use of O-rings helps of course (well, is critical).Excellent chart on internal canister pressure versus temperature. Did you measure it or reference it?

That is just standard engineering text book stuff. Reference.Why make custom jets? What is the advantage?

Two answers for that. “Standard” jets are much bigger and bulkier, and I have not found a source for them. OK, third answer: a small amount of pigheadedness?Maybe overheating the stove must be considered as well?

Well, yes, but only sort of. The stove part is designed to work at about 100 C anyhow, to make very sure the liquid fuel is vaporised. All stove parts are rated to over 200 C. So “overheating” is not really an issue.I assume CO (carbon monoxide) production is very low (?) with this design.

Right. In fact, CO production with the V7 is just the same as with the upright BRS3000-T stove. And that is known to be very low.Cheers

Jun 29, 2024 at 6:49 pm #3814232I found some custom jets on ebay! For some curious reason Primus kerosene stoves seem to need spares. However, while the average jet size for canister stoves is 0.30 mm, these Primus jets are all 0.50 mm: about 3x too big.

Cheers

Jun 30, 2024 at 1:57 am #3814245If anyone is interested, please email me direct at [email protected] .

I find the PM system a bit too difficult for this sort of thing.Cheers

Jun 30, 2024 at 6:29 am #3814247Ryan – Now would be a great time to do a stove bench test of remote inverted(able) canister stoves and include Roger’s latest iteration…

Jun 30, 2024 at 2:36 pm #3814267Probably worth a seperate thread as to not detract from this one but has anyone found the StoveBench Test metric of any value? If so , how did you use it and how did it add value? Inquiring minds …

Jun 30, 2024 at 5:04 pm #3814297has anyone found the StoveBench Test metric of any value?

The idea of finding a test that could be repeated for many stoves is a good idea. However, the choice to test at full throttle seemed fundamentally awkward to me. It isn’t real-life, and it resulted in questionable outcomes.

I understand that it was one way of trying to adjust for fuel flow, but I don’t think it produced the results that we all wished for.

Jun 30, 2024 at 5:36 pm #3814307Bill, I pretty much agree. Full bore is always questionable in my mind. It ends up only testing those stoves that work well at full throttle. Some can have flames that lift. Some produce gobs of CO, as Roger has reported several times. Others are intentionally limited by the intake of air to mix with the Butane/Propane blends and do not perform well at full bore. The test does NOT reflect how a stove would be used in the field with one or two people and a half or one liter of water. It is, however, useful as a full power test.

The big thing is there is no real measure of low and mid power efficiency, just on high. I know that I get far better efficiency on lower power. I try to balance that against heat loss in various conditions. This is a more meaningful/more useful metric in my book. But, what do I know, I still think my old SVEA is a fair stove.

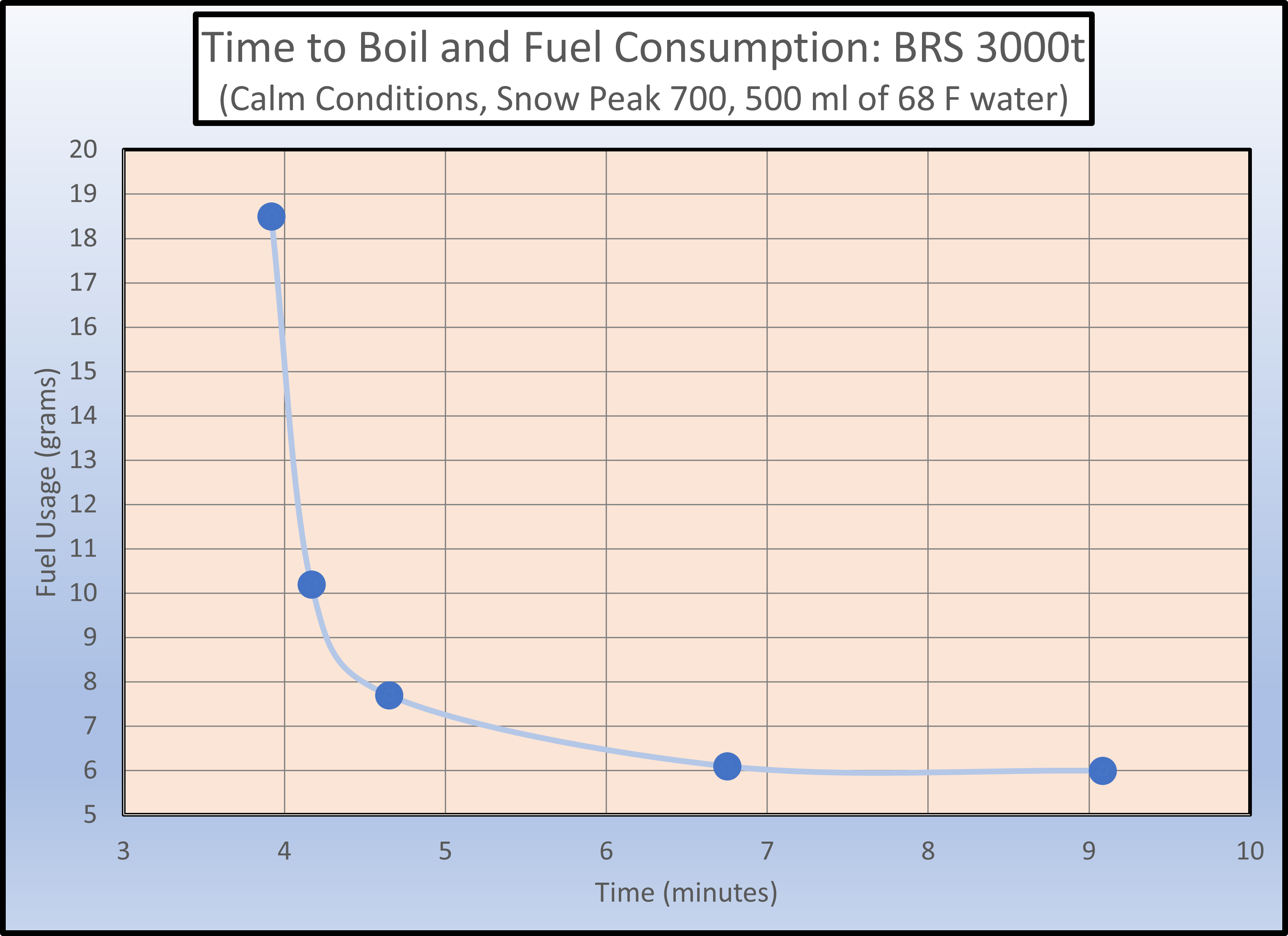

The vortex burners seem better in general. The older FM-300t, BRS, and others do well even with relatively small air intakes.Jun 30, 2024 at 6:14 pm #3814311Given that Roger is using the BRS 3000t as the burner componet, this chart is probably relavent. This is the fuel consumption verse time to boil water.

Jun 30, 2024 at 7:49 pm #3814319

Jun 30, 2024 at 7:49 pm #3814319

Ryan reported 4 out of 7 failed in his stove bench testing. ….bummer

Jun 30, 2024 at 7:57 pm #3814320I have had 0 failures on the bench and in the field.

I don’t know what went wrong for Ryan.

But what I can say is that you can NOT melt titanium with a propane flame. It is just not hot enough. It is used to make the nozzles for space rockets.Cheers

Jul 1, 2024 at 6:12 am #3814324Thanks, Jon! Good info…

I try to keep my runs around 6-9 minutes, usually 500ml/at around 60F. Note that ambient temps can alter your chart rather drastically, both Air temp/pressure and Water temp. I usually set the stove temp once and do other things around camp.

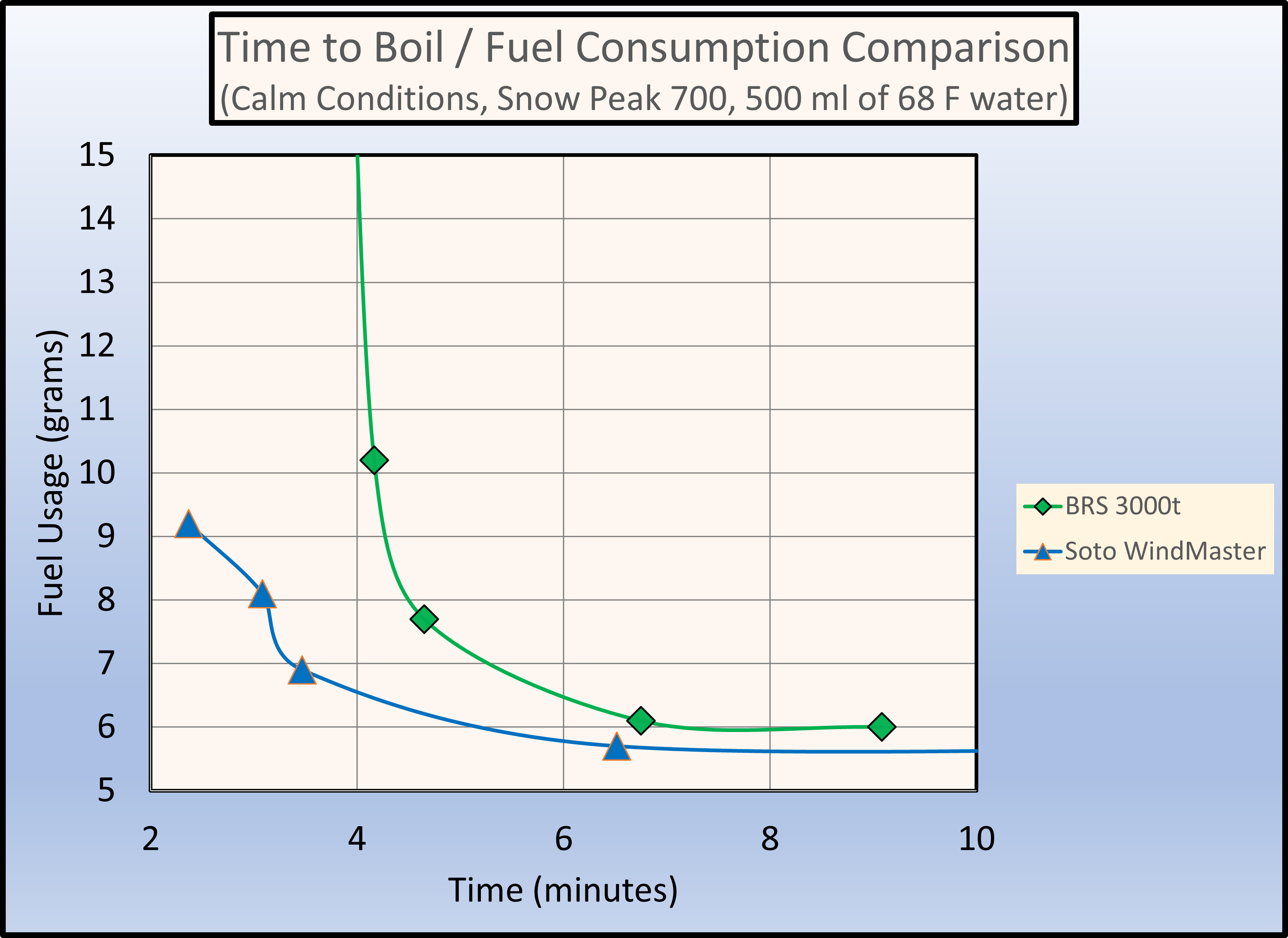

Jul 1, 2024 at 1:10 pm #3814336I dug through my files and found a better chart. This one comapres the Soto WindMaster to the BRS 3000t. This one graph shows a particular benefit to regulated stoves: a narrower dynamic output of the flames. As Roger has pointed out, an experienced user doesn’t need a regulated stove. From my work with alcohol stoves, it seems like most canister stove perform efficiently when you dial back the power output to 400 watts-600 watts. My 2 cents.

Jul 1, 2024 at 5:30 pm #3814354

Jul 1, 2024 at 5:30 pm #3814354Jon, Thanks!

Jul 2, 2024 at 7:12 am #3814366Hikin Jim had an issue about the same time as Ryan had his failures.

Photo of Jim’s stove lisping to the side due to support arm bending due to ???

https://adventuresinstoving.blogspot.com/2017/02/the-brs-3000t-worlds-lightest-stove.html

Jul 2, 2024 at 7:25 am #3814371From hiking jim – one arm bent sideways causing the pot to list to that side:

It doesn’t have to be so hot that it melts the metal, it just has to weaken it so it will bend easier.

I have a BRS3000 that I’ve used with no problem. Maybe keeping the stove on low helps. Maybe there was a batch of stoves with metal that had a lower melting temperature

Jul 2, 2024 at 7:52 am #3814373Therre is no doubt that the BRS 3000t had a one time reliability issue. My guess is that it was a manufacturing hiccup that has been resolved and has been put to bed. Realistically, if a stove manufacture had a persistent failure rate of 4/7 (57%) they would be out of business. Given the massive volume of BRS 3000t sold, even a 2% to 3% field failure rate would be a disaster on a high volume/ low cost product. I believe that there is sufficient data out there to say that the sagging is currently a non problem. Now, if only they could fix the feable performance in the wind…… My 2 cents.

Jul 2, 2024 at 8:11 am #3814374who makes BRS3000?

it’s not a company like MSR or SOTO that wants to maintain it’s reputation

on Amazon there are many “brands” for BRS3000. Are those different companies that make them, or do the different “brands” all buy from one company that actually makes them, or …

would one “brand” maybe buy some parts from different suppliers that charge less but have lower quality?

Jul 2, 2024 at 9:39 am #3814386Like Roger said: “They don’t really melt, they overheat and slowly bend under the weight and a full pot of water and food.”

Hikin Jim said:

Recommendations

I can’t exactly give a good recommendation to a stove that failed during testing. Neither can I give a stove that handles wind so poorly a good recommendation.Again, however, I’m aware that there are plenty of people who are using the stove and are not experiencing problems. It’s an inconsistent stove. Maybe you’ll get lucky. Maybe you won’t. Clearly there are duds out there, and even if you don’t get a dud, the right wind conditions could still cause a pot support failure. Also, your pot supports could fail over time, as they did in Failure #3, above.

I suggest the following:

Run the stove for 15 minutes on high with 2 cups of water on before taking it out on the trail for the first time. If your stove can handle a 15 minute run on high at home, then it’s probably going to be OK out on the trail. If it fails at home, just buy another one. It’s not like they’re expensive. The chances of getting two duds are fairly low I would think.

Make absolutely certain to shelter the stove from wind. If you fail to shelter the stove, wind may channel heat to a single pot support which may deform and fail. You should always shelter a stove anyway so that you’re not burning through an inordinate amount fuel, but it’s particularly critical on the BRS-3000T.

Run the stove at about 50% to 75% of full flame to avoid overheating the pot supports. It’ll take a little longer to boil, but you’ll actually save gas this way, and you won’t have so much heat blasting the pot supports.

If you wanted to really play it safe, you could limit the amount of water boiled at any one time to, say, 500 ml. You could also run the stove for no more than maybe 5 or so minutes at a time, give or take, and you could let the stove cool a bit between successive boilsLong Term Reliability

What impact will repeatedly blasting the pot supports with high heat have? I have received reports from people who had good results at first but whose pot supports deformed over time. So, there is the possibility that even if your stove is good at first that it may experience problems over time.Alternatives

BRS has a history of problems; some BRS stoves have been banned by countries in Europe due to repeated safety problems. -

AuthorPosts

- You must be logged in to reply to this topic.

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

HAPPENING RIGHT NOW (February 11-21, 2025) - Shop Hyperlite Mountain Gear's Biggest Sale of the Year:

Our Community Posts are Moderated

Backpacking Light community posts are moderated and here to foster helpful and positive discussions about lightweight backpacking. Please be mindful of our values and boundaries and review our Community Guidelines prior to posting.

Get the Newsletter

Gear Research & Discovery Tools

- Browse our curated Gear Shop

- See the latest Gear Deals and Sales

- Our Recommendations

- Search for Gear on Sale with the Gear Finder

- Used Gear Swap

- Member Gear Reviews and BPL Gear Review Articles

- Browse by Gear Type or Brand.