Topic

Lineloc Alternative

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

Home › Forums › Gear Forums › Make Your Own Gear › Lineloc Alternative

- This topic has 98 replies, 19 voices, and was last updated 3 years, 7 months ago by

Sam Farrington.

Sam Farrington.

-

AuthorPosts

-

Feb 5, 2020 at 1:42 pm #3630006

Back to the original topic – I used this kind of adjuster on snowshoe bindings I made long time ago, with some extra tricks:

- the combination of a washer and a ring locks safely, but can still be tightened under tension

- the release tab is hidden in a long loop on the main strap, and held in place with an o-ring, so it neatly stays in place.

- the free end is stiffened with glue, so it can be easily threaded through the rings

Feb 5, 2020 at 6:41 pm #3630034

Feb 5, 2020 at 6:41 pm #3630034Chris glad you showed those. I ordered some 2mm cord to replace some lines. 8 of the slide locks came with the cord. I tried them out on the old Pro Trail. They do the job and held great in a t-storm with 35-40 mph gusts. The Linelocs slipped a bit on the tent front. BTW, climbers used the ring method for descents back in the day before Figure 8s came out. UL hammockers still use rings on rainfly setups.

Feb 6, 2020 at 2:20 am #3630074Jan – cool stuff! I like the release arrangement and use of glue.

Daryl – did you continue to use your ring buckle on any gear?

Rummaging through my collection of bits and bobs…

On the right, a generic 1/2″ ladder loc that actually works with grosgrain – 0.8g.

I’m sure we’ve all seen the doodad on the left – a generic 3-hole tensioner. Rigged as shown, it works like a line loc – you’re not limited to half line length and can adjust right down to zero. It even loosens when you lift up on the tail. That’s some slippery 2mm UHMWPE braided hollow core in the picture. This, inspired by the Kong Slyde:

You don’t actually need the hole out to the side – that just keeps the coil in place. The long straight side of the 3-hole tensioner accomplishes the same thing.

This requires reasonable tolerance between the hole size and cord diameter. The slot in the Slyde is 12mm x 24mm and they recommend 9mm – 10mm rope. This one is ripe for some MYOG. Designed around 1.2mm Z-Line, this could be well under 1g.

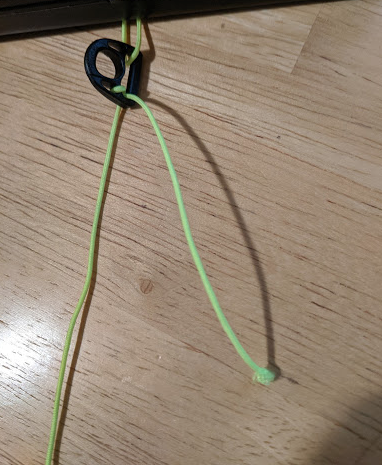

Feb 6, 2020 at 2:46 am #3630078And there it is:

That’s a 1/2″ Beastie Dee, 0.5g, with 1.2mm Z-Line. Works great as far as a quick bench test goes.

Feb 6, 2020 at 3:21 am #3630080Very nice, but I have to wonder how it would take shaking and tugging for 6 hours – overnight in a storm.

I wonder how well that would go with Spectra? My experience has been that it is so slippery that many knots ‘run’ along its length.

More testing!

Cheers

Feb 6, 2020 at 8:02 pm #3630188LineLoc 3’s are not suitable for use in shelters. Period. (See my comment in the thread linked to by the original poster for more detail.) The same applies to similar plastic tensioners offered by DutchWare that rely on a knife-edge of plastic to prevent line slippage. Such tensioners should not be used in shelters.

ClamCleats do have dramatically higher holding power than LineLocs, but they are in a different class of tensioner topology, so in standard configuration are not a replacement for LineLoc’s. (I was unaware of the alternate configuration shown by Roger and will have to look into that.)

LadderLocs may be a suitable replacement for LineLoc 3’s, given proper testing. It would be nice to have data on the holding power of various plastic tensioners.

The ability to prevent slippage under cyclic loading is an issue for any tensioner. I welcome experimentation such as this.

Feb 6, 2020 at 9:31 pm #3630198It may be worth while remembering that ClamCleats have been used on yachts to hold their ‘ropes’ (sheets) for a long time. Both engineering nylon and aluminium are used – the Al ones for racing yachts.

An early distinguished customer was Sir Francis Chichester. His vessel, Gipsy Moth IV, was fitted with ten CL201 cleats, which helped him to set the first speed record for single handed circumnavigation in 1966-67.Under tension, the rope in a ClamCleat is pulled further into the jamming part, and the grip tightens. Provided you match the Clamcleat to the rope it will hold.

That said, there is one situation where all plastic thingies will fail. I set up a ClamCleat CL266 with 0.8 mm Spectra, under load, and tried to adjust it just by pulling. Oops – the Spectra cut through the nylon! Bear in mind that 0.8 mm Spectra is less than the minimum rope diameter of 1 mm that the CL266 is rated for. This sort of thing will happen to any plastic thingie when thin Spectra runs hard against a plastic: under load the Spectra will cut into the plastic. Yes, I was experimenting at home, not out in the field.

A caution: I have seen Chinese knock-offs on ebay, and tested them. They are poorly made and will not hold as well. They might be OK with 2.0 – 2.5 mm non-Spectra cord on 3-season shelters pitched in forested areas.

Cheers

Feb 6, 2020 at 11:11 pm #3630206Am not sure about using tautline hitches in the kind of weather in Ryan’s video. Would expect the cord to ice up at the knot. But like Paul, am not enthused with the popular Lineloc 3. Am also not enthused with running the cord twice through the same hole, or with bar tighteners that have been great for a lot of applications, like making pulleys for webbing, but not the apps they were intended for.

But there are all kinds of acetal plastic tighteners out there, a number of which I looked at when working on a clamshell tent design posted on another thread last year. Found different ones on Amazon and some other sites.

Paul’s post on the thread linked in Rene’s OP focuses on the ‘knife edge piece of plastic’ inside the lineloc LL3. That always bothered me too. The LL is bulky, yet has some tiny plastic parts. Don’t see a need to use grosgrain or twill tape, when 1/4″ lace will do, and take a smaller tightener. The Dutchware tightener shown in Chris’s post near the beginning of this thread looks a lot more solid to me, altho needs 3mm cord – yet he says there are other smaller ones: https://dutchwaregear.com/product/line-lock-hook/

So it looks like ordering the least bulky yet strong ones available, stringing them with some spectra core cord, and break testing. Will have to think of a way to generate enough force to break them. Maybe a small hydraulic jack set up, or my farmer’s jack that is tall enough to set up to stretch a foot or two of cord.

I think there are sleeker and stronger line tighteners out there for 2-2.5mm spectra core cord. There was a thread on BPL a few years ago with names of arborists selling spectra cord at lower prices; don’t have a link, but maybe someone will be able to post one.

Feb 7, 2020 at 12:55 am #3630214The most commonly used brick in the U.S. for general masonry work is the modular brick. With an average weight of 4.2 pounds,

(the web)

Got any bricks?Alternately, very large bucket and a 1 L jug (1 L -> 1 kg)

Cheers

Feb 17, 2020 at 4:28 pm #3631797Mmmmmmmm

Feb 18, 2020 at 9:53 am #3631931It seems I have had many fashion belts over the years that use the two rings method.

Those three-hole plastic things are great. You can operate them with fumbling hands and semi-clouded thinking. You can get them from Coghlan’s and they’re cheap.

Feb 20, 2020 at 3:27 pm #3632295I’m really curious how strong the lineloc is. I wanted to test it myself but never got to it. The bar the string is wrapped around is quite thin, so it seems weak. On the other hand, I’ve linelocs as the main tieouts on my large mid, and it’s been through some high winds without any problem. It would be great to have a real number there, and a comparison to other adjusters. The one with the moving bar (sold by dutchware and others) seems to be stronger…

Feb 20, 2020 at 3:37 pm #3632300“…seems to be stronger…”

Just curious, what makes it “seem” so? As you mention, Lineloc 3s have served many well for some time.

Totally agree, twould be nice to have a real, scientific (god forbid!) comparison of the various options.

Feb 20, 2020 at 4:56 pm #3632318There are no less than 5 things to measure:

The strength of the bar(s) on the adjuster

The effect of string diameter

The effect of water (rain) on the adjuster

The strength of the tent

The likely loads due to windNote that the last depends on the wind speed, the wind direction wrt tent, the tent design, and just how well the tent was pitched.

Tricky, but any data is better than no data. What I will predict is that the load you can safely put on the tent before it ‘breaks’ will be a lot LESS than you think.

Cheers

Feb 20, 2020 at 5:20 pm #3632321“What I will predict is that the load you can safely put on the tent before it ‘breaks’ will be a lot LESS than you think.”

I was thinking exactly the same thing. Tent, guylines and linelocs are a system, and as a system are only as strong as the weakest element. I have a hard time imagining the weakest element of that system is the lineloc.

I predict that most of the guy systems in use (lines and tensioners) are much stronger than the structure we are attempting to secure.

Feb 20, 2020 at 6:56 pm #3632342As I’ve mentioned before, obtaining the failure load of samples (fabric, cord, gizmos) is fairly trivial, provided you own a bathroom scale. Suspend the sample, stand on the scale and gradually start pulling down on the sample, keeping an eye on the scale. Subtract the scale reading from your weight and you’ll have the load applied to the sample.

Knowing the strength of your tent is a separate concern from the strength of a lineloc. My list of variable is shorter than Roger’s:

– Is the lineloc supported by webbing/ribbon or cord (this tests the anchor portion of it – less interesting)

– Cord thickness/material (if you have a favorite, test with what you intend to use)

– Try it again wet if you like

Really, all you need to do is actually try it once. You might be surprised the impact a single test can have.

Feb 20, 2020 at 6:57 pm #3632343The guy ropes on my winter tent are Spectra sheathed in Dacron, a bit over 2 mm diameter. Spectra is too slippery by itself but Dacron is fine. I think, from memory, that the combination (probably) has a breaking load of over 100 kgf. That is the weight of a very heavy person. Can you imagine putting your whole weight on a tent pole? (I can, with a collapsed pole and tent as a result!)

My summer tunnel tent uses Spectra guy ropes of ~0.8 mm diameter. They have lasted for many years of overseas trip as well as Oz trips. I think they have a strength of >50 kgf. Custom toggles for them as 0.8 mm is less than anything commercially available can handle.

Cheers

Feb 21, 2020 at 12:31 am #3632373What’s the fail point of your tensioners?

Feb 21, 2020 at 12:37 am #3632374Dunno. They are self-tightening you see. I make them out of something like 2.5 mm sheet Lexan. Would the string break first? Dunno.

Cheers

Feb 21, 2020 at 6:30 pm #3632523Sounds interesting :)

Can you post a photo or drawing? Dimensions, weight?

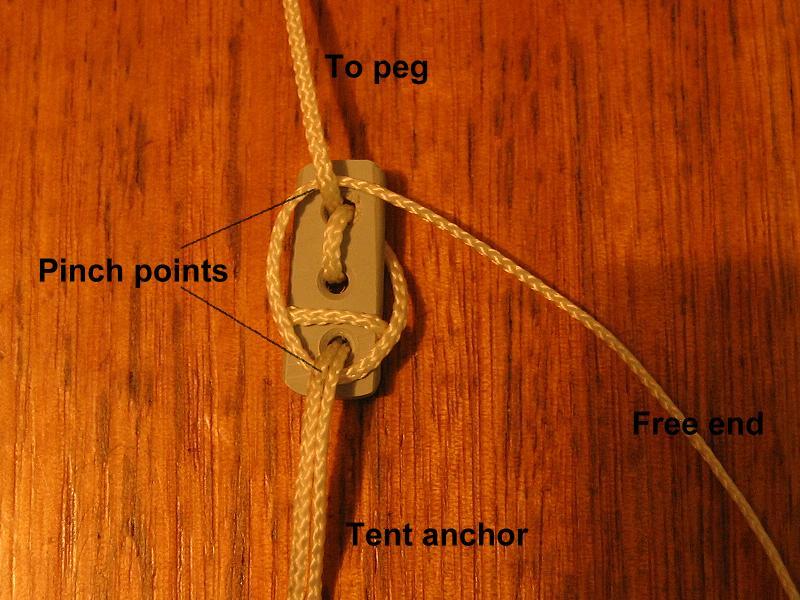

Feb 21, 2020 at 8:30 pm #3632565I don’t have a photo of the Lexan ones, but can show a PVC one.

The idea is that as the tension increases, so does the clamping of the free end of the guy rope. In this case the guy rope is (I think) a nylon cord.

The next photo is of an old aluminium version, with that 0.8 mm Spectra string.

Once again, you can see the ‘pinch points’ where the free end is squeezed under tension.I do also have versions which use two layers, with the free end caught between them .

Cheers

Feb 22, 2020 at 1:56 pm #3632673I’m trying to make sense of the knots. In the upper photo, is that a closed loop coming from the tent anchor, forming a lark’s head through the lower hole in the tensioner?

Then the line to the peg goes down through the upper hole, up through the middle hole, back down through the upper hole, and then wrapping around under the indicated pinch points to the free end?

In this case, adjusting the tension means unwrap the free end, pull to tighten, like a pulley, and then re-wrap to secure it?

Seems there’s some potential for the free end to unwrap in the wind, no?

I can’t make full sense of the aluminum one. A variation on the same theme? The wraps of the free end under the pinch points remind me of the cleat knot used on boats.

Feb 22, 2020 at 2:03 pm #3632676Try this then:

You go from the left photo (adjustment stage) to the right photo (locked stage) just by winding the free end around under the other strings as shown. Takes ~2 seconds, max. Hold well in a storm too.The free end would flail around and be a problem, except that I tie it to the peg end to stop that.

Cheers

Feb 22, 2020 at 9:24 pm #3632752“1mm dyneema 300lb breaking strain. 0.6g per meter – 0.0193 oz per yard

…repurposed these ulta tiny resin cord hand toggles. 0.02g or 0.0007oz

…its been up for a couple of days now and zero slippage…”

Feb 22, 2020 at 11:30 pm #36327581st URL: the 2nd photo uses exactly the same principle. As the load increases, the compression on the free end also increases.

However, one must remember that what holds securely in a static situation may not hold as well in a ‘dynamic’ one. Like in a storm! Not all ingenious devices work all that well in the field … :)

That said, I would think the one shown in the 1st URL should hold quite happily. It is a neat idea. My devices are definitely NOT the only way of doing this.

Cheers

-

AuthorPosts

- You must be logged in to reply to this topic.

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

HAPPENING RIGHT NOW (February 11-21, 2025) - Shop Hyperlite Mountain Gear's Biggest Sale of the Year:

Our Community Posts are Moderated

Backpacking Light community posts are moderated and here to foster helpful and positive discussions about lightweight backpacking. Please be mindful of our values and boundaries and review our Community Guidelines prior to posting.

Get the Newsletter

Gear Research & Discovery Tools

- Browse our curated Gear Shop

- See the latest Gear Deals and Sales

- Our Recommendations

- Search for Gear on Sale with the Gear Finder

- Used Gear Swap

- Member Gear Reviews and BPL Gear Review Articles

- Browse by Gear Type or Brand.