Topic

How to Make Cheap, Light CF Tarp Poles If You Don't Use Trekking Poles

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

Home › Forums › Gear Forums › Make Your Own Gear › How to Make Cheap, Light CF Tarp Poles If You Don't Use Trekking Poles

- This topic has 10 replies, 6 voices, and was last updated 8 years, 9 months ago by

R.

R.

-

AuthorPosts

-

May 9, 2016 at 5:21 pm #3401265

I like tarps but I don’t normally use trekking poles unless I expect to ford flowing water knee-deep or deeper, so I fabricated a pair of Carbon Fiber 3-section poles to use instead. Each section is 17″ long, for a total pole length of 51″. You can make them longer or shorter according to your needs and/or preferences.

Materials & Tools:

Two 3/8″ diameter x 48″ CF tubes

12″ of 1/2″ diameter aluminum tubing

16″ of 1/4″ diameter aluminum rod

Epoxy glue

3/8″ plastic rod end covers

2″ wide aluminum tape

Hack saw

Very small round file (I use 1/8″ diameter for 150 lb. Dyneema cord)

I used cheap, generic unidrectional CF tubes that I picked up from a local store for $20 each. Stronger and more rigid rolled, wrapped and braided tubes are available from various sources.

<div>

<div>

<div>

<div>

<div>

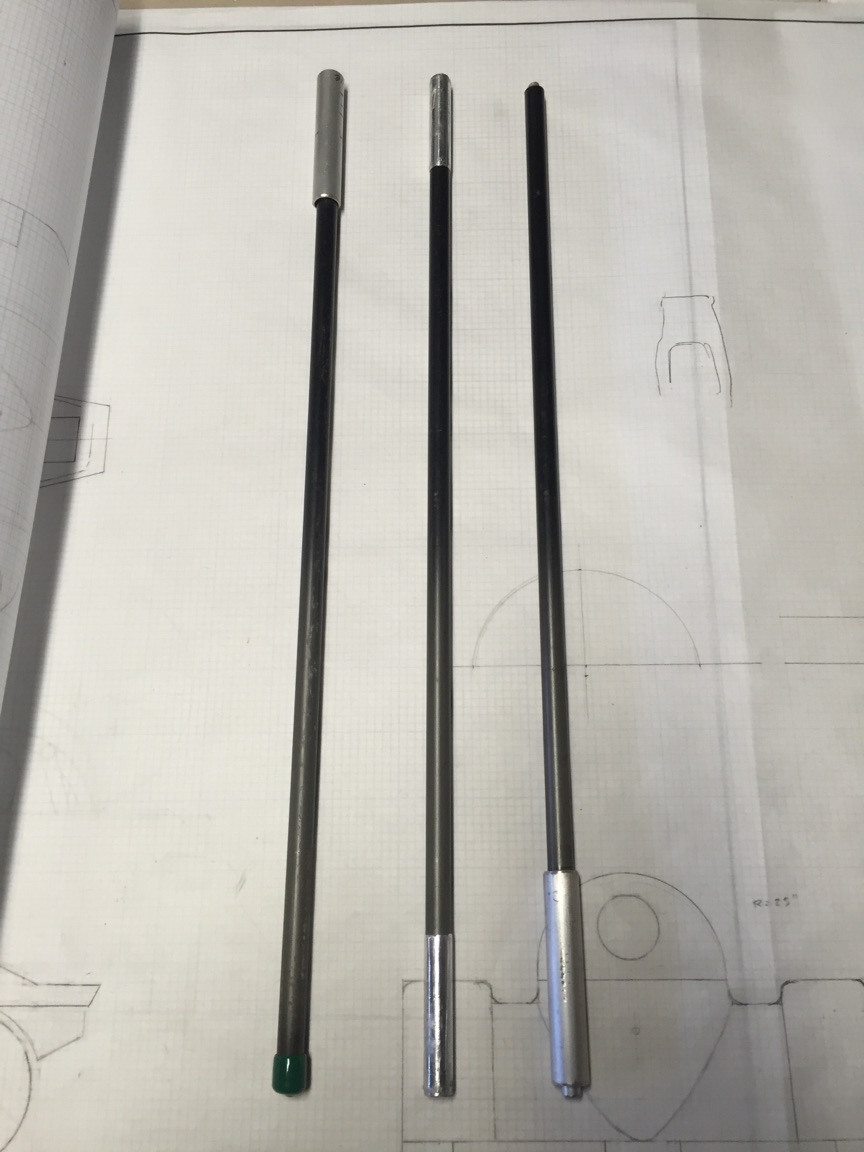

<div>Cut each each tube into two 15.5″ pieces and one 17″ piece, so all the poles would be the same length after the joints were installed. The top and bottom tube sections are made from the 15.5″ pieces; the middle sections are made from the 17″ piece.

</div>

<div>For the joints I took a “belt and suspenders” approach with both internal and external bracing. I believe external bracing alone is sufficient, and will shave a few grams off the total weight of the poles.</div>

<div></div>

<div>For internal braces, 1/4″ diameter aluminum rod happens to fit perfectly inside the 3/8″ carbon tube. I cut four 3″ pieces of aluminum rod (two joints per pole), and epoxied them 1-1/2″ into the ends of the 15.5″ carbon tubes.</div>

<div></div>

For the external braces, 1/2″ diameter aluminum tubing happens to fit almost perfectly outside the 3/8″ carbon tubes. I cut four 3″ pieces of aluminum tube for the joints, then epoxied the aluminum to the carbon tubes 1-1/2″ from the end of the carbon tube, so that the ends of the 1/4″ aluminum rod and the 1/2″ aluminum tube would extend the same length. While the epoxy was setting I put another carbon tube into the joint so that everything would be aligned.</div>

Once all the epoxy has set, I wrapped aluminum tape around each end of the 17″ pieces a few times to make them fit snuggly into the aluminum tubes. Wrap it a couple of times, see if it’s snug, add a few more wraps if necessary.</div>

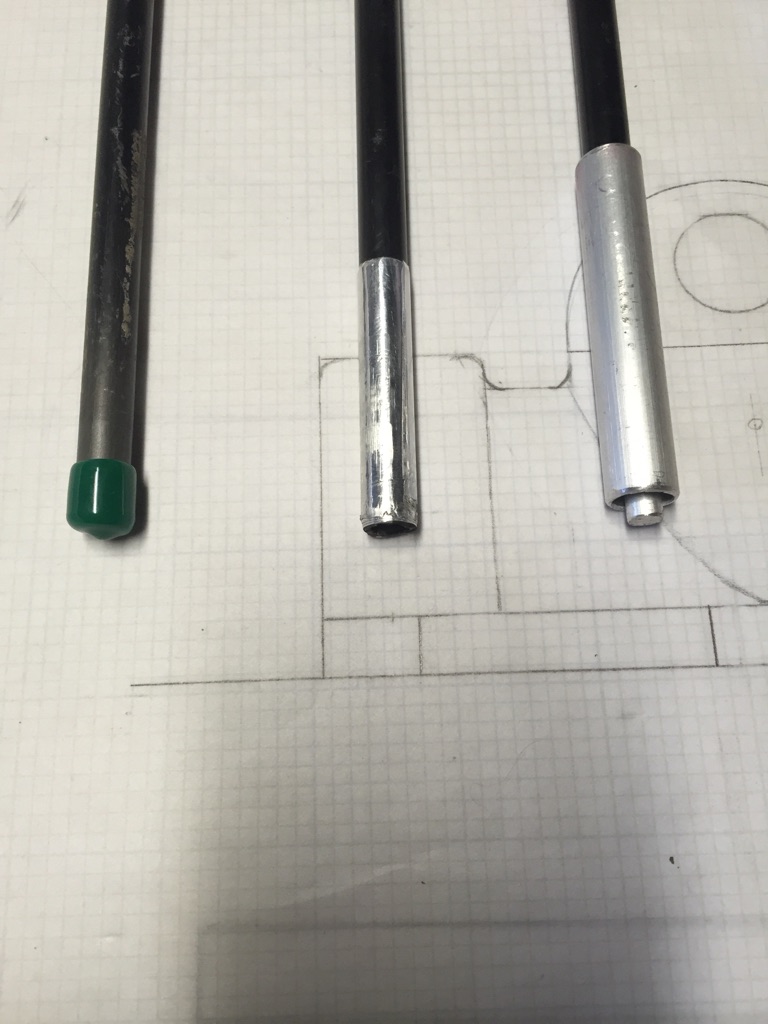

For the bottom end of the bottom poles I put little plastic rod end protectors from my local hardware store.

</div>

For the top of the poles I needed to make tiny saddles for the ridge line cord to run over and sit into, to keep the line in place. I cut two 1″ pieces of aluminum rod and filed one end of each into a little saddle. I tried to take a closer picture but my iPhone wouldn’t let me. If the saddle concept is not clear I’ll send you a drawing. After filing the saddles I epoxied the two aluminum rod pieces into the ends of the top tubes with about 1/4″ sticking up.

</div>

</div>

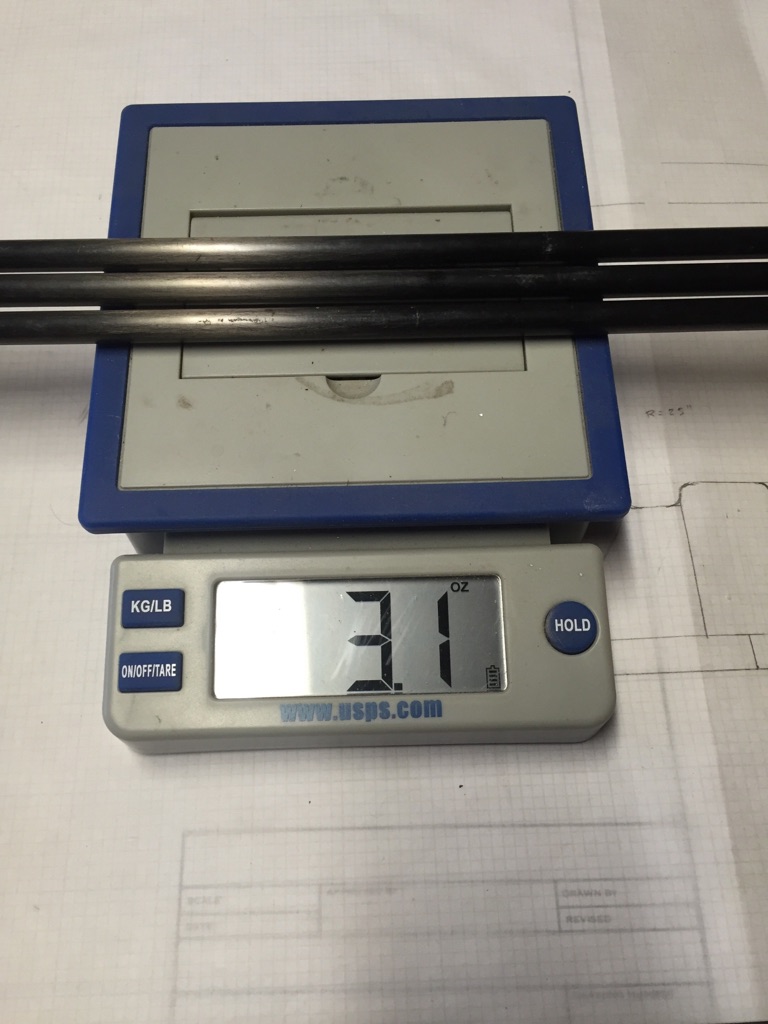

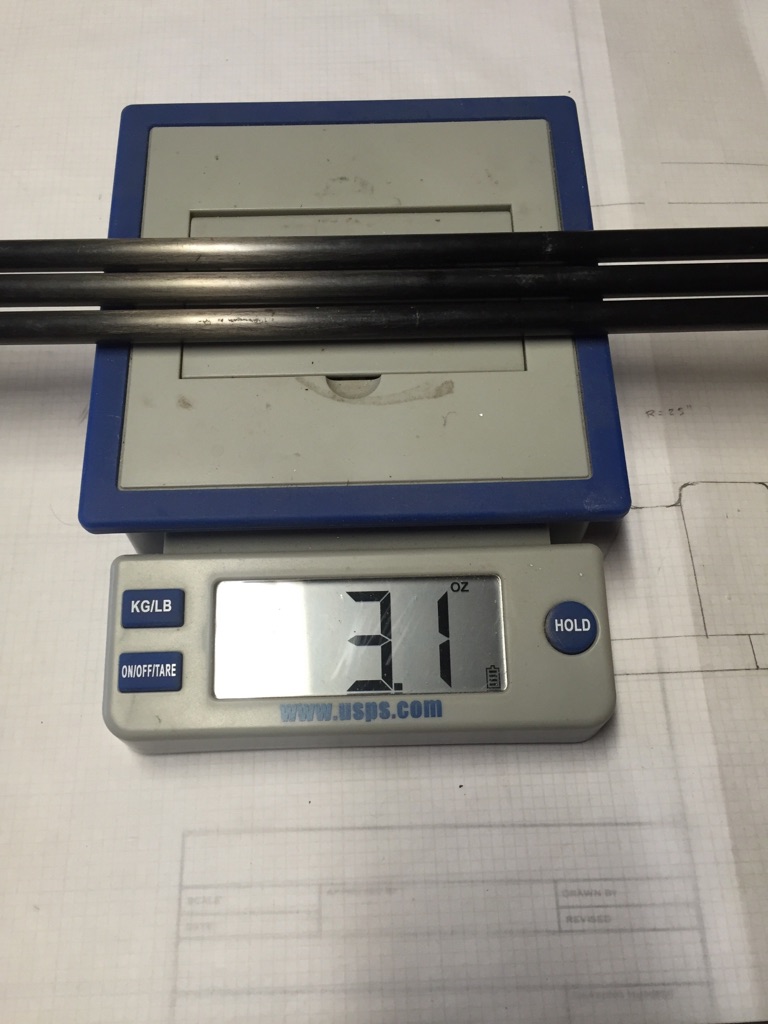

Finished poles weigh 3.1 oz each. You could shave that by skipping the internal bracing. May 9, 2016 at 6:05 pm #3401288

May 9, 2016 at 6:05 pm #3401288well done! question about cutting.. do you find that a hack saw produces a satisfactory cut? i’ve been eager to make cf tent poles but am worried about making a successful cut w/out introducing problems (splintering etc.). some online how-to resources recommend using a dremel but i don’t have one of those. so a simple hack saw would be great.

i assume also that the aluminum tape and end cap serve double duty by sealing and protecting the cut as well?

May 9, 2016 at 9:55 pm #3401376What is up with this new site? I can’t edit/revise the OP even though I only posted it this afternoon. And what’s with all the “</div>” garbage that popped up? I’m totally frustrated.

AG: I was trying to edit the OP to add some text and pictures about how to cut a CF tube with a hacksaw. If I can’t figure out how to edit the OP then I will add the info via another post.

May 9, 2016 at 11:23 pm #3401402I don’t think I would trust the saddles to hold the line in real wind. Don’t you like grommets on the tarp with tips on the poles to insert?

And you are correct that you for whatever reason no longer edit a threads original post. That’s something new.

</div> Don’t know what’s up with those things either. Did you copy and paste your text? See a lot of those things lately.

May 10, 2016 at 7:39 am #3401442</div> is html. Artifact of something. Sometimes shows up when I paste something from an html document.

At the top of your document, to the left of “reply”, is “edit”. Very faint. Click it.

Nice poles. 3.1 ounce!!! I have some Easton aluminum poles that are heavier and less stiff. I should make some of these. Can you get 21 inch sections?

edit: ohhh, from other thread you can’t edit the first post of a thread. I bet that was unintended. Maybe they’ll fix

May 10, 2016 at 11:28 am #3401511AG: I’m going to re-do the entire post to incorporate the changes and clean it up.

KT & Jerry: yep, I copied and pasted much of the text from an email, which explains the weird artifacts.

KT: I haven’t had any problems with the saddle holding the ridge line tie out cord in real wind (gusts to 45 mph). Grommets would work if your tent material silnylon, cuben fiber, etc., but they won’t work with the polycryo tarps I make they penetrate the polycryo and it just tears out – I’ve tried it.

Jerry: I’ve checked repeatedly, and no “edit” shows up anymore. I did edit the OP once in the first five minutes after I posted it, but it won’t let me anymore. I don’t understand BPL’s rationale for this. You can order CF tubes in various lengths. For 21″ poles I would order six 24″ tubes (three for each pole) and cut them down. Or it might be slightly cheaper to buy three 48″ tubes and cut two 21″ pieces out of each, which will leave you with three 6″ pieces of tube to play with. You could cut them into nine 1.88″ pieces and use eight of them for tie-out load spreaders if you’re also making a polycryo tarp (related thread here).

May 10, 2016 at 12:18 pm #3401530“I don’t understand BPL’s rationale for this”

I think it’s most likely unintended

They changed something totally unrelated which broke this edit capability

May 10, 2016 at 1:04 pm #3401544OK, here is the original post revised, cleaned up and with new photos and text:

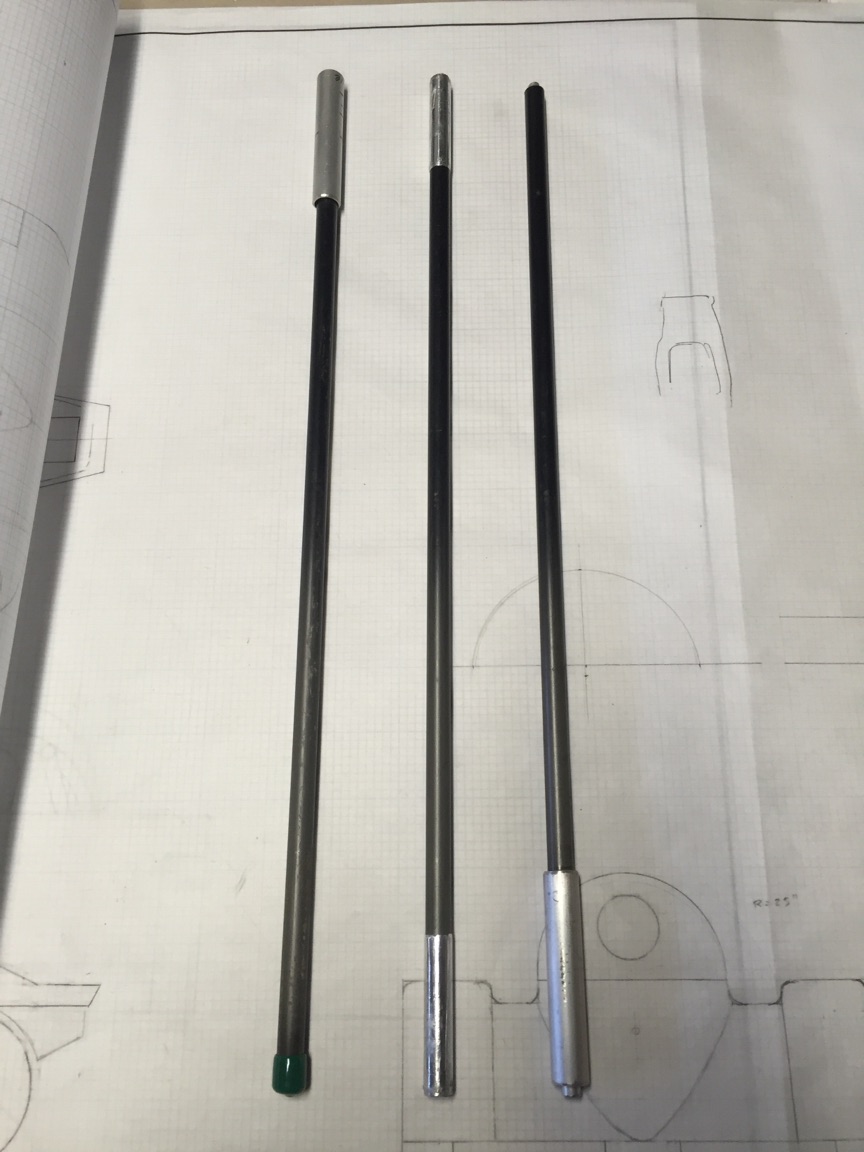

I like tarps but I don’t normally use trekking poles unless I expect to ford flowing water knee-deep or deeper, so I fabricated a pair of Carbon Fiber 3-section poles to use instead. Each section is 17″ long, and the assembled pole length is 48″. You can make them longer or shorter according to your needs and/or preferences.

Materials & Tools:

– Two 3/8″ diameter x 48″ CF tubes

– 12″ of 1/2″ diameter aluminum tubing

– 16″ of 1/4″ diameter aluminum rod

– Epoxy glue

– 3/8″ plastic rod end covers

– 2″ wide aluminum tape

– 2″ blue masking tape

– Dremel with abrasive cut-off disk (best) or hack saw (good enough)

– Very small round file (I use 1/8″ diameter to fit 1-3mm Dyneema ridge line cord)

– Fine flat fileI used cheap, generic unidrectional CF tubes that I picked up from a local store for $20 each. Stronger and more rigid rolled, wrapped and braided tubes are available from various sources.

Cut each tube into two 15.5″ pieces and one 17″ piece, so all the poles will be the same length after the joints are installed. Cut the 15.5″ pieces in from each end, leaving the 17″ piece from the middle. You will end up with four 15.5″ pieces with one factory end and one cut end, and two 17″ pieces with cuts at both ends. The top and bottom tube sections are made from the 15.5″ pieces, with the cut end at the top of the bottom pieces and the cut end at the bottom of the top pieces; the middle sections are made from the 17″ pieces. If you have a Dremel and cut-off disk use that. If not, a hack saw will work fine with the proper technique.

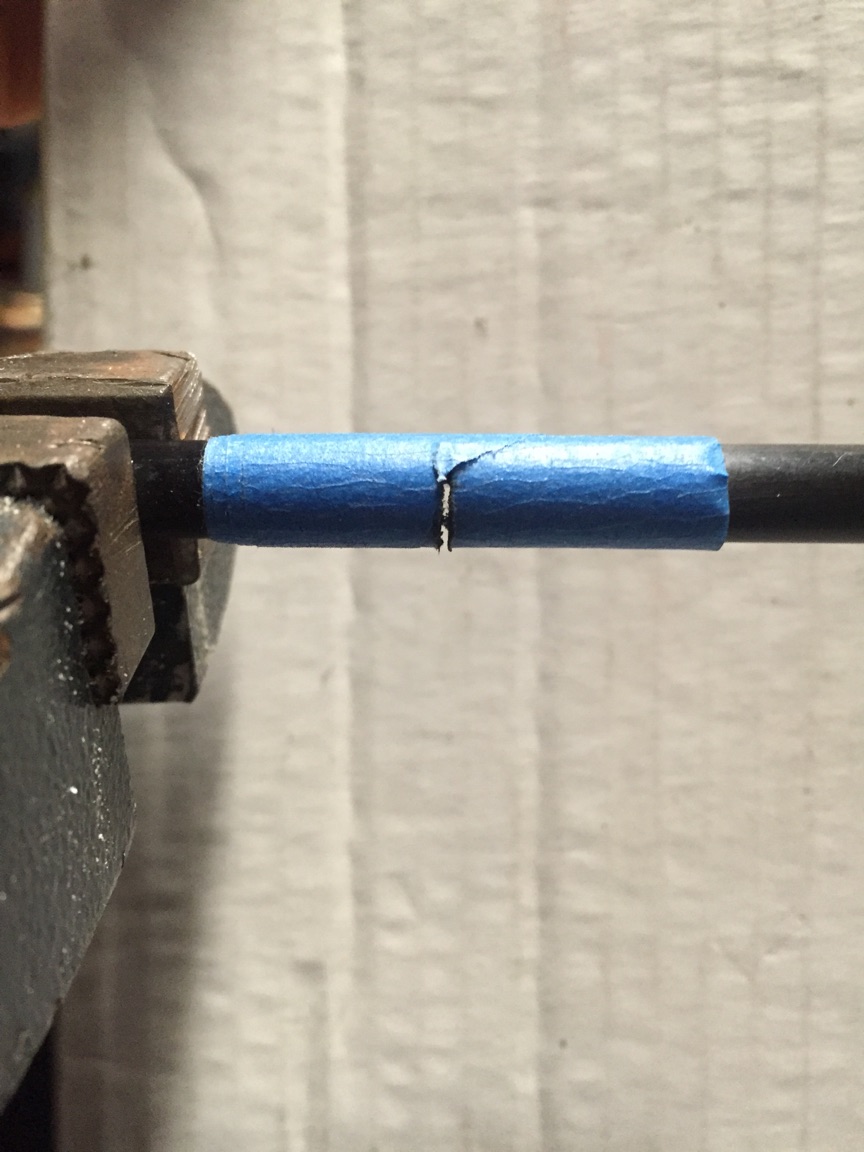

For cutting with a hack saw, first tightly wrap the area to be cut with 4″ of blue masking tape. If you’re going to use a vise while cutting only barely tighten it or the vise will crack/crush the CF tubes.

Next, cut down about 90% of the way through the CF tube.

Then rotate the CF tube so the uncut portion is on top, and cut down through the tube to finish the cut. Remove the blue masking tape. This technique avoids splintering the cut ends of the tubes.

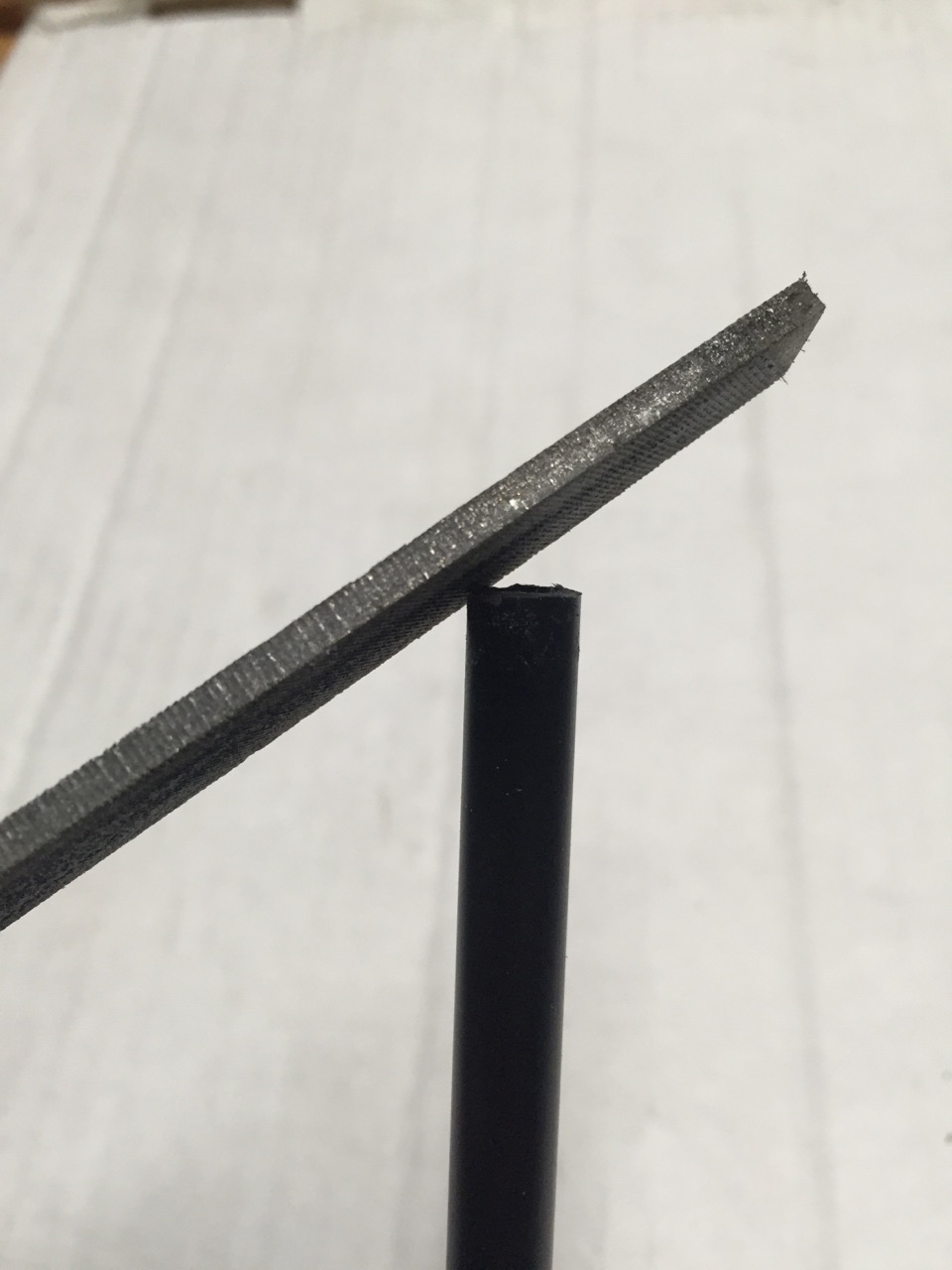

Finally, finish the cut by filing a slight bevel around it. File ONLY towards the center of the tube, rotate the tube, file towards the center, etc.

For the joints I took a “belt and suspenders” approach with both internal and external bracing. I have since decided that external bracing alone is sufficient, and will shave a few grams off the total weight of the poles.

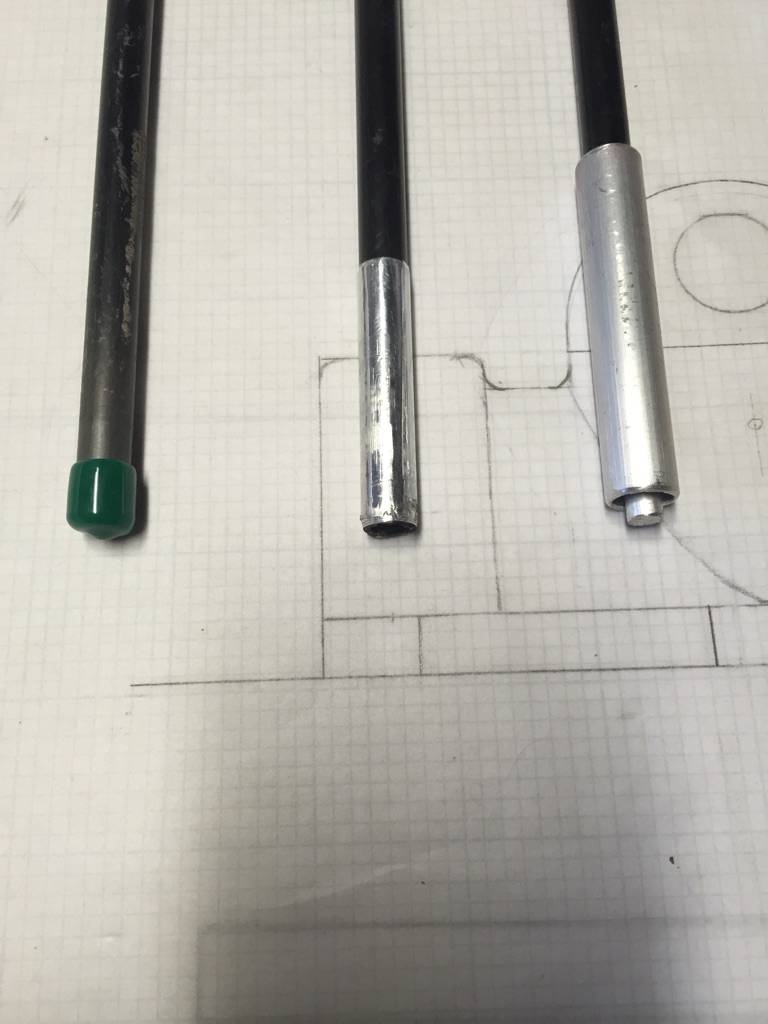

For internal braces, 1/4″ diameter aluminum rod happens to fit almost perfectly inside 3/8″ CF tubes. Cut four 3″ pieces of aluminum rod (two joints per pole), and epoxy them 1-1/2″ into the cut ends of the 15.5″ carbon tubes.

For the external braces, 1/2″ diameter aluminum tubing happens to fit almost perfectly outside the 3/8″ CF tubes. Cut four 3″ pieces of aluminum tube for the joints, then epoxy the aluminum to the cut ends of the CF tubes 1-1/2″ in from the end, so that the ends of the 1/4″ aluminum rod and the 1/2″ aluminum tube extend approximately the same length. While the epoxy is setting put another carbon tube into the joint so that everything will be aligned. The 1/2″ aluminum tubes also serve to protect the cut ends of the 15.5″ CF tubes and keep them from splintering.

Once all the epoxy has set, wrap aluminum tape around each end of the 17″ pieces a few times to make them fit snugly into the aluminum joints. Wrap it a couple of times, see if it’s snug, add a few more wraps if necessary. This wrapping also serves to protect the CF at the cut ends of the 17″ pieces and keep them from splintering.

For the bottom end of the bottom poles put the little plastic rod end protectors from your local hardware store.

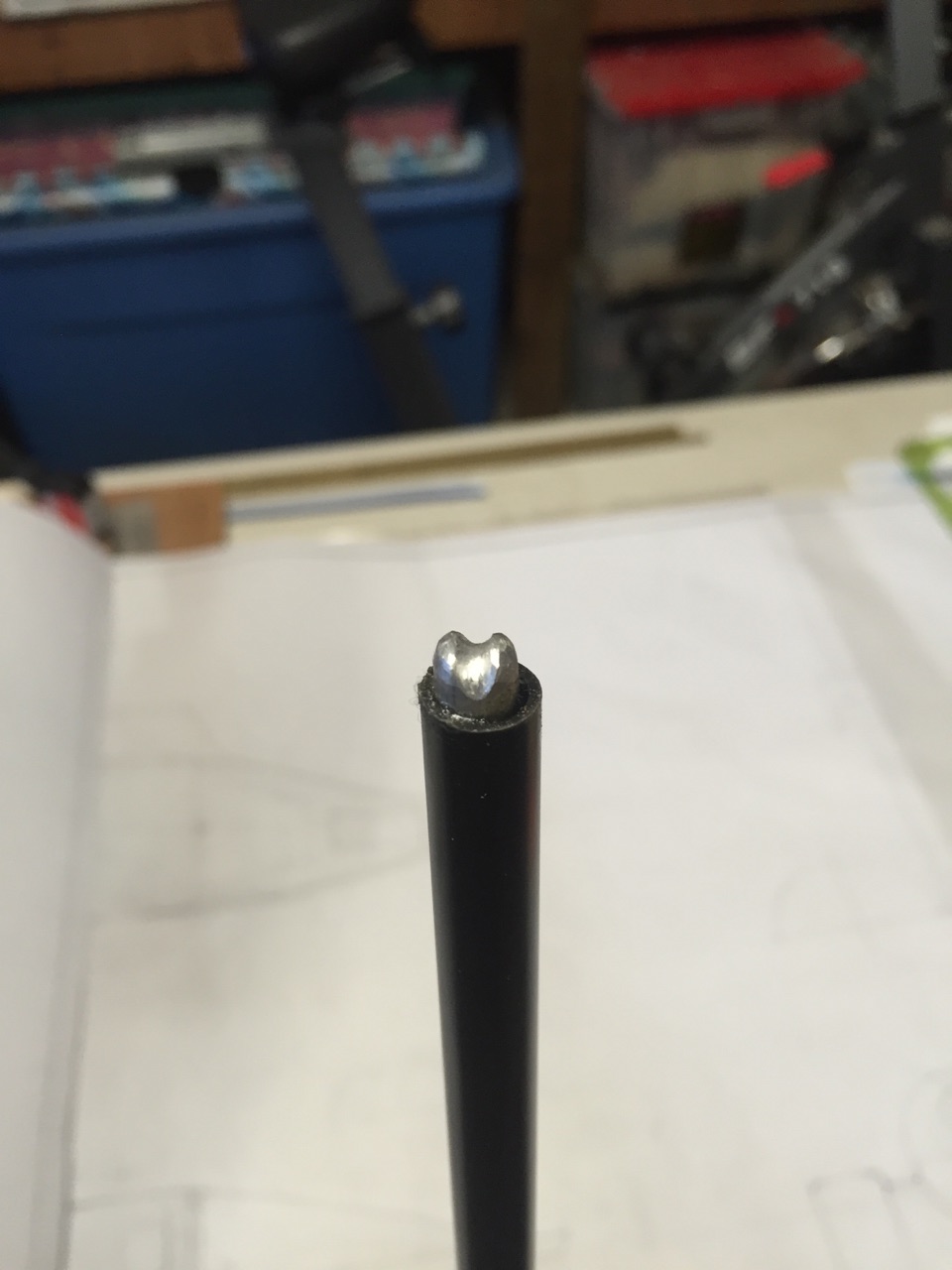

For the top of the poles file tiny saddles into two 1″ pieces of 1/4″ aluminum rod. Round off one end with the flat file and then file tiny saddles with the small round file for the ridge line cord to run over and sit into and keep the cord in place. I tried to take a closer picture but my iPhone wouldn’t let me. If the saddle concept is not clear I’ll post a drawing. After filing the saddles epoxy the two aluminum rod pieces into the top, factory ends of the top tubes with about 1/4″ sticking up.

Alternatively, if your tarp has grommets for the poles, you can just round off the ends of the 1/4″ aluminum rods and epoxy them sticking out 3/8″ – 1/2″. If the rod is too large to fit into your grommets use the flat file to file down to the correct diameter.

Or, if your tarp has sewn pockets for the pole ends, just put a plastic end protector on the CF tube and skip the aluminum rod.

Finished poles weigh 3.1 oz each. You could shave that under 3 oz by skipping the internal bracing. That’s lighter than a Ruta Locura trekking pole – at 3.75 oz I believe they are the lightest made. Also the same weight as a Ruta Locura tent pole selling for $60 each.

May 10, 2016 at 2:20 pm #3401560

May 10, 2016 at 2:20 pm #3401560very helpful details about how to cut carbon fiber successfully. thanks!

May 10, 2016 at 4:43 pm #3401599</div> is not supported by this Forum SW. When you go to create a new posting there is a box below the edit box which lists what you can use. If you start with PLAIN TEXT you will not go wrong.

Yes, we have had to restrict editing due to a serious hack by one ex-member. I agree that allowing someone to edit their own postings for a few days would be desirable, but I don’t know whether the SW can be tuned that way. I will check.

Cheers

May 10, 2016 at 10:16 pm #3401711That’s unfortunate about the hack.

An indefinite edit window can be put to very good use as it allows the OP to maintain an updated summary or results for long threads. This can make learnings more accessible as it spares readers from sifting through pages of comments.

-

AuthorPosts

- You must be logged in to reply to this topic.

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

HAPPENING RIGHT NOW (February 11-21, 2025) - Shop Hyperlite Mountain Gear's Biggest Sale of the Year:

Our Community Posts are Moderated

Backpacking Light community posts are moderated and here to foster helpful and positive discussions about lightweight backpacking. Please be mindful of our values and boundaries and review our Community Guidelines prior to posting.

Get the Newsletter

Gear Research & Discovery Tools

- Browse our curated Gear Shop

- See the latest Gear Deals and Sales

- Our Recommendations

- Search for Gear on Sale with the Gear Finder

- Used Gear Swap

- Member Gear Reviews and BPL Gear Review Articles

- Browse by Gear Type or Brand.