Topic

How to Make a "Polycryo" A-Frame Tarp

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

Home › Forums › Gear Forums › Make Your Own Gear › How to Make a "Polycryo" A-Frame Tarp

- This topic has 52 replies, 4 voices, and was last updated 4 years, 3 months ago by

Michael Ray.

Michael Ray.

-

AuthorPosts

-

May 8, 2016 at 2:23 pm #3400918

Mario, I’ve used a hook-and-pull scale to measure the tension on the tie outs and the normal range is 8-10 lbs. At 10 lbs the shock cord loops are stretched about 80-90%. To fully stretch the loops takes 15 lbs. I have never had a shock cord loop fail.

Tape Test Update:

It rained over both weekend nights. After about 12 hours the 3M dark silver “All Weather” tape failed from a combination of the washer tearing through and pulling the tape off the polycryo:

The glow-in-the-dark tape did not creep or de-adhere further, and I found that when it was dry I could press the tape and re-adhere it to the polycryo. Note also that there is zero deformation of the tape where the washer is pulling against it. This might be a reasonable choice after all.

The 3M transparent tape is still going strong after 36 hours. No creep, no loss of adhesion.

My wife made a great suggestion: use the transparent tape for the tie outs, but put 2″ squares of the glow-in-the-dark tape over them at the edge of the tarp and have the best of both worlds.

May 8, 2016 at 2:58 pm #3400931Step 1 is to clear a large, hard floor area to work on and vacuum it thoroughly. The polycro is static-y out of the box and attracts the smallest motes of dust and pet hair.

I suspect this static-y stays with this kind of poly and collects field debri as you use it……..correct?

Being that it is a “heat shrink” film, I ask how much will it shrink over 1 years time subjected to hot sun conditions while using it? How do these tarps look after bundling them up into your backpacks a dozen times or so?

May 8, 2016 at 4:25 pm #3400955No, the static neutralizes after fabrication and first use. I haven’t had any problems with debris or detritus sticking to it during use.

It does not shrink from mere hot sun exposure. I left one of my tarps pitched outside for 18 months through a winter with some below freezing nights and tow summers with many days days close to 100 *F. There was zero shrinkage and zero breakdown of the material, unlike a piece of polyethylene sheeting four times as thick which I put out for comparison and which degraded to little chunks of plastic in less than two months.

Below is a picture of the tarp I have used for most of the past three years. It has been on three week-long treks and multiple weekends, so at least 30 times being packed. It got “wrinkled” after being packed but that’s all, and most of the wrinkles smooth out when the tarp is pitched. This is one of the first tarps I made, which uses the now-replaced ripstop nylon sail repair tape and .75 mil polycryo. One of the corner tie outs came off once and had to be replaced, but other than that it’s been a trooper.

May 8, 2016 at 9:03 pm #3401036

May 8, 2016 at 9:03 pm #3401036If you’re making a polycryo tarp, I suggest you make two and take both of them on your next trip. Even with the 1.5 mil thick stuff, an undetected rent or hole can spread like mad. They’re smile light, which I liked, and when I woke up one morning to see the big rips, I borrowed enough duct tape, after mine ran out, so that I could finish my trip.

Also, I agree with using super-low-stretch lines and go for as big a tarp as possible if you’re hiking at high altitude, where it can snow. With a 9’Lx 8’W tarp I got caught several nights in a row with heavy snowfall in the sierra nevada. Even with slapping at the tarp during the night to unload the tarp, enough snow fell that it reduced my airspace to where I had about an inch above my quilt. It also reduced my floor space to less than half what I started. A larger tarp will allow you to pitch the tarp higher and steeper, which may help reduce the loss of air space. Maybe a 10Wx11L would suffice. YMMV

May 8, 2016 at 9:06 pm #3401037Thing 2. In the rain, water may track down the ridgeline and into the tent. It often takes nothing more than a thin cord tied to the ridgeline to provide another “escape” for the water.

OK enough out of me for now.

May 8, 2016 at 9:15 pm #3401040David, Thanks for getting back to regarding the shock cord you are using. That gives me a point of reference for my tarp-poncho project.

May 8, 2016 at 9:23 pm #3401044Thank you David and Jeffrey………good information

May 9, 2016 at 5:24 pm #3401268Jeffrey, you are correct that a tear can spread long and fast through polycryo, regardless of thickness. That’s the reason for “hemming” the tarp with double-sided tape, since all of the tears I have experienced started at the edges. It’s also one of the reasons for the ridge line cord, to minimize the tension on the material. I should have mentioned in the OP that when I use a polycryo tarp I take 4 feet of sail repair tape along just in case. I don’t like the sail repair tape for long-term high-tension applications, but it’s fine for short-term repairs.

The other reason for the ridge line cord is to prevent sag and prevent drips from running inside the tarp.

The 7′ width of the tarp allows a pretty steep pitch, though I wouldn’t normally use any tarp if I’m expecting snow:

The pitch shown above is 48″ wide at the base. It can be pitched even steeper, depending on the minimum width you’re willing to go with. The following pitch is 36″ wide at the base:

The pitch shown above is 48″ wide at the base. It can be pitched even steeper, depending on the minimum width you’re willing to go with. The following pitch is 36″ wide at the base: May 15, 2016 at 2:00 pm #3402563

May 15, 2016 at 2:00 pm #3402563Update:

After 5 days of continuous 20 lbs. hanging during rainy weather, the nylon washer tore through the 3M transparent tape, but the tape never creeped or de-adhered from the polycryo. Pretty good, since the normal load on a side tie out is about 10 lbs.

Although the top 1/4″ inch of the glow tape de-adhered during the rain, I was able to re-adhere it by pressing when dry, and the nylon washer never even started to tear through. Strong tape, but the de-adhering makes me nervous about field use.

I had some short 3/8″ diameter carbon fiber tubing pieces left over after posting a MYOG thread for tarp poles (here), so I thought I would try using some for tie out load-spreading:

I made two and attached them to the ends of a short piece of polycryo. Since I assumed they would spread the load better and not tear through I decided to hang 25 lbs. from each tie out, which is actually closer to the normal tension on a ridge line cord :

I made two and attached them to the ends of a short piece of polycryo. Since I assumed they would spread the load better and not tear through I decided to hang 25 lbs. from each tie out, which is actually closer to the normal tension on a ridge line cord :

After 24 hrs. the short lever arms created by the radius of the tubes were enough to pull the tape off the edge of the polycryo, although there has been no creep. It’s a bit hard to see, but it’s the small triangular area right above the end view of a CF tube:

I will spray them with water several times per day and leave them hanging until something fails, then report the results.

May 15, 2016 at 2:42 pm #3402568David,

Nice work there.

May 26, 2016 at 11:49 am #3404841I was wondering about how to make a light and cheap load spreader, along the lines of the CF tubes above.

How about a piece of folded PET from a soda bottle? Probably cut into a triangle above the fold. Then either pierced with a hot metal rod to open a hole, or simply threaded as per the CF tubes above.

I also wondered about using tape applied in a V, with the PET fold sitting at the bottom of the V. Then apply a second V, folded in the opposite direction, giving four points of contact (though overlapping), with two on each side. Also acts as a load spreader. You could even add a third layer, folded back on itself, in ‘traditional style’…

May 26, 2016 at 1:39 pm #3404864I have made the side attachments which the V tape you mentioned. I thought it would be a great idea, but in reality I think the straight tape is superior. The V does spread the load some, but the load ends up going straight from the tip of the tape to the ridgeline. I think the one attachment point failure I had was on one of the V’s on the side, which should have less loading. The tape tore. See this thread for the pictures of the attachment I am describing:

https://backpackinglight.com/forums/topic/59450/page/10/#post-3373344

Edit, the user friendliness of this website sure has gotten very poor the last month. The link above goes to the first page of a 10 page thread, instead of the post which I copied the link from. If you want to see the V tape go to page 10 near the bottom.

May 27, 2016 at 10:44 pm #3405160I wish I had seen this thread a few days ago….yesterday I made a polycryo groundsheet to protect the cuben inner for my supermid.

I used the same duck large patio door double thick poly that you are using. Actual measurement was 80×107 instead of 84×120, but whatever. I need to make a 88×88 sized sheet for the cuben inner (which was supposed to be 90×90, but whatever again).

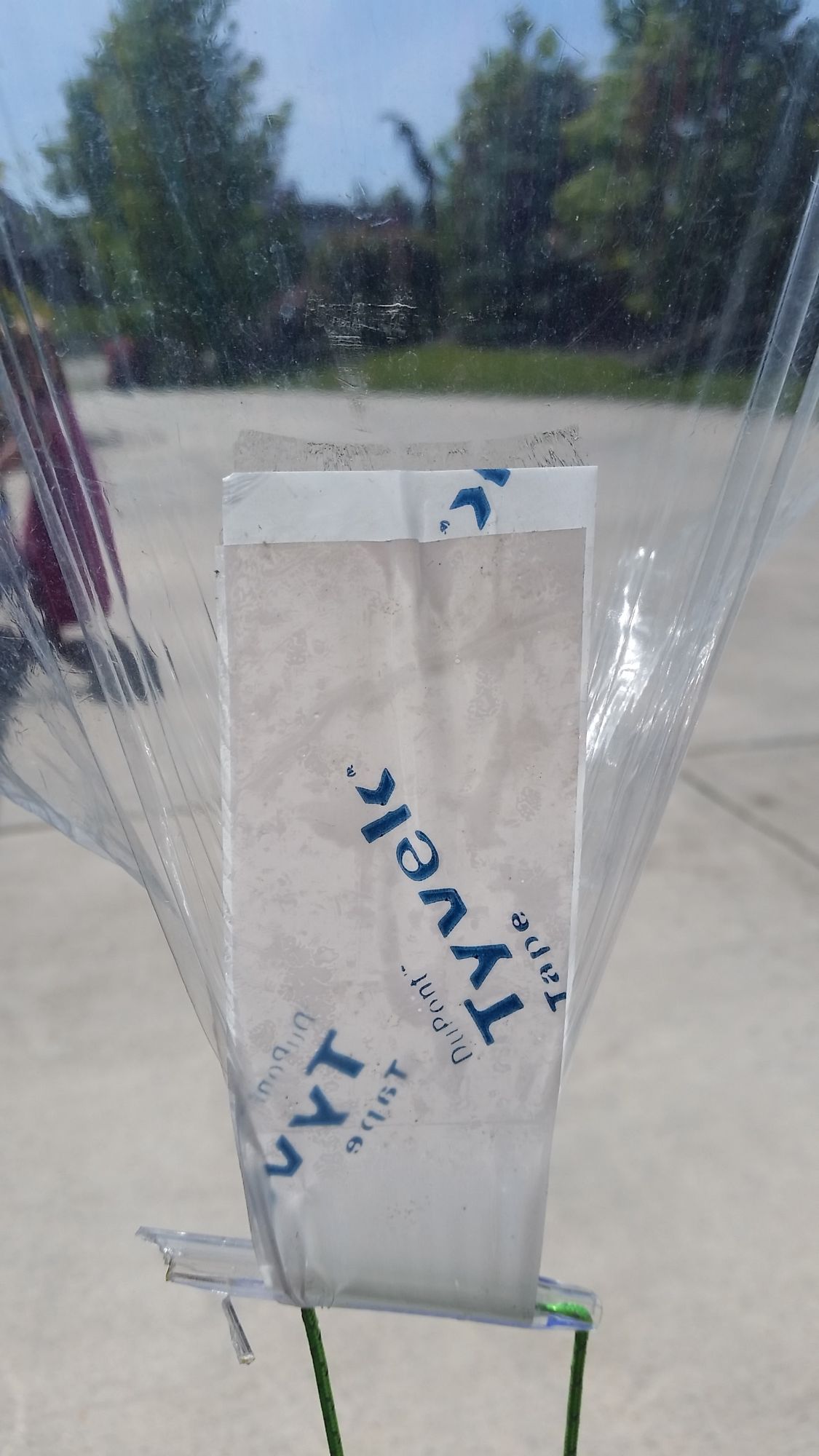

The tape I used was Tyvek tape. Its similar to tenacious tape in that its really thin and light..and the adhesive isn’t “gooey” like duct tape. Which…is why I think several of those tapes creeped…its because of that gooey nature.

Have you happened to try Tyvek tape? Its much cheaper than tenacious tape, and also WAY lighter than duct tape. The original polycryo sheet is 7.8oz and after adding a bunch of tape, 4 nylon washers, and 4 long 1.25mm zpacks guyline to 4 corners, it now weighs 8oz.

If you haven’t tried it….and don’t have any….maybe I can go ahead and do the same stress test you did…just need to find 25lb plates.

Anyway, just showing you what I did….I cut 2 pieces from the original sheet to make a square piece ->

Now, I can just pull out the groundsheet when I’m searching for a spot and trying to see if the shelter will fit or not. I can then stake out the groundsheet, put the shelter on top and have a perfect pitch every time. The supermid was already super easy to pitch right the first time…but I also need to make one of these for my triplex and for my duplex….which sometimes I do have to move a stake or two around. But once the groundsheets are made, no more issue.

Anyway…I like your idea better with the tieouts…all I did was put the washer in a corner and folded the corner a few times so there was several layers of polycryo and a few layers of tape ->

When I was originally making it..I didn’t worry about the tieouts…b/c it was just for a groundsheet.

But once I put it on the ground…I got to thinking…hey…this is a 88″ square tarp! I just need to add some ridgeline tieouts and I have a spare shelter on my trips. Maybe I could use it as a lunch shelter if its raining that we could huddle under…or…if there was a poor hiker that got his shelter trashed during his hike, he could just have this one.

I remember seeing your old thread about polycryo tarps…and when I went to search I found this very detailed one that you made..thank you!

May 30, 2016 at 12:26 pm #3405707I did a quick and dirty tape test for the Tyvek tape. It did creep a bit, but it held 25 lbs, and I could only test it for about 20 minutes…b/c then a hole in the polcryo started to spread and also the pen that I used for a “tube” started splitting. It might be worth while for you to test it…..it is super light.

May 30, 2016 at 3:31 pm #3405745

May 30, 2016 at 3:31 pm #3405745LOL. It warms my heart to see people still giving polycryo tarps the old college try. Don’t stop.

While I still have a few sheets left, I’ll do a little work in hope of figuring out a viable tape pattern as prophylaxis against rip expansion from the microscopic holes. But not in the wilderness–if my hiking friends didn’t have duct tape, life would have been more interesting than fun. :*]

Jun 8, 2016 at 8:01 pm #3407832Excellent write up! Thanks for the detailed instructions and the great tips.

Jun 9, 2016 at 1:57 pm #3407979Uline makes several double-sided tapes. Which one did you use? Thanks for a great how-to.

Jun 9, 2016 at 2:09 pm #3407984DGoggins: The trick with using a polycryo sheet as both a ground sheet and a tarp is avoiding microscopic holes or tears in the poly. When polycryo tears it tends to tear completely across the sheet, and all at once. A catastrophic failure. I always carry at least 4 feet of sail repair tape when I use a poly tarp.

Jeffrey: Very interested in a “rip stop” tape configuration. Would like to see what you come up with. That might be the perfect use for Tyvek take since it is so light and doesn’t need to carry a constant load like a tie out which leads to creep.

Cindy: I was afraid someone would ask that, because I’m not 100% sure which Uline tape it is. I ordered several rolls a couple of years ago, but don’t have the records anymore. I still have the last roll but it has no identifiable model or code marking, just “Uline” and “Made in Taiwan.” Clear, 1/2″ wide, with paper backing, if that helps. That being said, 3M 444 Hi Tack looks like it would be a good choice, since it is intended for <span id=”liContent”>bonding plastics.</span>

As promised, when I fabricated another tarp this past weekend I weighed everything at each step of the process. It was an A-frame, but I used 1/2 of a 7′ x 25′ sheet to come up with a longer tarp for better weather protection at the ends and to use with a hammock. It’s a Frost King product and comes on a 43″ wide roll, so the actual width is 86″ (vs. 84″ from the usual window insulation kit). Regrettably it appears to be the “normal” .75 mil thickness; I still haven’t found a source for thicker material in sheets larger than 7′ x 10′.

I also added 30″ zippers at each end, so the rectangular A-frame can be configured as a hexagonal floorless tent.

Weight of poly alone: 5.3 oz. Presumably a 7′ x 10′ sheet of the same material would weigh 4.24 oz [(7′ x 10′)/(7′ x 12.5′) x 5.3 oz]

With double-sided tape hems: 6.0 oz, adding 0.7 oz for 472 lineal inches of tape. A 7′ x 10′ tarp would have 408 lineal inches and would add 0.6 oz for tape.

With 10 side tie outs, each constructed from 10″ of transparent duct tape and a trimmed nylon washer: 7.1 oz, adding 1.1 oz, which comes to 0.11 oz per tie out. For a normal size tarp I only use 8 side tie outs, which would add 0.88 oz.

With ridge line tie outs and 1.1 mm Spectra ridge line cord: 7.9 oz, adding 0.8 oz. The only difference between this weight and the weight for a normal size tarp would be the weight difference of 30″ of 1.1 mm cord, or about 0.03 oz/0.97 g (@ 0.39 grams/foot) less a normal size tarp.

Shock cord loops, fabricated from 10″ of 1/8″ shock cord, weigh 0.08 oz/2.18 grams each, for a total of 0.6 oz with 8 side tie outs or 0.8 oz with 10 side tie outs.

Jun 9, 2016 at 3:53 pm #3408005Anonymous

InactiveHI DGoggins,

I used Tyvek tape on the cross linked polyolefin (“polycryo”) tarp that i had made. It seemed to work well. I didn’t use the tarp a lot though (a little more than a handful of times for weekend trips)–ended up giving it to a friend for their bug out bag.

Jun 18, 2016 at 10:46 am #3409549Instead of making the ridgeline and the two ridgeline guyout cords three separate pieces of cord, I used one continuous piece of cord, thus allowing the ridgeline length to be adjustable in case of stretch or shrinkage of the polycryo material. I simply attached the cord to the ridgeline guyout grommets with a larkshead hitch.

Jun 23, 2016 at 10:20 am #3410328Jean, I don’t quite follow. Can you post a picture?

Jun 23, 2016 at 2:20 pm #3410382Might be a random, already-considered suggestion, but has anyone considered Hexayurt tape for this application?

Not sure how heavy it’d be, but they use it for Hexayurts. It has to be strong, I’d think.

Jul 9, 2020 at 2:44 pm #3657213@gearmaker I’m surprised that I never posted on this thread!

Did you ever try several strips of tape narrow enough for a smaller D-ring and aligned at different angles as proposed by @autox. I also missed on the polycryo tarp tested thread that Rene had also suggested linelocs. It looks like those weigh 1.35 g so an additional 6 g for your 8 tieouts.

Any more tips you’ve learned? It didn’t look like you were selling these anymore when I checked your site. I’ll be making Rev 4 in the next couple weeks. It looks like 3M 2120 (e.g., TOUGH transparent duct tape) is still the winner for tape.

Jul 10, 2020 at 11:26 am #3657398@topshot: I never did try several strips of narrow tape since I gave up on polycro shelters. I guess the only tip I learned is that polycro is not durable enough to be relied on as a shelter. Nevertheless interested in seeing your Rev 4.

Jul 18, 2020 at 4:45 pm #3665122@gearmaker You wrote, “Scotch “Tough” Transparent Duct Tape (their glow-in-the-dark duct tape works well too)”

I assume you meant the Duck brand GITD rather than 3M/Scotch?

I discovered that my son used my last roll of 2120 and bought me Duck’s transparent version to replace it with. It doesn’t seem quite as strong to me. The local store where I got 2120 no longer carries it, but has several other “all weather” options. Lowes has some “Tough” but not the transparent (aside from “repair tape” without fibers like that Gorilla that failed early) and the only “all weather” one appears to be the one you tested above that didn’t do too well.

-

AuthorPosts

- You must be logged in to reply to this topic.

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

HAPPENING RIGHT NOW (February 11-21, 2025) - Shop Hyperlite Mountain Gear's Biggest Sale of the Year:

Our Community Posts are Moderated

Backpacking Light community posts are moderated and here to foster helpful and positive discussions about lightweight backpacking. Please be mindful of our values and boundaries and review our Community Guidelines prior to posting.

Get the Newsletter

Gear Research & Discovery Tools

- Browse our curated Gear Shop

- See the latest Gear Deals and Sales

- Our Recommendations

- Search for Gear on Sale with the Gear Finder

- Used Gear Swap

- Member Gear Reviews and BPL Gear Review Articles

- Browse by Gear Type or Brand.

The pitch shown above is 48″ wide at the base. It can be pitched even steeper, depending on the minimum width you’re willing to go with. The following pitch is 36″ wide at the base:

The pitch shown above is 48″ wide at the base. It can be pitched even steeper, depending on the minimum width you’re willing to go with. The following pitch is 36″ wide at the base:

I made two and attached them to the ends of a short piece of polycryo. Since I assumed they would spread the load better and not tear through I decided to hang 25 lbs. from each tie out, which is actually closer to the normal tension on a ridge line cord :

I made two and attached them to the ends of a short piece of polycryo. Since I assumed they would spread the load better and not tear through I decided to hang 25 lbs. from each tie out, which is actually closer to the normal tension on a ridge line cord :