Topic

Ecopak EPL/EPX Ultraweave

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

Home › Forums › Gear Forums › Gear (General) › Ecopak EPL/EPX Ultraweave

- This topic has 151 replies, 30 voices, and was last updated 1 year, 5 months ago by

Brock Dubbels (Spaceman).

Brock Dubbels (Spaceman).

-

AuthorPosts

-

Sep 4, 2021 at 9:48 am #3726642

I haven’t seen much discussion of these new fabrics here on BPL but they sound very interesting. Superior Wilderness Designs has an informative post here.

EPL200 sounds like a winner to me with similar construction to Hybrid 50D DCF fabric (seam tapable, waterproof) but with a much more durable exterior that employs UHMWPE fibers rather than polyester.

Any thoughts?

Sep 4, 2021 at 10:08 am #3726645It just occurred to me that Dave Chennault might have something to say about the fabrics and I see two posts. I’m running out the door and haven’t read them yet…

https://bedrockandparadox.com/2021/07/24/challenge-ultraweave-abrasion-testing/

Sep 4, 2021 at 9:36 pm #3726687The classic (and now obsolete?) DCF composite pack materials were nothing more than an expensive joke played on the UL community, IMO.

After building half a dozen packs with the new 200 and 400 Ultra I predict it a more promising future. It’s still a laminate; and one that seemingly rely on the lamination properties for its structure, so that could be a concern.

Sep 5, 2021 at 7:58 am #3726697I’ve read a few posts on Reddit where people with new packs think small areas of the fabric are delaminating on the inside of the pack.

Sep 7, 2021 at 11:04 am #3726840Agreed in reference to the DCF hybrid stuff. Super overrated.

Did any of the DCF hybrid stuff even have DCF in the face fabric? Wasnt it all just white polyester with a DCF waterproofing layer behind it? True woven UHMWPE is another story – that stuff is crazy durable. Which it seems like that new Venom fabric and Ultra are taking advantage of. Makes me wonder if Ursack is using one of those two as their supplier for the bear bags? Maybe some day we will get a giant monstrosity that is basically a full sized pack that is grizzly bear proof!

What I would really like to see is someone make true submersible dry bag style packs out of this new Ecopak stuff. Roll top bags (with a few exceptions) are not really ever considered submersible rated even if the seams are properly sealed. As much as I do not like most zippers the large IPX8 rated ones are pretty cool.

I would pay good money for a titanium framed external frame pack (frame design similar to what Seek Outside is doing) with swappable Ecopak or similar pack bags of different sizes attached to it with an option for rolltop or submersible zipper. And for the larger sizes the ability to add a thin UHMWPE framesheet + lightweight hoop on the opposite side of the frame/packbag for help with compression and load stabilizing. And hell – throw some ability to weight the front of the pack too like what AARN is doing (although I think personally I would stick to mounting stuff mainly on the hipbelt – dense / heavy stuff like cameras and water). AARN’s unique packstrap method where they have a bit of “stretch” is also very interesting. I have converted several of my packs to use the tensioning method that McHale packs use on their shoulder straps and it is also a big upgrade.

edit: BPL is automatically adding links now to posts? I did not link to any sites in this post yet I see links now to BPL’s own shop and to RSBTR for the venom fabric. There is no way for me to edit those out.

Sep 7, 2021 at 11:51 am #3726842If you want to disable automatic links, just spell the thing incorrectly.

My new Seek Outside Flight 2 pack was made with a black 200d UHMWPE fabric with what I think has a 0.5 mil PET (polyethylene terephthalate or Mylar) film laminated to the back, like Xpac. I don’t know exactly what the fabric source was. I only have one trip with the pack so far and I’m not that hard on fabrics, so I can’t speak to durability. I do wonder about the PET film though, as it does not look nearly as well bonded to the fabric as what you see in Xpac. It looks a bit ‘crinkley’ where the fabric has flexed. Time will tell. I’m still a big fan of Xpac in 210d. It lets a lot more light through so your pack isn’t like a cave inside.

Sep 8, 2021 at 2:15 pm #3726973Agreed that hybrid DCF never really made sense for a pack cloth. It’s essentially woven polyester with a PET backing – so basically the same as X-Pac except they add some non-woven dyneema inside that doesn’t really do anything other than jack the price because it’s inside (so it’s not helping with abrasion) and it’s not woven (so it’s not helping with punctures and holding the stitching). It’s works but there’s little rationale for paying vastly more for it versus X-Pac.

Philip, I think you’re referring to Seek Outside’s SpectraGrid HT fabric, which does partially use 200D UHMWPE. That looks like a nice fabric that is quite durable but it is pretty different from the EPL Ultra fabrics from Challenge. Ultra is mostly UHMWPE (about 70%) whereas I’m not sure of the % in SpectraGrid HT but it looks lower since it’s woven in there with a lot of 100D nylon. The other difference is that Seek Outside reports that it uses a PU coating versus a laminated PET layer for waterproofness. PU coatings commonly don’t hold up on pack fabrics and Seek Outside themselves recommend X-Pac as the more waterproof option, so it doesn’t look as waterproof as a laminate.

We’ve been testing the Ultra fabrics this summer and they seem like the real deal, as many others have said. EPL200 is mostly UHMWPE so it is a lot more durable than VX21 from X-Pac (which is mostly nylon) while weighting little over half, and the laminated coatings hold up better. The same guy designed both materials (Hale who was formerly at DP and is now at Challenge) and he reports the laminated is more reliable in the new materials.

Sep 8, 2021 at 2:56 pm #3726975Hey Dan. I have a one-off pack that SO sewed using a new batch of UHMWPE fabrics they are planning on offering next year. My old Flight One was 210d Xpac with SpectraGrid accents/pockets. Cheers.

Sep 8, 2021 at 3:21 pm #3726977I made a pack out of laminate and it delaminated inside after a while

Ide rather just use a nylon about 200D. PU water proof interior

Just one opinion

Sep 9, 2021 at 12:06 pm #3727023Here are detailed images of the fabric in my SO Flight 2. This is the outside face of the fabric. On the right is a daisy chain of 3/4″ webbing for scale.

And the inside. You can see how the Mylar film is a bit crinkley. I assume this is due to the high denier (‘coarse’) weave of the fabric.

Sep 9, 2021 at 5:24 pm #3727044

Sep 9, 2021 at 5:24 pm #3727044Looks like Ultra 400.

Sep 10, 2021 at 12:30 pm #3727087Is there a standard for testing the durability of laminated fabrics? Seems like it would be relatively straightforward to subject this stuff, Xpac, DCF, etc. to the same abuse, probably repeated flexing, and post-test for hydrostatic head, as well as check for any visual delamination. Washing machine cycles, as used to wear test coated fabrics, might serve.

Anecdotes are looking very positive for Ultraweave, but a little head-to-head objective testing would settle the issue with at least some amount of certainty.

Sep 10, 2021 at 4:53 pm #3727118Is there a standard for testing the durability of laminated fabrics?

Ah, there’s the rub. You first have to define the word ‘durabilty’ – in a manner which permits measurements.

And of course, a definition which suits one brand of fabric will not suit another brand, just like ‘breathability’ and so on.Cheers

Sep 11, 2021 at 10:54 am #3727146Got my hands on some black Ultra 200 via LiteAF and it definitely feels a bit more durable than previous pack materials being woven vs a laminate (I’ve heard and read the 200 is 3X more durable than the laminate). There is still a waterproof lining on the inside which needs sealing (which I’ve seen done by the pack maker).

Despite its toughness and likeness to a “mini-Codura” nylon, still wouldn’t hold a candle to a Mil-spec nylon for general travel (being thrown into luggage compartments, scraped against concretes, etc..), but for trail backpacking think the 200 will be fine.There’s 400 and even 800 out there for more rugged use (been looking for a part backcountry/part urban black backpack for Europe and/or Asia myself – as designs proliferate these could be “the fabric” .. maybe one of the pack makers will offer one with a solid zipped pocket to replace the ubiquitous “drying”/cargo netting). For the waterproofness the issue will still be the laminate.

Sep 12, 2021 at 1:05 pm #3727217Kevin @SO told me it’s the 200d fabric, but again, I don’t know the manufacturer at this point. It’s more like the EPL in that it’s a woven ultra PE with a Mylar laminate as opposed to the EPX which seems to be an ultra PE face with an x-grid mid layer and interior 70d ripstop “scrim”. I guess all those layers are why the EPX is almost twice the weight of the EPL for the same denier face weave.

Heres the pack if anyone is interested:

And in action:

Sep 12, 2021 at 2:19 pm #3727232Sep 12, 2021 at 3:58 pm #3727238Nice country!

CheersSep 12, 2021 at 11:31 pm #3727252Philip: Nice pack. That material looks great. It appears they used the SpectraGrid HT stuff for the side pockets and then fully woven UHMWPE for the main bag. Seems a bit odd to uses the less durable material for the side pockets since they can see a lot of wear but I’m sure they had a rationale.

Note that EPLX and EPX don’t have any UHMWPE. The EPLX and EPX stuff is regular woven polyester for the face fabric so there is zero UHMWPE in those fabrics (they are just polyester and then different based on the presence or not of the 70D inner scrim). Certainly the inner scrim (EPX) and X-poly (EPLX and EPX) adds weight but the main reason those are heavier is because polyester is heavier than UHMWPE. Only the EPL Ultra is the stuff with mostly woven UHMWPE.

Will: Challenge has a lot of different fabrics with similar names which makes it confusing. Even the title of this thread has it wrong, because we’re really talking about the versions with the tough and light woven UHMWPE called EPL Ultra, which is quite different from the regular EPL and EPLX materials they offer. The key word here is “Ultra” because Challenge is using that to refer to their fabrics that include UHMWPE (ultra high molecular weight PE).

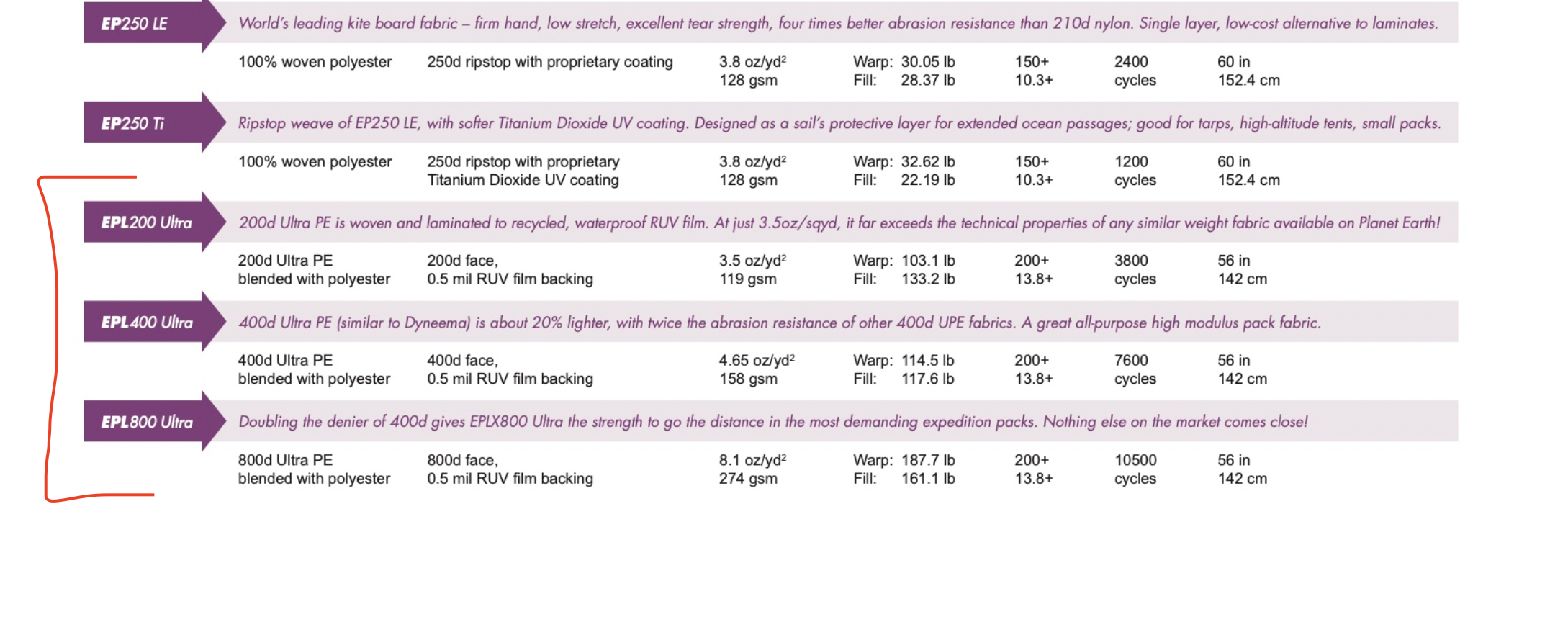

The stuff you link to is EPLX in the 200 weight. I’m sure it’s a nice fabric but it’s just a regular polyester face fabric with zero UHMWPE. The good stuff is the EPL 200 Ultra. You can see that at the bottom of Challenge’s materials guide:

That is available at Rocky Woods too, but unfortunately the decided to invent their own name for it just to make all this even harder to figure out. When Rocky Woods sells EPL200 Ultra they’re calling it DiamondHide. This is it here:

https://www.rockywoods.com/DIAMONDHIDE-uhmwpe-200D-Fabric-Sold-per-Foot-White-LightingSep 13, 2021 at 6:21 am #3727255“Even the title of this thread has it wrong, because we’re really talking about the versions with the tough and light woven UHMWPE called EPL Ultra, which is quite different from the regular EPL and EPLX materials they offer.”

Yes, I’m definitely confused by the similar names of the fabrics. I’m open to changing the thread title so that people can find this more easily in the future. Maybe “Ecopak EPL Ultra (and related variants)”?

Sep 13, 2021 at 10:08 am #3727264Dan, thanks for clearing that up. The names were real head scratchers, for sure.

Sep 13, 2021 at 1:07 pm #3727269Challenge hasn’t released any explanation of their naming, but as far as I can tell it works like this:

The first part of the name is EP, EPL, EPX, or EPLX, where:

EP = Short for EcoPak, which is their name for their entire family of these fabrics. Every fabric they offer in this family starts with EP.

Then the X and L letters after EP denote the various layers in the material, where:

X = Refers to the X-ply reinforcement strands (like X-Pac fabric from Dimension-Polyant, but not affiliated other than same designer)

L = Has a plastic layer laminated on (L = laminate?)Unfortunately there isn’t a letter to denote the presence of the interior woven protective layer (which is the same fabric naming problem that X-Pac from DP has – you’d think they’d would have learned) . Right now the EPX stuff has the inner layer while the EP, EPL, and EPLX do not, but seemingly that could change and make all of this more confusing.

Then the next part of the name has a number (e.g. 200) that refers to the denier (size) of the outer (“face”) fabric threads, where obviously higher numbers is tougher versions. So for example, we have EPLX200, EPLX400, EPLX600 etc. Then an RS suffice is added if that face fabric also has a ripstop (e.g. EPLX450RS)

And then lastly there are additional words or letters added at the end to denote special versions. The UHMWPE fabrics are denoted by adding “Ultra” (e.g. EPL200 Ultra, EPL400 Ultra etc). Right now they don’t offer a non-Ultra EPL200 but seemingly they could. They do offer EPLX200 and EPX200 which are non-UHMWPE fabrics since they lack ‘Ultra’. The switch from polyester face fabric to UHMWPE face fabric is a pretty massive difference, so ideally it would have been featured more prominently in the name rather than as a suffix that is often left off.

Aside from Ultra, other special versions include “KC”, “LE” and “Ti”. I think KC has something to do with Kite Cloth. Not sure what LE is. Ti refers to having a UV resistant titanium dioxide coating.

Sep 15, 2021 at 3:13 pm #3727444We have several packs out for testing in 200D and 400D Ultra. We use the SpectraGrid for pocketing, as it is more pliable. The SpectraGrid itself, actually did really well on a recent trip to Alaska where 3 of us had SpectraGrid and we had a lot of rain. So far the feedback on the Ultra has been very good. Taber abrasion tests etc are off the charts, and field testing seems to corroborate these specs. The finish is a little different than XPAC to make the fabric a bit more pliable a quiet.

Sep 16, 2021 at 4:29 pm #3727522What about that “Venom” pack fabric? Surprised we havent heard about that – from what I remember it was 100% UHMWPE face fabric with a TPU coating (which I assume is more like the stiff coating they use on Dry Bags but tinner and on the inside?). It seemed a lot like the fabric Ursack is using but maybe with extra waterproofing ? I also remember it being pricey as hell but who knows if thats just due to the reseller markup….. I have no idea if its true here specifically but sometimes buying a full roll from whoever the manufacturer is direct can be much much cheaper. The other advantage of TPU being you could probably weld it easier (at least I think thats why so many dry bags use it). Might be possible to sew a pack together and then weld the inner coating for waterproofing the seams?

Also I swear I saw a fully spectra woven fabric before…..basically just another brand of UHMWPE but they might have their own coated version or lamination?

The other DP fabric that always interested me was one that was like X-Pac but I believe no X-threads but had a decent amount of some type of Aramid in the face mixed in – believe it was very light and they said it was made mainly for a military contract. Could be cheaper than UHMWPE but still add enough extra abrasion resistance to be an upgrade? From what I remember it was something like 2.1oz a square yard and a blend of kevlar and polyester laminated to 0.5 PET

Sep 17, 2021 at 4:43 pm #3727580Fully woven UHMWPE/spectra packs have been around for a long time (e.g. McHale, CiloGear) but always extremely expensive (e.g. $700-$1000) and not in a laminated (waterproof) form. Ultra 200 at $30/yd is still very expensive compared to traditional pack material ($5-$10/yd) but way less than some of those older woven UHMWPE options at $100/yd+.

Regarding Venom, the TPU coating adds a lot of weight so it’s 3.9oz for 100D UHMWPE whereas Ultra 200 is lighter (3.5oz) while using 200D. The waterproofing looks quite good in Ultra, but if someone is having their doubts and/or just really values waterproofness than Venom could be the right choice.

Sep 25, 2021 at 10:47 am #3728134Anyone have any suggestions how to repair/stop the delamination? I picked up a used pack with Ultraweave 400. After looking through the pack, I noticed it’s delaminated in about a 2 sq in section and there are some minor runs or stretching in the weave over the same area. The seams along the bottom may be delaminating as well.

Would some silicone and tenacious tape or silnylon do the trick?

-

AuthorPosts

- You must be logged in to reply to this topic.

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

Our Community Posts are Moderated

Backpacking Light community posts are moderated and here to foster helpful and positive discussions about lightweight backpacking. Please be mindful of our values and boundaries and review our Community Guidelines prior to posting.

Get the Newsletter

Gear Research & Discovery Tools

- Browse our curated Gear Shop

- See the latest Gear Deals and Sales

- Our Recommendations

- Search for Gear on Sale with the Gear Finder

- Used Gear Swap

- Member Gear Reviews and BPL Gear Review Articles

- Browse by Gear Type or Brand.