Topic

Down -vs- Climashield APEX loft question

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

Home › Forums › Gear Forums › Make Your Own Gear › Down -vs- Climashield APEX loft question

- This topic has 2 replies, 3 voices, and was last updated 5 years, 8 months ago by

James Marco.

James Marco.

-

AuthorPosts

-

Jul 29, 2018 at 10:26 pm #3548893

Hey MYOG users –

I was hoping to get your thoughts on the practical insulation offered by various lofts of Climashield apex, versus comparable warmth in with down. Obviously there are CLO or R values per inch for both, I’m hoping for your experience. Links to a nice summary showing equivalent warmth thicknesses would be great too.

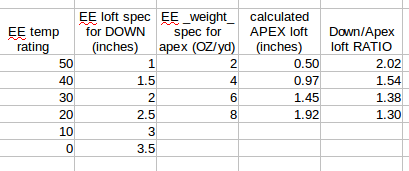

Using EE down loft specs for each temp rating and actual Climashield APEX thicknesses that I just put together from RSBTR apex product listings, here are what Enlightened Equipment thinks are equivalent.

Is this consistent with your experience?

Basically I have several box-baffle down pieces for various lofts, which i am using as my starting point to make synthetic replacements. I’m happy with the insulation performance so would like to get as close as possible in APEX to the same insulation (over say same-weight or same-loft)

Thanks!

Jul 30, 2018 at 10:46 pm #3549064I think the down/Apex loft ratio should be about 2 for all temperatures. Maybe EE is overly conservative, for example, you only need 6 oz/yd2 Apex for 20 F ?

I have a 5 oz/yd2 Apex quilt that I use down to 35 F or so which would be consistent with EE rating

Another rule of thumb would be use twice the weight of Apex for the same warmth as down. Therefore, the loft/weight is 4 x for down compared to Apex.

It’s probably safe to use the EE values

Aug 1, 2018 at 1:25 pm #3549376Yeah, I believe Jerry is correct. It should be about 2.0 across the board. Increasing loft, does not improve cold weather performance that much, though…so be careful. There are limits.

Loft/temp only tells part of the story, even though it is a fair metric to use when comparing down to down. Comparing down to synthetic (Apex in this case) can lead to false temp rating assumptions.

Down is highly branching. Each plume is divided into a hundred or more barbules which in turn have hundreds of barbs. These can trap air (a dead air space is highly insulating) in, around and between them. Synthetics are a long fine continuous filament with no branching. They rely on layering to do the same job as down’s branching. This is why the weight is generally so high. There is NO KNOWN way to get branching and a long, fine continuous fiber at the same time and be commercially viable.

Humidity effects this. It has a higher effect on down than plastic, of course. So, getting down wet means a 90% collapse in size (some say more.) It also means they do not trap air well. Water in plastic does not have this drastic effect. The weight of the water will compress it somewhat, but it will still be able to trap air. I personally do not recommend sleeping in puddles to test this.

In very cold temps, down is such a good insulator, that it can actually cause the condensation point to be within the down, itself…and freezing there. Without regular drying, this can build up producing a cold bag after a couple nights. Again, Synthetics do not do this as much. They are not that good of an insulator, and, they tend to be less effected by freezing vapour, though the same thing does happen even in synthetic bags. This has been well discussed here, with many people using a sacrificial synthetic overquilt over an insulating down bag at temps less than 20F.

At above 20F, even in near 100% relative humidity, down is always lighter for the warmth by about 3:1. After adding shell materials, it is closer to 2:1. It is very common, in fact usual, to see shells outweighing or weighing the same as the fill on many bags using good down.

Down is a natural material. I do not agree with the so called ratings. When you get hot, you perspire more adding to the humidity. Down collapses somewhat and makes itself less of an insulator. When you are colder, you perspire less, adding less humidity to a bag. The down fluffs up a bit more and is warmer. In other words, down is self regulating. Ratings often tout only the lower number, and often the extreme lower limit. You should always compare the upper limit, also. Weather in the woods can change a LOT over a few days. To make maximal use of the self regulation, you also need a clean bag, not one covered in in more than a month’s worth of body oils. Synthetics do NOT do this at all.

Thermal conductance of down vs synthetics is less. But, because so much less is used to begin with, when compressed the thermal conductivity seems like more. Practically, it makes no difference, because to get the same weight of down into a bag as synthetic, you would typically be talking about a 40F difference in temperature rating. Example: a 0F synthetic at 5pounds2ounces would be about the same as a -40F down bag at 4pounds10ounces. Only soaked in a lake where the actual thermal conductivity would be important would they feel about the same. I would guess that neither would be comfortable at 32F when soaked, though.

And finally, the actual lofting is a LOT dependent on the use/age of the bag. Putting 100nights on a down bag is only about 5-10% of it’s lifetime without noticing any loss of temp rating. Putting 100nights on a synthetic bag is usually ~50% of its lifetime and decreasing in temp rating. Much is dependent on care, of course. My 40F down bag has well over 1000 nights on it and is still usable at 45F. Somehow, I doubt any synthetic bags ability to last half that lifespan without loosing a lot more temp rating. I have used synthetic bags (I believe Hollofil was the big brand in the early 70’s) for <200 nights that went from 15F-too warm- to 50+F-too cold. A lot of the loss of loft is due to “kinking”. Down feathers do not kink easily. The layers of hollow fibers making up Apex kink easily, especially when compressed tightly or laid upon. (https://www.prima-outdoor.com/materials-climashield-xp-apex) The finer the fiber and the more crossing over you have (for air entrapment) the more susceptible it is to kinking. Think of a straw… Glues or heat bonding (to prevent clumping) does not prevent this. So, you have large amounts of loft that doesn’t last very long, or, small amounts of loft that weighs a lot for the loft. Apex is a good compromise.

But, you really cannot compare it to good down. Cheap down has a higher percentage of feathers in it. A feather is NOT the same as a down plume. Most feathers have some down-like barbules at the butt end, but they also include a shaft which is easily kinked, also. In my book, Apex is roughly equivalent to 500fp feather down. Though the feather down will have increasing longevity if you start with about a 20 degree over-temp. By the time it degrades, it will have good longevity at temp. But, in either case, you cannot really compare feathers vs down, or, apex vs down, or, apex vs feathers. All have different characteristics that you can use to your advantage much like the synthetic overquilts used at very low temps. Or, the relatively inexpensive cost of 500fp filled bags (500FP@70USD vs Apex@200USD vs 850FP@260USD.)

-

AuthorPosts

- You must be logged in to reply to this topic.

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

Our Community Posts are Moderated

Backpacking Light community posts are moderated and here to foster helpful and positive discussions about lightweight backpacking. Please be mindful of our values and boundaries and review our Community Guidelines prior to posting.

Get the Newsletter

Gear Research & Discovery Tools

- Browse our curated Gear Shop

- See the latest Gear Deals and Sales

- Our Recommendations

- Search for Gear on Sale with the Gear Finder

- Used Gear Swap

- Member Gear Reviews and BPL Gear Review Articles

- Browse by Gear Type or Brand.