Topic

DIMENSION-POLYANT Technical Fabrics: Properties and Development

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

Home › Forums › Gear Forums › Make Your Own Gear › DIMENSION-POLYANT Technical Fabrics: Properties and Development

- This topic has 83 replies, 17 voices, and was last updated 6 years, 8 months ago by

Roger Caffin.

Roger Caffin.

-

AuthorPosts

-

Jan 11, 2018 at 5:10 pm #3511843

Given the $8k+ minimum to buy in, new styles of Xpac are often cost prohibitive smaller for startups, especially cottage and craft businesses.

Perhaps some daring entrepreneurs or philanthropists can invest in unobtanium for the masses.

I will say, however that Dimension Polyant has been wonderful at providing access for us as a small company, with stock minimums low for such a prolific and advanced sailcloth mill.

By contrast, Cubic Tech in my experience has been a lot more occult and obscured with their dissemination of information. Even more so since the DSM buyout. Interestingly, at the the same time the marketing of DCF has exploded since the takeover.

I cross my fingers that high quality UHMWP technology will eventually become accessible to enable lower prices for end users, but I am curious whether the DSM buyout will advance that agenda or not.

Enough thread drift.

Dimension Polyant fabrics are great!

Jan 11, 2018 at 5:21 pm #3511845Please forgive if this has been discussed. Is the unique appearance of LS is due to manufacturing processes or if it is a graphic print?

Jan 11, 2018 at 5:52 pm #3511851Is the unique appearance of LS is due to manufacturing processes

Good question Matt. After comparing some LS21 and LS07 from Quest Outfitters, the LS21 is much darker, more uniform in color and less “graphic print-like” than the LS07. Definitely like the look of the LS07, but it feels like a special-use fabric for gentle-care UL and SUL packs, unless you reinforce it. Here’s a photo of the LS07 along with VX-07 and VX-21 in black (good color combo):

And here’s a photo of LS-21 (left) vs LS-07 (right)

Jan 11, 2018 at 6:13 pm #3511856

Jan 11, 2018 at 6:13 pm #3511856I wonder why LS07 and LS21 look different, if they have the same LiteSkin face? Are we seeing some of the underlying nylon?

Taylor: Thanks for the info on LS + film and LS vs VX waterproofness. Helpful. Nice to know what is possible.

“V21 is X21 without the X.”

Oh nice. I was thinking V21 was just VX21 without the X (so still with .25 PET + 50D poly, rather than only .5 PET). PM sent. I guess I should have known from your custom run thread.

Jan 11, 2018 at 6:29 pm #3511860Hi Matthew,

The appearance of the LS is a result of the materials used and manufacturing process. It’s not a printed graphic.

Dan , yes. The difference in appearance between the LS07 and LS21 is the backing fabric. The LS07 has a light rip-stop which provides just enough texture on LS to create a different optical appearance when compared to the the LS21, which does not have a rip-stop backing fabric.

Generally, LS has been trending from grey to black. Early versions of LS were grey. Currently black is the standard.

Cheers,

Taylor

Jan 11, 2018 at 6:46 pm #3511863Taylor – Are you a backpacker? If yes, it might be interesting to hear your opinions about which fabrics you would use in a pack…

Jan 11, 2018 at 7:33 pm #3511872Another question for you Taylor – which DP fabric (if any) would you use for the roll-top collar on a light-weight backpack? The roll-top fabric will be folded, rolled tight, creased and compressed many times per day, easily developing wear and tear. I wonder if a good 70d silnylon or coated nylon would be a better option for this use than any of the Light Skin or X-pac fabrics.

Jan 12, 2018 at 7:13 am #3511996If so, that means that the ASTM test you cited is irrelevant for most of our needs

Taylor is probably too polite to say it, but these tests aren’t for us. Neither cottage companies nor DIYers are what pay the bills at DP, and when we start buying thousands of yards at a time then we can start griping about the tests and the X-plys. I for one am exceedingly grateful that DP interacts with us as much as they do.

The face fabric test makes sense to me in the broader context, talking to some larger companies about Xpac and what constitutes “failure” I am starting to get the picture that for warranty purposes and for the larger public face fabric longevity may be more pertinent then total fabric longevity. One guy in particular pointed out it didn’t so much matter when the fabric quite working, but very much mattered when the customer sends something back for refund or replacement.

I did some amateur abrasion testing a while ago, and I noticed the machines favoring smooth fabrics over textured ones well outside of what their known real-world performance was. The testing numbers are great to have but must be taken with a grain of salt like all lab data.

Jan 12, 2018 at 4:02 pm #3512030Hi Matthew,

I’m admittedly not a backpacker. My background is in mechanical engineering where I worked for a large sailmaker for 5 years before jumping ship to work for DP. I spend most of my free time sailing in the summer or skiing in the winter so I certainly appreciate functional, lightweight gear.

If I were to design a lightweight day pack, to take sailing or skiing I’d make the body of the pack from X21RC or LS21. The X21RC and LS21 are light but still have a medium hand. If lightweight were the sole objective I’d use LS07 with localized VX03/VX07 reinforcement adding strength, structure or durability where needed.

Jan 12, 2018 at 4:14 pm #3512035Hi Lester,

For a roll top you’ll probably want a fabric with a stiffer hand than a coated nylon. Think trying to roll up a dry paper towel versus a wet one – a little stiffness with help make a tight, tidy, roll. VX03, VX07 Soft, LS07, or LS21 have a stiffer hand such that they will roll nicely, and have much better long term waterproof-ness than a coated nylon. I have a LS21 roll-top daypack and it’s working out well in terms of wear and tear.

Cheers,

Taylor

Jan 12, 2018 at 4:19 pm #3512037To Luke’s point – real world testing for any fabric/laminate is the best data point.

Jan 12, 2018 at 5:15 pm #3512045real world testing for any fabric/laminate is the best data point

+1. Along with that, tear strength, puncture resistance, resistance to crease pinholing and (as mentioned above) waterproofness are just as important as abrasion resistance, depending on the application. And then environmental conditions (wet, dry, sandy desert grit, mossy forest duff, etc), level of care (babying vs rough handling) and construction quality (stitch strength, reinforcement and force distribution) likely play an even bigger role. “Thru-hiker tested” is definitely one standard that looks at most of these variables.

Thanks again Taylor for the insights. As Luke said, I’m grateful for your interaction here at BPL.

Jan 12, 2018 at 8:48 pm #3512076have much better long term waterproof-ness than a coated nylon.

That would depend on the coating. I use a silnylon throat on my packs (VX07 fabric?) and they have lasted very well. However, the throat is always covered by the lid (same DP fabric), so a bit different from a ‘roll-top’. A PU coating would NOT last nearly as well: the film would start peeling off.Cheers

Jan 12, 2018 at 11:13 pm #3512099Where can I buy these Fabrics online, generally? And where can I buy them in Canada if possible? Thank you

Jan 12, 2018 at 11:17 pm #3512100If I remember correctly, the DP web site does offer small cut lengths for MYOG. But Taylor_at_DP would be better able to answer you.

Cheers

Jan 14, 2018 at 5:48 am #3512345Derrick: QuestOutfitters has quite a few XPac options and their shipping to Canada is quite reasonable. They ship via the lowest cost method which is often $5-$10 for fabrics in a flat envelope and they’ll refund anything they charge over this.

Quite a few other good companies sell XPac too I’m sure.

Jan 15, 2018 at 2:22 pm #3512514Hi Derrick,

To echo Dan, one of our distributors either Quest Outfitters or Rockywoods both stock DP fabrics and sell them by the yard. I’m happy to facilitate of you have a special fabric request.

Cheers,

Taylor

Feb 10, 2018 at 9:08 am #3517621Taylor has been so kind as to post me some samples. There are 4 little oval swatch bundles and some A4 sheets. Photos and colours should be on the DP web site.

Oval swatches

Bundle #1

X10 cotton duck in various colours, but with the X grid and the film backing. Not light. Probably good for sails etc, but not likely to be of interest to BPL members.

Bundle #2

VX21 in a huge range of colours, plus a coule of VX25 in quite eye-blinding fluoro colours, VX25 is slightly heavier than VX21.

Bundle #3

VX03 in black, then several VX07 in reasonable colours inc the red VX07 I used for my packs. Then VX42 in black, white and silver. I used black VX42 for the bases of my packs as it is much heavier: good for dragging over rocks.

Bumdle #4

The new and different.

Bright white D40 Ultra PE / polyester – heavy.

LS07 in black & white. Crossed scrim at the front with a plastic overlay for protection, and a fine-weave ripstop at the back. NO X-grid! Is the what Big Agnes are using for their new airmat (seen at the latest OR)? Airtight.

LS21 in black. A slightly heavier LS07, solid non-ripstop (nylon?) woven back layer. Airtight.

LS42 in black&white. A slightly heavier LS21 with a tougher back panel in silvr. You could use this reversed for a pack as the weave looks solid.

TX07 in black at the front. There’s an X-grid and a back cover of faintly pink ripstop (why pink??), but the front looks as though it is just a plastic film by itself. I am not sure how to use this one!

WX20 in black: plain weave front face, X-grid, and a heavier plastic back face. it’s not all that heavy, but rather waterproof and could be taped easily.

X21 RC in cloud grey, plain weave fron face with the black X-grid really visible, similar to WX20.

X21 RC in black – same as above but the X-grid is now invisible.

X21 in slate.

X33 in camo, like the above.

X42 in olive with X-grid, slightly heavier than X21

X50 in camo (2 dark green versions) and a sort of white camo.

X51 in black – a heavier version.A4 sheets

LS07, LS21, LS42, X21: see above. I can’t help feeling that a rather nice pack could be made from any of these. The X21 would be a tougher unit. One problem with all of these: they CURL! You would really have to peg this stuff out before cutting. It’s not soft and floppy like silnylon.

VX07, VX21, VX25: as above, in lots of colours, some bright. Some of us will be rightly familiar with these older styles, and they still make good packs.Very, very preliminary assessment

As I said above, the VX fabrics make good reliable packs. VX07 for the body and VX42 upwards for the base.

The LS07 and LS21 – new and untested so far. They look as though they should be waterproof for quite a while. To my mind, the films in these fabrics should last about as well as in the older VX07 etc – I THINK. I rather like the ones withOUT the X-gris as I have found a lot of wear over the heavy grid threads – but my packs do get used a lot.

It would be interesting to make a new LS07 bag for my summer pack frame. It would be very light, and waterproof once I taped the main seams.Cheers

Feb 10, 2018 at 2:24 pm #3517633Roger,

Thanks for adding your input. In regards to taping seams on an LS07 pack, the inside of the fabric has a DWR coating. So it may not work so well, unless you have a different tape than what I tried – I made some attempts with some 3M transfer tape, trying to add wear patches to a cuben bag without sewing more seams. They did not hold up.

That said, you could always seam grip on the outside of the pack, I think it would take that pretty well.

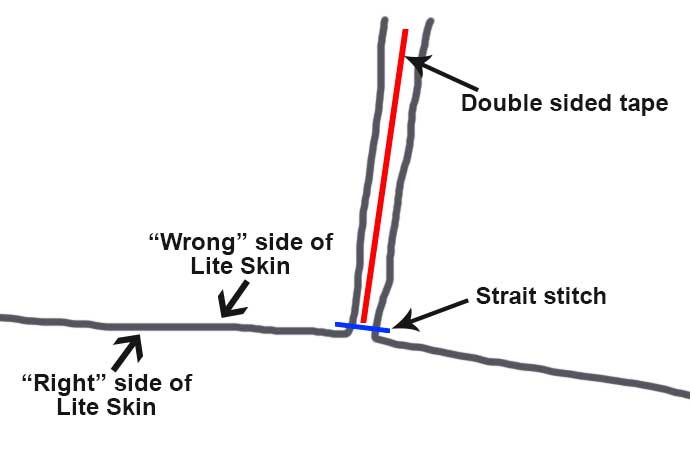

Feb 10, 2018 at 5:53 pm #3517657Thanks Roger for the rundown. For seam taping the LS-07 (or other lite skins), could you use double sided tape, sandwiching the tape between both “right sides” in the seam allowance and then strait stitching the seam (see image below)?

Nick – what seam tape would you recommend for the X21 RC with the exposed PET film backing – single sided Mylar tape, single sided Dyneema Composite Fabric tape, or something else?

Feb 10, 2018 at 9:27 pm #3517682

Feb 10, 2018 at 9:27 pm #3517682Yeah, the DWR can make for problems. I was able to tape the seams on VX07 using 3M9485 transfer tape. I think other brands make also be able to offer similar adhesives.

I have not tested the front face of the LS series: could one put the plastic film to the inside and the fabric (with DWR) to the outside? Worth exploring.

On the other hand, the X21 RC fabrics have a solid film face which should take a tape very nicely.

I have given up trying to sew through tapes. The eye of the needle gets gummed up with adhesive in a very short time and the thread jams and the needle breaks.

Cheers

Feb 10, 2018 at 10:09 pm #3517685Roger – there’s hopefully no need to face the “wrong” side of the Lite Skin fabric outward. If the OUTER “right” surface of the Liteskin does not have a DWR (only non-woven face with no extra coatings or applications), then that’s what the double sided tape is sticking to when sandwiched into the seam allowance of a straight stitch. So ideally, the tape would stick well, just like other non-woven fabric, such as Tyvek. As long as the tape is set back from the seam line by 5 mm or so, one should have room for two rows of stitches (double stitch) without sewing through the tape. On the other hand, if the tape is placed too close to the straight stitch line, or if using a flat felled stitch, one would be forced to sew through the tape.

Feb 10, 2018 at 10:30 pm #3517686Hi Lester

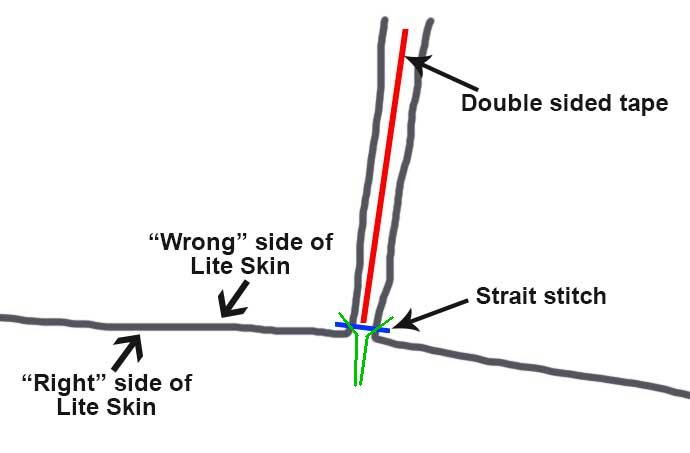

OK, I’m slightly lost here. I cannot see the point of putting tape between the two bits of selvedge in your diagram. It is not going to seam seal the stitching, so why do it?

Cheers

Feb 11, 2018 at 12:02 am #3517708If the two bits of selvedge (seam allowance) are bonded together by the inside faces with double sided tape, would that not prevent water from ingressing into the pack via the stitch line?

Feb 11, 2018 at 12:15 am #3517710Hi Lester

Yes, the tape would block ONE path for the water. But remember that the pack fabric may be under some tension (’cause you stuffed your pack full!), so the sewing holes will be slightly stretched. Water will come in through two other paths, as shown by the green lines:

Cheers

-

AuthorPosts

- You must be logged in to reply to this topic.

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

LAST CALL (Sale Ends Feb 24) - Hyperlite Mountain Gear's Biggest Sale of the Year.

All DCF shelters, packs, premium quilts, and accessories are on sale.

Our Community Posts are Moderated

Backpacking Light community posts are moderated and here to foster helpful and positive discussions about lightweight backpacking. Please be mindful of our values and boundaries and review our Community Guidelines prior to posting.

Get the Newsletter

Gear Research & Discovery Tools

- Browse our curated Gear Shop

- See the latest Gear Deals and Sales

- Our Recommendations

- Search for Gear on Sale with the Gear Finder

- Used Gear Swap

- Member Gear Reviews and BPL Gear Review Articles

- Browse by Gear Type or Brand.