Topic

DCF Seam Strength Test

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

Home › Forums › Gear Forums › Make Your Own Gear › DCF Seam Strength Test

- This topic has 31 replies, 1 voice, and was last updated 2 years, 2 months ago by

Bendrix B.

Bendrix B.

-

AuthorPosts

-

Oct 3, 2019 at 1:42 pm #3612473

I’m starting to design a tent and have been thinking about the best seam type to join the panels. I did a little test of a couple of different types and the results surprised me a bit, so I thought I’d share them here. There’s been quite a few discussions here about what seams are the strongest and what fastening method is best (bonded, sewn, or both), but I don’t remember seeing anyone post pictures of seam test results (at least lately).

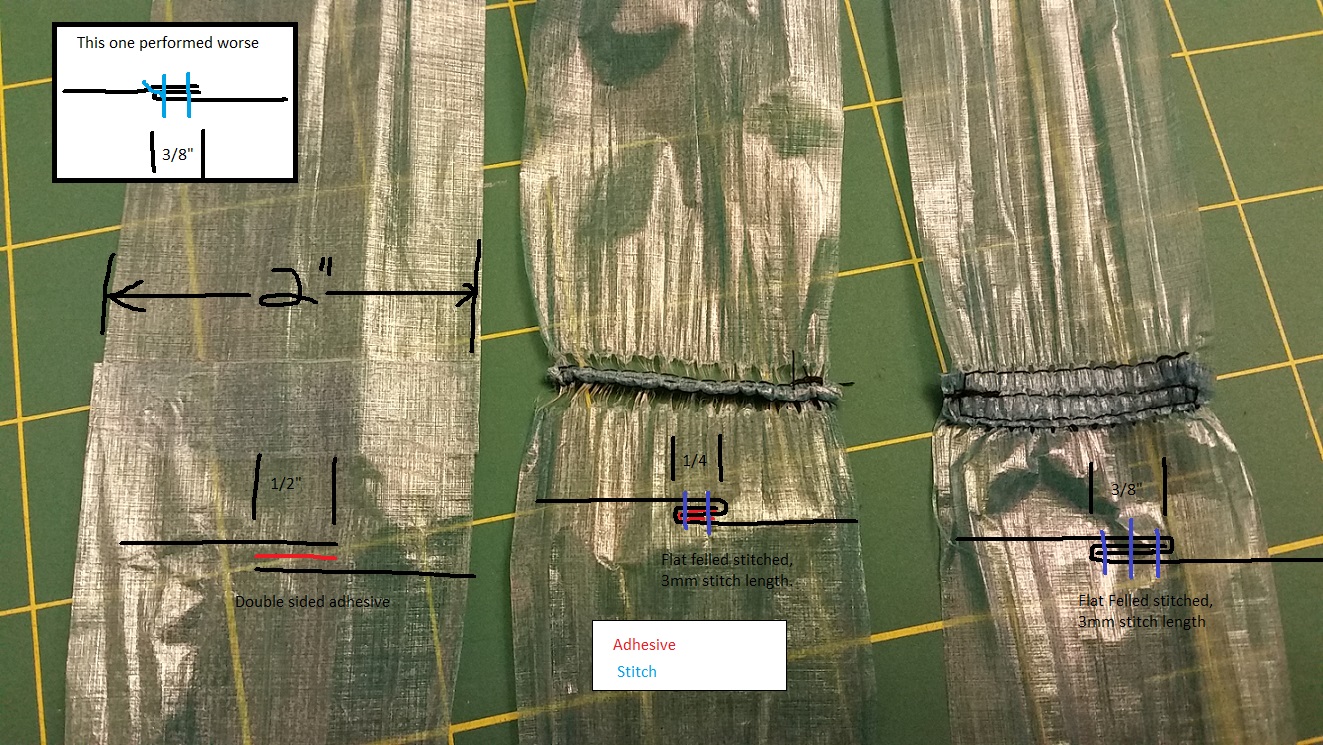

I tried a couple different widths of the flat felled seam, with and without some adhesive in it, a standard 3/8″ seam with two top stitches, and a 1/2″ wide double sided adhesive seam. I joined 2″ wide strips of 0.5 Oz/yard DCF, gripped the ends then tried to pull the seam apart. Here’s what happened:

I could not pull apart the bonded seam but I could pull apart every stitched seam that I made. The bonded seam performed as if there were no seam at all, and it was just like trying to pull apart a continuous piece of 2″ wide DCF which I cannot do. Clearly the stitches damaged the material enough to create weak points that grow under stress and fail with less force. The one caveat is that you can still peel apart the bonding if you try, so from that standpoint a stitched seam still wins. Another benefit to a bonded seam is the smaller seam allowance needed. The 1/2″ wide bonded seam needs a 1/4″ seam allowance while the 3/8″ wide flat felled seam needs a 9/16″ seam allowance. I think I may go with bonded only seams for much of my tent….

Oct 3, 2019 at 2:34 pm #3612475Craig,

Simple but dramatic test.

Thanks for doing/posting.

Oct 3, 2019 at 7:13 pm #3612509JACKPOT!!! I’m working on a tarp myself. Thanks for the timely info.

Might you add a strip of single-sided adhesive over the bonded seam to prevent peeling? Would that alleviate that potential issue? Again, thank you for the very helpful news!

Oct 3, 2019 at 7:29 pm #3612512Nice to see some recent tests.

A few thoughts on some more tests.

- Run a line of stitching across each end of the tapes seam. This would prevent peeling. I don’t think the holes will enlarge at all; would need seam sealing.

- Any stitched seam – add seam sealing before testing to see if or how much it helps.

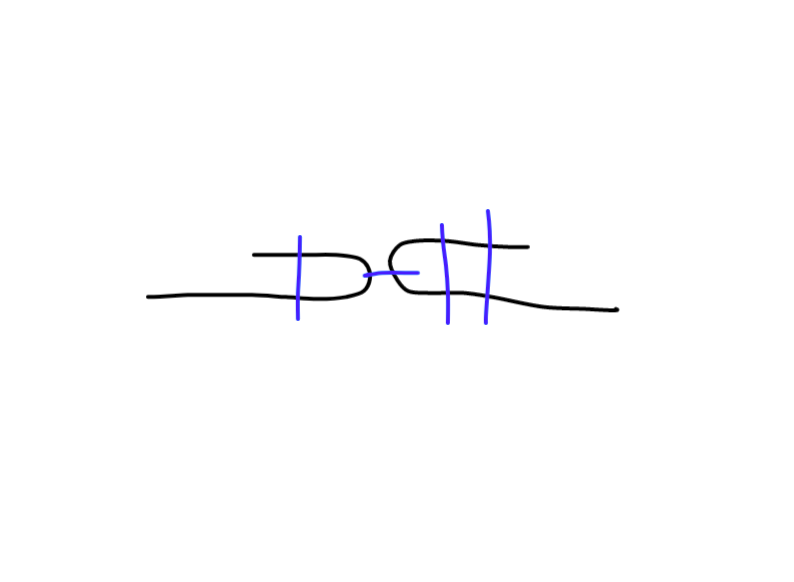

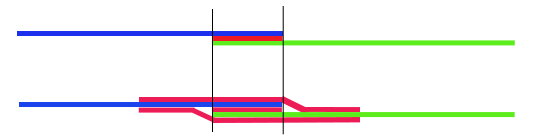

- Try the following, which will also require seam sealing. In your previous sewn samples, the fabric is flat and the thread pulls through it sideways. In this arrangement, the fabric is folded backwards around the thread, sort of like a pulley. Then the loose end is secured with additional lines of stitches. The pulley effect will cut the load on the end stitches (vertical blue lines) in half. The left and right sides are different so you can test the effects of one or two rows of end stitches in a single test.

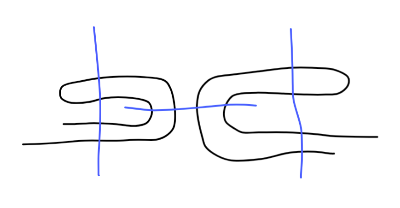

- Here’s a more secure version. Again, two tests in one. Folding the free end of the fabric back in to the seam pads the ‘live’ part of the fabric from the load applied by the thread. You can again experiment with two vertical blue stitches, and seam sealing. You can also laying a single layer of tape over either side for both strength and seam sealing. The trouble with taping after sewing is that if you don’t load the stitch to take the slack out of it before taping, the tape takes all the load.

Oct 3, 2019 at 10:39 pm #3612525Thank you very much for providing these test results!

I have used the following seam previously: bonded strip then sewn through (once or twice) and then taped on top/bottom or both. I find this is an extremely easy to make and ‘should’ be plenty strong while limiting potential creep.

This along with a couple other threads from here and hammockforums is the thread that convinced me to use this approach – https://backpackinglight.com/forums/topic/tarptent-stratospire-li-vs-zpacks-duplex/. * i do not have any real world strength testing though.

I find that sometimes these types of solutions are overly complicated for our uses. Thoughts?

Oct 3, 2019 at 11:57 pm #3612545One of my first uses of DCF was to make a backpack… stitched seams… FAILED! seams pulled apart and continued to open holes!

Since I’ve used 3M tape (9485?) no stitching for a rain jacket (used all last winter, no problems, still dry and sealed). Asymmetrical pyramid tarp tent..used it on about 14 nights of backpacking… no problems!

I usually use 1″ double sided tape so allow 1″ seam allowance on both sides.

Les

Oct 4, 2019 at 9:45 am #3612591I’ve posted this before, but it’s relevant here. Colin Ibbotson at Tramplite is an engineer and renowned for the quality of his shelters. His take is that you need to both sew and over-bond. I’m sure he’ll have done a lot of testing before he came to this decision.

===========

Most manufacturers simply stick their shelters together with double-sided tape leading to designs that are weaker, and pitch less taut, than a Tramplite shelter. Simply, if you want to resist wind effectively then you need a tough and taut shell. With a Tramplite shelter, every major seam is rolled twice, double sewn and finally over-bonded. This gives an immensely tough seam, comprising of a minimum 6 individual layers of DCF, that is immune to fabric de-lamination while allowing immense pressure to be applied to the pegging/guying points (which are directly attached to the seams). With shelters that are stuck together, you are effectively only bonding the 2 outer faces of plastic film together and any de-lamination of the DCF fabric can lead to catastrophic failures. Any shelter built this way and used on exposed sites, and in consistently high winds, is more likely to delaminate over time but even when new, and performing as designed, is still much weaker than a Tramplite and will flap easily.

<div>

<div>

So why are most DCF shelters simply stuck together? Profit! You can build 3 of those shelters in the time it takes Tramplite Gear to lovingly craft 1. For the customer, there are no advantages other than sometimes a cheaper price.</div>

<div></div>

<table class=”tr-caption-container” cellspacing=”0″ cellpadding=”0″ align=”center”>

<tbody>

<tr>

<td> </td>

</td>

</tr>

</tbody>

</table>

</div>

Oct 4, 2019 at 11:57 am #3612594The MLD Grace Duo is the most meticulously crafted shelter I have ever owned, or seen. It is a thing of beauty and exudes bulletproof in every way. It is also my understanding that MLD claims to have never received a report of seam failure on one of their DCF shelters.

Those two data points lead me to believe that bonding only, done correctly, is a very effective DCF construction technique. With my understanding of, and experience with, DCF I find it very hard to believe that disrupting the material’s integrity by sewing yields a superior seam. The OP’s results provide another data point supporting the superiority of bonding over sewing.

MLD likely considers their seam bonding technique proprietary, but as a leading bonding-only DCF constructor I would be very interested to hear Ron’s thoughts on the techniques presented and discussed so far.

Oct 4, 2019 at 1:40 pm #3612603There are often many ways to achieve a desired result; In this case it’s joining two separate pieces of material such that it behaves as if it was a single piece. It sounds as if Mr. Ibbotson has done some pretty extensive R&D on his seams to accomplish this goal, which is pretty awesome. He’s definitely shown it can be done! Is this the only possible way to do it? I think probably not. As an engineer myself, I like to test things on my own so I can get a feeling for how my materials behave. This is an essential part of the design process for me. Actually Geoff, I remember you posting that description before, but at the time I couldn’t really picture the seam described. Now reading it again I can, and it definitely sounds bulletproof. So thanks for sharing again. While it’s bulletproof, it’s also pretty complicated, as he even says himself :-). I’m curious how closely I can get to the performance of that seam with as little effort as possible! I’d be satisfied if I could get 95% of it.

Ok, so on to two other tests that were proposed above: Rene, you are definitely correct about the pulley effect decreasing the shear force on the side stitches by half, but in this configuration, all the force of the fabric goes through the horizontal joining seam thread. No DCF material spans this seam, so the material cannot aid in holding it together. This was the easiest seam to pull apart by a lot.

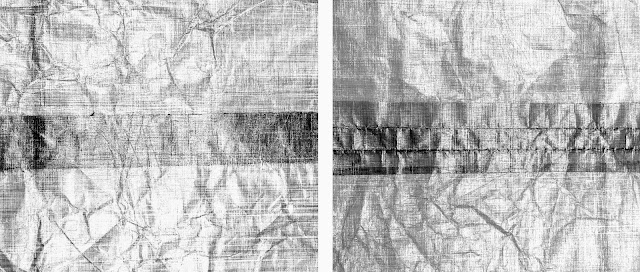

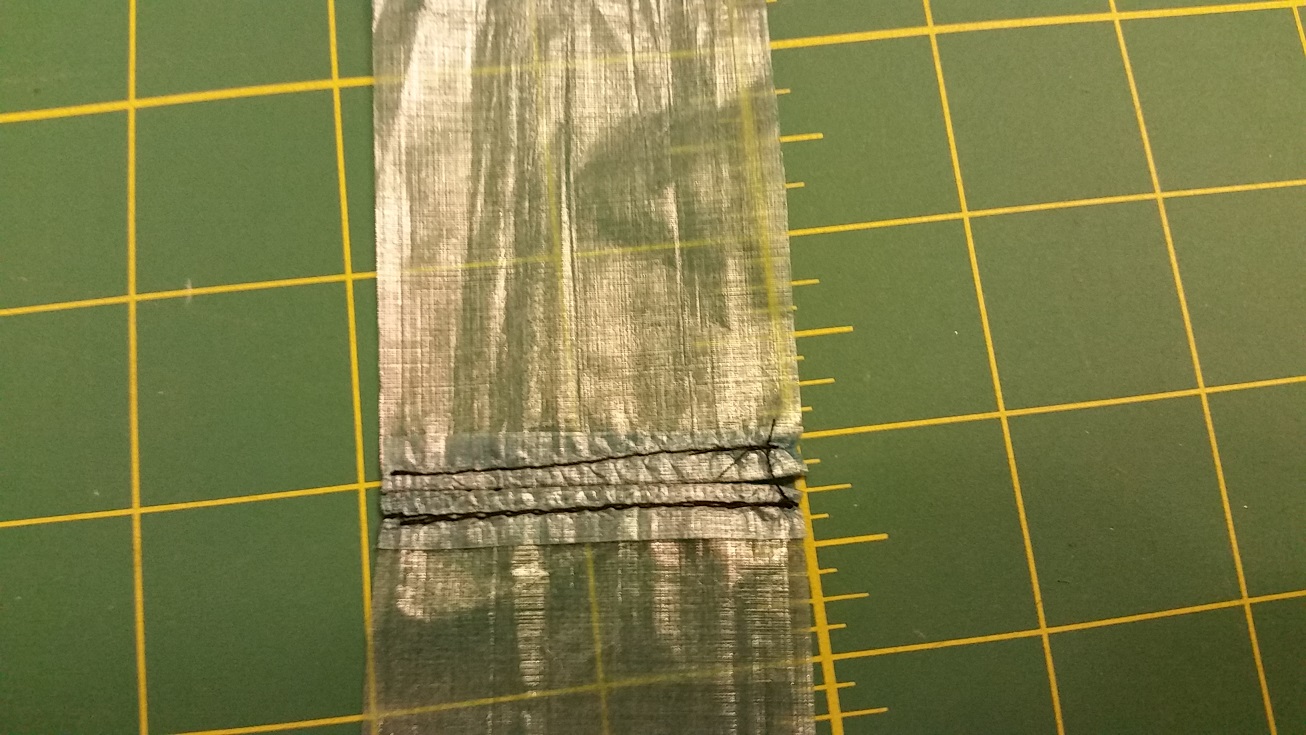

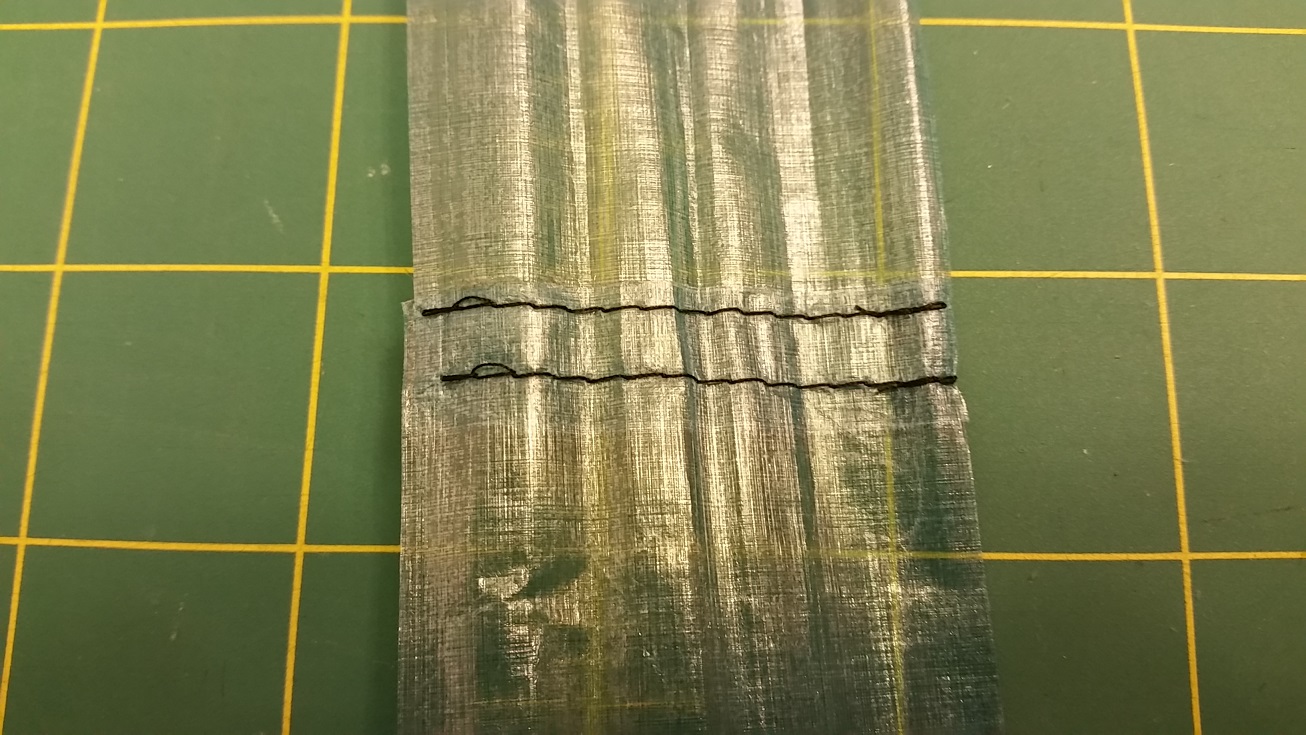

Eric, I suspected that tacking down the edges of a bonded seam would compromise the material and It would come apart, but that was not the case, at least within the amount of force I’m able to exert on these pieces. There would probably be some difference between ultimate failure points if you actually put them in a machine to measure where they pull apart. Anyway, here’s my original test piece with two rows of 3mm stitches after I tried several time to pull it apart. Taping on top of this certainly wouldn’t hurt either, and is probably necessary for waterproofness.

So far so good. Will this simple seam be immune to delamination under repeated stress and motion? I certainly wouldn’t trust it as much as Mr. Ibbotson’s seam, since the edges are still essentially raw. And the material is compromised a little more because of the stitches. If I had my wish, I would just melt the two pieces of material together so they actually FORM one piece. But that’s way outside of my capabilities at the moment…..

Oct 4, 2019 at 3:29 pm #3612615IMHO sewing DCF is an old school carry-over that hinders rather than helps.

Assuming that bonding takes place at a molecular scale, poking holes in the laminate is only introducing stress points at a very gross level. Bonding by itself distributes the shear forces across a much wider area.

“Over-bonding” plus the initial “alignment-bond” further distributes that force to both sides of a laminate and reduces the internal shear forces within each laminate.

Oct 4, 2019 at 3:36 pm #3612617The bonded seam that Greg illustrated is exactly what I was thinking…which looks a lot like the ridge seam on the Grace Duo. If you need the strength required to withstand gale force winds on unprotected sites, then perhaps an ultralight material such as DCF is not the proper choice?

Oct 4, 2019 at 3:41 pm #3612618I thought the whole point of sewing DCF was because tape by itself is prone to creep. Puncturing DCF clearly weakens the material, but taping by itself slowly fails over time. But… perhaps I got this wrong, I didn’t think any reputable cottage manufacturers were just taping anymore, but it sounds like MLD does.

Oct 4, 2019 at 3:49 pm #3612619“I didn’t think any reputable cottage manufacturers were just taping anymore, but it sounds like MLD does”

Yep. From the MLD Grace Tarp webpage (fabric options section):

DCF (DYNEEMA® COMPOSITE FABRIC A.K.A. Cuben Fiber) VERSION:

• Available in the light and very sturdy .75 weight DCF, the .68 CAMO DCF, and the super-light 3-season only .5 DCF.

• DCF ridgeline is bondedAnd from their “Fabric Mojo” page:

We use a special, permanent adhesive tape/ glue with high levels of UV inhibitors to limit sewing that can weaken the CF substrate. Our DCF tarp and shelter seams and ridgelines are bonded for maximum strength and require no seam sealing whatsoever!

Oct 4, 2019 at 4:42 pm #3612624Yeah, adding the extra layers on top and bottom (overbonding) would definitely beef things up and help distribute shear forces, provided that those strips are also .51Oz DCF. I would think it would help prevent de-lamination of the panels being joined as well. And at this point the seam drawn by Greg looks remarkably similar to the seam Tramplite describes! The overbonding joins should be just as strong as the original bonding joint, so essentially you could eliminate the initial joint and have the whole thing be just as strong with the 2 overbonding strips. So perhaps that is what makes Tramplite seams so tough (the overbonding) and not the rolled and double sewn initial seam.

However, by putting two 1″ wide overbonding strips along all of your seams, you have just increase your seam allowances by 1″! That is a decent amount of material when I’m trying to reduce my areas by as much as I can. I think it’s highly likely that for my use case I could get away with only one bond. I’m pretty much a fair weather backpacker, so I’ve never really been in bad conditions that might put that much stress on a shelter. However, my design will be freestanding with the canopy being pulled taught by the spring force of aluminum poles, so there will be SOME amount of force on the seams.

I’m interested to see what happens, and that’s what makes this kind of endeavor so fun!

Oct 4, 2019 at 5:47 pm #3612629“… provided that those strips are also .51Oz DCF”

Maybe. The over-bonding is “unifying” only one polyester side of the DCF, and I have to wonder if a lighter tape would suffice. The absolute difference between .51 and .33 would be small, so “better safe than sorry” may be the way to go. (Horrors! and extra ounce!!)

“However, by putting two 1″ wide overbonding strips along all of your seams, you have just increase your seam allowances by 1″! ”

I might be missing your point, but over-bonding does not require an additional seam allowance. The over-bonding tape itself is added material, but the panel dimensions shouldn’t change.

Oct 4, 2019 at 6:11 pm #3612635

Oct 4, 2019 at 6:11 pm #3612635The other factor to consider is the performance of the bonding tape in cold. I remember a materials scientist here saying that the glues used don’t do well in freezing weather. If you rely entirely on bonding tape without sewing, you might get a catastrophic failure if the glues lost too much strength. On the other hand, people use Ron’s shelters in tough winter conditions and it seems that he’s not seeing failures (though we don’t know what he’s using as a bonding agent). I’ve seen accounts of HMG mids in full winter conditions too, and they seem to do ok.

It’s surprising that all this seems to be so contentious, given how long DCF has been around. It would be useful if DSM gave more comprehensive technical guidance for use in various applications.

Oct 4, 2019 at 6:47 pm #3612641Cuben Fiber was originally developed for high performance sails on racing yachts. Does anyone know whether those were sewn or were constructed entirely with bonded seams? One would think the forces encountered in that application would easily be greater than those in a shelter.

Oct 4, 2019 at 7:39 pm #3612648JCH, above, prompted me to do some searching which turned up this from Lawson –

“The reason you don’t see more cuben mountaineering tents is because of the construction techniques that would have to be used.. The shelter would have to be both bonded and sewn as bonding alone doesn’t work in cold weather. The adhesive looses all its strength and the shelter will just fall apart.

I had a problem with my drybags in cold weather. People were stuffing their down bags in them and then going out in cold weather mountaineering, snow shoeing, skiing, hunting, etc and the seams were failing. The down bag would literately push the seam apart… So I paid 3M to test the problem. Well they found that ALL roll adhesives loose about 50%- 90% of their bond strength at 0F. Put it this way. 9485PC which is the adhesive that Cubic Tech use to recommend before selling their own, and most likely the adhesive most companies are still using has a T-Peel bond strength of 90.4oz/in at room temp and 12.5oz/in at 0F..

So the problem can be fixed by sewing the seams after bonding, BUT then your sewing through a non-woven material which creates a whole set of new problems.”

https://backpackinglight.com/forums/topic/103910/#post-2204504

So, 1) have the bonding agents improved in the last 4 years? 2) are the typical loads low enough to not matter?

Oct 4, 2019 at 7:49 pm #3612650Greg – I remember quite well Lawson’s posts, and suspect the issues still exist, although it would be nice to have new test results on the newest adhesives to verify or debunk that. I suppose my point is, and has always been, that one must select a material for ALL of it’s properties, not simply the ones that are appealing :)

DCF is fantastic in the right circumstances, as are bonded seams. Very low temperatures or high winds in an exposed site (and almost certainly not both) are probably not those circumstances.

Oct 5, 2019 at 12:04 am #3612674Yeah, great points about the low temperature performance of bonding. I had kind of forgotten about that too. I’ll have to think about that….

My point about the overbonding strips adding one inch to the seam allowances was just that it was extra material, so (if it was the same .5Oz DCF) you could just think of it as having a wider seam allowance rather than independently figuring the weight of the overbond strips. And yes, it might be the lighter DCF which would do the same thing (hold down the edges of the main bonded panels) at a little bit lower weight.

Oh, and the adhesive I used to bond my test pieces above was 3M 9482PC (the 2 mill stuff).

Oct 5, 2019 at 3:37 am #3612693I do not use DCF for a number of reasons, but one is that sewing does not work for the reasons described by the OP and well documented on BPL.. Given the fragility of the Mylar that holds llght DCF together, would not expect it to hold stitches adequately. And for tents and packs, I want to sew for several more reasons, including the use of highly curved seams and the ability to seam rip and re-sew without having to restart a project from scratch..

Always wondered about the ability of adhesives used for DCF to withstand cold, hot water etc. at various temps above 0 degrees F. If there are virtually no reports of failure of MLD tarps as stated above, perhaps Ron B would be willing to share some info about adhesives.

The only bonds I’ve seen on very light tent and pack fabric, other than heat sealing, that satisfy me are the use of Seam Grip on the PU sides of nylon fabric that is Silcoated on one side and PU on the other. There is a dearth of info about which of these fabrics are TPU coated, so won’t go into that.

Specifically, I wanted to install reinforcement patches on nylon tents at stress points without having to put needle holes in the areas away from the perimeters of pattern pieces. Was delighted to find that the urethane coated sides of Sil/PU nylon would bond with very thin coats of McNett Seam Grip, with no creep and no peel. No, the patches did not peel away, taking the original PU coat with it, as has been suggested on BPL. However, there was no testing in extreme temps and moisture. But, as Seam Grip has a good rep for durability, was optimistic. A low viscosity 2 part PU adhesive might work even better. (Used sil/PU nylon from a Sea to Suimmit Escapist tarp, 15D, around 1.07 oz/sq/yd. In a BPL thread on this subject, several solvents were suggested that thins the Seam Grip, making it much easier to apply thinly; but they all produced much weaker bonds. Have yet to try a spray contact PU adhesive, if one can be found, and am wearing a reliable gas mask in a well ventilated area, probably outdoors.)

So suggest that if folks want to stick with all-weather DIY DCF shelters, there is a need to know more about specific adhesives and their durability.

Oct 5, 2019 at 7:12 pm #3612738Re. the pulley seam – as far as I can see, the needle holes didn’t enlarge. Enlarged holes are the first step to failure of the fabric. So this looks like a solid step in the right direction.

Am I correct in concluding the seam failed because the thread broke in several places? It looks like you include a lock stitch at the ends of your seams, and that the failure didn’t simply unravel from one end like a zipper.

If that’s the case, using a smaller stitch length, to distribute the load across more stitches, or using a heavier thread, will raise the strength of the seam. For reasonable values, I’ll bet you can match the tensile strength of .51 DCF. You’ll know you’re there if the fabric tears at the pulley seam instead of the thread failing. And then you can try doubling the free end of the fabric back through the seam to reinforce it. I think the left side of my #4 diagram is the winner.

Oct 5, 2019 at 9:56 pm #3612762Greg, I like the idea of your diagrams without stitching and simple ‘overbonding’ with tape. This certainly adds some extra material yet still simple to construct.

I wonder if this type of seam would work well with a small 1/2” ‘alingment’ bond with 1” tape on top to overlap the seam and extend beyond the original bonded seam by about 1/4”. Or maybe the tape should be off center to give 1/2” overlap on top side then another overlapped tape on the reverse side. more tape more weight but stronger bond.

i simply propose these widths as 1/2 and 1 inch rolls seem to be the easiest to come by.

I would love to test some of these seams myself but all i have for scrap is 1.0oz dcf which i feel may give different results compared to using .5 or .8 variants.

Oct 5, 2019 at 10:56 pm #3612766^^^

Over-bonding is not my idea, it comes from Colin Robinson at Tramplight Gear. (Scroll to the bottom) And he sews the seam as well.

My contribution is one of conjecture and speculation, and it has not been tested.

Proceed with caution.

Oct 6, 2019 at 4:00 am #3612791Greg,

Thank you for the link. Very interesting reading, and well presented. -

AuthorPosts

- You must be logged in to reply to this topic.

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

Our Community Posts are Moderated

Backpacking Light community posts are moderated and here to foster helpful and positive discussions about lightweight backpacking. Please be mindful of our values and boundaries and review our Community Guidelines prior to posting.

Get the Newsletter

Gear Research & Discovery Tools

- Browse our curated Gear Shop

- See the latest Gear Deals and Sales

- Our Recommendations

- Search for Gear on Sale with the Gear Finder

- Used Gear Swap

- Member Gear Reviews and BPL Gear Review Articles

- Browse by Gear Type or Brand.