Topic

My SuperCat Stove blows out. Defective windscreen?

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

Home › Forums › Gear Forums › Gear (General) › My SuperCat Stove blows out. Defective windscreen?

- This topic is empty.

-

AuthorPosts

-

Oct 7, 2013 at 7:14 pm #2031686

Anonymous

Inactive"I think one of the biggest problems was that both stove and fuel were about 35F. It's probably a good idea to keep both in an inside pocket if wind chill temp drops below 50F, in fact I think this may be the biggest problem below that point."

This is where the Starlyte really comes into its own. You can preload it with fuel, pop it in a pocket and have it at body temperature, ready to go, when you want to heat up some water.

Oct 7, 2013 at 9:38 pm #2031736surprised that this problem was (over)analysed so much.

It was windy and the windscreen is only 2.25" high(!)….

Since I went to using cone style windscreens (nearly 5years ago) I've not had a problem with wind or ''lack of oxygen "(?!)

When messing with the various styles of homemade alcohol stoves, the Cat stove was the type I always found to be unreliable and erratic in operation. After building several I gave up on it.

I've used a Starlyte with split cone (nesting ) for 3 years now. Never an issue.

Oct 11, 2013 at 5:46 pm #2033296You say your cat stove needs air–witness the asymmetric flame with holes on only one side of the screen. We all know the stove is sensitive to wind. I saw something by Jim Wood where he

a. made one big hole on the leeward side of the screen and

b. raised the cat stove in the windscreenHe named that his fire bucket. Does "a" by itself produce an asymmetric flame? Does adding "b" help improve the supply fresh air for the 'starved' side by increasing the reservoir of air below the stove? How well does this work? If Jim is reading this, he can enlighten us.

I use several layers of tin foil for my windscreen and paper clips to hold it together and raise or lower the bottom of the screen. I haven't had to deal with big wind yet. I need to get my 18" fan out!

If I make a fire bucket, I'll run some tests.

Oct 23, 2013 at 9:56 pm #2037256> -Placement. I find it's better to brush off combustible materials and place the stove in a hollow in the ground, than it is to place it on an elevated flat rock. Wind speed decreases exponentially towards the ground, so even a few inches makes a difference. Plus, it will effectively make your windscreen taller.

My guess is, this was the majority of my problem. I was using a handy picnic table supplied at the camp sites. I should have just moved to the ground.

> -Cat can hole size. The original instructions suggest 3/16" is more wind resistant than 1/4". I find it boosts efficiency too (I estimate 15%). However, a good 3/16 hole punch is probably about $7.

I read that too, and my holes are 3/16, via uni-bit. Could go smaller (5/32 or 1/8), but would that help?

> -Black. Painting the stove and the bottom/lower sides of the pot with black barbeque paint increases efficiency (I estimate another 10-15%).

Great tip. Will paint. Thanks.

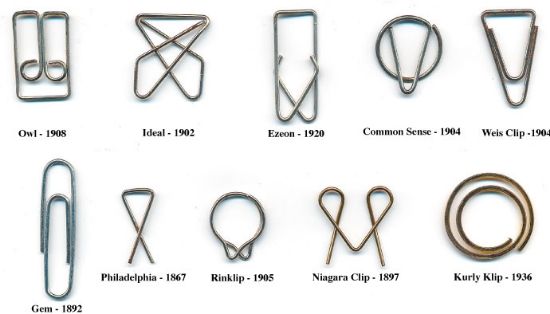

Oct 23, 2013 at 9:59 pm #2037258Have redesigned a 3" windscreen (to fit an MSR Titan Kettle) and this screen has NO holes along the bottom. Instead, I am using three "owl" paperclips to hold the screen up off the ground, tripod-style. The owl clips hold better than standard paper clips, and the amount of air you let in (and even *where* you let it in) is now micro-adjustable.

Oct 24, 2013 at 8:37 am #2037348I didn't know there were so many designs of paper clips. You mentioned the owl so I had to look it up and found these:

Oct 24, 2013 at 9:03 pm #2037651Whoa, COOL! How fun it would be to test these competitively.

I've tried Owl, Ideal, Weis, and Gem (everybody has), and the Owl has the tightest grip so far. Also good for not scratching, as it has no raw tips to contact the flashing (like the ubiquitous Gem).

Love to get a Rinklip for testing, (should be called a cat's head) — never seen one.

What a great photo you found, Zelph.

Oct 25, 2013 at 2:32 pm #2037817I recently did way too much testing on stoves/screens, luckily I got some help from sgt rock with tips, and, being scientifically inclined, I tested his final conclusions, which were themselves based on extensive empirical testing on his part.

My tests simply confirmed what he found years ago: taller wind screens are not more efficient, I tested by creating screens in 1/2" height increments, starting at I think 6", and could not initially figure out why taller screens were not efficient and resulted in incomplete alcohol combustion, readily evident by the sharp smell of alcohol in the air above the stove. Optimal efficiency was hit in his and my tests with 1/4" air gap, and a short screen, 4", and a LOT of air volume via holes or slots at the base. I believe the air volume depends on external air temp, ie, my suspicion is that in the cold, you want less air coming in. Not confirmed, but I believe that's the case.

With a roughly 2" stove height, or stove/stand height, a 4" high screen gave the best efficiency, I believe this is because there is too much air resistance on taller screens as the air rises between pot and screen, and that obstruction impedes the flow of cold air into the chamber, which then creates an inefficient combustion process.

[add] I also believe that for jet type stoves, which burn faster, you may want a wider air gap, not sure, didn't spend much time testing those, I was just testing for best efficiency. But my feeling is that a jet stove will create more heat, which is why it cooks faster, and might need a wider air gap, maybe 3/8", maybe 1/2", not sure.

I had by the way noticed no significant wind advantage with tall vs short screens, though I have only tested to 4", ie, 2" above edge of bottom of pot. My working theory, or I guess hypothesis is more accurate, is that any moving wind OVER the top of the screen creates turbulence which then disrupts the flame. I always test with fan moving air now, so these things get more obvious even inside.

To counter the problem of wind hitting the air holes, simply take a piece of foil, thick, or flashing, about 1.5" high, and create a second wind block, about 1" out from base of main screen. This handles the issue of moving air entering the holes, ie, light breezes, but does not handle the problem of air moving over the top and creating that turbulence.

As far as I know, and this is how I now think of my stove screen, the screen is mainly there to function as a cylinder wall, basically, the holes are the carburation, and the top gap/height is sort of the exhaust system, basically. This means that the main purpose of the screen is not to block wind, but rather to heat/make efficient the stove/pot setup. So for wind, use a second wind block like a foam pad, a rock, tree, etc, your tent, a cooking tarp, a jacket stuck on sticks, whatever.

However, the shorter bottom external wind blocker screen, to my surprise, works really well in terms of shutting off small air movements through the holes at the base. A bit fiddly, but that's fine.

Whenever you get a strong, pungent dose of alcohol fumes while the stove is burning it means it's not burning efficiently, and the gas is not combusting fully, something I noticed when talking in an older thread to one of the stove guys who said the smell of the fuel didn't bug him, it took me a long time to realize that was because his design (flat cat) was already efficient and working well, not because he was more tolerant of toxic unburned denatured alcohol fumes.

[added]After reading some other comments, I wonder if adding a screen cover over the top, between top and pot, coupled with the bottom wind blocker, for the air holes, might actually work in the wind. It's possible it might, though I'd have to test it a bit to see. Though screen would be a pain I think to add on, I have some, I can check and see if it works. Wind is obviously easy to emulate with a fan so it's not hat hard to test it.

Oct 25, 2013 at 9:43 pm #2037916Very interesting stuff, Harald. This is exactly the post I needed to read. Thanks for writing it. Fascinating that screen height becomes counterproductive at some point. That's really counterintuitive, I'd have thought it would help warm the pot. Instead, it must interfere with combustion. And to your point, all my initial tall screens worked poorly. Especially if they were snugged in too tight.

By coincidence, I have been on a similar track of using a secondary screen myself; I made a secondary yesterday but it is still in the garage and I haven't tried it yet. But here's my thinking:

The idea was to hike the main screen up off the ground using owl clips as a tripod, thus raising the screen up 1/4" or 3/8" off the ground. That would allow plenty of air to enter, much more than a "many holes along the bottom" design. As you say, the side jetted alcohol stoves need a lot of air. But I want air to enter as LOW as possible, so as not to have a direct shot at the stove's jet holes, which are about 1" off the ground. The secondary screen is to be a tighter ring inside the main screen, 3/4" high (although ideal height unknown at this point). At this point I've designed it to go INside the main screen, closer to the stove. The idea here was (1) to provide a block to direct wind ingress (air would need to thread under the main screen and over the secondary, at which point the air flow should be headed upwards, helping the stove breathe), and (2) to possibly reflect more heat back at the stove (the secondary ring being pretty close to the stove–ideal closeness, I don't know yet).

I find your precise recommendations for space between pot and screen very interesting. My own experiments have shown 1/4" to be too tight, but I was using a 30 hole side-jet supercat (now a 14-hole simmercat), which (as you note) probably needs more air. I haven't nailed down a precise best gap yet, having not run the experiments carefully, but I'm guessing it'll be around 1/2"

Hopefully you can see the inner ring here. It is sitting directly on a "reflector disc" I generally use to reflect heat up and protect the ground.

Oct 26, 2013 at 11:35 am #2038053

Oct 26, 2013 at 11:35 am #2038053delmar, thanks for your precise observations. Since you're using basically a jim woods fancy feast stove, which in my tests is both the fastest and hottest burning and least efficient, that's an excellent counter example to my Ion type sgt rock tests, which focus purely on efficiency.

You found also what I found by accident, lifting the entire screen up provides the exact amount of air flow required, which is what I aimed to match with holes, by simply calculating the area of air gap lifting it creates, then putting that into holes, ie, making the area of holes match the area that the lifted screen created. I found this during my fairly exhaustive testing process, which I did in many stages, height of screen, lifting it to create air flow, determining optimal height off ground (I believe 3/16 to 1/4, depending of course on the overall screen diameter, I assume the bigger the diameter, the less gap is required). I used paperclips too, but found them too annoying to actually use for the final design because they slip, fall off, etc, but you can create the same result quite simply by first determining the optimal bottom air gap height, then simply leaving 6 or 8 nubs on the base of the screen and cutting out the space between them. 1/2 to 3/4" per nub should be strong enough, and it's a lot easier than cutting out those air holes, which is a real pain.

Here's my how to make alcohol stove windscreen instructions.

Note that I did not update that with the second screen information because I didn't test it adequately, but maybe I'll do any update and do some tests with second flashing external screen and a top mesh screen for wind.

I like your idea of making the second screen a permanent part of the design, that allows you to always have the main screen lifted, and, more important, to have the air gap as low as possible on the main screen surface.

Just as an aside, I believe a lot of the stove issues are all about air turbulence, and something I realized when trying to match the air gap area with holes was that a bottom gap creates a completely smooth area of incoming air, like water pouring down a big pipe, all around the outside edge, evenly, as opposed to discrete jets of air shooting in. My thinking re lifting the screen vs holes was that on dirt the screen might sink in a bit thus making the gap smaller whereas holes would always be above the ground. But sometimes I overthink things, making the gap on the bottom is a lot neater and easier, for sure.

Another thing worth noting is that if you have holes on only half the circumference, which is a common design, that's what I did first too, the air flow is not even, and is even less efficient, it's quite striking testing this stuff how dramatic the differences are, and it's also striking that lifting the screen so it's got a gap all around its circumference is so obviously the most efficient that the overall design should be based on that idea in my opinion, that's why most of the efficient setups out there use really big air holes, it's pretty simple actually.

To avoid speculation and incorrect theories, here's my thinking on the second screen, an image would show it better, but I'll try to put it into words. Since I'm assuming some behaviors of air flows and I may be wrong, the best way to actually determine if this idea is wrong or right is by testing both methods, inside/outside second screen in wind. If there's one thing I learned during testing, it's that air / alcohol /screen works in weird and very specific ways that can only be determined by empirical testing.

Let's assume we make the main screen with the bottom air gap, I put my holes as close to the bottom as possible, but simply having it raised is better because that places the gap as low as possible to the ground, but I didn't figure out a clean way to do that so I went with holes. My thinking is: with the second screen on the outside, what happens is that all moving air approaching the screen bottom is stopped, and the air the screen chamber pulls in basically gets sucked down from the top of the second outer screen. This makes the inner chamber work like a cylinder, with the proper air flow, but with protection against air turbulence, since the air is getting pulled in. Obviously, things to test with this approach would be the overall diameter of the second screen, the outer one in my case, to see is there is also an optimal spacing between the main screen and the outer screen, and an optimal height for the outer screen. That type of testing is much harder though.

The problem I would expect to see by placing the second screen inside the main screen is that the moving air is going to create air turbulence in the burn chamber, which should in theory have a strongly negative effect on stove efficiency. That's in theory, however, if you are using a fancy feast type stove, those are hot, very very hot, the hottest I tested, fastest boils by far.

I was also taken in by the 'intuitive' idea that a screen should be taller to trap the heat against the pot body as far as possible, however, unfortunately that simple could not be verified empirically so I had to admit that sgt rock was right, that's not actually how the burning / efficiency works with this setup, which is when I started to realize that the stove/screen/pot/gap between stove/screen were one system, not a few, which is of course when I hit the efficiency numbers I'd been looking for for so long.

Determining optimal gap for the fancy feast stove would require the same testing, but it's actually very easy to do since all you have to do is take a longer piece of flashing, raise it 3/16 or so, then clip it together to form varying diameters, until you find the most efficient. 3/8" to 1/2" for that sounds about right to me.

I didn't do much testing with the external second ring because my first try, a strip taken from a heavy foil baking pan, worked perfectly, and removed the issue caused by fan moving air across the bottom, so I didn't test it further, but now I'm wondering if I should make a real second screen, out of flashing, and do a bit of experimenting with it. Problem is, of course, that experimenting takes forever, heh.

If it's true that screen over the top helps with the air turbulence however, that is significant, would be interesting to see.

By the way, if you used some type of framed pack, and aren't alone, two packs pushed against each other to form a V shape should create a decent wind break for a stove, unless it's very windy.

Oct 26, 2013 at 2:44 pm #2038115Start watching the video at 2:20 The operator controls the flame/heat. You, the stove designer controls the heat output by your stove design. Give your stove all the oxygen that it needs and then add a little more. Never deny your stove oxygen. In the case of the oil lamp, the oxygen comes in from it's base. When the operator raises the wick too high(gives it too much fuel) it burns dirty/sooty. Lowers the wick/decreases fuel and it burns clean. Same with alcohol stoves(wick style) The globe/windscreen of the oil lamp has a small opening in it's top. when the operator puts his hand in back of the opening and blows, the flame goes out. The same thing can happen to your stove if windscreen is too close to your pot, small opening at the top, gust of wind can blow stove out especially like the Ion by Sgt. Rock (no exposed wick etc.) and others.

All you ever wanted to know about DIY stove related stuff can be found on my website bplite.com

Oct 26, 2013 at 6:52 pm #2038176Your site is fun, I'll check it out. I wouldn't draw many conclusions from oil lamps, different fuels, screen material, etc, too many variables changed. The main one being regular alcohol non wicking stoves work via vaporization of the fuel via boiling the main fuel container.

I tested some of the things I was wondering about above, and found, thanks to a nice breezy day today coupled with a fan, that yes, screen material over the top of both the external small screen and the main gap between pot and screen helps a little bit, but it doesn't help enough, and since it's so fiddly and awkward, it's an idea that I think might be fun to play with and test but not something I'd use in real life.

However, using a folded up 3/16" pad as wind break, folded up to 2' wide, worked very well, coupled with the outside second ring. A fine rousing boil reached, didn't boil quite as long when the entire set up was out of the wind completely, ie, both cases 10:30 boil time, out of wind, 2:30 boil, in wind, with pad screen, about 1:30 boil. In other words, lost about 1ml efficiency from air movement or whatever, starting at 15ml each time of slx. This is about what I'd expect, by the way, since no wind ion/screen gives about 12.5ml 70F 2 cup boil, give or take.

Didn't test varying diameters of outer screen, just stuck to about 1" gap, maybe 3/4".

Since none of my stoves work in the wind with any particular effectiveness, I don't think the air gap size is really an issue, if the wind is gusting enough to blow out an ion stove/screen setup, I wouldn't get a boil anyway unless I put it behind a bigger wind screen, then it boils fine, not quite as well as when out of the wind totally, but close enough.

I'll post some pics, and maybe do a new how to once I decide on the right outside ring diameter. I used the method I suggested to create the bottom screen air gap, creating 5 x 5/8" nubs ( for narrow pot screen size, about one nub every 2.5") and then cutting out 1/4" or so, that works fine, and looks a lot neater than cutting the holes higher up.

Re wind/ion screen, my tests actually showed the direct opposite of being blown out, what happened before I added the larger full pad screen in the wind direction side was actually a sort of overflaming, ie, it got too hot in the chamber, maybe from wind blowing in, I don't know the reason, but flames shot up the side of the pot, which is always a sign that the burn is not going to work, and it didn't, flamed out long before boil hit. So wind in fact made it flame up, not out in this test. Add that as a data point, that is, the result was not going out, it was flaming up too much.

Speaking just for myself, my goal isn't to test stoves endlessly (the only reasons I stopped using the penny stove was it had too many parts, and was too hard to prime, and wasn't that efficient, though it's good for two person cooking), but to find a stove that works well and hits all the design goals (the ion solved all these problems, and is way easier to make and use), this thread was nice because I was able to simplify the design a bit more, making those screen holes was a real pain, and turned out kind of ugly, now it looks ice and neat and is way easier to make. I'll tweak the second screen, external, a bit, and see if I can find any real differences, my guess is there won't be major differences but a wider diameter is probably better than a more narrow one, to keep the air input area nice and big while still covering the holes.

Just as an aside, however, I did find that wind blew out the ion with a wide pot when using the simmer ring, but that's a very very weak flame, so that's not really a surprise, that was an earlier version though without using the pad screen.

Oct 27, 2013 at 12:37 pm #2038324Harald, during the winter months spend some time at the site. I wish you well on your adventures in stove making.

-

AuthorPosts

- You must be logged in to reply to this topic.

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

Our Community Posts are Moderated

Backpacking Light community posts are moderated and here to foster helpful and positive discussions about lightweight backpacking. Please be mindful of our values and boundaries and review our Community Guidelines prior to posting.

Get the Newsletter

Gear Research & Discovery Tools

- Browse our curated Gear Shop

- See the latest Gear Deals and Sales

- Our Recommendations

- Search for Gear on Sale with the Gear Finder

- Used Gear Swap

- Member Gear Reviews and BPL Gear Review Articles

- Browse by Gear Type or Brand.