Introduction

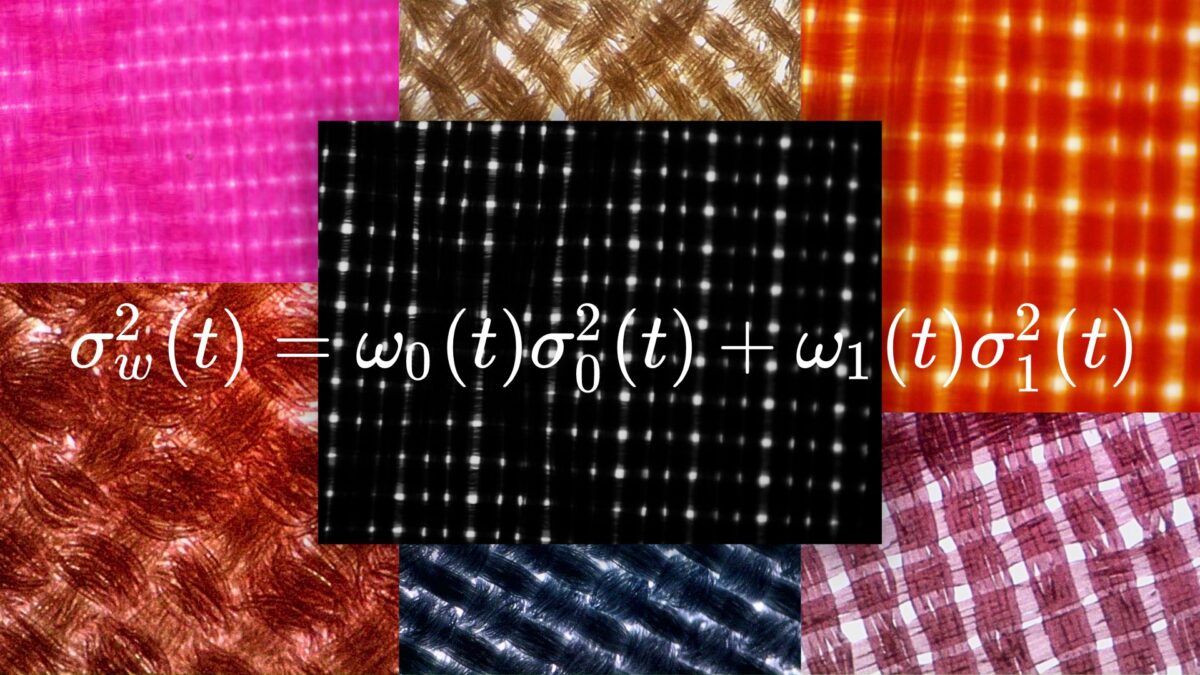

Wind shirts (which can include jackets, pullovers, and hoodies) are thin, lightweight, and compact garments made with non-waterproof, breathable, woven nylon or polyester fabrics. The air permeability rate of such fabrics may have some impact on the perception of user comfort while wearing wind shirts. The purpose of this report is to investigate the relationship between air permeability, fabric porosity, weave type, and yarn structure via photomicrography and image analysis. This is not an exhaustive research study, but rather, an exploration of some of the fabric design attributes that have an impact on air permeability rates.

The air permeability rate (APR) of a fabric is one measure of the fabric’s ability to allow airflow through it in response to differences in air pressure across the fabric face. APR is most commonly measured using the procedure described in ASTM D737, which creates a fixed air pressure across the fabric face and then measures the flow rate of air passing through it.

In contrast, the moisture vapor transmission rate (MVTR) generally defines a fabric’s ability to allow for the diffusion of moisture vapor molecules through it in response to differences in moisture vapor pressure between the inside and outside faces. MVTR is most commonly measured using one of the procedures described in JIS L-1099, which measures the evaporation of moisture through the fabric in the absence of an air pressure gradient.

The general term breathability is the fabric attribute describing excess heat and moisture leaving a user’s clothing system while active. Both MVTR and APR can affect the overall breathability of a fabric, and in some cases, are correlated. High levels of breathability are generally desirable for windshirts, which are designed to be worn in stormy weather when the high water resistance of a rain jacket is not needed. In addition, windshirts are usually made with fabrics having higher APR than fabrics used in rain jackets, allowing for better overall user comfort during high levels of physical exertion.

“The term ‘comfort’ is a nebulous one, which defies definition, but the sensation of comfort is easily recognized by the person experiencing it.” – K. Slater, Comfort Properties of Textiles (1977)

Table of contents

Table of Contents • Note: some sections may only be available to Premium or Unlimited Members.

Products featured in this report

- Ripstop by the Roll HyperD Fabrics

- Pertex Quantum Air Fabrics

- Mountain Hardwear Kor Airshell Hoody

- Patagonia Airshed Pro Hooded Pullover

- Katabatic Gear Crest Windshell

- Black Diamond Alpine Start Hoody

- Arc’teryx Squamish Hoody

- Arc’teryx Norvan Windshell Hoody

- Rab Vital Hoody

Updates

- May 11, 2024 – A photomicrograph of the 2020 Kor Preshell Hoody was incorrectly labeled as a 2023 Kor Airshell Hoody. This has been corrected in both the image caption and the text.

Member Exclusive

A Premium or Unlimited Membership* is required to view the rest of this article.

* A Basic Membership is required to view Member Q&A events

Home › Forums › What Properties Influence the Air Permeability of Wind Shirt Fabrics?