Topic

Uber Bivy Top Material Analysis Mystery

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

Home › Forums › Gear Forums › Gear (General) › Uber Bivy Top Material Analysis Mystery

- This topic has 23 replies, 12 voices, and was last updated 5 years, 7 months ago by

Paul McLaughlin.

Paul McLaughlin.

-

AuthorPosts

-

Dec 10, 2015 at 11:15 pm #3369946

Mystery Material

Mystery Material at 20mm FOV

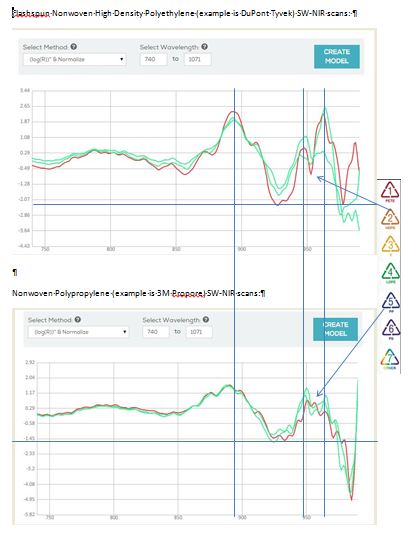

Paul McLaughun sent me a sample of the fabric used in the MilesGear – Uber Bivy to analyze. It looked identical to the Tyvek 1422R which I analyzed on 10/3/11. I tested his mystery fabric sample’s air permeability at .18 CFM which was also similar to Tyvek 1422R at .15 CFM. I smugly thought OK, the virgin HH will also test about the same at 492mm H2O. Gasp… my HH tester read >3,515 for this material. Knowing that Tyvek had a very large number of versions, I checked their specs to see which version this might be but, nothing matched its characteristics. I next did a short wave near infrared (SW-NIR) spectrometry analysis (to see if the material was the same as used in all of the Tyvek variations; it was not. Caveat – this is a machine which is new to my lab and I am still learning how to use it. The analysis showed the material was the same as the 3M Propore samples and different from the Dupont Tyvek samples

Nisley’s SW-NIR scans of his Tyvek 1422 and the mystery material

I aged the material with 5,400 Cubex wet-flex cycles and retested it at >3,515mm H2O. The other pertinent test result was the thickness which varied from .339mm to .361mm.

Based on my analysis, the material appears to be Kappler ProVent 10000. The Kappler spec’s for this material list the HH at 1,200mm H2O which it greatly exceeds. My GUESS is that since it was specifically designed for hospital wear, they only tested the HH to the point that it passed the Blood Penetration Resistance requirements.

Rain will not penetrate this bivy and the low surface energy insures that it will never require a DWR and will not wet out.

Dec 11, 2015 at 3:12 am #3369968Richard, what’s the weight? And how durable do you find the fabric? On par with tyvek 1422r? Perhaps the aging test suggests it is more durable?

Dec 11, 2015 at 7:35 am #3369981Edward,

The link Richard included in his post says the material is a polypropylene microporous membrane and that it weighs 2.3 ounces per square yard.

Dec 11, 2015 at 10:52 am #3370018Richard Nisley knocks it out of the park again! You are without a doubt the MVP of this forum. Thank you for the information!

Every time the Uber Bivy comes up in conversation, it seems like nobody really knows how to categorize it. Well, now we have our answer. It’s a lightweight waterproof/breathable bivy tent. I suspect MilesGear’s sales are about to get a big boost.

For point of comparison, the final weight is about the same as a Borah Snowyside with a full eVent floor. Breathability is lower (.18 CFM vs eVent’s .53), but the extra interior space provided by the pole might make up for that.

Dec 11, 2015 at 10:55 am #3370019The piece of fabric I purchased was 58.5″ x 152″ and on my scale 15.2 oz. That calcs out to 2.215385 oz/sq. yd.

Dec 11, 2015 at 1:31 pm #3370052I used to own a Miles Gear bivy using this material. Never had any issues with condensation. I also measured the temperature inside the bivy to be 15-21 degrees warmer than the outside temperature using some min/max digital thermometers.

Anyone think this material would appropriate for a small bivy dome tent? Kind of thinking along the lines of a larger version of the Integral Designs eVent Wedge bivy tent.

Dec 11, 2015 at 2:20 pm #33700582.2 or 2.3 oz/yd2 is like WPB fabrics like GoreTex or eVent. But it sounds like it’s more breathable and adequately waterproof. Maybe good for a jacket.

Not so good for a tent because it’s too heavy. And you don’t need a tent to be breathable. I don’t think water will breath through it unless it’s next to your body and there’s a temperature gradient across it.

Better to use 1.5 oz/yd2 or lighter fabric. That 1.0 oz/yd2 fabric would be good. Or Cuben.

Dec 11, 2015 at 3:49 pm #3370075The manufactured cost / performance ratio of this material is the primary differentiator from the fabric alternatives Jerry mentioned.

Relative Cost

Relative Performance

Dec 11, 2015 at 6:45 pm #3370094

Dec 11, 2015 at 6:45 pm #3370094I bought 10 yards of similar stuff from Dave a couple years ago except it was 1.8oz/yd from what I remember. Might be a different fabric altogether. Not sure. He said that he ended up going with the white material for durability reasons. I made some overmitts with some of the white material and they have proven to be waterproof so far.

Ryan

Dec 11, 2015 at 7:17 pm #3370102AS far as a tent material goes I would have my doubts. I’ve only played with it a bit since I got it, but it seems as though when stretched enough it does not bounce back – in other words, it is not very resilient. It seems to be very low stretch, but at a certain point it finally does give and in a way that suggest damage is being done ( you can hear a slight tearing sound). I tried a quick seam and it seems to hold fairly well, but I’d be afraid that under load it would deform and not come back, and that that sort of abuse might harm the waterproofness as well – though I have no data to back that up, it just seems possible that anything that disturbs the structure might affect the waterproofness. Remember that this is a nonwoven material, and that there is no membrane or coating; the properties are inherent in the structure of the material

So, bivy for sure, tent maybe not so much. And cheap, light overmitts for the rain – oh, yeah!

Also – as far as weight goes, this stuff is as light as the lightest eVent I’ve ever seen – and that is essentially unavailable for MYOG (it’s the stuff that BPL sold a few years back, I managed to get some off the gear swap and it is 2.25 oz/yd).

So it’s a niche product, but seems like it would fit that niche very well. And at $5/yd, the price is sure right.

Dec 11, 2015 at 7:34 pm #3370103Thanks, Paul, that’s kind of what I figured. Certainly seems like an ideal bivy fabric. I’ve preferred tents in the past, but the draw of the bivy is strong

And thank you, Richard, for your valuable testing

Dec 11, 2015 at 8:36 pm #3370118That looks similar to the liner material used in the Arctic Oven tents…I wonder if it is?

BTW: Arctic Oven tents are not UL…

Dec 11, 2015 at 9:48 pm #3370131It looks like a duck…

and it sounds like a duck… but… ?

”

- What material is used in the manufacture of an Arctic Oven tent? The body of the Arctic Oven tent is made from Vapex™, a polypropylene fabric, made specifically for Alaska Tent & Tarp. It is a multi-ply, spun-bound composite with a huge water vapor transmission rate. Highly water repellant and extremely breathable, Vapex™ is the engine behind the Arctic Oven’s condensation-free interior. The fly of the Arctic Oven tent is made from heavy duty 4oz coated oxford nylon.”

Dec 12, 2015 at 7:33 am #3370156so much for my theory you need temperature gradient to get water vapor to go through tent?

maybe it would be warmer inside that tent

Dec 12, 2015 at 7:52 am #3370161Anonymous

InactiveI imagine that the durability per weight factor is fairly low, but otherwise looks like an interesting, well performing, lost cost material.

Awhile back i experimented with using 1443R (“Kite”) Tyvek as an easily accessible, easy to work with, poor man’s membrane for MYOG WPB. The unfortunate thing about all of these non woven materials, is that they have relatively low tear strength per weight. I gave up on 1443R for this use, but i wasn’t using particularly good lining materials either (cheap crappy polyester from Joannes).

Now that i know lightweight, good quality, durable polyesters are available at reasonable prices (i didn’t before), i may revisit this project.

More specifically, i’m looking at the 1.1 oz uncalendared ripstop polyester, taking the DWR off, and adding a thicker silicone coating to replace the DWR–this would be the outer/face fabric, the kite tyvek the membrane, and then nylon tulle would be the inner, skin touching fabric. (It’s too bad that the 15D polyester used for the membrane silpoly is not available without a waterproof coating).

This would get it in the 2.7 oz/yd2 range, which is heavyish, but not bad for a material that would provide moderate rain protection, with (probable) twice the air porosity as eVent, be fairly durable, and not require a DWR.

If one used an UL nylon (.67) instead, you could get it to around 2.25 oz/yd2–adding a little extra for the heavier silicone DWR vs factory DWR. Perhaps there are better and lighter materials to use for the “membrane” though? Maybe i should experiment with stretching and/or needle puncturing some Teflon film?

Dec 12, 2015 at 7:59 am #3370163Anonymous

InactiveJerry, my limited understanding is that the old, non measurable CFM WPB fabrics relied on temperature and humidity gradients to pass moisture vapor, but the newer, more air porous (measurable CFM’s) WPB fabrics can pass moisture vapor regardless.

So eVent, Neoshell, and some of my proposed homemade WPB fabrics could pass moisture in a tent application.

Dec 12, 2015 at 8:08 am #3370168I’m still skeptical that tent fabric will pass water vapor, especially a tarp open at the bottom. Besides, if it’s open at the bottom, the water vapor will be blown away by air currents, doesn’t need to pass through the fabric

Maybe an enclosed tent would work

Dec 12, 2015 at 12:59 pm #3370209So now I’m re-thinking my position on this stuff as a tent material. Mostly in the sense that I’d sure be interested to see how it would do, because the idea of the bivy/tent (small enough to fit in tiny oddball sites but with poles and enough interior space to change clothes and read/study maps in comfort, and useable both with and without the poles for versatility) is intriguing to me. If only I had the time to play around with the patterning – I expect that would be demanding given the low stretch.

Dec 17, 2015 at 9:39 am #3370936With electricity, Current = Voltage / Resistance

“Resistance” is analogous to the vapor diffusion resistance

“Current” is analogous to the amount of water vapor going through the fabric

Without any voltage across a resistor,no current will flow, even with a small resistance

You need something analogous to “Voltage” to make water vapor pass through the fabric – air pressure like wind blowing on one side, temperature difference from one side to the other, or humidity difference across the fabric. Temperature and humidity are inter-related.

Dec 17, 2015 at 10:42 am #3370942A bivy or small tent made of this material could have a substantial temperature difference across the fabric. Based on my past measurements, I would expect the interior air temperature to be 15-21 F warmer

How do nonwoven materials do with UV?

Dec 17, 2015 at 11:02 am #3370944Both the non-AP WPB’s as the AP WPB’s need a vapor pressure gradient across the material to move moisture vapor and the vapor pressure gradient results from the difference in vapor pressure on both sides of the material. That vapor pressure is the result of temperature and RELATIVE humidity (which indeed depends on the temperature).

But in the non-AP WPB’s there is a solid, hydrophilic layer which can pass vapor by ‘transforming’ it first (which functions better the higher the relative humidity)or there is no such hydrophilic layer but the pores aren’t consistent in size and/or distribution, both slowing the breathability rate. AP WPB’s have no such hydrophilic barrier and the pores are more consistenly sized and distributed resulting in easier vapor transfer.

Dec 17, 2015 at 11:08 am #3370945John,

Your experience and the science concur on the potential for a high temperature difference inside this material (.361mm thick spun bound polypropylene in both dry and wet conditions).

It has the lowest thermal conductivity of any natural or synthetic fiber:

Polypropylene fibres retain more heat for a longer period of time, have excellent insulative properties, and combined with its hydrophobic nature keeps a shelter dry and warm.

Its Specific Gravity is 0.90 – 0.91 gm/cm3. Because of its low specific gravity, polypropylene yields the greatest volume of fibre for a given weight. Polypropylene is the lightest of all fibres and is lighter than water. It is 34% lighter than polyester and 20% lighter than nylon.

It absorbs less than 0.1% moisture and so the the inherent low thermal conductivity and weight doesn’t increase in moisture.

UV resistance is not one of its positives and non woven construction is not the reason, It is a result of the polypropylene material. If it will be used in the sun for long periods of time, you need to wipe the surface down every year or so with a UV protectant such as 303. Alternatively you may be able to purchase the fabric with a UV protectant pre-applied.

Jul 20, 2017 at 1:14 am #3479894Richard,

Awesome job with your analysis of my “Mystery Fabric”. Sorry I did not see this post until today when a customer forwarded it to me. Yes, the fabric I use on the top of my bivy sacks is indeed Kappler ProVent 10,000. The early green fabric was ProVent 7,000. By the way, feel free to email me with any other questions.

It is amazing how well it is able to get rid of moisture inside the bivy, add warmth, and be fully waterproof. A few weeks ago we had 4 of us in our old bivy sacks from about 2011 and got caught in a great thunderstorm with lots of hail and rain. We were outside sheltered by a big tree and watched the bivy sacks get covered in hail and have standing puddles of water on them for an hour or two. After it had passed, we opened them up and all was dry! A stress free night :)

Sep 3, 2018 at 10:06 pm #3554419Resurrecting this old thread because I finally made a bivy out of this stuff and took it on a trip. 4 nights in the Sierra in dry weather and about 30 degrees except the last night it got down to 20. No condensation at all, Seemed to add some warmth and definitely cut the wind nicely – we had a breeze most nights. Liking it so far!

-

AuthorPosts

- You must be logged in to reply to this topic.

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

Our Community Posts are Moderated

Backpacking Light community posts are moderated and here to foster helpful and positive discussions about lightweight backpacking. Please be mindful of our values and boundaries and review our Community Guidelines prior to posting.

Get the Newsletter

Gear Research & Discovery Tools

- Browse our curated Gear Shop

- See the latest Gear Deals and Sales

- Our Recommendations

- Search for Gear on Sale with the Gear Finder

- Used Gear Swap

- Member Gear Reviews and BPL Gear Review Articles

- Browse by Gear Type or Brand.