Topic

Testing Moulder Strips at -15F/-26C

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

Home › Forums › Gear Forums › Gear (General) › Testing Moulder Strips at -15F/-26C

- This topic has 39 replies, 10 voices, and was last updated 7 years, 10 months ago by

Bob Moulder.

Bob Moulder.

-

AuthorPosts

-

Mar 27, 2017 at 10:17 am #3459778

See the actual write-up in the second, editable post.

By way of background info, Bob Moulder has been promoting a copper strip strapped to the side of a butane/propane canister and extending up into the flame as a way to maintain the temperature and therefore the pressure in the canister even in extremely cold conditions and while subject to the evaporative cooling of using the butane. David Gardner, Gary Dunckel and I all had ideas about materials (aluminum versus copper), sizes and geometries and assembled our own versions.I live in Kenai Alaska and, after three non-winters, we had a real winter again in 2016-2017. Snow for skiing. Significantly below 0F temperatures, repeatedly. And February and March have been fabulous with clear blue skies almost every day and clear cold nights almost every night. Mostly, it’s been 20-25F during the day and 0 to 5F at night, but occasionally colder. I got some of my Moulder strip variants tested at my house at -11F.

My son is very, very good at math (this enters the story). I volunteer as a competitive coach math at the middle school and ever since he’s enjoyed and excelled at regional, state-level and national math competitions. He once again did very well at the first-level American Mathematics Competition (350,000 students around the country take this 25-question, 75-minute exam) in February. When I called the local school to confirm dates for last week’s second round (for the top 5,000 students nationally), it turned out they hadn’t returned a critical form 2 weeks prior. Calls were placed and the only other school for 1000 miles around able to offer the test was in Fairbanks which is 500-miles to the north. I debated putting Drake on a twin-prop, then the jet, but while a 17-year-old can take a cab, can he rent a hotel room? There just seemed to be a lot of possible failure points. And we’ve both always loved a good road trip and it was a fabulous time for a road trip: 300-mile visibility, clear days, clear nights, views of Denali from all along the route, snow-covered scenery, 12-hour days + twilight but some dark nights to see aurora, no road construction and NO MOTORHOMES yet!

The forecast was for cold nights so I loaded up my, Gary’s and DavidG’s heat-transfer strips, stoves, canisters, and a pot in hopes the forecast was right.

We drove up, had Thai food for dinner (for some reason, Fairbanks has a lot of good Thai places, which my town does not), got to bed early, and got Drake to the local high school for the test. I went back to our hotel room to test Moulder Strips.

Drake did really well on the American Invitation Mathematics Examination (15 questions in 3 hours) that morning, with a personal-best score, therefore a new, highest-ever in Alaska score, about 20th nationally, and easily qualifying in the top 250 who will sit for the USA Mathematics Olympiad: 3 questions over 4.5 hours the first day and another 3 question over another 4.5 hours the next day (they’re hard questions) from whom 30 are selected for an intensive summer program from whom the 6 who represent the USA at the International Mathematical Olympiad (in Rio this year) are selected.

Here’s Denali (in the center) from the north, as we drove south last Wednesday after the testing of math students and Moulder Strips.

Mar 27, 2017 at 10:20 am #3459779

Mar 27, 2017 at 10:20 am #3459779I got back to the hotel and it was still -15F/-26C

I used a 2×12 and an ice chest to set up a table / test stand outside the window of my hotel room. This allowed me to mostly stay in the warm room while leaning out to adjust things, add snow, etc. During most of the testing, the two windows (one double-paned window, a 6″ gap, and a second double-pane window) were closed. There was no wind and no sun on the test area. I used no windscreen or IR reflector at any time, and the canister sat directly on the frozen wood. Pretty ideal conditions for testing Moulder Strips, I think, because any sun, wind screen and its resulting IR reflection, or a more insulating base would make canister use even more viable. Of course, in windy conditions, you’d want a wind screen of some sort and the lowest useable temperature might change (up or down).

For all the tests, I used a 30-40% full MSR 110-gram canister. A pretty good mix of fuel and presumably what you’d bring for camping in negative F temperatures. All the Moulder Strips (sticks, wires, etc) were secured to the canister with a velcro strap. The strap is 1.5″ wide, has loops on one side, hooks on the other and is sold to, say, cut to length and secure a length of garden hose or an extension cord in a neat bundle. Not the lightest option (there are far thinner velcro straps for instance), but it is pretty insulating and hence does double duty. 15 inches handles any canister and weighs 9 grams. Even with the high-performing CMS (Classic Moulder Strip), it didn’t melt, but a bit of carbon felt or just a scrap of paper over the strip would eliminate that possibility.

For all the tests, I used a 30-40% full MSR 110-gram canister. A pretty good mix of fuel and presumably what you’d bring for camping in negative F temperatures. All the Moulder Strips (sticks, wires, etc) were secured to the canister with a velcro strap. The strap is 1.5″ wide, has loops on one side, hooks on the other and is sold to, say, cut to length and secure a length of garden hose or an extension cord in a neat bundle. Not the lightest option (there are far thinner velcro straps for instance), but it is pretty insulating and hence does double duty. 15 inches handles any canister and weighs 9 grams. Even with the high-performing CMS (Classic Moulder Strip), it didn’t melt, but a bit of carbon felt or just a scrap of paper over the strip would eliminate that possibility.

All of the Moulder Strips, Dunckel shunts, and Thomas wires were simply held to the side of canister. No goo or water or thermal compound was between the strip and the canister. This is one obvious area for (even more) future improvement, but tricky to achieve in a neat, sturdy, reusable manner.

The stove is a BRS-3000T which is a relatively short stove. Comparing each other’s experiences, it appears an additional inch of stove height significantly (1) increases the time lag between starting the stove and getting a good thermal feedback loop going, (2) increases heat loss off of the longer length of metal out in the cold weather, and (3) makes for a warmer minimum ambient temperature for a particular heat shunt.

I used a 1980’s-era stainless steel 2-liter pot. It came with thin layer of copper on the bottom, but that is now oxidized and blackened by use over stoves and fires. It seemed as “black”, emissivity-wise, as an anodized aluminum pot and much blacker than a shiny new pot. So it would have emitted more of its own IR and reflected much less of the flame/stove’s IR than a shiny pot, (but not emitted much while holding ice water). While holding boiling water, it still wouldn’t reflect much, but it would emit some of its own, so that’s not the most demanding test and I focused on performance with ice water in the pot, not boiling (although I did bring each set up to a rolling boil).

I started each test with a bit of water and lots of snow in the pot and kept adding cups of snow to keep the pot full of ice water for several minutes. Only after each set up had long been in stable operation, did I stop adding snow and let the pot of water (1 to 1.3 liters at that point) come to a boil. I left the pot lid off at all times, so that too was more demanding than typical use would be.

Mar 27, 2017 at 10:20 am #3459780

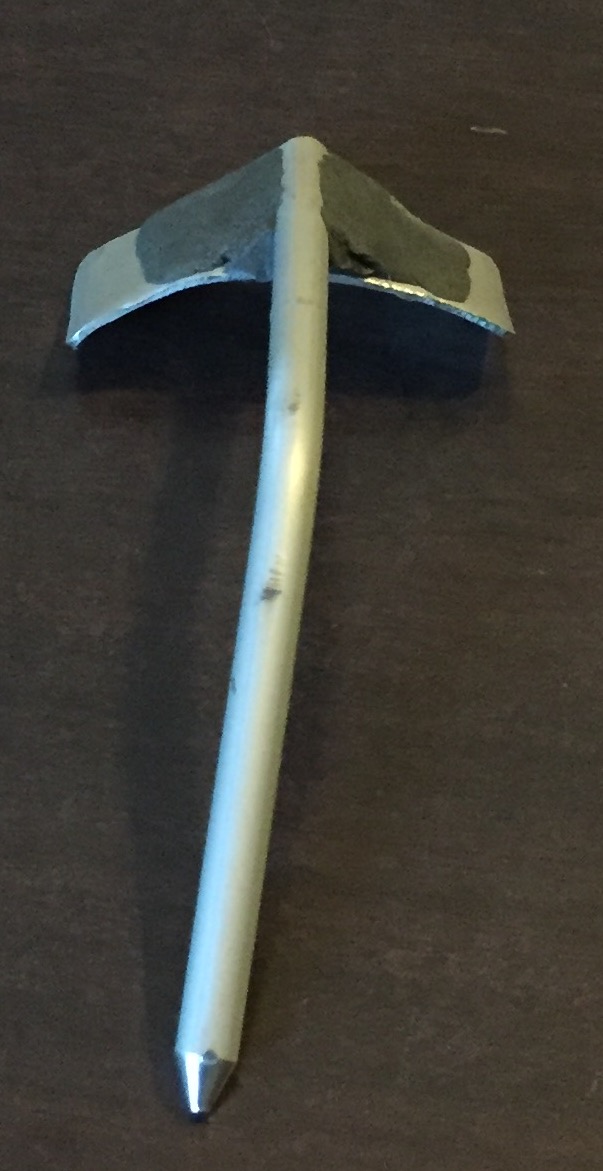

From bottom left to top right we have:

Classic Moulder Strips (CMS) sent to me by Gary Dunckel in a little PIF’ing lovefest we had this winter. 1.0″ x 0.021″ copper, 19 grams. By far the most malleable, easiest to bend and adapt in the field. And the most effective shunt tested.

The “Butterfly” (my name for it) created and sent to me by David Gardner, 7.6 grams.

The “Left-Winger” by DavidG, 4 grams.The “Paddle” by DavidG, 10 grams

My slightly flattened and significantly curved length of 4-gauge copper wire, 35 grams, previously tested at -21F when it worked well.

My flattened pre-1983 copper US penny soldered onto 12-gauge copper wire, 10 grams, previously shown to be marginal to inadequate at -11F. Somewhat flimsy. There are better options.

Each time, I positioned the strip as close to the bottom of the canister as I could. This is important because that’s where the liquid is. I was using 30-40% full canisters, so not quite worst case, but much of the sidewall height was steel with no liquid butane behind it.Results:

The “Butterfly” by David Gardner, 7.6 grams, aluminum rod flattened and curved in two directions. It worked very well at -15F and was the lightest option that was not at its limit. It sustained good pressure and a good flame while melting 1.5 kg of snow into water and then bringing it to a full boil. I estimated the temperature of the rods just before they went under the velcro as 160F. The winner for lowest weight at -15F and colder. It is, however, bigger and harder to pack depending on your pot/canister combo (perhaps it can store around your canister, completely within your pot?).

The “Left Winger”, also by David Gardner was about 170F just above the Velcro. It also allowed a flame to be maintained while melting over a kg of snow, but the flame wasn’t quite as vigorous (lower pressure) and melting the snow took longer. Presumably it was conducting half as many BTUs down to the canister as the Butterfly. It seemed to be at it’s usable limit and I wouldn’t want to count on it and only it, at -20F or colder. At 4 grams, it was by far the lightest option that enabled operation at -15F. Therefore, it is the lightest option I know of that allows easy, assured operation in normal, semi-sane, about-zero-F and higher winter-camping temperatures. It is half the size of the Butterfly, but I’d still be careful packing it.

The “Paddle” by DavidG had a temperature of 130F just above the velcro but has a lot less contact area down at the bottom of the canister where it is in contact with the liquid-filled portion. It’s sturdy and easy to pack away. It clearly was at its limit – the flame was quieter, smaller and the melt and boil times were longer, but it did bring a liter of water to a boil with no lid and a non-heat-exchanger pot. (P.S. I never go snow camping without a HX pot). So at 0F or a bit colder? Should be fine. It’s small enough that it could be easily kicked into the forest duff and be hard to locate. Maybe some fluorescent paint on the non-canister side of the paddle? Or some orange high-temp paint (like for car manifolds and BBQs) on everything but the contact area? Some paint at the tip would burn off, but the rest would remain. It’s obviously easier to “bang one out”, literally, in fabrication then the Butterfly or Left-Winger.

The Classic Moulder strip, (thanks GaryD!) was 19 grams and would work on almost any stove and a 110-gram canister. The BRS-3000T didn’t even need that much length and/or could use that same length on a 220-gram canister. This was the easiest to position, easiest to secure, transmitted the most heat down to the canister (it was 180F just above the velcro and above boiling just a little higher). I may have been at some risk of melting the velcro (GaryD sent carbon felt, but I didn’t use it). Any little piece of medium-temperature material (paper, a few twigs, a bit of cotton bandana) between the strip and velcro would eliminate that possibility.

I zoomed in on this spot because when I splashed some water drops onto the Moulder Strip, it boiled away quickly (those dried water spots) well below the top of the canister. The upper remaining water drop is simmering in this photo and the lower drop is about 180F and evaporated away quickly. Yet, one inch to the right (over the “DA” of “!DANGER!”) is a frozen drop of water. So, like politics, all heat transfer is local. If it seems odd to have that frozen droplet so close to a boiling drop, remember that (1) it was -15F that morning which is as far below freezing as 79F is above freezing, (2) I’ve got no windscreen and no “Adams reflector” directing IR photons at that vertical side, and (3) that drop is on to thin steel and velcro with gaseous butane inside the canister at that level – all of which are lousy conductors of heat.

So I declare the Classic Moulder Strip and the DG Butterfly as both capable of use (with a decent fuel mix) at -15F/-26F and colder. -20F? Sure. Colder than that? Not sure. But if you brought BOTH of them or TWO of one style, I’d expect you could make your morning coffee at -40F/C. Thing is though, -40 is wickedly non-fun IME, even with a hot cup of coffee.

Mar 27, 2017 at 11:34 am #3459788Thoughts and conclusions:

Bob, with his original, Classic Moulder Strip, knocked it out of the park and we can now use good fuel blends down to at least -15F and crappy cheap 100% n-butane down to at least 0F. All for 19 grams.

DavidG, as he prone to do in his machine shop, came up with some even lighter options. A 10-gram sturdy option and a 4-gram more delicate version both good above -15F and the Butterfly at 7.6 grams capable to at least -15F.

It does seem that aluminum offers a weight advantage, just as density divided by heat conductivity suggests.

I don’t like either of my versions as much as the simple CMS nor do they do anything that DavidG’s 1/8″ aluminum shunts don’t do for less weight (although you can buy a foot of #4 copper wire at any Home Depot and bang one out for $1.39). And it was tested to -21F.

DavidG describes his aluminum welding rod as easy to flatten. That was not my experience with an aluminum tent peg. Is that because the welding rod is pure aluminum while the tent peg is some alloy or heat-treated for stiffness? The second most popular sport in my town after fishing is welding, so I’ll source some aluminum welding rod and play with it.

Anyone have a source of 1″ x .04-ish” malleable aluminum sheet metal? Or maybe 0.5″ x 0.06-ish”? I mean, other than your local stop sign? For a CMS but out of aluminum.

Mar 27, 2017 at 2:46 pm #3459821Excellent work David

Mar 27, 2017 at 2:51 pm #3459822yeah, good data, thanks

Mar 27, 2017 at 4:00 pm #3459830Fantastic write-up!

because the welding rod is pure aluminum while the tent peg is some alloy or heat-treated for stiffness?

Most likely.

You can actually get Al welding wire in different alloys, and it won’t be tempered anyhow, while tent pegs will be tempered alloy (if they are any good, that is!).

So yeah, unfair comparison.Cheers

PS: check local Council depot for damaged/discarded road signs!Mar 27, 2017 at 4:36 pm #3459840Council depot

must be some Australian thing : )

Mar 27, 2017 at 4:42 pm #3459843“Council depot” = “County maintenance yard”? I once needed to disguise a discharge stack for some toxic compounds in a residential neighborhood so I picked up a used lamp post at the county yard for pennies per pound. Painted it white, routed the discharge up through it, attached a pulley at the top, ran an American Flag up it, and everyone was happy.

Back to Moulder Strips:

I had high hopes for this one. Aluminum, round (minimum heat loss on the downward leg), transitioning to more surface area at the bottom of the canister:

That fillet is JB Weld which is plenty strong enough and has a high-enough temperature rating. The round portion is from an aluminum tent peg. The curved portion is a section cut from crutches (really cheap at the thrift store), flattened a bit for the curative of the canister.

And it didn’t work very well. The pressure / flame level I started with reduced over time at -15F/-26C. And since we have lighter options that work better, this goes in the trash heap of failed projects. Or maybe is handed off at the next GGG to one of you Southerners who snow camp in balmy 10F and 15F weather.

I suspect the JB Weld is a poor thermal conductor (could I have mixed aluminum shavings into it?). I didn’t want to play with it a lot at -15F, but maybe on a milder day, I’ll get it into stable operation and gauge the temperature profile from top to bottom.

Mar 27, 2017 at 5:17 pm #3459849“Council depot” = “County maintenance yard”?

That’ll do.the JB Weld is a poor thermal conductor

Just so. Quite poor.

But I think there is a version which is heavily laced with aluminium powder – try that.Cheers

Mar 27, 2017 at 5:27 pm #3459851David, I am very impressed with the thoroughness of your testing and the details that you reported. I guess I am also thrilled with your opinion of the Moulder strip, since that validates what Bob and I have settled on as well. If you (or someone else) can duplicate the results with a similar version in aluminum at a lighter weight, that would be pretty impressive.

By the way, that small piece of carbon felt that I gave you was intended to keep the heat from the hot copper from melting a neoprene cozy. I also found that the heat doesn’t much affect Velcro. I think that Velcro must be made by the same people that make Twinkies – no one really know what chemicals are in either one, and they both seem to be nearly indestructible with a great shelf life.

Thanks for taking the time to do this testing in your local ‘lab’, and for sharing your results. Also, you must be quite proud of your son’s accomplishments. He must have some great genes!

Mar 27, 2017 at 5:40 pm #3459854the heat doesn’t much affect Velcro.

Yes, we do know what Velcro is made from. A lot of it is made from nylon, with a melting point over 260 C. That’s so far above the touch test (TM) temperature for canisters it is not funny.

Some Velcro products are made from polyester: MP >260 C as well.Cheers

Mar 27, 2017 at 6:21 pm #3459867Gary Dunckel wrote:

OK, Roger, that explains Velcro. But what about Twinkies? They have a shelf life of at least 5 years, some say.

Cheers back at ya…

Mar 27, 2017 at 6:35 pm #3459872David, huge thanks for all the testing… and all the preparation involved—couldn’t have asked for a better venue and conditions!

IIRC I once measured the temperature of the strip under the Velcro at 142°F, which makes for a nice temperature gradient considering the strip is red hot at the top and 180°F at the bend per your measurement. That is a superb photo that shows the hot water droplets evaporating with a frozen drop in such close proximity.

While the temperature at the canister might not melt Velcro, I plan to keep using the silicone because there can be long-term heat deformation and degradation below the melting point, and because the silicone gives a better grip and probably traps more heat near the canister.

Thanks again, and mega congratulations to your son, of whom you are no doubt very proud, and quite justifiably so. Such young people are our hope for the future.

Mar 27, 2017 at 7:44 pm #3459882Thanks, David!

Mar 27, 2017 at 8:14 pm #3459892But what about Twinkies? They have a shelf life of at least 5 years, some say.

Better ask David: he is the expert at dealing with severely contaminated industrial waste.Cheers

PS: I think I tried one of those sorts of things once – just one. It was that awful I spat it out in disgust. But I forget what brand it was.Mar 28, 2017 at 6:37 am #3459947No offense, but I had a similar experience with Vegemite. ;^)

I’ve really, really tried to learn to appreciate that stuff but it has thus far repelled my efforts.

Mar 28, 2017 at 7:14 am #3459954Bob, I think the key is to spread the vegemite ON the Twinkies. Salty and sweet, a concoction savored by the gods themselves…

Mar 28, 2017 at 12:10 pm #3460021http://www.onlinemetals.com/merchant.cfm?pid=23101&step=4&showunits=inches&id=747&top_cat=60

I would guess shipping would be 15 bucks or so :(I may have a road sign in the garage (don’t ask don’t tell), but I’m stuck in Saudi for a couple of weeks.

A thought for a quick option: some round aluminum tube could be cut in half-ish lengthwise, then part of it could be partially flattened out to fit the canister OD and to allow the bend. Super soft pure aluminum sheet would be ideal though.

Has anyone tried to insulate the strip in-between the really hot part and the canister? It could also help to fold the middle section or the entire uper end of a flat strip in on itself to reduce its area for heat loss – similar to a rod with it’s ends hammered out.

It would be fun to play with this but I live in Houston.

Mar 28, 2017 at 12:14 pm #3460022Amazon prime (a bit thin, but maybe other thicknesses available)

1100 Aluminum Sheet, Unpolished (Mill) Finish, H14 Temper, Meets ASTM B209, 0.032″ Thickness, 12″ Width, 12″ Length https://www.amazon.com/dp/B00GJ9KPSS/ref=cm_sw_r_cp_apa_QEQ2yb1HX7TTK

Mar 28, 2017 at 12:16 pm #3460023Or maybe an old baking sheet?

Edit: now if we can multipurpose an aluminum spoon or potty trowel…

Mar 28, 2017 at 1:40 pm #3460049Stephen, thanks for your thoughts and ideas. After I posted my Q about a source of aluminum, it dawned on me: A $1.29 aluminum ruler from Walmart. The width and thickness is just about right to make at least one (maybe two) and you’d only need to cut it to length. Which you could do by rubbing it 142 times against a concrete curb in a pinch (or go to the hardware section and test drive a hacksaw). So on the AT, you could MYOG one very easily. Tougher, for sure, on the PCT.

Probably an alloy or heat treated to make it stiffer than pure aluminum, but Roger is going to chime in and tell me how to deal with that.

Right, Roger?

Mar 28, 2017 at 2:05 pm #3460061I’ve been thinking about the safety of this device. The idea is you want a feedback mechanism to replace the heat needed to evaporate the fuel in the canister. If you have too much feedback, you accumulate energy in the canister, which could lead to failure.

My concern always was that getting enough heat back into the canister at -15°F ambient would result in a device that feeds too much heat at 100°F ambient. I know this strip has been tested under a variety of conditions and shown to work (and not blow up the canister!). I initially assumed that meant the process was somewhat insensitive to the feedback heat rate. I.E. a run away condition at warm temperatures was happening slower than it takes to complete a boil. That would not be an inherently safe process but might work out in actual usage.

I had an epiphany last night I wanted to share, though perhaps many of the fine minds on this thread have already realized this. The required amount of feedback heat is only a function of the amount fuel evaporation rate (fuel flow rate) and is independent of ambient conditions. Furthermore, if you have that feedback heat rate you are keeping fuel at a set temperature (also independent of ambient conditions). On a warm day the feedback heat rate would keep the fuel at ambient conditions driving the heat transfer to ambient to zero. What that tells me is it is possible to design a Moulder Strip (c) that is inherently safe.

I still have some secondary concerns about changes in flowrate. A lower flowrate shouldn’t change the feedback heatrate much (should be based on flame temperature) but could significantly reduce the amount of needed feedback heat. If I get some time I will put together a model and see what kind of results it gives me.

David, to your question on malleability of aluminum. Yup I agree pure Al will be more malleable, but primarily your tent stakes are work hardened (extruded). You can release much of that internal stress by annealing it. though… a quick google search suggest you anneal aluminum at 750°F.. a bit higher than my oven goes :(

Mar 28, 2017 at 2:06 pm #3460062ruler – dual purpose – you could also use it as a ruler. It would show just how long the strip was so you could better describe it.

Mar 28, 2017 at 3:24 pm #3460083Hi David

but Roger is going to chime in and tell me how to deal with that.

Chuckle. An awful lot of hardened aluminium alloys can be softened by heat. You can use your stove for that. Pliers for holding help as well.It might be worth noting that the Easton 7075 aluminium alloy tent poles are hardened to an extreme T9 temper – which is almost completely ruined by heat over … try over 150 C I think. Even over 100 C might be a problem for them.

All that aside, I have found that most hardware stores carry sheet aluminium and strip aluminium these days. It is NOT hard stuff by any means, but it would be ideal for the sort of forming you want to do.

Cheers

-

AuthorPosts

- You must be logged in to reply to this topic.

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

Trail Days Online! 2025 is this week:

Thursday, February 27 through Saturday, March 1 - Registration is Free.

Our Community Posts are Moderated

Backpacking Light community posts are moderated and here to foster helpful and positive discussions about lightweight backpacking. Please be mindful of our values and boundaries and review our Community Guidelines prior to posting.

Get the Newsletter

Gear Research & Discovery Tools

- Browse our curated Gear Shop

- See the latest Gear Deals and Sales

- Our Recommendations

- Search for Gear on Sale with the Gear Finder

- Used Gear Swap

- Member Gear Reviews and BPL Gear Review Articles

- Browse by Gear Type or Brand.

For all the tests, I used a 30-40% full MSR 110-gram canister. A pretty good mix of fuel and presumably what you’d bring for camping in negative F temperatures. All the Moulder Strips (sticks, wires, etc) were secured to the canister with a velcro strap. The strap is 1.5″ wide, has loops on one side, hooks on the other and is sold to, say, cut to length and secure a length of garden hose or an extension cord in a neat bundle. Not the lightest option (there are far thinner velcro straps for instance), but it is pretty insulating and hence does double duty. 15 inches handles any canister and weighs 9 grams. Even with the high-performing CMS (Classic Moulder Strip), it didn’t melt, but a bit of carbon felt or just a scrap of paper over the strip would eliminate that possibility.

For all the tests, I used a 30-40% full MSR 110-gram canister. A pretty good mix of fuel and presumably what you’d bring for camping in negative F temperatures. All the Moulder Strips (sticks, wires, etc) were secured to the canister with a velcro strap. The strap is 1.5″ wide, has loops on one side, hooks on the other and is sold to, say, cut to length and secure a length of garden hose or an extension cord in a neat bundle. Not the lightest option (there are far thinner velcro straps for instance), but it is pretty insulating and hence does double duty. 15 inches handles any canister and weighs 9 grams. Even with the high-performing CMS (Classic Moulder Strip), it didn’t melt, but a bit of carbon felt or just a scrap of paper over the strip would eliminate that possibility.