Topic

Synthetic quilt design

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

Home › Forums › Gear Forums › Make Your Own Gear › Synthetic quilt design

- This topic has 9 replies, 7 voices, and was last updated 7 years, 11 months ago by

Jerry Adams.

Jerry Adams.

-

AuthorPosts

-

Jan 1, 2016 at 4:09 am #3373482

So I’m designing a quilt for use in the UK and thought I’d post my design process for some critiquing.

I’m going with synthetic for a few reasons:

- The weather here is generally wet.

- Ease of construction

- Cost. By my estimation I can make the entire quilt for less than the cost of 250g of 860fp down, which wouldn’t be enough anyway.

I would like to use the quilt for as much of the year as possible, so I’m aiming for 0 to -5 Celsius (32F to 22F). I think that 200g/m^2 (6oz/yd^2) Climashield APEX should be sufficient for this.

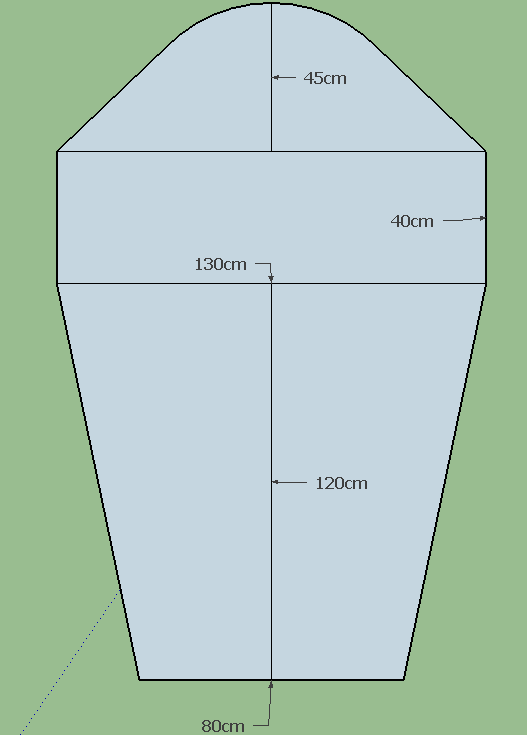

My basic pattern is shown below. It is mostly influenced by the article by Roger Caffin on quilts

http://backpackinglight.com/myog_down_quilt_bag/

and by the As Tucas quilt, as I would like to pull it over my head and these both have ‘hoods’. There would be a sewn-in footbox and for reference I’m 173cm tall, 67kg.

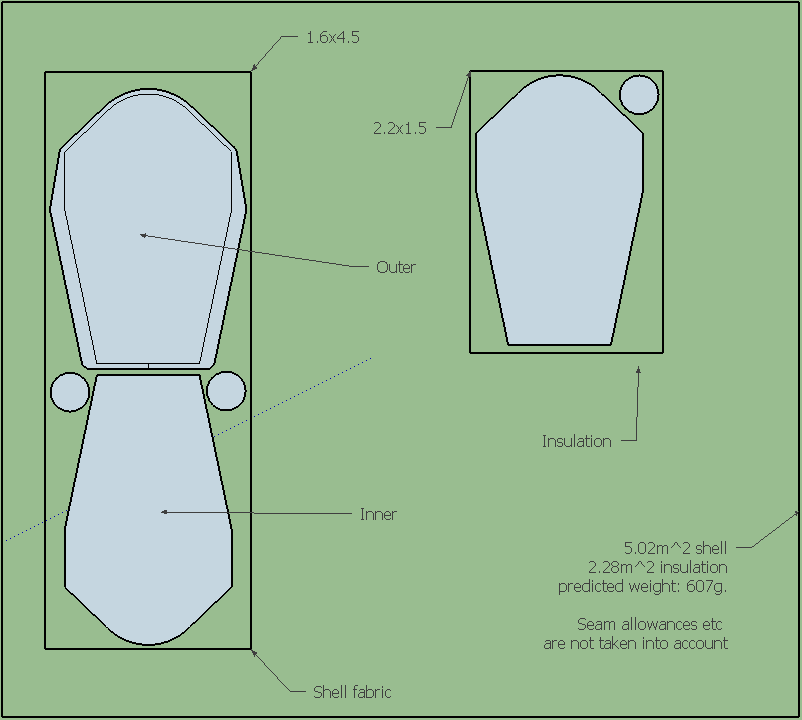

For a shell I would use some 30g/m^2 nylon. (Both inside and outside)

http://www.extremtextil.de/catalog/Ripstop-parachute-nylon-100-nylon-30g-sqm::1970.html

I have a few questions as well.

Will this fabric be sufficient?

Will I need a differential cut? I’ll have ~3.8cm (1.5″) of insulation so that would need an extra 25cm fabric on the top layer, I think.

Any comments would be appreciated.

Ben

Jan 1, 2016 at 6:34 am #3373484Hi Ben.

I made a climashield quilt 6 years ago. I also made it to my own design. I have a couple of thoughts re your plan.

The fabric looks fine for the inside, I think I would prefer something with a DWR for the outer. Like this:http://www.extremtextil.de/catalog/Ripstop-Nylon-PTX-Quantum-downproof-35g-qm::1567.html

I’m not sure about the lower edge width? Seems pretty small to me. Even if you have an end panel (which is not mentioned?) 80cm is a small girth e.g. that makes only a square 20cm x 20cm (8″x8″). As Tucas regular quilt uses girth of a 100cm with an end panel. Having size 12 feet, mine is even bigger.

I’m not sure what you mean by differential cut and am confused as to what your 25cm figure is describing.

I made inner and outer all the same dimensions and it turned out fine.

Hope this helps.

(UK based too)

Jan 1, 2016 at 7:12 am #3373485Too want synthetic quilt. Don’t know, buy EE Prodigy 30F, or make my own.

Also in the dutchwaregear.com sale price for 6.0 oz Climashield = $14.00

Jan 1, 2016 at 7:14 am #3373486For a down bag, a differential cut makes sense. For a synthetic quilt, it’s not quite as important. If you pull the quilt tight, it will compress the insulation anyway, just a bit less with a differential cut. The quilt needs to be cut large enough for the way that you sleep, with extra around the edges to keep out drafts (maybe draughts in the UK). With a synthetic quilt, especially with Climashield, it is not that difficult to make a large quilt smaller, but it is difficult to make a small one larger. SInce most fabric and Climashield in the US is 60″ (152cm) wide, I have used that for the width of my quilts. My current length is 84″ (213cm). I taper the bottom 40″ (100cm) to a 45″ (114cm) width and use a draw string to form the foot box. I sew a couple of ties in the middle and end of the taper and sew union or omni tape along the taper to hold it closed. I don’t think that it would be a bad idea to cut the outer fabric a bit larger than the inner fabric, but I haven’t bothered. I’ve made two quilts with Climashield 5.0 and have been quite happy with them. They don’t pack down very well, but they are very comfortable. I can’t say how cold they will go, because I haven’t gotten there, yet.

Jan 1, 2016 at 11:29 am #3373510I would use the lightest fabric you can get your hands on, without regard to water or wind resistance. You can get some stuff in the .7 oz/yd range, which would be about 24 gms/sq. m.

Differential cut is pretty easy with a synthetic – make the lining the same size as the insulation, quilt the insulation to the lining only, and make the shell larger. You’ll have to do a few tucks here and there as you join them together but that’s about it. If you use more than one layer of insulation, then quilt one to the outer and one to the inner; thus you’d have one piece of insulation matching the size of the inner and one matching the size of the outer. I would not make the differential cut as large as theory says; If you investigate you will find that no sleeping bag manufacturer does that. Maybe half of the theoretical amount.

But her’s the real key with differential cut: it really only matters for that part of your quilt that is sewn together into a bag – for most folks that’s the foot section, coming up some fraction of the way to the knees or hips, as you prefer. Only there does the effect of a smaller lining avoiding compressed insulation really come into play. And, less important than the actual differential is having the outer large enough to allow full lofting of the insulation. Mostly this isn’t an issue unless you are planning a pretty trim cut, but it’s worth keeping in mind if you are.

Also, as to size, I’d try to confirm that the size works well for you by trying out a similar quilt or making some kind of mockup. Tastes vary in these things, and someone else’s idea of the perficet quilt may not be yours.

Jan 2, 2016 at 10:24 am #3373605Well thanks for your feedback guys.

Yes, there will be a circular end-piece to the foot-box. I have tried a mock-up from a quilt (a traditional bed quilt) and I think this footbox will be roomy enough, I belly sleep and tend to point my feet. I have added 5cm to the length, as it was only just long enough to get tucked over my head.

On the fabric front, I would love to use lighter fabric but the only place I can see to get it is ripstopbythroll and because of shipping that would add about 50% to the cost, not worth it for the 30g saving it would give. The same issue means that I can’t really get Climashield from the US, dutchwaregear don’t even ship it internationally. Thanks for the suggestions though.

I’ve refined the design a little to give about 50% of the theoretical diff cut for most of the bottom of the bag and added some side pieces. These are actually just part of the outer but they are meant to cover the sides of the insulation.

Jan 2, 2016 at 10:25 am #3373606

Jan 2, 2016 at 10:25 am #3373606By 50% to the cost I meant to the cost of the entire quilt (about £25 extra in £55).

Jan 2, 2016 at 10:18 pm #3373705Also you can use primaloft gold 6.0 oz (Loft=2.8 cm)

May 2, 2016 at 10:09 pm #3399407How much quilting is required with the Primaloft Gold? Can you use it without the scrim?

May 3, 2016 at 8:19 am #3399483They say it’s 0.92 clo/oz/yd2 and 6 inches quilting

I would take that to mean you need a square grid that’s 6 inches square

That’s like the old Primaloft One – they must have rebranded that

Apex is 0.82 clo/oz/yd2 but requires no quilting (except around perimeter). It weighs a little more, but it’s easier to make. The 6 inch quilting would reduce the warmth a little.

The Gold may not last as long.

6 oz/yd2 is very heavy and bulky in the pack. I had a 5 oz/yd2 quilt, but switched to down.

-

AuthorPosts

- You must be logged in to reply to this topic.

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

Our Community Posts are Moderated

Backpacking Light community posts are moderated and here to foster helpful and positive discussions about lightweight backpacking. Please be mindful of our values and boundaries and review our Community Guidelines prior to posting.

Get the Newsletter

Gear Research & Discovery Tools

- Browse our curated Gear Shop

- See the latest Gear Deals and Sales

- Our Recommendations

- Search for Gear on Sale with the Gear Finder

- Used Gear Swap

- Member Gear Reviews and BPL Gear Review Articles

- Browse by Gear Type or Brand.