Topic

Poor man's Cuben or "Polycryo" on Roids? Proof of concept model

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

Home › Forums › Gear Forums › Make Your Own Gear › Poor man's Cuben or "Polycryo" on Roids? Proof of concept model

- This topic has 31 replies, 8 voices, and was last updated 4 years, 8 months ago by

Craig B.

Craig B.

-

AuthorPosts

-

May 19, 2019 at 3:26 am #3593614

Anonymous

InactiveX marks the spot (non editable post).

May 19, 2019 at 4:05 am #3593622Anonymous

InactiveThis was a quick, fun project, and unlike usually, I didn’t spend any extra money, but just used left over materials I already had.

Cross linked Polyolefin plastic film, or as often called here “polycryo” has several advantageous qualities. It has good abrasion and puncture resistance, it’s lightweight, highly waterproof, it’s clear/see through, and it’s inexpensive. It however also has some significant drawbacks. The chief and most significant being a rather low tensile strength. Moderate issues are that very little sticks to it (adheisve wise), having a low surface energy and it’s UV resistance isn’t the best. Some people might not appreciate it’s see through quality, but most of us Star gazers would.

In some ways, it’s like the opposite of DCF material.

I wondered, could one dramatically improve the tensile strengths of polycryo, so that one could create a light weight, see through, fairly inexpensive tarp that you wouldn’t have to baby and worry about strong winds or the like?

The below is my solution after thinking about what I already had on hand. The below is a model, scaled down sized version. In the future when I have more time, I may make a 7’x10′ tarp version to combine with a bivy, since I’m shorter than average. You can buy window weather treatment film that comes that size and only weighs approximately 4 oz. As you will see, you will need two.

Materials used/needed:

1. Lightly used “polycryo” film. If making a full sized tarp to actually use in the field, I would recommend only using brand new material.

2. Spectra/Dyneema/highly oriented UHMWPE based fishing line. I used 80lb test Spectra fishing line, because that is what I had on hand. It is probably over kill, and one could easily get away with using 50lb or even less. But the less lb test rating, the thinner the line and the harder it will be to work with, and to secure with sewing/thread later. Edit to add: Do not use Fluorocarbon coated fishing line. Too slick.

3. Low temperature hot glue gun/hot glue sticks. Do not use a high temp gun for this project. You will damage/weaken both the Polycryo material and likely also the UHMWPE based fishing line. Even with using the low temp gun, I would drip out a little and let it hang from the gun nozzle a bit, before applying to the materials. I was also careful to keep the gun’s nozzle from directly touching either material.

4. Some common, cheap, clear dispenser tape. This is to hold down and taut the polycryo while hot gluing the highly oriented UHMWPE fishing line to the polycryo.

5. Some high strength, low stretch fabric. I used strips of (aluminized) DCF, because I had scrap pieces left over. If I make a full sized tarp, I will likely use 1.6 oz/yd2 silpoly from RipStopByTheRoll for these “border pieces”. DCF would be more ideal, but unless my financial situation changes, it costs too much for me at this time. I would still need to order at least 3.5 yds, to get the necessary length of strips for this project. 1.6 oz/yd2 Silpoly should work fine. I would not use silnylon, nor 1.1 or lighter silpoly. The former has too much stretch for this application and the latter isn’t strong enough and also will have slightly too much stretch. Since we’re using such small amounts of this material and just for a border, it’s ok if it weighs a little more.

6. A sewing machine/thread. If using DCF material as the reinforcing/structuring border, I might actually use regular size and strength thread and use a wider stitch setting on two of 3 rows (1 row of more close together stitching), and do a few separated rows, rather than one or two rows of larger/higher strength thread. The smaller the holes, the better. I would also tape over it with DCF based tape after.

In the next post, process will be discussed, some pictures shared, along with outlining of future testing. Stay creatively thirsty and think holistically my friends.

May 19, 2019 at 4:38 am #3593624Anonymous

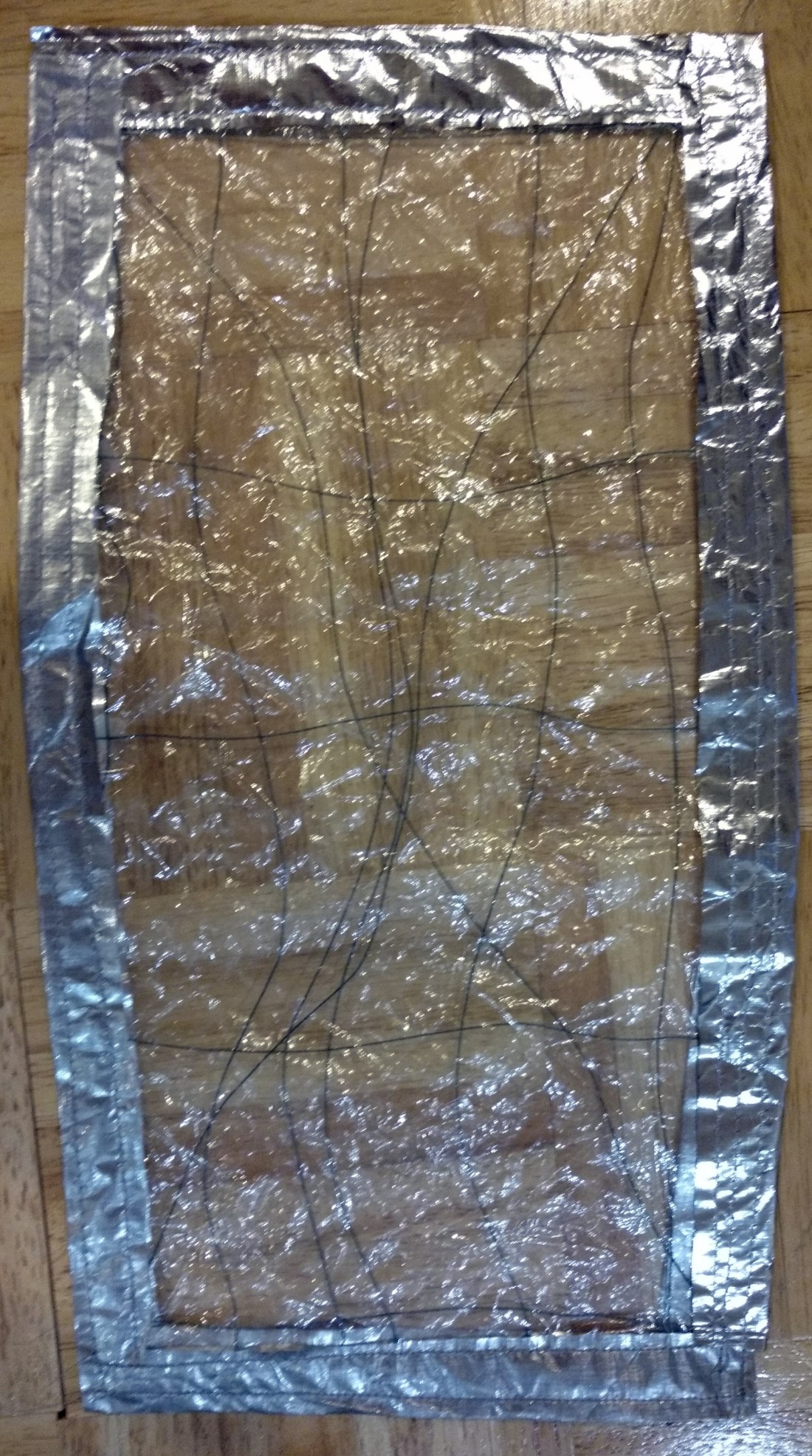

InactiveProcess and pics:

I cut out a rectangular piece of polycryo material, and cut a matching piece. Took one of the pieces, and taped each corner to a wooden floor, trying to make it evenly taut. I then cut a number of pieces of fishing line, some the length of the polycryo piece, some the same width length, and two pieces the length of the diagonal cross section (to make an X).

I started with the long, length section first. I hot glued one end of the Spectra fishing line to the top middle, then stretched it out straight to glue the other opposite end. Did the same with the far right and left sides, and then about half way in between these sections.

Did similar width wise, and then the two diagonal pieces. I tried to make the Spectra lines as straight and taught as I could. To be honest, I probably didn’t need as much as I used for such a small area. The length of the mini model tarp is a little over a foot and slightly under a foot in width.

Here is the finished part of this process, without the other layer of polycryo added on top:

Note, I trimmed the excess length of Spectra fishing line off afterwards.

I then carefully added the 2nd layer of polycryo onto the top of the above, by hot gluing the corners down one at a time (small amounts each time, and while still warm, I pressed flat with my finger–usually didn’t hurt. For the above, earlier part of process as well). I also glued the half way sections of the length and width of the two polycryo pieces.

I then carefully lifted the taped corners up and removed same.

Next, I cut strips of DCF. I wanted them wide enough so that I could easily fold them over halfways, and have enough space to sew 3 rows of thread through. These strips were about 2″ in width before folding. I used a clothes iron on a very low setting to have it fold over and stay well creased and closed. If doing similar, make sure it’s a very low setting, as once you reach about 200*F and above temps, you start weakening the UHMWPE fibers within the mylar sandwich, especially with any prolonged contact. Brief run overs near those temps will not do much though.

Then I lined up the strips to the edges of the polycryo-Spectra fishing line composite/sandwich material, and sewed 3 rows for each border side. Using a wider stitch for 2 rows, and a closer stitch for 1.

Between all the handling, and trying to stretch out the composite material with my hands, the Spectra strips did get looser and less taught, when it was all relaxed. However, putting any stress of pulling on any part of the composite, immediately made the inner lines taught and prevented the polycryo from stretching. The sewing job wasn’t the best, because this was a quick, dirty project just to get a proof of concept model. If actually making a tarp to use in the field, I would go slower and be more careful with that part.

Next post will discuss further testing and some odds and ends notes.

May 19, 2019 at 5:15 am #3593628Anonymous

InactiveIn the near future, I will sew attach some “guy tie outs”. In my backyard, there was a screw hammock hook installed into a tree before we moved in. I’m going to hang this mini tarp from that, and to the bottom part of the tarp, attach a number of weights to see how much it can hold, vertically, horizontally, and diagonally. I only have about 70lbs worth of weight to hang off it though. However, that seems sufficient. I will take pictures of this testing (or maybe video). (Actually, it might be easier to just hang a 5 gallon bucket of water with a couple weights in same, from it).

I know a regular polycryo tarp, as different members have posted here over the years, wouldn’t be able to take near that kind of weight before the polycryo material catastrophically failed by ripping apart.

In this application, the polycryo is only really providing the waterproofness of the main structure, and some puncture resistance to anything that might fall on top. The combination of Spectra fishing line, and high strength-low stretch border material is providing the huge majority of tensile strengths.

I expect a 7’X10′ tarp to weigh somewhere in the range of 12 to 15 or so oz total. If using such a tarp in the field, I might consider finding some kind of clear, UV spray type coating that I could put on it, to increase it’s UV resistance for long term use. Especially for desert or high mountain use. If in a rainy and forestry setting, probably not that necessary, and it would likely wash off in any even moderate rain.

The nice thing about such a tarp, beside the see through nature and super high waterproofness of same, is that it will be more insulative than any other kind of tarp material, since there are two layers of WP material, with a definite but small air gap. Should minimize condensation some.

In the winter, you could sew some velcro tabs to the corners of the bottom, and velcro a corresponding HeetSheet or the like to the bottom (make sure it’s slightly loose, so there is a bit of gap between the tarp material and the IR reflective material), and if using a larger tarp, and closing it up more, you could have a fairly warm set up at fairy low weight, especially if you bring a small beeswax candle or two to combine with one’s body heat. I would not use anything hotter, as polycryo material does not like heat and will shrink up once exposed to 150*F+ temps. I would not try cooking under it if you can, and if you must cooker under it, raise it up higher and put it where there is the most distance between the flame and tarp bottom.

If you happen to get punctures or tears in the material, Tyvek tape will be your best bet at patching same, as Tyvek tape is designed to stick to, well, Tyvek, which is a low surface energy polyethylene material. “Polycryo” is a cross linked blend of polyethylene and polypropylene if I remember correctly (and cross-linked through irradiation). It will not stick as well to polycryo as to Tyvek, because Tyvek has a somewhat semi fibrous structure, which helps in that regard as far as adhesion, but as long as you’re not pulling at it or the like, it should stay on for quite awhile. DCF tape would be pointless to use, unless that’s all you have on hand at the time.

Next post, potential alternatives, but using similar, core concept.

May 19, 2019 at 5:34 am #3593630Anonymous

InactiveIf you want a more overall robust material, and don’t want or need a semi-see through material nor a super high waterproofness, you could tweak the concept and apply it to this: Use just a single layer of 7D silnylon, and using silicone, attach the Spectra or Dyneema fishing line to it and once cured, use strips of some high strength/low stretch material to sew on the borders.

This will definitely take longer and be much more expensive. It will take longer, because you’ll have to let each end of the fishing line’s “adhesive” (the silicone) cure before doing the opposite ends. So just attaching the fishing line will take at least two days in time in and of itself. You will also have needed to sew two separate pieces together to make a large enough tarp.

Note: neither the hot glue nor the silicone is meant to be a true adhesive, long term bond, just meant to temporarily hold the fishing line in place while you sew the border materials on. I would not use tape, because you won’t be able to take it off before sewing, and if you sew through it, it will gum up your sewing machine some.

You could also of course use a lightweight, single layer silpoly as the waterproof part of the composite, instead of the silnylon or polycryo, but again, you must have a higher strength, low stretch border material such as DCF or at the very least, 1.6 oz/yd2 Silpoly.

May 21, 2019 at 3:35 am #3593909Anonymous

InactiveA thought occurred to me to increase strength while decreasing cost. Rather than use DCF for the entire border/perimeter section, you could use just little, individual strips of DCF to secure each end of the Spectra fishing line, and then use 1.6 oz/yd2 Silpoly for the overlaying border.

That way, one could use only 1/2 yd of DCF material, and get stronger anchoring of the Spectra lines, but without having to buy 3.5 to 4 yds of DCF.

Downside is that it would add some extra time to such a project. For example, say making a large square tarp, say 11’X11′, and say 11 Spectra/Dyneema line ends for each side (one spaced every foot apart), and 4 ends from two diagonal lines, that’s 48 individual ends, and assume a little over a minute of sewing for each (a box with an X in same would probably secure the best, but might not be necessary), that’s about an extra hour.

May 21, 2019 at 12:57 pm #3593929That looks like a bit of work, good experiment : )

How much does that weigh compared to Cuben, or compared to something like the silpoly that weighs 0.93 oz/yd2

May 21, 2019 at 2:11 pm #3593937Anonymous

InactiveIf online specs are to be believed, then one 7’X10′ “polycryo” film sheet weighs 4 oz. In this application, we are using 2, so 8 oz for that size, plus say a 3″ or so (folded in half) border of 1.6 oz/yd2 Silpoly plus little strips of DCF (I would use the 1.43 or 2.92 oz/yd2 stuff personally), and plus some 80lb test Spectra or Dyneema fishing line.

Just roughly guestimmating (no specific math involved beyond the prior), I would expect a finished tarp of that size to weigh between 12 to 15 oz or so.

But it will also be see through, more waterproof, and more insulative than any other kind of UL tarp. And less expensive, unless you use regular, inexpensive 1.1 oz/yd2 Silnylon. Currently on Amazon, you can get a two pack of the 7’X10′ sized polycryo film sheets for about 14 dollars. A half yard of 1.43 DCF is 17.50, and 4 yds of 1.6 oz/yd2 Silpoly is 23. I don’t remember specifically how much I paid for the Spectra fishing line, as I bought it awhile back, but it was around 20 dollars for 200 meters for a Japanese made product. So for actual cost of material used, we’re talking less than 5 dollars (or you can get highly oriented UHMWPE based, 80lb test fishing line from China for about 3 dollar total for 100 meters). Then whatever odds and ends that you would normally need for any tarp.

So it would cost around 60 dollars total, not including shipping and guy/tie out material (however, if you’re thrifty like me, you would combine left over DCF [core, tensile strength] with Silpoly [outer, abrasion resistance] for the guy outs. That way, you could also make it extra wide to a taper, sort of a double/folded over connected triangle).

It would be a lot of work if making a tent out of this composite, but not so much a flat tarp, especially if you just go with the pre sized dimension stuff like the 7’X10′. I would expect it to be a weekend project for a practiced DIY’er. Most of the work/time will be sewing the small DCF strips to the individual highly oriented UHMWPE line ends (for that, you might be able to get away with just doing an X over the line, then the rest will be secured when you sew the 1.6 Silpoly border on). In a 7’X10′ tarp, you would have 42 ends. 1 per foot (38), then the 4 ends from the 2 diagonal lines.

May 21, 2019 at 2:38 pm #3593945Anonymous

InactiveHypothetically speaking, one could use just one layer of the polycryo film for less weight and cost, but I’m not sure I would do that personallly. 4 oz extra is not much for some peace of mind. A falling branch would likely tear/rip/puncture the film on the top, but much less likely go through the top, the Spectra lines below, and then also through the film below the Spectra lines. Something also tells me that two layers of film, partially hot glued together, will stay within the sewed border matrix much better than one layer.

If using 7D Silnylon or Membrane Silpoly, one layer would be fine. You could get a very low stretch, very robust tarp out of using this composite concept application. And the Membrane Silpoly is already pretty reasonably priced, so it wouldn’t be too expensive.

My spouse is going on a month long solo trip this summer, and I will probably make her a 11.5’X11.5′ square tarp out of a Membrane Silpoly-composite, so that if it gets cold or very rainy, she can do the old, hiking pole in the middle, triangular “pyramid tarp-tent like” configuration, but also have an open tarp when it’s hot and fair’ish weather.

May 27, 2019 at 8:08 pm #3594980Anonymous

InactiveEither today, or most likely tomorrow, I will put some pics up of weight testing.

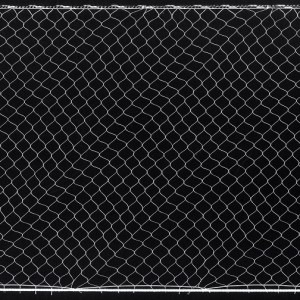

May 28, 2019 at 1:04 am #3595038This type of fish sein netting could be sandwiched between the polycro for added strength:

https://duluthfishnets.com/store/gill-nets/50-long-x-6-deep-mono-gill-net/

$29.00 for a net 6′ deep x 50′ long (monofiliment)

May 28, 2019 at 1:25 am #3595043

May 28, 2019 at 1:25 am #3595043Anonymous

InactiveWould be easier/more convenient to use, but most likely heavier since it’s nylon and since there is more material involved.

May 28, 2019 at 1:41 am #3595046We can make sacrifices for more strength :-) Stretch the netting out to the max for lighter weight.

It’s all about experimenting. There are seins available with larger opening for less thread per foot.

I gave you a link to the least expensive :-)

May 28, 2019 at 2:04 am #3595047Anonymous

Inactive“We can make sacrifices for more strength :-)”

Definitely, and that’s what I would call all that extra sewing that I would prefer not to do… ; )

But folks with a bit more money than myself but not enough for a full DCF tarp (which would require almost twice the DCF amount of the latter), can buy 3 to 4 yds of DCF and use strips for the border and not have to do all that extra sewing, without completely breaking the bank. Good news is that if doing a 7’X10′ tarp, you would have enough DCF left over to do another tarp of the same size, if you wanted or needed to for some reason.

But I had to live up to the “Poor man’s” part of the title as well…

Anyways, for this purpose, we don’t want a material that will stretch noticeably, as that could potentially allow the polycryo to rip or tear. That’s why highly oriented UHMWPE fishing line + DCF borders, or U.F.L.+ DCF strips + 1.6 oz/yd Silpoly borders would work so well in combo for this application. Very little stretch potential, which keeps the polycryo stable within the strengthening matrix.

May 28, 2019 at 2:30 am #3595052You are doing very well. We appreciate your ideas. Thank you.

May 28, 2019 at 2:34 am #3595055Anonymous

InactiveYour welcome, and thank you for the kind and encouraging words.

Definitely needs to be tested though.

May 29, 2019 at 1:42 am #3595208Anonymous

InactiveDidn’t have enough time to test yesterday or today. Will have enough time tomorrow.

May 29, 2019 at 7:40 am #3595243When I was doing my own “poor man’s Cuben” experiments, I used a single layer of Polycro and one inch wide reinforced tape (as used in packaging). I ran it around the perimeter to prevent tears starting from the edged. Then ran tape from from all pull-outs to the edge so that forces in the material get carried trough the filaments in the tape rather than through the body of the material.

Worked quite well and used a minimum amount of material added to the single layer of Polycro. And much easier to build than gluing two layers together.

Something to consider

May 29, 2019 at 2:26 pm #3595263Anonymous

InactiveHi George, yes, have also done similar in the past myself. The main issue for the tape method for me is using such tarps at more extreme temps–especially extreme cold. A lot of tapes lose a lot of adhesive strength at lower temps. Just do not want to rely on tape alone, especially if there will be any snow loading and/or strong winds. My favorite times to go out are during the rare “polar vortex’s”, because usually, there are very, very, very few people out during these.

Also, what I like about this particular concept is that it can be applied to other UL but semi fragile materials like Membrane Silpoly that would be harder to tape. In the case of Membrane Silpoly, you can use just one layer with this method.

And, unlike tape, this method will not just moderately improve tensile and shear strengths, but radically improve same.

I imagine that you could probably cut down the amount of fishing line used, and if one used thin highly oriented UHMWPE based cord instead (like Zing It), you probably use use as little as 3 or 5 per length and 3 or 5 per width, and two diagonal. Basically, if you have one line of cord or fishing line end per guy tie out, you should be ok. These lines in combo with the border material, will take almost all the shearing and pulling forces.

Once everything is attached via a little silicone and some sewing, theoretically, you could also take some fishing line and do some quick netting/tying between the main support lines so that you put cord/line side up, and you also have much more protection from falling branches or the like.

I’m going to also make a Membrane Silpoly prototype tarp and torture test it against one without any similar reinforcing.

I’m waiting on some 1.6 oz/yd2 Silpoly material to arrive.

Anyways, the advantage of sewing is permanency (of the life of the fabric) and able to be used at extreme temps without loss of strength. Would suggest taping if one doesn’t have a sewing machine, if they use their tarps during more moderate temps, and/or only want to apply this concept to polycryo.

May 29, 2019 at 6:41 pm #35953072″ x 180 shrink film tape and a variety of shrink related products. https://mrshrinkwrap.com/roll-of-2-x-180-shrink-film-tape-msw-702.html?___store=default&refSrc=862&nosto=nosto-page-product1

Check out the emergency tent/tarp lay flat pallet shrink bags:

https://mrshrinkwrap.com/100-x-70-shrink-bag.html

May 29, 2019 at 11:14 pm #3595336

May 29, 2019 at 11:14 pm #3595336Anonymous

InactiveGot home from work, whilst a thunderstorm is starting, no go.

Thanks Dan, will check it out.

May 30, 2019 at 2:57 pm #3595429Anonymous

InactiveAlong Dan’s line of thinking, there is the below stuff which weighs .67 oz/yd2. As it’s a Aramid, Kevlar type fiber, there will be no stretch. Unfortunately it only comes 33″ wide, so I’m not sure how much easier and more convenient it would be than just using one line of UHMWPE cord or fishing line per guy out of a tarp.

http://shop.fiberglasssupply.com/Carbon_and_Kevlar_Fabric-Vector_Net_XPTR_226_1_Spacing.html

May 31, 2019 at 1:34 am #3595522Anonymous

InactiveBloody heck, if it’s not one thing, it’s another.

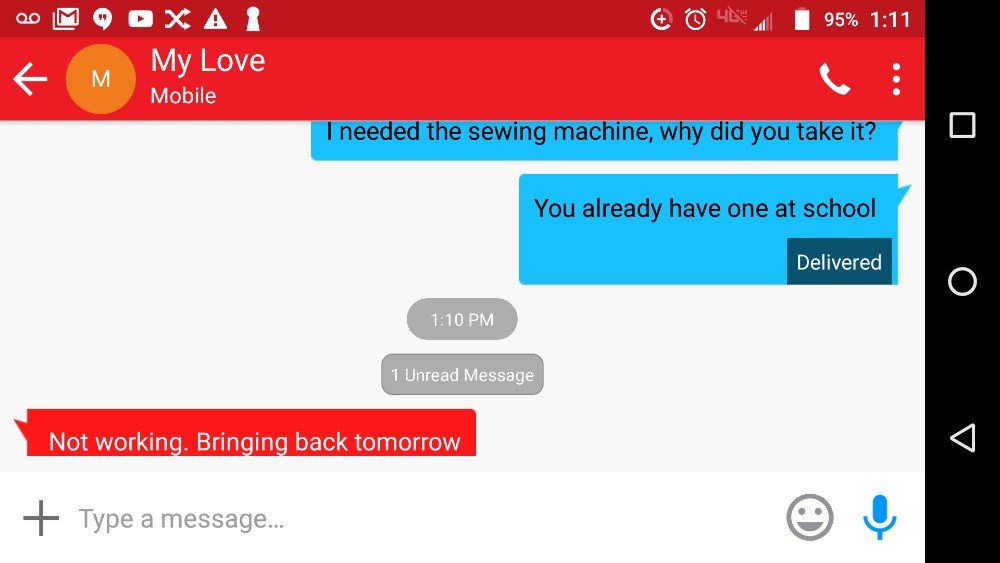

Woke up this morning and was going to sew some guy outs onto the mini-tarp so I could commence on testing it today.

Did a double take, where’s the bloody sewing machine…???!

My spouse is an art teacher, so I texted her during one of her breaks:

Looks like I won’t be testing until Saturday now. However, I wasn’t completely idle, and did some other testing, which I will talk about on another thread.

Jun 1, 2019 at 11:38 pm #3595815Anonymous

InactiveAs you will see, this particular prototype failed pretty badly since it catastrophically failed at 30 lbs (the below bucket is a 5 gallon, filled about 4/5 full):

While examining it afterwards, none of the Spectra lines broke, but one end of the stressed support line had come loose from the sewed sandwich it was being held in. It is crucial to make sure each end of each line is firmly and completely secured. That is why it failed.

80lb test Spectra fishing line is fairly thin stuff. I’m thinking to remedy this, I should move up to thin cord rather than fishing line, and make sure I concentrate the sewing more on the line, rather than just sewing over it a few times in a straight line.

Next I will be testing Membrane Silpoly both with border+cord reinforcement and without any reinforcement to see how they compare. This time, using thin cord rather than much thinner fishing line, and making sure each end is very well secured before testing. I also will be using less cord. There will be only one per the middle guy outs (width wise), the 2 diagonal and the 1 middle lengthwise. So only 8 individual ends to secure all in all.

Jun 2, 2019 at 7:11 am #3595863Anonymous

InactiveShould mention that with the Silpoly reinforcement, there will be other differences and changes as compared to the Polycro. With the latter, it was initially secured with some hot glue. I won’t be able to use hot glue with Membran Silpoly.

Besides moving up to thicker cord, vs fishing line, I have also decided to use black kevlar cord rather than low surface energy, slippery UHMWPE cord. Kevlar has a similar surface energy to nylon, somewhat low, but definitely more bondable than Spectra etc.

The black Kevlar cord will initially be stabilized/fastened to the Membrane Silpoly via strips (say 2″x4″ or so) of 1.6 oz/yd2 Silpoly and silicone adhesive. Both the bottom of the cord and the layer of covering fabric will be treated with adhesive silicone.

After fully cured, then strips of DCF will be (more) carefully sewn over the ends of the cord, and then the border of 1.6 oz/yd2 Silpoly. Oh, and the Kevlar cord will be knotted at the ends, to be thicker, so if it does happen to start to slide out of it’s sandwiching sleeves, the knotted end will hopefully get caught before it moves appreciably.

Ordered some black kevlar cord. More testing will commence soon. Btw, for weight references, 100 ft of 300lb, 1.3mm diameter Kevlar cord weighs 1.29 oz. In a full tarp, say a 10’x10′ or 10’x11′, there will be about 44 to 48 or so feet total used. So the cord by itself will add about .63 oz. But by the time that you add a little silicone, some strips and border of 1.6 oz/yd2 fabric and some DCF strips to the 8 points, it will add another couple to few ounces.

-

AuthorPosts

- You must be logged in to reply to this topic.

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

Our Community Posts are Moderated

Backpacking Light community posts are moderated and here to foster helpful and positive discussions about lightweight backpacking. Please be mindful of our values and boundaries and review our Community Guidelines prior to posting.

Get the Newsletter

Gear Research & Discovery Tools

- Browse our curated Gear Shop

- See the latest Gear Deals and Sales

- Our Recommendations

- Search for Gear on Sale with the Gear Finder

- Used Gear Swap

- Member Gear Reviews and BPL Gear Review Articles

- Browse by Gear Type or Brand.