Topic

New HMG Dirigo 2

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

Home › Forums › Gear Forums › Gear (General) › New HMG Dirigo 2

- This topic has 176 replies, 44 voices, and was last updated 5 years, 5 months ago by

Sam Farrington.

Sam Farrington.

-

AuthorPosts

-

Sep 7, 2019 at 9:27 am #3609298

Long time ago I did some testing with a home-made Suter Tester of various fabrics for various people for Hydrostatic Head. I am not sure what happened to all the results. I think at least some of them were either posted or returned to owner.

Anyhow, I am in the process of rebuilding my Suter Tester into a far more solid and reproducible form with digital output. I am waiting on the last bits from eBay for this: some little ball valves.

If I get the time and energy, I will supplement this with a tensile tester, doing what is known in the trade as a tongue test. This is very common. The problem is that there are only 24 hours in a day!

Sam: if you have a good camera with zoom capability (not a phone), then you may not need a microscope. Make a primitive lightbox and mount the camera as close to the top as it will focus. The digital images should ‘show all’, and you will have a record as well. (Document!)

Cheers

Sep 7, 2019 at 11:06 am #3609299Seeing that the thread has drifted over the horizon we may as well continue…

In practical terms, here’s the choice of fabrics I’ve spotted for a truly storm-worthy 3.5 season lightweight shelter:

- RSBTR 20d Silpoly PU4000 @ 20d/1.4oz finished/4000mm hh

- RSBTR 30d Mountain Silnylon 6.6 @ 30d/1.4oz finished/>3000mm hh

- Thru-Hiker 30d? Shield 6.6 Silnylon @ 1.4oz finished />1000mm hh

- Extremtextil 30d Silnylon 6.6 @ 1.2oz finished / 2000mm hh

- A wide choice of 30d 1.1oz nylon 6 ripstop @ c1.4 oz finished, varied hh.

If there’s anything else out there, I’d appreciate a heads up.

Richard’s aged hh figures for the non-PU 20d silpoly weren’t confidence inspiring, so the PU4000 seems the only practical lightweight silpoly on the market for long-term usage – very waterproof, but questionable strength.

Let’s reject nylon 6 as 6.6 is a much superior fabric unless price is your only consideration. Personally I’m OK with trusting the vendors that it’s genuine 6.6, and you can easily check that the stretch when wet is within parameters to confirm.

The Extremtextil 6.6 is not the 20d with the controversial weave – it’s new. Seems to have a lighter coating than the RSBTR 6.6 but a lower hh, which figures. The Thru-Hiker 6.6 has a marginal hh. For long-term use, the more generously coated MTN 6.6 looks like the best bet.

So the final shortlist is the Silpoly PU4000 vs the MTN 6.6 silnylon. Which to choose?

First, it’s worth noting that Hilleberg classify their high quality 20d 6.6 silnylon as Yellow Label, for clement conditions. Which immediately sets bells ringing for a weaker 20d silpoly. No-one is using anything in 20d for foul-weather shelters that I can see.

You can see that the PU coating on a 20d silpoly takes the weight up to match the 30d silnylon 6.6. They both have hh to spare. Finished weight for weight, the 6.6 is going to be very much stronger, as it’s a stronger material at a higher denier. Yes, it will have a bit more stretch and water absorption, but not nearly as bad as a nylon 6. which is what most people are used to.

We know for sure that a good 30d silnlyon can take severe weather in a small shelter – the Akto and the Warmlite, for example, have an extensive track-record for surviving challenging conditions.

But as I’ve posted above, vendors are much more wary about silpoly,. They either use a much higher denier like Nordisk, or they don’t recommend exposed use like Yama and TrekkerTent, or they simply don’t offer it at all – on his Fabric Mojo page Ron Bell says he doesn’t feel it’s suitable. It may be OK with the right construction, but there’s no firm proof as yet from a widely used shelter and I don’t want to be the one who finds out on a nasty night many days walk from safety.

Given that there’s no weight penalty for the 30d silnylon vs the 20d silpoly PU, my instinct is to accept the slightly greater stretch and sleep more securely when the elements go crazy.

On the balance of benefits, I’d tend to agree with Roger. Sudden extreme variations of humidity aren’t common, and you can design around the issue by using strong stretch loops on the lee and/or extending the poles. And as walkers our tents are rarely exposed to extended sun and you don’t hear of old Atkos or Warmlites shredding in the wind so the UV performance of 6.6 seems to be fine in practice.

TL:DNR: 30d nylon 6.6 is proven for use in nasty conditions while 20d silpoly is experimental at best. Are you feeling lucky?

Sep 7, 2019 at 12:22 pm #3609306The PU4000 fabrics from RBTR should not be used as outer fabrics for a shelter. Great for floors where high HH is desired and seam tension is low. But the fabric rips easily from holes and seams when under tension. Their normal Silpoly is significantly more difficult to tear.

Sep 7, 2019 at 3:06 pm #3609316John – just noticed that RSBTR have launched a 2nd generation of their 1.1 silpoly with an improved HH of 2000mm. It’s lighter and stronger than the the PU4000, so as you say it probably the best bet for a fly if you’re taking the poly route. I don’t think any other vendor has anything similar.

Sep 7, 2019 at 3:19 pm #3609319John, I think you will find that floors really get a workout from kneeling on them. Even sleeping on them produces more pressure than wind loading say at 40mph.

Sep 7, 2019 at 4:16 pm #3609329My MYOG tent uses PU4000 for the floor. It has over 100 nights on it and still going strong. My tent inner just hangs from the outer via light shock-cord, so the floor is generally loose and never under great tension. Not like the concentrated loading a tie-out or peak of a pyramid tarp or something would see.

Max’s “Reflection on how to buy things” was interesting. I had no idea the commission was 8%. I use websites of gear reviewers and sites like Outdoor Gear Lab to learn about products and find more information, but I mostly ignore their opinions. I do put more trust in the opinions and experiences of random internet strangers, like you all on BPL here, even if I disagree sometimes :) The Dirigo 2 is such a strange design. I really don’t see why anyone would buy it.

Sep 7, 2019 at 10:24 pm #3609359Yes, floors do get a workout when you kneel on them, but not when you sleep on them using a mat of any sort. My now oldish blue tent uses the original Westmark silnylon for the floor, and it survives. Probably hundreds of nights on all sorts of surfaces. I have had to patch a couple of very small holes or stretched spots (usually pointy roots I missed when clearing the site), and I did recoat it once during a 2-month long trip, but it still functions very well.

That said, I must point out that we do NOT kneel directly on it. Most of the time in the evenings and the mornings Sue is on her airmat, while I am sitting on a foam sitmat doing the cooking. It is a light-weight fabric, and we take care of it. I am always a bit puzzled by the damage people report to their gear: we just don’t get that amount.

Techie details: I find 1,500 mm HH is quite enough for the fly (but watch the aging figures), and 2,500 mm is enough for the floor (it doesn’t get UV). My 2c.

Cheers

Sep 8, 2019 at 11:28 am #3609403Does anyone know what the HH was on Ron Bell’s silnylon floors circa 2012? I was using one of his inners under a duomid for several years but pretty infrequently – it didn’t see a lot of use. Then in 2018 the floor failed spectacularly during a day-long storm in the Rockies. Kind of disappointing. To Roger’s point: it’s hard to avoid kneeling on a floor when you’re stuck in a tent all day. (I’ve heard Ron is using burlier silnylon these days though).

Z.

Sep 8, 2019 at 1:09 pm #3609411Roger, a 180 pound person (not your wife of course) will exert a bit of force on a floor. 20×72 for a pad works out to about 10sqft, or. 1.8foot/pounds on the floor. While light, this is enough to poke holes, or, stretch the floor around any sharper objects, as you relate. Kneeling, standing, etc can cause more. For example, a 3’x3″ knee pressure will give you slightly more than 1400ft/p per knee (assuming you have two knees.) Not good on the floor.

Sep 8, 2019 at 10:18 pm #3609446To Roger’s point: it’s hard to avoid kneeling on a floor when you’re stuck in a tent all day.

Probably so, but I don’t think we have ever stayed in our tent for a day. Not once. Even in bad weather we have always got moving, in the hope it would improve later on. It usually has. The ponchos and over-trousers help.a 180 pound person (not your wife of course)

Quite right. A little more than half of that is all.1.8foot/pounds on the floor. While light, this is enough to poke holes, or, stretch the floor around any sharper objects,

Just so, and we have had that happen.As I said, little bits of stick or tree roots (tiny stuff) sticking up. In the Alps I either pitch on good grass (we get some lovely grass under our big snow gums) or on a bit of heather. You would think the heather would make holes, but it is soft and springy and compresses. Where we have to be very careful is on areas which are recovering from our big fires: that really does leave sharp burnt twigs sticking up.a 3’x3″ knee pressure will give you slightly more than 1400ft/p per knee

That was what precipitated the recoating of the floor on one trip. I found my knees were getting wet when I briefly knelt – but there was huge storm and water everywhere. The balcony of a small cheap hotel in Courmayeur and some tubes of silicone adhesive from the local hardware store.On the other hand, with better fabric we have sat on our tent floor and floated once. Very hard and flat ground (helipad) and a huge thunderstorm, with inches of water around the tent. We really were floating! Cooking dinner was an exercise in foundations.

Mind you, normally even in reasonable rain, the ground under our tent does not get very wet. Normally the soil absorbs the water rather than letting it form sheets under the tent. You can often see the outline of the floor when we pack up the tent in the morning.

Cheers

Sep 9, 2019 at 1:22 am #3609472Ha, hey, I was sleeping with my wife through a major thunder storm most of the night. We woke up in the middle of a largish mud puddle a couple inches deep. We stayed dry in the old Sirius. I didn’t notice it till I went to get out and felt water well up on my forearm. Every time we moved we could see waves from the tent. I really didn’t want to get out of the tent that night, let alone pull the gear out and empty it in the morn.

Sep 9, 2019 at 2:16 am #3609479Probably so, but I don’t think we have ever stayed in our tent for a day. Not once. Even in bad weather we have always got moving, in the hope it would improve later on. It usually has.

That’s a good policy when you’re through-hiking, but doesn’t really work when you’re base-camping with intention to do some summits or whatever. Also in the Rockies a day can easily be wiped out by, say, 5 hours of hail on and off – not pretty. That’s unlike anything I’ve ever seen in Australia anyway.

So on the issue of floors, yeh, it’s nice to know that your floor can withstand a day of crawling about on it in conditions like that. That’s why I’m curious if and how silnylon has improved in the last ten years, as I don’t know much about that….

Sep 9, 2019 at 2:36 am #3609482We get hail in the Oz alps (KNP) here – out of a blue sky sometimes. Poncho over a big canvas hat.

If the hail gets big enough to hurt – which only happens near Sydney, not in the mountains, then we find a snow gum to shelter under. Or some granite boulders.

Cheers

Sep 9, 2019 at 2:59 am #3609486I live in Sydney and grew up in Sydney. I’ve never dealt with golfball-size hail for hours on end in Sydney or anywhere else in Oz, only in America.

Also I have never seen any snow gums or granite boulders near Sydney, sounds like you mean ‘near Canberra’?

I choose not to try to summit a 14,000 ft peak in an ongoing hailstorm, as I value my life. But if others are happy to attempt it, best of luck to them.

Sep 9, 2019 at 4:00 am #3609496Hi Zacc

I think you may have completely misread what I wrote.

Cheers

Sep 9, 2019 at 6:33 am #3609502Hi Roger,

We were originally talking about the conditions under which one might spend, or indeed might have to spend, all day in a tent. I indicated that this might well happen in some conditions in America, and I suggested that I have never experienced any comparable conditions in Oz myself (though I am sure they exist in the Alps and Tassie). I suggested that dealing with such weather on a base-camping style trip in particular could well result in not bothering to move anywhere.

I am happy to hear that you are resilient in the face of hail. Terrific. My suggestion was that there are nonetheless circumstances when one would not try to be resilient, either out of concern for their life or at least for the logic of the trip one has designed.

I also wanted to point out that there are no snow gums or granite boulders that I know of anywhere ‘near Sydney’ in any use of ‘near’ that one would employ for geographical distances in Oz. That’s why I thought you meant maybe ‘near Canberra’. Is that possible?

Regards,

Zac

Sep 9, 2019 at 7:24 am #3609507We get hail in the Oz alps (KNP) here

ie KNP, not Sydney.

Sydney hail can get larger as it falls another 1,500+ m before it hits. Golf balls.I am happy to hear that you are resilient in the face of hail.

Nah, just a bit stubborn. :)

We do not regard hail as life-threatening, as long as it is not too big. The falls of big stones here don’t last very long.Cheers

Sep 10, 2019 at 6:31 am #3609669“A few reviews on RSBTR stressed how easily the silpoly PU4000 tore, which was a bit concerning, while the 6.6 nylon is pretty tough stuff, at least before the UV gets to it. There’s a big difference between nylon 6 and 6.6, and an even bigger difference between the 6.6 and the silpoly PU. I suspect your figures are for nylon 6, not 6.6?”

The PU4000 stuff is pretty much the worst case scenario for poly because PU is harmful for tear strength and that material was loaded with it. Best to try to standardize coatings (e.g. silpoly vs silnylon, sil/PU poly vs sil/PU nylon etc). Probably the two best known polys are the PU4000 stuff and RSBTRs membrane stuff, but neither is really representative of what a good 20D poly can do. RSBTRs new 20D 1.1oz silpoly (which is actually sil/PU coated but with a reasonable amount of PU instead of a ton) is a much better representative.

It’s been a few months since I was deep into the literature on the topic of poly vs nylon 6 vs nylon 6.6, but I did read a lot about it (I have a folder of academic papers on it) and generally found that nylon has an advantage in tear strength but it’s commonly much overstated (e.g. it’s 15 – 25% typically, not double) and that virtually all fabric tests are a best case scenario for nylon as they don’t expose how it loses strength when wet, and with UV exposure. With the same coatings, it’s hard to see nylon having more than a 10% strength advantage if we’re looking a year down the road and in a wet storm (where nylon would have UV degradation and lose strength in the wet). Factors like stretch are a big debate.

“Are you really arguing that for exposed use with some risk of snow load the 20d silpoly PU 4000 would be a better choice?”

Certainly not PU4000 and I suppose I wouldn’t argue for a better 20D silpoly as a superior choice either in that context. My view is that in real world conditions the difference in strength is small enough that for many people other factors like sag and water absorption are also important differences, but clearly in your application strength is the top consideration, and here a new (non-UV degraded) nylon 6,6 is the strongest. But even then, if you plan on keeping it for 5+ years, I suspect you’d be better with poly because it’s hard to see nylon not UV degrading to become weaker than poly within a normal lifespan of a tent.As for reputable companies offering serious conditions shelters in poly, I’m not sure where you read TrekkerTent recommends it for sheltered use only. Perhaps that is written somewhere, but if you go to their website and click “3 season shelters” they are seemingly all 20D poly without any disclaimer like that. Their materials page further says 3 season = 20D poly and 4 season = 40D nylon. So maybe they do have a disclaimer somewhere, but most buyers are seemingly thinking they are buying a legit 3 season tent for UK/Scotland usage when they’re buying one. They’re selling 20D poly to a lot of pretty hardcore users (since seemingly everyone in the UK/Scotland is a pretty hardcore user with the winds they have).

Sep 10, 2019 at 8:12 am #3609670it’s hard to see nylon having more than a 10% strength advantage if we’re looking a year down the road and in a wet storm (where nylon would have UV degradation and lose strength in the wet).

I can’t see why the nylon would necessarily have UV degradation. For a start, the coating will offer some protection, and secondly hard-core walkers don’t leave their tents erected for a full day. Instead they strike the tent early in the morning and start walking. I will quote my tents as examples which do not seem to have any UV degradation.

Of course, if you are talking more about the consumer market, then maybe these things are a problem.Factors like stretch are a big debate.

Here I will totally disagree with you, at least for mountain tents. In a big storm the elasticity of the nylon is of huge benefit: it allows the tent to absorb the hammering and bounce back. To my mind there is no debate at all (having been in rather big all-night storms on mountain tops).

Once again, if you are talking about consumer-grade tents which won’t see (or shouldn’t!) a storm on a mountain top, then the elasticity may not be so important.Their materials page further says 3 season = 20D poly and 4 season = 40D nylon. So maybe they do have a disclaimer somewhere,

Why should they have any extra disclaimer above and beyond the statement just quoted? If the customer wishes to ignore the specifications and misuse the gear, it is on his own head.Cheers

Sep 10, 2019 at 2:36 pm #3609694Yeah, As Roger says, stretch and elasticity are important to a tent. We always have small branches falling on the nylon fly in any winds greater than 20mph. I had a 3″dia, 20′ long live branch come down on the tarp a few years back. It actually absorbed the impact and I didn’t have to get out from under the tarp till I tore down the next morning, just shifted to the other side. (It was a strong lightening/wind storm.) My daughter has an older poly dome tent that was holed by a branchlet off a much smaller live branch.

Nylon and nylon 6,6 are both pretty good. 20D nylons are a bit weaker, but not enough to cause problems. A simple bungie (cord or hair ties) works well for stretching. Most of the stuff I have read indicates a 15-30% increase in strength for nylon over the same weight of poly. Nylon 6,6 is even stronger. Given a 10% increase, when wet still begs the question. Nylon is stronger. UV damage isn’t much of an issue either. Most of my camping is in a forest. And, as Roger says, I tear down each morning and set up a lot later in the day. The only reason manufacturers use poly is cost. For camping, nylon is generally a better choice.

Sep 10, 2019 at 7:43 pm #3609717Nylon vs Poly vs UV vs Sag .. and on and on.

We have found color is a big part of UV degredation of nylons. Darker more muted colors fare a lot better. That being said, we have never had a customer tent that we would consider have an issue with UV and we have done things like zipper repairs on tents several years old that had 500 plus nights use on them. For us, using more muted colors and it is a non issue. Darker colors also attract fewer bugs.

Nylon and Sag .. I am convinced that almost every time we have heard a comment from a customer about sag they have not been using our poles which adjust easily in one inch increments.

30 D Nylon 6.6 vs SilPoly 20D .. We built a few shelters out of Silploy some as custom for a couple of customers, that have used our shelters a lot of nights over the years in harsh environments .. we did it as a test and they could get our standard shelter if they wanted later … the customers all wanted to just go with a Nylon shelter. At least from our customers it was a shutout of Nylon over silpoly and these customers are in very wet , humid , environments.

Yes there is a lot of mistrust for manufacturers and marketers. Sad state right ? Max’s post regarding reviews unfortunately was pretty spot on …

Sep 10, 2019 at 9:49 pm #3609733We have found color is a big part of UV degredation of nylons. Darker more muted colors fare a lot better.

Very much so. I one had a tent made from yellow and blue nylon. It did stay up in the day, for many many days (we were rock climbing every weekend). Eventually the yellow fabric became brittle and threatened to tear; the blue parts were going strong.The only reason manufacturers use poly is cost.

For the consumer market (Walmart etc) this is a perfectly good justification. There will be thousands of tents which get used once or twice and never again.Cheers

Sep 10, 2019 at 10:26 pm #3609740Yeah, I can add that the white nylon tarp we used over the old pup tent didn’t last nearly as long as my forest green tarp. Eight vs sixteen years. This was not nylon 6,6.

Sep 11, 2019 at 1:55 am #3609752Dan: “Factors like stretch are a big debate”

Roger: “Here I will totally disagree with you, at least for mountain tents. In a big storm the elasticity of the nylon is of huge benefit”

I wasn’t arguing that stretch is good or bad. I just said it was debated because it’s a big topic that I didn’t want to get into.“No-one is using anything in 20d for foul-weather shelters that I can see.”

Not a 20D, but Black Diamond seems to be using mostly (entirely?) poly for their 4-season tents. For example, they switched their HiLight to a 30D poly which they are selling as a “4 season mountain tent”. I won’t argue for 20D poly as a 4-season material, but I think it’s well proven for 3 season use.“The only reason manufacturers use poly is cost.”

It’s certainly not true that this is the “only reason” since there are other clear advantages to poly (e.g. no sag) and I also suspect it’s not really “a reason”. There are some cheap polyesters in heavier weights that used in cheap tents, but down in the 20D range the costs seem pretty similar as things like weaving and coating likely form the bulk of the cost, much moreso than the actual fiber. I haven’t looked into it personally but the high volume silpolys and silnylons seems to get down to about $2/yd at wholesale, high volume pricing. If we look at Black Diamond again, there seems to be no correlation between their use of nylon vs poly, and how expensive the shelter is.“I can’t see why the nylon would necessarily have UV degradation….hard-core walkers don’t leave their tents erected for a full day.”

I think people vastly underappreciate how much UV degradation is going on with nylon because it takes about a huge reduction in strength (e.g. 80 – 95%) before you might notice it. It also occurs as a negative asymptote, where you drop 10-20% strength quite quickly but it slows thereafter because the degraded outer layer is sheltering the material below. UV degradation is also radically more substantial in lightweight fabrics compared to better known cases (e.g. climbing webbing left on a mountain) because lightweight fabrics have a much larger % of the material within the depth that UV can penetrate.How much UV degradation a tent is experiencing depends on a lot of factors, but very roughly speaking nylon is going to lose 10-30% of it’s strength after a couple days in the sun. It might take 100 days of baking in the sun in the alpine to notice a problem (e.g. degrade >80%) but dropping 20% doesn’t take long at all. There’s so many factors, but even if someone is packing up somewhat early and hiking until dinner, they might drop 20% strength in a few weeks of use from a few hours of low angle sun each morning/evening.

Given that users won’t notice UV degradation of fabric strength until it’s massive, I don’t think it’s sound argument to say nylon is beefier than poly because it starts off stronger and the user didn’t notice any degradation.

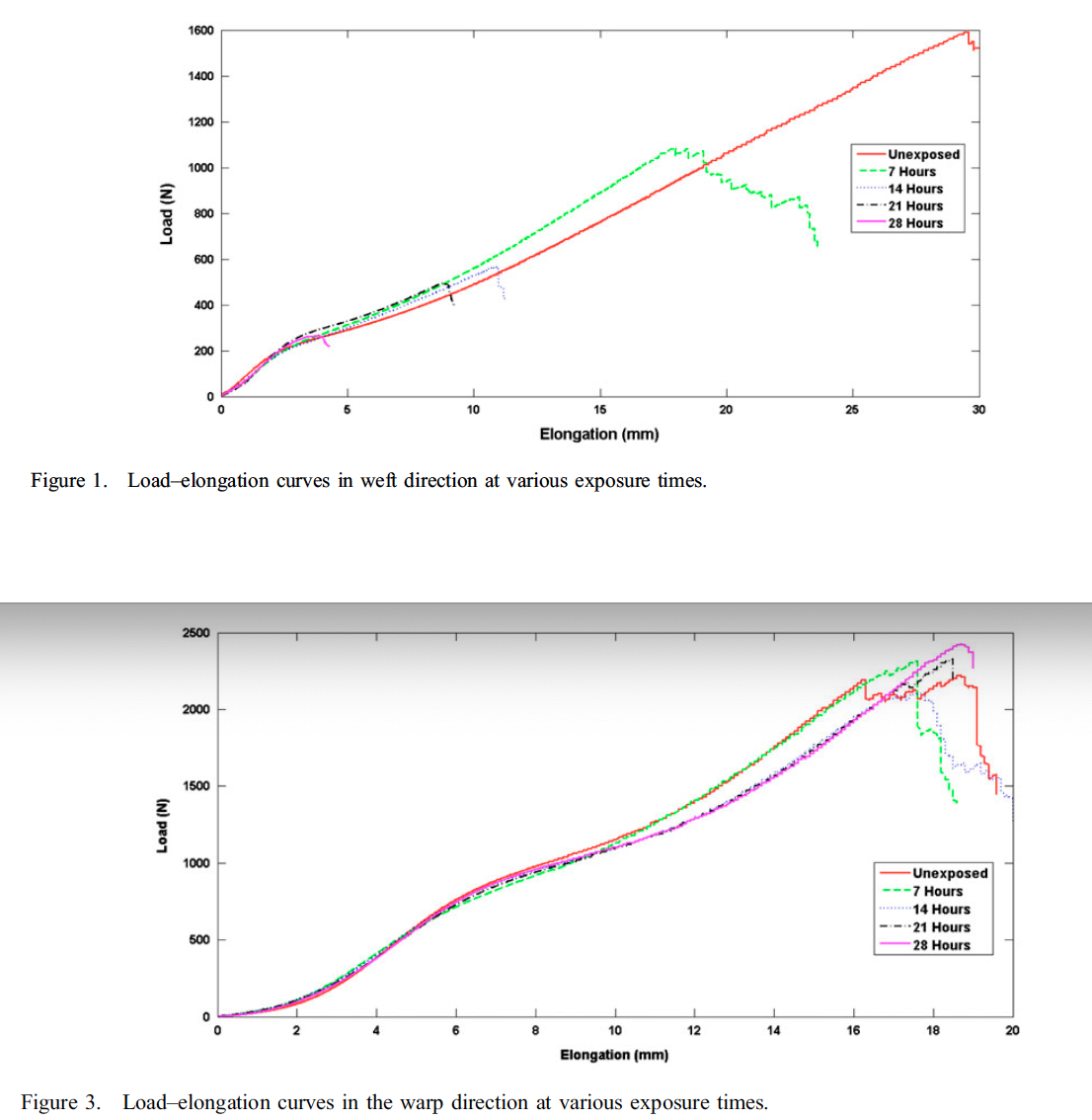

To illustrate how much more radically nylon degrades that poly, here are a few figures from a paper for nylon (top) and poly (below). We can’t compare this UV dose to real world conditions, but it is equal for both fabrics and it shows nylon degrading 85% over the test, while after the same exposure the poly is as strong as new.

Nylon (top) and poly (bottom):

I’m certainly not arguing that nylon is not strong enough. Just that the fact that used nylon tents are holding up so well when they might have 50 – 80% degradation, also means that a poly that starts out 20% or even 40% weaker, is going to hold up well. The bomber tent isn’t the one that is super strong when new, it’s the one that never gets so weak it’ll fail. In a hypothetical choice between a nylon tent that degrades from 100% to 50% strength over its life, or a poly tent that sits at 75% the entire time, I suggest the poly would be the better one to have because you are never using as weak of a shelter.

Sep 11, 2019 at 4:07 am #3609764BD switched their HiLight to a 30D poly which they are selling as a “4 season mountain tent”.

It’s still a pop-up, just with some fancy marketing. The poles are too long. I cannot see that as an endorsement of polyester.

I suggest that their idea of ‘foul weather’ and my idea may differ slightly.Given that users won’t notice UV degradation of fabric strength until it’s massive, I don’t think it’s sound argument to say nylon is beefier than poly

Well, this tent (my ‘blue tent’) was made in 2005.

This photo is from May 2006.

The tent has been in several 2-month-long walking trips in the European Alps, and various week-long walking trips in our Australia Alps. I have posted pics of it numerous times here. It is still going strong 14 years later. So much for UV degradation. (I am sure there has been some, but not quite as much as you are claiming.)Btw – that paper you are quoting: I think it is for bare nylon, and probably undyed, yes? But we do not use bare nylon fabric (the silicone coating is a bit protective), and the darker shades of nylon (eg blue) are very good at resisting the UV anyhow.

Wacker make a lot of silicone polymers for coating. This is what they say about the UV resistance of the silicone itself:

Resistance to UV Radiation and Weathering

Compared to other materials, silicone elastomers are particularly resistant to UV radiation. Even harsh weather con-ditions, as found in coastal regions or deserts, have little effect on their properties. Typically silicones show only slight changes of mechanical and hydrophobic properties, even after ex-tended accelerated weathering tests of more than 3,000 hours.Well, it works for me, anyhow.

Cheers

-

AuthorPosts

- You must be logged in to reply to this topic.

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

Trail Days Online! 2025 is this week:

Thursday, February 27 through Saturday, March 1 - Registration is Free.

Our Community Posts are Moderated

Backpacking Light community posts are moderated and here to foster helpful and positive discussions about lightweight backpacking. Please be mindful of our values and boundaries and review our Community Guidelines prior to posting.

Get the Newsletter

Gear Research & Discovery Tools

- Browse our curated Gear Shop

- See the latest Gear Deals and Sales

- Our Recommendations

- Search for Gear on Sale with the Gear Finder

- Used Gear Swap

- Member Gear Reviews and BPL Gear Review Articles

- Browse by Gear Type or Brand.