Topic

Myog 4p 4 season tunnel tent (Caffin style)

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

Home › Forums › Gear Forums › Make Your Own Gear › Myog 4p 4 season tunnel tent (Caffin style)

- This topic has 21 replies, 11 voices, and was last updated 6 years, 6 months ago by

Eric Blumensaadt.

Eric Blumensaadt.

-

AuthorPosts

-

Jun 16, 2018 at 10:41 pm #3542419

Hello all, I have just about finished my latest tent project: a 4 season, 4 persons 4 poled base camp tunnel tent. I’m hoping to use it with my family of 4 and eventually as a base camp while climbing in the Canadian Rockies or in Alaska (well, one can hope!).

All plans have been greatly detailed and adjusted to my liking by Mr. Caffin. Without his tremendous help the tent would most likely still be in the planning stages… Such a big tent made it difficult to measure and cut all the panels as efficiently as possible but, in the end, it turned out alright. The provided plans were very detailed and after giving them some thoughts took a lot of the guessing work out of the equation which was great to mainly focus on the sewing. Still, there were no free lunches!

Total weight of 2990g all included (stuff sac, poles, guys, fly and inner) BUT it still needs to be seam sealed with some tape and flowable Permatex.

Poles: 4 identical poles each with 3 elbows. 8.8mm OD and 7.5mm ID. They are really stiff hence the use of elbows. Ordered from HaoZhong Carbon Fiber (They are not 2D wrapped, time will tell how that goes). I had gluing issues but after testing Gorilla Glue original and Lepage repair gel did the trick. The pole sections are linked with an outer sleeve (external insert). It still feeds in the sleeve well enough but if I end up having pole issues I’ll make them internal.

Fly and sleeves: 40d silnylon from Extrem textile. Vents are held up by thick (3.9mm) and flexible heavy-duty grass whipper wire. 12 guy outs with lite lineloc 3’s. Front corners have bungees to keep tension but lineloc 3’s have been used at the rear end. The sleeved are opened at one end only. I added a slight cat curve in the ridge line between the poles. Corner reinforcements where bonded with silicone and stitched.

Inner: I used 2<sup>nd</sup> fabric on sale at Extrem. It is very airy! Maybe too much? I do not think it will be possible to have humidity build up in the inner tent which is good.

Floor: I used the same 40d silnylon from Extrem. 3500mm rated and impossible to tear with bare hands.

Zips: #3 coil

Internal guys have been added but are not in the pictures.

Stitching: Rasant 120 and 75.

I still need to seam seal the fly and add an inner mesh door.

Jun 17, 2018 at 1:10 am #3542431

Jun 17, 2018 at 1:10 am #3542431Nicely done

That looks like a spacious tent

Jun 17, 2018 at 4:25 am #3542442That looks great. What are the dimensions?

Jun 17, 2018 at 4:47 am #3542443Looks awesome!

Jun 17, 2018 at 6:00 am #3542448Groundsheet: 2,200 mm long x 2,184 mm wide

Interior ht at peak: 1,219 mm

Outside dimension 3,761 mm x 2,400 mmI was a bit surprised when the design worked out. I had not thought it possible to design such a 4-man tunnel tent, but it proved OK.

The photos are taken indoors. When pitched outdoors the fabric will be TAUT!

It is very airy! Maybe too much? I do not think it will be possible to have humidity build up in the inner tent which is good.

Debatable. If the inner tent is too air-tight you can get a lot of condensation inside it. A highly breathable inner lets the humidity pass through and freeze on the fly, which is obviously better. Personally, I would rely on the outer tent, the fly, to cut 99% of the wind, rather that relying on the inner. Reason being that if the fly does not block the wind, spindrift is going to build up inside against the inner tent. That would not be good.Pierre – I do like the contrasting colour for the verandahs. I wish I had done that.

Cheers

Jun 17, 2018 at 11:13 pm #3542598Thank you all for the kind comments!

Roger, I am sure my cutting and sewing skills are not as precise as the plan you provided me with. The tent does fit 4 regular mats and the inner’s angles are not too pronounced as to hinder the usable interior space. Being so wide also makes for a huge vestibule despite the short span between the 4 poles.

As for the color choices… I tried to use smaller left over pieces of silnylon I had on hand and it worked out better than expected.

I will update with pics once I have sealed it and set it outdoors but it will take a few weeks.

Jun 17, 2018 at 11:45 pm #3542603Hi Pierre

We want to see it in the mountains, with family inside it!

Cheers

Jun 18, 2018 at 3:46 am #3542649Thank you, Pierre, for the thread, pictures and details. Very nice, and very sturdy I’m sure. It would be very interesting to know a little more about the materials and joinery for the elbows.

Jun 18, 2018 at 7:17 am #3542674neat! I am very envious of those skillz

Jun 19, 2018 at 3:11 am #3542777Sam, you’ll be disappointed to learn that I had no involvement in developing the elbows… I had to ship some things to Roger and he had to send stuff up north so he help me (well saved me really). Therefore they are stainless steel tubing bent with Roger’s home made bender. To make them fit the bigger I.D. of my poles we only had to use a short sleeve of a smaller O.D. than my pole’s I.D and some glue.

I started with high hope of using Ti tubing but ended up with only enough to make 2 elbows… That idea died rather quickly!

Madeline: Thank you but really, I bet everyone could do the same if time isn’t a factor. I only work when I feel ready to and stops regularly before any bigger/more committing steps.

Cheers

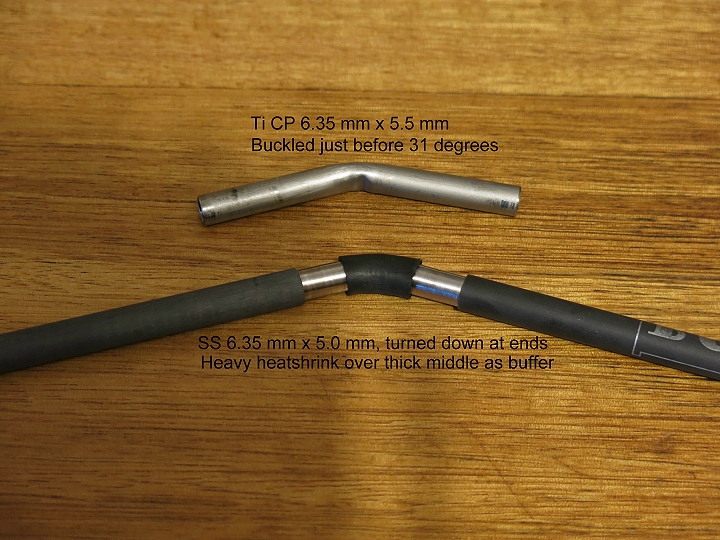

Jun 19, 2018 at 6:25 am #3542808Working Ti is hard – much harder than SS. Even the softest Ti – ‘CP’ is difficult.

So I take a length of SS tube, turn the ends down to fit inside the CF pole, and then I bend it with a special bender, as shown here.

Cheers

Aug 4, 2018 at 7:01 pm #3549834Well, the tent is still untested but it is sealed and now has a polycro ground sheet. Taping the seam looks very neat but for me, it is much cheaper, faster and easier to use floable Permatex and a finger. I do not think I will try the taping again.

Total 100% finished weight: 3292g. Now, I only have to convince the family to get out!

Cheers

Aug 5, 2018 at 9:38 am #3549923Hi Pierre

I taped some of the simple groundsheet seams, but I used Permatex for the rest.

Cheers

Aug 9, 2018 at 9:15 pm #3550707Total 100% finished weight: 3292g

7.25 lbs (don’t speak metric) for a 4-person, 4-season shelter. That’s pretty impressive at less than 2 lbs per person.

Aug 10, 2018 at 5:32 am #3550782Wow – nice work!

Great to see another creation from you.

Can you tell us how long it took to make?

Aug 10, 2018 at 2:13 pm #3550812Bonjour Nick and Rene, thank you for the kind comments.

I had to go back about 2 years in my emails to find the start of the communication between R. Caffin and I. We discussed plans for a while and poles. After I got the plans from him and had the time to study them I started making the poles. The sewing started a little over a year ago. I do remember the tracing /cutting of the end panels was done in June 2017. The rectangular panels, pole sleeves and the many guy outs had been done before that. I did not work on the tent everyday, most likely not even every week since I always priorities family and training (almost daily). The panels were long and seams straight which makes the sewing simple and faster I find.

Cheers

Aug 13, 2018 at 12:52 am #3551136Bonjour Pierre,

First of all, like pretty much everyone, I must say your work is inspiring, and thanks for sharing your thoughts and answer online !

I’m currently on a quest to find / or MYOG a light 4p 3-season tent. I already spend a decent amount of time reading your posts, as well as Dr Caffin’s ones on the MYOG tunnel tent.

Looking at your two last tents, the 3p cuben one and this one, raises one question for me : Why did you go for a 3-bends pole design on this one, and not a simple semi-circular one like you did on the cuben tent ? From what I understood, the main reason Roger uses this design is because the inherent stiffness of the CF poles prevented him to make tight arches for his 2-man tents, and that didn’t seem to be a problem for you on your cuben tent. Avoiding bends would have made the project easier, wouldn’t it ?

Thanks in advance for your answer,

Pierre-Yves,

Aug 13, 2018 at 1:13 am #3551138I designed that tent, and one of my constraints was that the CF poles had to be limited to a safe amount of curvature. I don’t think you could get enough curvature in a CF pole to do without the elbows – well, not safely, anyhow.

Cheers

Aug 13, 2018 at 1:30 am #3551141Hi Roger,

I know you did and I understand your concerns. However, the CF poles Pierre used in his Cuben tunnel tent seem to handle a pretty tight curvature. Is that beyond safe point in your opinion ?

Pierre-Yves.

Aug 13, 2018 at 2:55 am #3551152Bonsoir Pierre-Yves, I am glad you find some inspirations and insights in my tent project. Thank you for the feedback.

I must admit that for this tent (4S4P) the only thought was to go along Rogers designs. Well, other than some minor changes to the inner tent and the pole sleeve being closed at one end. The pole used are also bigger in diameter than the ones used on the Cuben one and much stiffer.

For lesser experienced seamstress like me, it proved difficult to align the pole elbows and the matching sleeves angles from Rogers plans. Roger obviously has a few decades of experience and I am only beginning!

Thigh curvature: Sam Farrington could tell you more about this but we both believe that for a 3 man tent it is ok. I would not do the same for a 2 man tent (ie: needs elbow or pre-bent Al sections)

My experience also thought me that using tent pole as probes should only be a last ressort. A carbon fiber avy probe feels stiffer and if venturing in such terrain, I will bring a real probe instead of planing to use a tent pole. It was not a smart place to cut weight. As a last ressort, sure but not planing it this way when packing.

Cheers

Aug 13, 2018 at 4:15 am #3551166Is that beyond safe point in your opinion ?

As I mentioned above, I did the design and I made sure I stayed within what I felt were safe limits. This was done by setting a limit to the curvature allowed in the poles. A background to this is the testing I had done on the flexibility of both the tubes I use and the tubes PD used.Cheers

Aug 15, 2018 at 3:14 am #3551429I am jealous! I want it but do not have the skill to sew it.. Great job Pierre.

Maybe you can bribe the family with a dinner at a 4 star restaurant if they will camp with you – in the winter, of course. ;o)

-

AuthorPosts

- You must be logged in to reply to this topic.

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

LAST CALL (Sale Ends Feb 24) - Hyperlite Mountain Gear's Biggest Sale of the Year.

All DCF shelters, packs, premium quilts, and accessories are on sale.

Our Community Posts are Moderated

Backpacking Light community posts are moderated and here to foster helpful and positive discussions about lightweight backpacking. Please be mindful of our values and boundaries and review our Community Guidelines prior to posting.

Get the Newsletter

Gear Research & Discovery Tools

- Browse our curated Gear Shop

- See the latest Gear Deals and Sales

- Our Recommendations

- Search for Gear on Sale with the Gear Finder

- Used Gear Swap

- Member Gear Reviews and BPL Gear Review Articles

- Browse by Gear Type or Brand.