Topic

Myog 2p 4 season semi-geodesic tent

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

Home › Forums › Gear Forums › Make Your Own Gear › Myog 2p 4 season semi-geodesic tent

- This topic has 16 replies, 5 voices, and was last updated 8 years, 6 months ago by

Sam Farrington.

Sam Farrington.

-

AuthorPosts

-

Jul 1, 2016 at 4:59 pm #3411832

Despite all my good sense and my love for tunnel tents, I tried to rise up to the challenge presented by a friend. He wanted me to do a lighter alpine climbing tent usable in any conditions and able to sustain side wind better then my bigger winter cuben tunnel when side guy lines can’t really be set up due to the terrain (narrow ledges comes to mind) I made the fly go as low as I could in order to avoid adding a sod cloth.

I used Silpoly/pu 2000 for most of the fly but because of some (well, many) mistakes, I used Silpoly for the front vestibule. The Silpoly was much more confidence inspiring. The application of the pu coating really changes the behavior of the fabric! It makes it much more easy to tear while increasing its waterproofness. It is always about tread offs. Due to this, I used many reinforcements and what I call the ”Caffin folds” in most important seams.

So, now for the important part…

Fly and inner, 1060g

Poles: 480g (Thanks to Sam F’s knowledge I made my poles out of carbon arrow shafts. the two poles that have a more pronounced curvature have 3 pre-bend aluminum sections at their middle.)

Bag: 27g

The seam sealing and the guy lines have to be added to that but the tent is drying so this will wait. I also have to fix the front vent. I wanted to use some intricate guy lines in order to give it a shape but this made entering the tent more like a yoga class. I go back to the trusted grass wire sniper. It should be an easy fix.

The tent fits 2 regular mats easily and could fit 3 motivated climbers without the inner tent.

Lastly, if I were to do this again, I would use 2 full pole sleeve and the other 2 poles would be using clips and maybe partial clips… I now realize there is a reason Hilleberg does it this way… It simplifies the set up ever so slightly.

Jul 1, 2016 at 5:02 pm #3411834

Jul 1, 2016 at 5:02 pm #3411834That’s a work of art. Well done.

Jul 1, 2016 at 5:09 pm #3411838Wow Pierre, really impressive. Nice work!

Jul 1, 2016 at 5:21 pm #3411841Hi Pierre

I would call that an unconventional tunnel tent! Four poles – good sideways wind-resistance. Perhaps a shade tricky getting the panels between the poles exactly right?

The crossed poles are a bit complex though. If you don’t cross them you can probably get the same sideways strength, and inserting them is simpler. This took 100 kph all night (a couple of nights) without damage.

PU coating: good for groundsheets as the HH is better. Allows taping of seams, although you CAN tape silnylon seams with siloxane tape. But yes, the PU coating seriously reduces the tear strength. I would not use it myself for a fly.

Cheers

Jul 5, 2016 at 1:13 pm #3412424Thank you all for the comments!

The seam sealing is now dry and the front vent has been fixed.

Final total weight is 1611g

Roger, I was thinking side wind resistance without the side guy lines. When the width of the ledge can’t accommodate more than just pegging the rear and the front parts.

Cheers

Jul 5, 2016 at 4:30 pm #3412467Hi Pierre

1.6 kg – a good weight. CF poles are good stuff.

Ah – ledges. I do not have much experience with camping on narrow ledges, but I wonder whether the side guys matter as much there? It seems to me that when camped on a ledge, the wind can NOT go sideways very much at all: there is a rock face in the way after all. The wind can go downwards onto the tent, and I have experience of that. Side guys don’t help there: you need internal cross guys for that. On the other hand, out in the open the wind can go sideways at very high speed. Testing all this could be ‘interesting’.

A question which might be interesting to test; are crossed poles as in your semi-geodesic design any stiffer against a sideways wind than straight poles as in a conventional tunnel? I have reservations, as the poles in the geodesic design are longer and hence more flexible. Not by much, I agree.

Cheers

Jul 5, 2016 at 7:32 pm #3412505I like your thinking Roger. The wind might not go in the direction I had envisioned at all. Your rational makes total sense.

Inner guys: I did placed one already just between the front pole crossing points but I have to admit being too lazy to add the one going thu the inner tent. I’ll work on that.

My semi geodesic tent poles are longer than they would be in a similarly sized tunnel tent but I’d think the support added by the crossing points complexifies the strength analysis. Wouldn’t you agree? I’ll let you ponder and think about the math since this will quickly move beyond my abilities.

Cheers

Jul 5, 2016 at 10:19 pm #3412543Horizontal internal storm guys

personally, I think these can be as important as the external side guys. I have seen how effective they are in bad winds, and I am sometimes amazed. The only problem with them is that they do get in the way of the occupants a bit. Mind you, when a storm is raging outside, we are quite happy to put up with such very minor inconveniences – compared with having the tent collapse for instance. :-)I regret to have to say that none of the tests I have done show any benefits to the crossing of the poles as you have on your latest tent. The only thing which was of any benefit (apart from the internal horizontal storm guys) was reducing the fabric span between the poles – which is why my winter tent has 4 poles rather than 3. The difference in performance due to the extra pole has been quite remarkable – although really I should say ‘due to the reduction in fabric span’.

Cheers

Jul 6, 2016 at 10:57 am #3412653Well, you make a good case against the semi geodesic tents. I’m not surprised! I’ve always loved my tunnels more than any geodesic tent I’ve tried too. This makes me think I’ll have to make some more tunnels to make up for this laps in judgment… I may even try your elbows to diminish the stress on the carbon poles. In any case, thank you for all your insight!

Jul 6, 2016 at 4:25 pm #3412745Hi Pierre

My main concerns about the crossed semi-geodesic poles is the difficulty in getting the poles into the sleeves in bad weather. That would worry me a bit. It’s hard enough in really bad weather anyhow!

Elbows are a problem. I machine mine, but not everyone can do that. There are a few commercial elbows on the market, but most of the angles available are not suitable. Email me direct if you want.

Cheers

Jul 6, 2016 at 5:19 pm #3412752I will get in touch with you when I get around to building a yet another tent! I have two packs to make and test first and then I have to work on a better tent design. It will be a while. Nevertheless, A very kind offer thank you very much.

Pierre

Jul 12, 2016 at 9:19 pm #3413914Pierre,

Assume by omission of the word, “membrane,” you were using the 1.1 oz fabric with a PU coating on one side, and a sil coating on the other. This is around the same coated weight as 30 D silnylon: 1.3-1.4 oz/sq/yd.Your comment about the weak tear strength suggests that the lighter ‘membrane’ fabric would be even more susceptible to tearing. It would be helpful if you could expand a little on this.

How much of the weakness is due to the polyester material, and how much is due to the PU coating is undetermined. But having done some seams with the new PU coated nylons, such as used on the StoS Escapist tarps, I’m inclined to believe that the polyester material, rather than the newer PU coatings, have more to do with the weakness of the material.

Although Snow Peak has manufactured a light polyester material for its Lago tents that is quite strong and intended for winter camping. However they state that they make it in their own factory, because other light polyester tent fabrics available in the Asian market are not as strong as they desire.Have not devised a simple tear strength test, and have the same concerns as Roger about how well a canopy of these polyester fabrics would resist tearing in high winds, no matter how well reinforced with patches at stress points.

The one big thing polyester materials have going is the absence of sag in changes of temp and humidity. Less flapping and spraying in wind driven rain, so much drier to occupy and get in and out of in bad weather.

If all we wanted in a tent were reasonably dependable protection in sheltered locations, these concerns might not matter.

However, given the long stretches of trails in unforested terrain in the mountains of the western US, CAN, AU, and other areas, I think a tent that will withstand severe weather in such locations is probably the gold standard. Dropping down from the CDT in CO, for example, still leaves one in beautiful, but unsheltered terrain, and it is nice to be able to pitch camp without descending for miles out of your way.We’ve seen on these forums a couple of UK contributors who have designed and used tents in the Scottish highlands that appear to meet this standard. One was a two hoop tunnel that sloped in the rear foot area, and the others where hard to describe, so will just say “semi-geodesic.” All were made with around 30D silnylon from Extrem Textil, as I recall.

So I think that right now, nylon is the way to go despite the sagging, but with a tent design that counteracts the sagging as much as possible. And for the above reasons, I’m not as concerned about the PU content of the newer coatings on nylon.

One other point: With a little measuring and math, I found that canopies of ‘side entry’ tents that slope down at the foot and head ends run about 40% lighter than tunnels with the same floor area.

With plenty of room to move about in the center of the tent, the lowered canopy over the head and feet is not a big problem, so long as there is an inner of net or breathable nylon to catch condensation and spattering caused by the wind. The 40% difference allows for a tent significantly lighter than a tunnel.So I think you are on the right track with designs that depart from the classic tunnel shape. You might look at the XX Tarp Tent design I posted on MYOG back in 2011 for some ideas. After many design revisions, including solving pole insertion, I think this approach will yield a much lighter and stable tent, with as few as 4 pegs. But a cross between a MSR Hubba and a Tarptent Moment might also yield a very stable structure without the weight of a ‘geodesic’ frame with multiple pole crossings.

The greatest advantage I see with a tunnel over tents with crossing poles is that the tunnels, even if lower at the head and/or foot ends, can be raised in one motion after the poles are first inserted while the tent is flat on the ground. This is a big deal in high winds. Maybe someone will come up with a tent with crossing poles that goes up with one motion as a tunnel does.

Good luck with your efforts.

Jul 12, 2016 at 11:15 pm #3413929The greatest advantage I see with a tunnel over tents with crossing poles is that the tunnels, even if lower at the head and/or foot ends, can be raised in one motion after the poles are first inserted while the tent is flat on the ground. This is a big deal in high winds.

Absolutely. There are videos on YouTube illustrating this. Some of them show people trying to get a ‘pop-up’ erected in high wind. In some of them you would expect the poor guy to die of wet wind chill before he could succeed. They would be hilarious if they were not so serious.

And yes, I can erect and pull down a 2-man tunnel tent in winds of 100 kph by myself, at the first attempt ( … there is no try).

However, I do NOT like side-entry tents myself, as I have yet to find one which does not risk filling the groundsheet with rain when you try to get in and out. A good vestibule on the other hand is excellent for getting under cover in bad weather without risking water on the groundsheet, and it is good for packs and for cooking. Eh – my 2c.

Cheers

Jul 13, 2016 at 6:15 am #3413943Bonjour Sam, the main fabric used was membrane silpoly with the pu 2000 coating on the inside. This was much weaker then anticipated but because of the online comments I still went ahead with its use. I also used light silpoly at 1.24osy but only for the front vestibule since I ran out of the membrane fabric due to some mistakes. This silpoly is a mix on both sides of silicone and pu and was much more confidence inspiring.

I have used tunnel tents for most of my life and the ease and safety of set up is really hard to beat. No matter how tired or how windy. I did use an external clips with three crossing poles while on Denali and that was also very good (Vaude Power Odyssey). Maybe a combination of complete sleeve and clips for other poles would have been better.

The silnylon sag is not only due to humidity but also to temperature drop which reinforces my dislike of the fabric so my search continues. I may try some 1.6osy silpoly or high quality silnylon in the future. I’ll include bungees at all guy lines if going the silnylon route.

Jul 13, 2016 at 6:44 am #3413945I have my own way of dealing with silnylon ‘sag’ on my tunnel tents.

At the entrance corners of the tent I have ‘adequate’ length loops of 4 mm bungee cord, and I stretch these out tight when I pitch the tent. The pink lines point to them. When the fabric stretches a bit in the night, the stretch in these loops keeps the roof tight. It works.

Ah – but ONLY in the downwind end! At the ‘back’ end, which goes INTO the wind, the loops are short loops of 3 mm nylon cord, with no stretch. You never EVER want to let the windward end of a tunnel have any room to move at all. I have some horrible videos of what happens …

Of course, since the bungee cord is 4 mm and seriously stretched, that means there is a bit of a load on the end stakes. Yep, very true. On my snow tent they are deadman anchors of reasonable size, in packed snow.

https://backpackinglight.com/make_your_own_gear_titanium_snow_stakes/

https://backpackinglight.com/myog_ti_snow_stakes_part_2/

Cheers

Jul 14, 2016 at 7:19 am #3414130Re: “However, I do NOT like side-entry tents myself, as I have yet to find one which does not risk filling the groundsheet with rain when you try to get in and out. A good vestibule on the other hand is excellent for getting under cover in bad weather without risking water on the groundsheet, and it is good for packs and for cooking.”

There is no reason why such a vestibule cannot be designed for a ‘side-entry’ tent.

There are many examples, and the vestibules are more spacious.Re: “The silnylon sag is not only due to humidity but also to temperature drop which reinforces my dislike of the fabric so my search continues.”

Tests of the StoS Escapist tarp material with a sul+PU coating on both sides suggest that any NYLON material, no matter how coated, will sag with rising humidity and dropping temps. The newer mixed coatings appear to exhibit less sag, however. The old and for some reason much reviled thread from “Hang ’em High’ on this site illustrated the sag on both PU (Eureka dome) and sil coated (Tarptent) nylon tents. Another approach to nylon sag is a light frame underneath the outer canopy that stretches the fabric on the bias, as on the XX tarp tent mentioned in the earlier post above. The poles can be installed on that tent while it remains on the ground, but it will not go up with just one motion like a tunnel. With this and other domes, there are at least two poles that must be separately placed in their ground level grommets or receptors in order put the tent up. And between the first and second placement, the tent is quite vulnerable to the wind. A stake pre-installed at the rear vestibule (end cover) might limit that, however. The issue then becomes whether avoiding that limited vulnerability in the dome tent design justifies a heavier tunnel shape.

Re: “Ah – but ONLY in the downwind end! At the ‘back’ end, which goes INTO the wind, the loops are short loops of 3 mm nylon cord, with no stretch. You never EVER want to let the windward end of a tunnel have any room to move at all. I have some horrible videos of what happens …”

Yes, there was a link on one of the threads here to a video of a Warmlite tunnel collapsing on the smaller back end in high winds, in Iceland or Greenland as I recall. The tent was correctly pitched with the small end pitched toward the wind. The UL thin-walled and T6 alloy rear pole was blown from a hoop to an ‘S’ shape.

Re: “the main fabric used was membrane silpoly with the pu 2000 coating on the inside. This was much weaker then anticipated but because of the online comments I still went ahead with its use.”

Yes, the online comments report adequate strength with the ‘membrane’ PU 2000 coating.

And of course no sagging due to the polyester material. I still would appreciate knowing more about “much weaker than anticipated.” This may be a common situation with reports of materials used successfully in light to moderate conditions that do not expose a tent to wind and rain that penetrate the fabric, or even tear it apart.

Everyone blithely thinks all is AOK until really serious conditions strike, as you might experience on Denali, for example; but also in any expansive area above timberline. You may be suggesting that the slightly heavier polyester fabric is the safe option for those wishing to camp in such areas (most us us?).Sorry about the partial images of the logged-in home page when attempting to add a link.

Until the learning curve clicks in, will experiment with just typing out the URL for links, inviting others to copy and paste them to their browsers. Another couple seconds or so needed to follow the link – no big deal IMO.Jul 15, 2016 at 7:04 am #3414378Not a fan of picturing digital or paper models that have not been sewn full size. There are always many devils in the details when real construction of a full prototype is attempted.

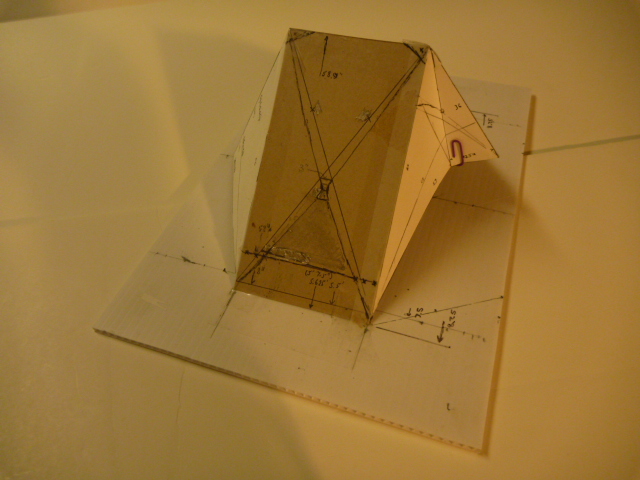

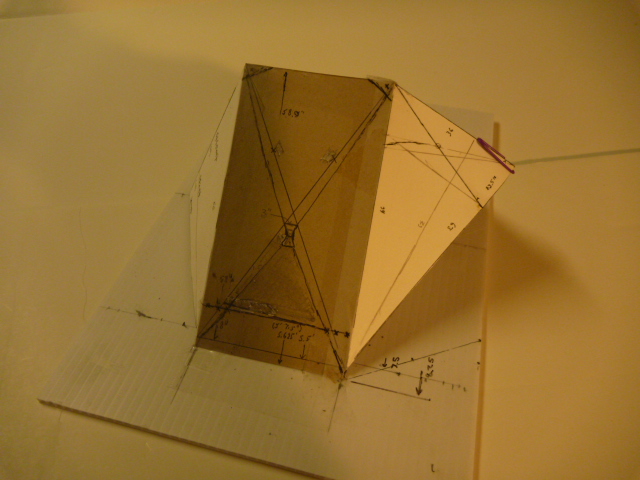

However, an exception will be made in this case to illustrate my two above posts on this thread:

The XX tent is a common A-frame design, but is bowed out by carbon poles:

This makes the tent much more spacious inside. The carbon poles also greatly increase stability and expand the fabric canopy on the bias to greatly limit sag if nylon. The RBTR membrane polyester also expands on the bias (it is a woven thread material), but is far less susceptible to sagging in higher humidity and lower temps.Paper scale models look like the following, but like many digital models shown in this forum do not show the essential catenary cuts at the seams or dome effect of the bowed out poles:

With the front cover locked down for severe weather, to be supported by one guyline:

With the front cover fully open to form an awning, to be supported by one trekking pole:

Doors on the awning will open with zips at both left and right. The zipped up awning can be open most of the time, except when severe weather strikes. The trekking pole can be easily removed and the awning locked down and tightened, all from inside the tent.Hope this is helpful. There appear to be some bugs in the script of this post. Will redo when there is more time.

-

AuthorPosts

- You must be logged in to reply to this topic.

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

Our Community Posts are Moderated

Backpacking Light community posts are moderated and here to foster helpful and positive discussions about lightweight backpacking. Please be mindful of our values and boundaries and review our Community Guidelines prior to posting.

Get the Newsletter

Gear Research & Discovery Tools

- Browse our curated Gear Shop

- See the latest Gear Deals and Sales

- Our Recommendations

- Search for Gear on Sale with the Gear Finder

- Used Gear Swap

- Member Gear Reviews and BPL Gear Review Articles

- Browse by Gear Type or Brand.