Topic

More 3D-printed gear

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

Home › Forums › Gear Forums › Make Your Own Gear › More 3D-printed gear

- This topic has 44 replies, 13 voices, and was last updated 4 years ago by

Ben H..

Ben H..

-

AuthorPosts

-

Dec 4, 2020 at 1:18 pm #3687285

That’s awesome! Those tents were great. Is that experience with the vents why you don’t put them on your pyramid tents?

Dec 4, 2020 at 2:10 pm #3687297We took the Mt. Shasta beginning mountaineering class with ASI sometime in the mid-90’s and stayed in 4-person mids; I think we dug steps down to the sleeping area in the snow, so we did have sort of a bench It was a fun and really well-run trip, and in addition to learning ice axe and crampon techniques, I also gained a sense of confidence on steep exposed slopes for the first time ever, having been indoctrinated with a fear of heights from an early age.

Jan 15, 2021 at 8:09 am #3693891Here’s a second version of the folding scalpel knife. The first version was fine, but it required a tiny threaded bolt. I had only a couple of them, and they would be difficult to source. The new version is 100% printed, of course except the blade. Now it’s easy to make plenty of them for giving away. Also, a lock that prevents accidental opening has been added.

Weights 4.5 g / 0.16 oz including the blade.

Jan 15, 2021 at 8:54 am #3693907Here’s a second version of the folding scalpel knife…

Bonzo like. Bonzo want. Bonzo pay.

Jan 15, 2021 at 10:08 am #3693925Jan, that looks like a great design.

I’ve been feeling unmotivated as a designer lately and had thought about making a vocabulary of interlocking parts that could be used on future projects or shared with my students. To that end, I’d be interested to see the profile of the shape you used for the pivot. I’m assuming it is tapered to lock into a corresponding tapered hole in the grey part. Seeing it would give me a head start on making a similar pivot of my own.

Feb 10, 2021 at 4:52 am #3698482Finally, I got to publishing the first thing – the scalpel knife v2 pictured above. It can be downloaded at https://www.thingiverse.com/thing:4752640, and there’s also all the information needed for printing it.

Making one should be as easy as it can get: It’s all printed, no special hardware is needed (apart from the blade, of course). It’s designed to be printed out of PETG, a very common material that’s easy to print at home.

Enjoy!

Feb 10, 2021 at 6:07 am #3698486Making one should be as easy as it can get: It’s all printed, no special hardware is needed (apart from the blade, of course). It’s designed to be printed out of PETG, a very common material that’s easy to print at home.

Again…Bonzo like. Bonzo want. Bonzo pay. Anyone want to take me up on that?

Feb 10, 2021 at 6:58 am #3698489@Bonzo,

The problem with selling these is that value of the things is too small compared to the logistics around it. If you were the only person interested in it, I can throw a few of them into an envelope and send them to you. If there was a group buy where I’d send fifty of them in a single package, I’m in. But all the things in between would cost too much of my time (which I don’t want to spend in the line at the post office).Feb 10, 2021 at 8:06 am #3698494I was thinking the same thing…Do I buy a 3D printer to have one really cool and lightweight scalpel knife or do we find someone who’s able to print them and sell them?

Matthew or David Gardner? Right up your alley…

Feb 10, 2021 at 11:32 am #3698553It doesn’t make sense to 3D print something and ship it overseas. As long as the person is willing to share the file, specified material and build parameters, just find a local service to print it up. I just went to Craigslist and entered 3D Printing and it came back with a lot of hits. I suspect that there are a lot of hobbiest that need to earn some money in order to pay for their machines and materials. My 2 cents.

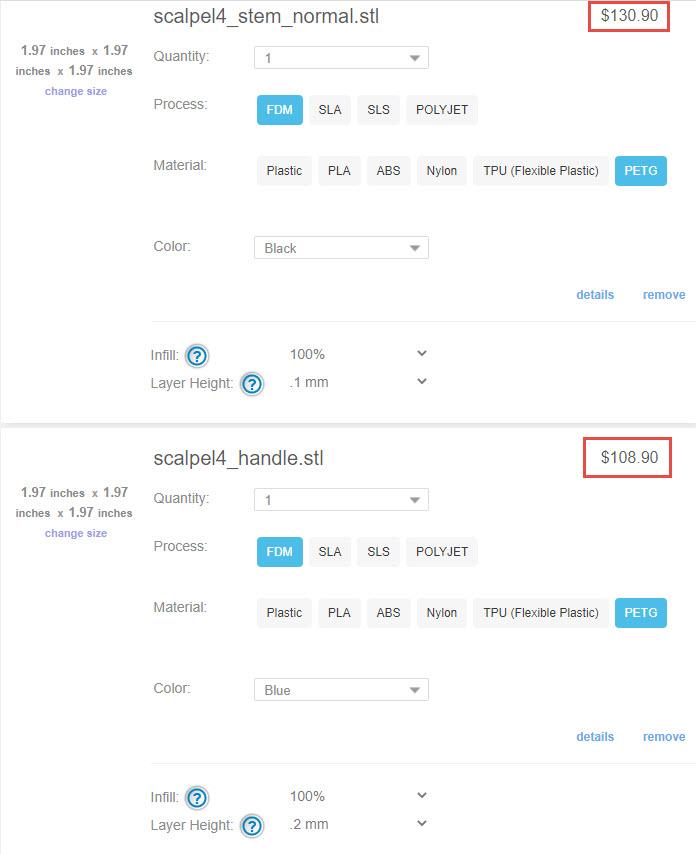

Feb 10, 2021 at 12:03 pm #3698559Clearly I did something wrong…I downloaded Jan’s files and submitted them to MakeXYZ.com (there’s a local guy who uses that as his front-end). The price came back as $239.80 for just 1 unit!!!

The good news is that the price qualifies for free shipping…

Feb 10, 2021 at 12:18 pm #3698564You are asking for 0.1 mm (0.004″) which is pretty thin. Cost is going to be based on hours to complete the job. Your job says that it is 1.97″ tall at 0.004″ that’s 492 layers.

Feb 10, 2021 at 12:25 pm #3698565The parameters in the screenshot were the only options I had. The handle was set at .2 mm, but Jan’s notes said:

“Designed for PETG, printed with 0.4 mm nozzle. It’s important to have good layer adhesion, otherwise the pivot may break off. Both parts can be printed with 0.2 mm layers, but the blade stem looks better if printed with finer layers.”

That’s why I chose 0.1 mm for the blade stem.

I don’t know anything about 3D printers (except that the technology is very cool). Given what I paid Jan for the Silky Boy blade handle I figured I was clearly missing something with this estimate. It’s not a big deal, but I’m curious about what other people find. I was expecting (and this may be optimistic) something between $20-30 total for the two parts.

Feb 10, 2021 at 12:43 pm #3698570The orientation of the part should be such that the generates the lowest height on the platform (Z-Height). That will minimize the build time. In general, operators will nest part of a similar make to make sure that the “bus is fully loaded” before starting a job.

MakeXYZ looking like a point person to access shops that have 3D printers (and don’t do the printing themselves). I would try Craigslist as they are probably a lot more willing to optimize the job.

Feb 10, 2021 at 1:57 pm #3698592I’m totally down to print once I return to my classroom. I’ve been teaching from home since around March 15 of last year. We may be returning to our classrooms in March but it’s not certain yet. I’d be happy to print up a bunch of them once that happens.

Feb 10, 2021 at 3:35 pm #3698615Each component is $5-10 shipped on Shapeways:

I am not sure which material option to select (you can get it done in platinum for a couple thousand dollars!)

Feb 10, 2021 at 3:49 pm #3698620Jan, what number blade did you use? #10?

Feb 10, 2021 at 5:23 pm #3698641Thanks Ben! That seems WAY more reasonable! I’ll give it a try and report back.

Feb 10, 2021 at 7:44 pm #3698694Jan says it’s a #24 blade in the “Print It” summary.

Feb 11, 2021 at 7:40 am #3698729Thanks Kevin! $8/100 blades shipped on Amazon:

-

AuthorPosts

- You must be logged in to reply to this topic.

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

HAPPENING RIGHT NOW (February 11-21, 2025) - Shop Hyperlite Mountain Gear's Biggest Sale of the Year:

Our Community Posts are Moderated

Backpacking Light community posts are moderated and here to foster helpful and positive discussions about lightweight backpacking. Please be mindful of our values and boundaries and review our Community Guidelines prior to posting.

Get the Newsletter

Gear Research & Discovery Tools

- Browse our curated Gear Shop

- See the latest Gear Deals and Sales

- Our Recommendations

- Search for Gear on Sale with the Gear Finder

- Used Gear Swap

- Member Gear Reviews and BPL Gear Review Articles

- Browse by Gear Type or Brand.