Topic

Measuring Waterproofness in Outdoor Performance Fabrics with a DIY Hydrostatic Pressure Test Device at Home

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

Home › Forums › Campfire › Editor’s Roundtable › Measuring Waterproofness in Outdoor Performance Fabrics with a DIY Hydrostatic Pressure Test Device at Home

- This topic has 3 replies, 3 voices, and was last updated 4 years, 11 months ago by

Roger Caffin.

Roger Caffin.

-

AuthorPosts

-

Mar 10, 2020 at 9:14 pm #3635216

Companion forum thread to: Measuring Waterproofness in Outdoor Performance Fabrics with a DIY Hydrostatic Pressure Test Device at Home

In this article, I present a DIY testing device (and test results for 30 fabrics) that allows me to measure the hydrostatic head of “waterproof’ fabrics at home.

Mar 10, 2020 at 11:39 pm #3635231Nice DIY engineering and interesting test results. With fabrics and coatings and suppliers appearing and disappearing rapidly, seems like independent testing could be a full time job.

Any estimate on total cost of parts?

Any thoughts on how a version 5 setup might stop the silicone-coated fabric creep? Seems like the top clamp could be a plate with a large hole and a LOT of downward force, or maybe with edge clamps like an electric sheet sander. So says my armchair from halfway around the world :-)

How much does HH degrade with age and/or use? How much “buffer” do you recommend?

Yet it seems as though all the recent fabrics you tested are more than good enough, and we can obsess over other parameters like weight, condensation, slipperiness, water absorption, noisiness, stretch, and UV resistance instead. Your thoughts?

Factory sealing silnylon/silpoly with diluted silicone caulk adds about a week and some cost to an order – if it’s offered. Would siloxane tape be much better or worse? Is DIY sealing with siloxane tape reasonable?

Thanks.

— Rex

Mar 10, 2020 at 11:59 pm #3635232

Roger,

Great article… thanks!

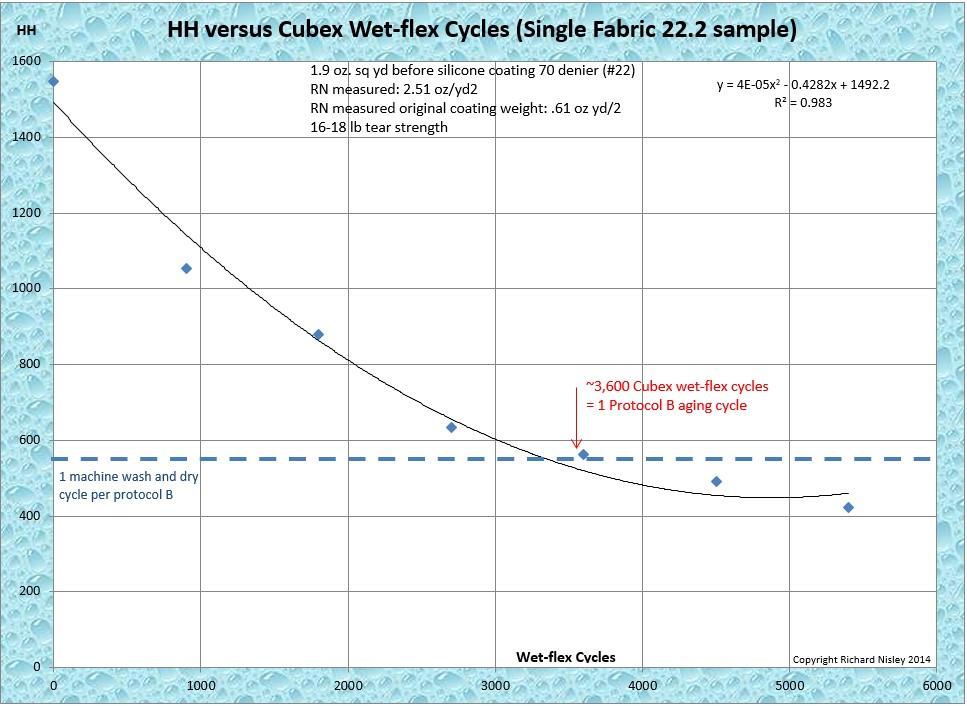

Obviously if a virgin fabric doesn’t test >1,500mm HH initially, it should probably be discarded from consideration. Unfortunately, this only tells someone one-half of the information needed before they burn a lot of labor on a DIY project. They also need to know how its HH will degrade from use as compared to other fabrics with similar initial weight characteristics. Every fabric I have Cubex tested for HH aging, yields a unique degradation curve; an example is shown above.

I suggest that your next companion article addresses you building a Cubex HH aging tester. In the interim, people could use a very crude washer/dryer test. It is of marginal use because most fabrics, of interest to UL backpacker, fail between the first and second cycles of the crude washer/dryer test; as a result, it offers little differentiation. A fine-grained curve is required to select the best fabric in the weight range of interest.

Mar 11, 2020 at 11:30 pm #3635376Toatl cost of parts?

Well, maybe $20 – $30 from China/ebay, but a lot of the materials (tubing, plastic etc) came from ‘stock’. BUT regardless, it was NOT expensive. The little pressure gauge was remarkably cheap compared to industrial units.How to stop the creep?

Well, ‘use the force Luke’. In other words, more force from the screw on top. But before one gets carried away here, does it matter all that much if there is some slip when the HH gets over 10,000 mm? It was interesting to see that there were NO marks on the fabrics afterwards.Obsess over other parameters?

Yep.

I would pay some attention to tear strength with the really UL fabrics. I would also avoid where-ever possible any ‘rip-stop’ fabrics, as they leak much faster and the ripstop does NOT add strength. Well, not in my testing, anyhow.Sealing seams?

Do NOT use silicone caulk as found in those cartridges. It is the wrong stuff! Use instead the little tubes of silicone adhesive now widely available. The Permatex Flowable Windscreen Sealant was (sort of) the original stuff, but there are lots of very similar brands now. They are all quite ‘flowable’ and don’t need diluting.Note as well that while the caulk goes off in a couple of months in its cartridge no matter how you seal it up, the adhesives in little tubes can last for years if the cap is put back on properly. A different chemistry.

Cubex?

I could, but I note that a lot of companies use banks of Maytag washing machines instead. Anyhow, I doubt I want to go that far myself.UL Fabrics

Yes, these need careful design and sewing. You can’t just rip off the sort of seam you would use for a shirt, but they CAN be sewn to be very strong.Cheers

-

AuthorPosts

- You must be logged in to reply to this topic.

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

Trail Days Online! 2025 is this week:

Thursday, February 27 through Saturday, March 1 - Registration is Free.

Our Community Posts are Moderated

Backpacking Light community posts are moderated and here to foster helpful and positive discussions about lightweight backpacking. Please be mindful of our values and boundaries and review our Community Guidelines prior to posting.

Get the Newsletter

Gear Research & Discovery Tools

- Browse our curated Gear Shop

- See the latest Gear Deals and Sales

- Our Recommendations

- Search for Gear on Sale with the Gear Finder

- Used Gear Swap

- Member Gear Reviews and BPL Gear Review Articles

- Browse by Gear Type or Brand.