Topic

Making a DCF 8×8 Mid

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

Home › Forums › Gear Forums › Make Your Own Gear › Making a DCF 8×8 Mid

- This topic has 12 replies, 2 voices, and was last updated 2 years, 6 months ago by

Stumphges.

Stumphges.

-

AuthorPosts

-

Aug 21, 2019 at 10:05 pm #3607080

Hey all! New member here, excited to get in on the backpacking action!

So as the title states, I’m going to be making a 1.0oz/y^2 DCF Pyramid tarp, approx 8.5’x8.5′.

I’ve found Jerry’s silnylon guide, and it has been really useful. I’ve also found other useful BPL links on DCF construction techniques, so thank you all very much!

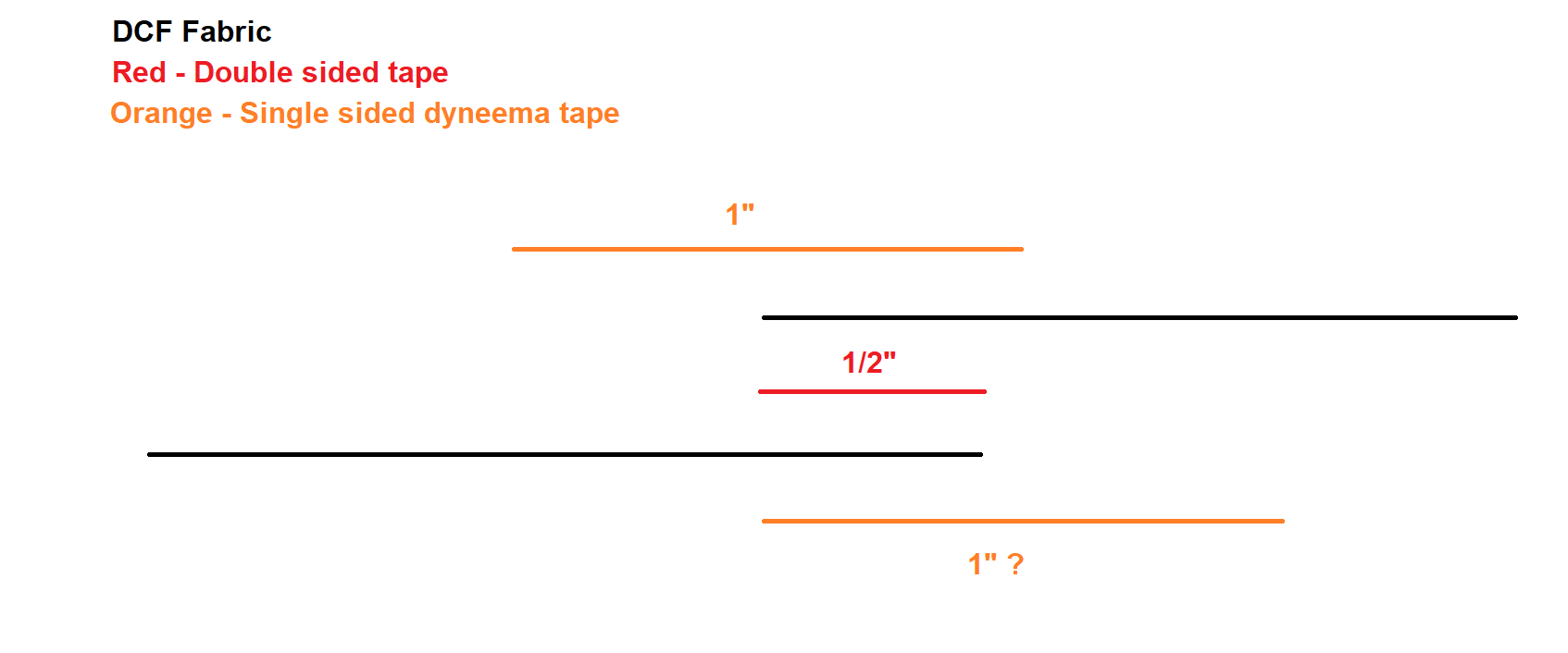

I do have some specific questions, though. As far as merging edges, I’m planning on taping them using double sided tape, then going over that with single-sided Dyneema tape. Is this acceptable? Do I need to tape on both sides, or is just the outside fine? See this:

Is the orange inner tape necessary? Should I also sew through the red taped portion before taping the seam?

I would also like some input on how I can reinforce the top of the mid. I’m planning on getting a half yard of some 5oz/y^2 DCF/Nylon to put as a cap, but I don’t know exactly how to bond it effectively. Can someone point me in the right direction for that?

Also, can I tape the zipper on, or should I sew that as well? I would have to seal it, but that’s probably fine. Thanks for any advice in advance!

Aug 22, 2019 at 9:58 am #3607113If you are looking for the ultimate in DCF construction, the touchstone is Colin Ibbotson’s rare and much coveted TrampLite Shelter. By the way, it’s full of innovative design ideas you might want to check out:

http://www.tramplite.com/2018/11/original-tramplite-tarp-discontinued-uk.html

Colin is an engineer and works to an obsessionally high standard. His shelter is designed for tough conditions and extensively tested. I’ve seen nothing but rave reviews.

Here are his views on DCF construction – he strongly recommends a flat felled seam before you bond:

Most manufacturers simply stick their shelters together with double-sided tape leading to designs that are weaker, and pitch less taut, than a Tramplite shelter. Simply, if you want to resist wind effectively then you need a tough and taut shell. With a Tramplite shelter, every major seam is rolled twice, double sewn and finally over-bonded. This gives an immensely tough seam, comprising of a minimum 6 individual layers of DCF, that is immune to fabric de-lamination while allowing immense pressure to be applied to the pegging/guying points (which are directly attached to the seams). With shelters that are stuck together, you are effectively only bonding the 2 outer faces of plastic film together and any de-lamination of the DCF fabric can lead to catastrophic failures. Any shelter built this way and used on exposed sites, and in consistently high winds, is more likely to delaminate over time but even when new, and performing as designed, is still much weaker than a Tramplite and will flap easily.

So why are most DCF shelters simply stuck together? Profit! You can build 3 of those shelters in the time it takes Tramplite Gear to lovingly craft 1. For the customer, there are no advantages other than sometimes a cheaper price.

Aug 22, 2019 at 2:34 pm #3607144

Aug 22, 2019 at 2:34 pm #3607144As far as the roof peak reinforcement, I’ve had great success gluing together DCF using Loctite UK U-90FL Adhesive. I’ve never experienced delamination, and it remains flexible.

Is 5.0 DCF necessary? Seems like overkill. My Zpacks hexamid uses a 2.92 oz DCF cap and that has never presented any wear issues after 4000+ miles of use. To simplify matters, you could just buy one of Zpacks’ circular patches in a 7.5″ diameter if you think the adhesive backing would be sufficient. After all, this will not be an area of the shelter that will be stressed laterally.

Food for thought. Good luck!

Aug 22, 2019 at 7:52 pm #3607184Hey Geoff, thanks for pointing him out! I’d not seen that product before, and it looks super bomber! I’ve also found this comment chain that has been very useful.

I think I am the most nervous about sewing a good seam (x8). I’m a novice at sewing, so it appeals to me to just tape and be done. Ultimately I’m not planning on taking it on any thru-hikes, just run of the mill weekend trips that shouldn’t be too hairy.

Matt, good point, 5.0 is probably more than necessary. The patch is tempting, but I want the peak to be white, since I’m making it myself. How viscous is the adhesive? Is it a gel, or more liquidy? Just trying to imagine the process of applying it. Looking at ripstopbytheroll the 2.93oz DCF has a nylon side, I assume I would want to bond it DCF to DCF sides?

Aug 22, 2019 at 10:37 pm #3607200A few thoughts and answers …

The adhesive is gooey (i.e. doesn’t run much). It’s a two-part mixture that you squeeze out with a glue gun, and then mix together with a scrap of cardboard (if you don’t buy a mixture attachment for the gun). So, depending on the type of glue gun you choose, it is pricier than just run-of-the-mill glue. Others may have more cost-effective idea if you do not plan on doing other projects where you can recoup the additional cost over time.

Yes, glue the DCF to DCF.

If you need a shove to try sewing, here it is … Sewing is creative, rewarding, and terribly addictive. Anyone can sew a straight line as long as they go slow. The biggest challenge will be managing all the fabric needed for a shelter through, around, over the sewing machine. But, again, patience and sloth work wonders. Perhaps, start out with smaller projects to get the feel, but think about … you only live once.

If sewing still isn’t for you, you could glue the seams, and then tape them. Likely bomb-proof. But others who have tried it will have better first-hand experience.

Aug 23, 2019 at 10:12 am #3607263Cameron

If you go the bonding only route, you might want to be careful about severe cold. There are people here with a background in adhesives who have run tests that indicate the bonding gets weak enough to potentially fail as temperatures drop.

I’d echo Matt and encourage you to consider learning to sew. It opens up a whole world of opportunities for MYOG, and other fields too – for example you can make really cool bags as gifts. It’s a bit of a learning curve, but there’s plenty of info on YouTube. And once you get the hang of it, it’s fun.

Aug 23, 2019 at 4:37 pm #3607312Alright, you guys have convinced me! Especially since I’ll probably take this winter camping, I really don’t want the adhesive to fail if I get caught in a winter storm. I’ll probably get some ripstop nylon to practice seams on, I was looking and I think the french seam seems easy enough and still good looking. I’m still hoping I can do the double sided tape first and sew through it, since the material is tricky enough. Hopefully the needle doesn’t get stuck on it though, I’ll have to experiment.

Unrelated, I’m planning on adding a slight cat curve to the ridge lines, but I’ve seen some say DCF doesn’t need them, since it doesn’t stretch. I though the cat curve helped give it a taut pitch easier, is that right?

Aug 29, 2019 at 10:04 pm #3608151I have not worked with either CF or DCF, because the cost is so high. I have, however, screwed up flat tarps built with 1.1 osy silnylon 2nds, at like $3/yard. Yeah, I’d probably be a little more careful with DCF.

To each their own; I highly recommend building a mock-up or two with cheap fabric first to at least test your design. I also recommend picking up a half-yard or so of the DCF you plan to use to play around with. Cutting non-hybrid DCF is a real pain, in particular cutting curves.

Aug 29, 2019 at 10:28 pm #3608154I haven’t done DCF or CF either, maybe sometime. Something I’ve heard is that fabric can become weathered after a somewhat short time, but I’ve also heard from people that didn’t have this problem.

Yeah, make a first version with cheaper fabric to get the size and shape correct.

Sewing is fairly easy to learn. The main problem is the top fabric layer slipping relative to the bottom, but you can figure out how to do that. Flat felled seam stronger than French seam. French seam is good for clothes that don’t have a lot of tension across the fabric like a tent.

Sep 3, 2019 at 5:55 am #3608721My humble opinion @ Cameron

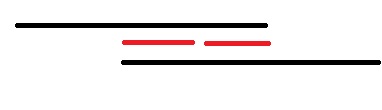

Your planned way of DCF taping (three times) is thoughtful and safe but could be a bit overwhelming. I would recommend doing a just simple flat bond but running two tapes, with perhaps 1 mm gap in between, like:

if you want more reliability, simply increase the tape to e.g. 18mm / 20 mm.

To my knowledge this may be the standard way by Locus gear for ridge treatment. Different DCF cottages boasts their unique DCF construction based on their DCF/physics/production knowledge which may not be always right.

Oct 13, 2021 at 1:30 pm #3729565Brook, what is the function of the gap between the two strips of adhesive?

Have you confirmed that this is the way Locus Gear bond their ridgelines?

Oct 13, 2021 at 2:09 pm #3729569It seems like you could just use one wider tape instead of two narrower ones.

However, the actual adhesive failing isn’t really the worry with a seam like that. Rather, the main worry is that if the seam isn’t aligned with the strands in the DCF then under load it will permanently stretch/deform the fabric which doesn’t look good and leads to eventual delamination. The simplest way to avoid this is to add a DCF backed tape over the seam where the strands in the tape are aligned. That’s what most companies do. I don’t think many simply use a double sided tape but they could if the orientation of the fabric was ideal.

Oct 13, 2021 at 5:01 pm #3729606Thanks, Dan. I thought perhaps the gap had some purpose.

I’ve never seen a Locus Gear DCF-B shelter in person. But from their photos, and the best ones for close ups are from inside of the peaks, I can’t detect any evidence of reinforcement. It looks like they just tape the two edges together as in Brook’s schematic.

I agree with you entirely regarding seams on or near the bias needing reinforcement, I just don’t know if LG do anything like what the OP shows in his schematic (lapping the seam with reinforcing tape outside and inside).

How are you doing your seams, Dan? Curious in particular about the ridgeline above your long side panels.

High bias DCF is such a no-brainer. It’s a real pity that its production was not scaled up.

-

AuthorPosts

- You must be logged in to reply to this topic.

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

Our Community Posts are Moderated

Backpacking Light community posts are moderated and here to foster helpful and positive discussions about lightweight backpacking. Please be mindful of our values and boundaries and review our Community Guidelines prior to posting.

Get the Newsletter

Gear Research & Discovery Tools

- Browse our curated Gear Shop

- See the latest Gear Deals and Sales

- Our Recommendations

- Search for Gear on Sale with the Gear Finder

- Used Gear Swap

- Member Gear Reviews and BPL Gear Review Articles

- Browse by Gear Type or Brand.