Topic

Heat Exchanger pots

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

Home › Forums › Gear Forums › Gear (General) › Heat Exchanger pots

- This topic has 53 replies, 19 voices, and was last updated 5 years, 9 months ago by

DAN-Y.

DAN-Y.

-

AuthorPosts

-

Dec 21, 2015 at 10:11 am #3371568

That’s interesting. Great idea. Just technique rather than bringing another piece of equipment.

Dec 21, 2015 at 11:51 am #3371585“that makes sense – a cozy around the entire pot would be even better”

And that is part of the efficient of the JetBoil – that enough heat is extracted from the flame, that the neoprene around the pot (usually) doesn’t melt.

Then there are cozies that are used after you turn the burner off – a hat, bandana, sweater, etc. Those REALLY retain the heat much longer. Which gets in to the whole realm of knowledge and technique (pre-soaking food, bring to a boil and then let sit, turning off the burner at 95C instead of letting the pot boil over at 100C, etc) that weigh nothing compared to having more gear (HX pots, etc).

Editted: I stepped away from the computer and then duplicated Jerry’s thought (which was more concise).

Dec 21, 2015 at 1:29 pm #3371598Free design idea: Surface roughness also stirs up the boundary layer, so simply gluing any bumpy stuff on the outside of the pot (pumice is light and high temperature. Are there aluminum BBs?), could really help.

David – I have a Ti pot that has Aluminium Thermal Spraying on the base. The aluminium is in the form of small grains, so the overall effect is like coarse sandpaper. The manufacturer, EpiGas, claims that this improves the thermal efficiency, although I am unable to verify this. The major attraction for me is the excellent friction which prevents the pot from sliding around on (off!) the stove.

Dec 21, 2015 at 1:32 pm #3371599Free design idea: Surface roughness also stirs up the boundary layer, so simply gluing any bumpy stuff on the outside of the pot (pumice is light and high temperature. Are there aluminum BBs?), could really help.

David – I have a Ti pot that has Aluminium Thermal Spraying on the base. The aluminium is in the form of small grains, so the overall effect is like coarse sandpaper. The manufacturer, EpiGas, claims that this improves the thermal efficiency, although I am unable to verify this. The major attraction for me is the excellent friction which prevents the pot from sliding around on (off!) the stove.

Dec 21, 2015 at 2:01 pm #3371603Just technique rather than bringing another piece of equipment.

And THAT is what BPL is really all about. Yeah, sure gear is great fun, but skill, knowledge, technique – they are where you win.

Cheers

Dec 22, 2015 at 12:04 am #3371733All this takes me back to a boiler style pot/windscreen/everything.

Really, only in boiler style pot you can completely insulate the pot from the outside world, seal the opening for pouring water to retain even more heat. make the hot exhaust gases run through a hole in the middle and complement the hole with fins to get same HX effect (along the whole way from bottom to top). Actually your alcy stove can burn within pot, so the pot acts like a windscreen too, eliminating the need for another piece of gear (this will decrease the length of the way hot gases run through the hole however).

The efficiency of alcy stove heavily depends on how the heat is being kept within pot. Since alcy stoves do not burn hot like gas stoves and thus it takes x2 or x3 more time, the important thing is to retain the heat. I think boiler-style pot will help dramatically in heat retention. Also, controlling the upper opening where hot gases escape, you can control the flame.

I was trying to build this kind of device, but I’m not really made for building such things…

Dec 22, 2015 at 7:20 am #3371762” Just technique rather than bringing another piece of equipment.

And THAT is what BPL is really all about.”

I don’t think so. BPL and society are mostly about some new piece of gear with a fancy name that everyone gets until a new piece of gear with a fancy name appears. Back when I was young I walked a mile to school in the snow…

(okay, take off my crotchety old man hat)

Dec 22, 2015 at 8:39 am #3371778“All this takes me back to a boiler style pot/windscreen/everything.”.

“Really, only in boiler style pot you can completely insulate the pot from the outside world, seal the opening for pouring water to retain even more heat. make the hot exhaust gases run through a hole in the middle and complement the hole with fins to get same HX effect (along the whole way from bottom to top). …”

Yes, but you are still only heating one side of the container: the inside. The outside is still subject to radiative losses. The inside of a container of water is always smaller. There is less surface area to absorb heat. These are not as efficient as you would think.

Better would be a ported container allowing both the inside and outside to absorb heat, similar to a bundt pan. Of course, this does away with the more traditional he “fins” and simply substitutes a larger surface area to accomplish the same thing. Try this: Boil a standard 2 cups in a regular pot and time it. Boil the same two cups in an aluminum bundt pan. Usually, depending on the size of your burner, the bundt pan will boil quicker.

But this does not really say if it is more efficient. A typical alky set-up boils as close to fully efficient as you can get. Using a modified bundt pan over such a slow burner does little to effect fuel consumption. There just isn’t enough heat. splitting 1 part of heat into two halves will not make the water boil any faster. Adding more heat, decreases boil times, but, you increase fuel consumption, too. I tried this about 15 years ago with some simple heavy duty aluminum foil. Try it yourself. These tests were accurate enough to clearly distinguish Ethanol from Methanol, so, I am assuming they were good enough.

Dec 22, 2015 at 9:59 am #3371798Thanks for your post James,

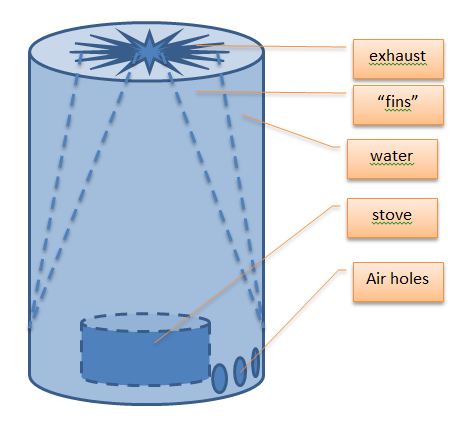

What I thought of is not just a regular cylindrical cavity that goes through the pot, but rather a star-shaped prism. I hope this simple illustration I made with a flask and round (!!!) piece of paper explains it better:

I made the same star out of heavy duty foil (50nm) and tried place it within a 1L beer can to make a boiler. I ended up realizing that it is too difficult to cut star shapes on top and bottom of the beer can. So what I did I turned the shape of top and bottom of this heat exchanger to round. But then I got leaks. I’m telling you I’m just that bad at producing something.

The star-shaped HX is really easy to make: Cut round shape out of heavy duty aluminium foil, then hold it in half, then in quarter, and so on. You should make it the way so when you unfold it, you get that star shape. In the illustration I made a 8-rayed star, but in a real prototype I made a 16-rayed star. After folding/unfolding you cut out a circle hole in the center and expand it a bit. That’s it. BTW, the area is calculated via big circle – circle hole in the center. The area is much greater than pot bottom or side surface. So I’m pretty much convinced that this HX is very effective. Imagine that fins are not just flat pieces of metal, but “hollow” with liquid circulating in them. For better mixing of water through convection you may twist a bit the whole HX to make it a spiral-like.

All-in-all I’m going to get back to this project once again. The total weight of the boiler should be some 150 grams. I have also the idea of how to make air getting in.

Dec 22, 2015 at 11:34 am #3371814A basic kitchen pot extracts about 30% of the BTUs produced in the burner stove. Normal BPing pots are about the same. Yes, wider pots are better. A more moderate flame setting is usually better than the highest setting. A dark (or almost any painted, non-shiny metal surface helps absorb IR that the burner assembly is radiating and weighs almost nothing. I did an extensive post some years back on radiant heat from (and therefore to – emissivity is bidirectional) aluminum painted white, black, red, and left shiny metal. Any paint had the same effect. Do all this very light stuff right, and maybe you’re at 35% efficiency.

Then we get into HX fins / vortex generators, surface roughness, windscreens, etc. What works and how well is so dependent on pot size, burner type, burner setting, that, yeah, it helps, but whether it is worth the weight is variable. Because you’ve added weight, maybe bulk, it might be more fragile or harder to pack, and you’ve maybe gotten to 50% efficiency. You certainly could with a good design. So if you previously needed 500 grams of fuel for a longer trip, you’d only need 300 grams now.

Considering chimney pots – that’s what a home water heater is. The exhaust gasses go up the middle and they are, not so much HX fins, but air stirrers in there to mix up the hot gas and the insulating boundary layer of cooler gases flowing against the water tank. A pretty simple cheap HWH is 82-85% efficient. Which would be fabulous in a BP pot. But a major part of that efficiency is the height – most of us don’t want to carry a 4-foot-tall pot. The height is of course more surface area and more chances to mix up that boundary layer and get hotter gases against the tank, but it also creates “draft” – the buoyant effect of hot gases in a vertical tube that helps maintain velocity and “pays for” the drag encountered in those mixing fins.

And as Gregory notes about “boiler style pots” which I call chimney pots, “only in boiler style pot you can completely insulate the pot from the outside world”. HWHs have a significant layer of insulation all around the outside. Of course your HWH sits in your basement for 20 years, you don’t carry it on your back and you don’t have to fit in your in your 40-liter pack. Still, the outside insulation only has to resist 100C temps so you can use some item of clothing you’d have with you anyway.

I should make another go of cobbling together an aluminum MYOG chimney pot from probably a small OD aluminum Coors beer bottle and a larger aluminum something (Heineken pot? Walmart grease pot? I’m accepting ideas here! something tall?) I ordered a bunch of SS insulated coffee mugs because they already have a watertight annular space around a “chimney”, but the annual space is tiny (cause it was the insulating vacuum space) and I want more than 200 cc capacity. But I’m not a TIG welder and JB Weld has its limits both in temperature and strength.

Dec 22, 2015 at 12:19 pm #3371817Keep in mind that Hot Water Heaters burn all of the fuel prior to the hot gases entering the flue. For a pot design, you will either need to do this or allow extra air to enter the flue for complete combustion. Alcohol and Esbit have a rather slow burn rate so this can be a challenge. Second, Dave is correct in that HWH utilize a tall aspect ration (flue length to diameter) as this helps with the heat transfer process. The perfect heat exchanger has the exit gases leaving at near the same temperature as the water. Best wishes.

Dec 22, 2015 at 12:27 pm #3371818You are so right David. The benefits are so questionable. For example you can’t really use boiler to hold utensils, lighter, fuel like you do with your pot. It could be more fragile although the fins of the star HX are “inside” of pot…

I think I wasn’t clear enough regarding the insulation of the pot outer surface. I was talking about insulation DURING heating the pot. If you have any kind of insulation on pot that you have on fire, most likely it will melt and burn. Well, asbestos could fit though. But it makes no sense to insulate outer pot walls since part of the heat the pot absorbs from the walls while hot gases flow around them to the top and away into atmosphere. I don’t think you can do any insulation on a regular pot. Only on those with burning inside (boilers).

Now, imagine you can insulate the pot on one side and accumulate as much heat inside as possible with huge area HX. Me too thought about very tall pot, but making a ‘normal’ size boiler with the same area of contact b/w hot gas and water will be much better for packing.

BTW, what HWH is? Sorry for probably stupid question.

Dec 22, 2015 at 12:56 pm #3371820Jon, what if you burn the alcohol inside the pot and hence get also almost 100% of IR waves trapped within the cavity – almost zero loss of heat via IR. I’ll make a brief sketch to illustrate:

Dec 22, 2015 at 1:02 pm #3371823

Dec 22, 2015 at 1:02 pm #3371823HWH = hot-water heater. I realize the first “hot” is redundant (who uses a water heater to make cold water?!?), but that’s what they are called in North America.

Focus less on total surface and think more about how to disturb the boundary layer of gases nearest the HX surface. Consider your bare skin in cold weather: without wind or motion, a significant boundary layer of still air, a millimeter or two in thickness, quickly warms near your body. Wind continuously removes that insulating boundary layer (or more accurately, greatly reduces its thickness) which causes the “Wind Chill” effect on warm objects in cold air. If it were all about surface area, fur would make animals colder.

Flipping that around, to heat the pot, you’re trying to get the bulk flow of hot gases to interact with the pot surface. More surface area may help, if the fins are larger enough “pipes” to conduct heat to the main pot, but often their bigger effect is to mix the gases, get the cooler boundary layer off the pot, and hotter gases towards the pot.

Dec 22, 2015 at 1:12 pm #3371827Nice diagram. Yes, that would capture almost all the IR from the stove and its flame. Note that there is less IR in a alcohol stove than in a pre-mix butane, propane, or WG flame which burns hotter and heats the metal stove parts to a much higher temperature. Energy emitted by radiation goes as the FOURTH power of absolute temperature of the emitting object. Stuff starts to glow dull red at about 525C = 977F = 798 Kelvin and a lot of my canister stoves glow more than that, call it 1000 Kelvin. Versus, what, 300F = 422K or less for the hottest bits of an alcohol stove? 798^4 / 422^4 = 12.8 times more IR emitted. So the bigger and hotter the burner is, the more you should focus on IR capture. For cool flames like alcohol and Esbit, focus more on mixing the hot gas flow path (actually, do that in all cases).

Dec 22, 2015 at 1:15 pm #3371828The tricky part is that alcohol stoves rarely do what you want them to do. First, since the stove is fairly “enclosed” the ambient temperature around the stove can be high. This can cause a pretty strong thermal feedback to the stove rapidly increasing the burn rate. You can compensate for this but it could take a lot of trial and error. When the flame front hits the walls of the flue, it could chock off the air flow and inhibit combustion. The trick is to get the hot gases rising through the flue to suck additional air in through the air inlet ports. Here is an old video of a cyclone style stove with and without a flue (https://youtu.be/Rh3IpKIWrJo) . Note that the will be a big interaction between the inlet air volume and the flue length/diameter. The basic idea looks fine: getting it to do what you want is the hard part. After you dial everything the question will be “how do I make one of these things?”. If you want to experiment with the idea, it may be best to purchase an off the shelf kettle and tweak it to emulate you concept. Best regards.

Dec 22, 2015 at 1:18 pm #3371829Not to drift the thread too much, I would love to see induction make it’s way into the outdoor world.

Who knows, maybe one day we could boil water with a micro induction kit and some 18650 batteries!

http://www.miito.com/technology/

Dec 22, 2015 at 1:33 pm #3371834I have always wondered if it was possible to build and immersion stove. Drop the whole stove into an open vat of water. Something like a pulse jet, that way you could potentially capture more energy.

Dec 22, 2015 at 1:48 pm #3371838good point David

further, why would you have to heat hot water? If it’s already hot, you don’t need to heat it

it should be called a cold water heater

to pay penance for my stupid comment, I tested a Kelly Kettle for backpackgeartest.org

a pot with a hole in the middle to burn stuff in

kind of heavy though – 13.2 ounces. Illustrates the point that it’s tough to add stuff for efficiency that will ever pay back in less fuel weight used

it’s intended application was for boaters so weight not that important. They could stop somewhere and make a cup of tea with just a few twigs. It worked pretty good for that.

Dec 22, 2015 at 2:11 pm #3371845I pondered that long and hard during my backpacking hot tub experimentation days. To skip the pump, tubing, and above-water HX would have been sweet. What I kept bumping up against was that anything of sufficient cross-sectional area to handle a 100,000 BTU/hour weed burner (that’s 10-20x the output of a BP stove) was (1) pretty heavy if rigid and water-tight and (2) hard to secure down against buoyant forces. The best I did was expandable aluminum dryer vent line which are wonderfully light, but somewhat fragile and it needed to be lashed to a frame to have any rigidity and weighted down along its length with bags of (locally sourced) rocks.

But for a BPing application? That could be a pretty small diameter U tube – an inch or so, with a plumber’s propane torch inside it. Realize that once you’ve got an immersion heater, the pot itself no longer needs to tolerate a flame. Heck, the “pot” doesn’t have to be a pot. Dig a hole in the sand, line it with a sweater for insulation and then a piece of HDPE tarp to make a basin. Heat your water in that. Or use any wide-mouth water bottle you would have been carrying anyway.

Dec 22, 2015 at 2:11 pm #3371846For all this effort, might as well get a Flat Cat Gear Bobcat system to boil the water and a cozy to retain the heat. :^)

I found that Esbit and alcohol stoves with very high windscreens can be just as (and in some cases, more!) efficient than a Caldera Cone. I got repeatable results doing some Esbit testing last spring/summer. I know they’re repeatable because I repeated it, startled as I was by the results.

I bought a Backcountry Boiler (insert saga here) thinking that it would be a good UL water heater, but for the reasons alluded to above and much discussed elsewhere I can’t find a way to make it practical for my needs.

Dec 22, 2015 at 2:18 pm #3371851On some episodes of “Survivorman”, Les Stroud did something like that, putting hot rocks into the water when no fireproof vessel was available for boiling. Seemed to work pretty well.

Of course, after watching that show a few times you figure out that his two major skills are going hungry and sleeping cold. :^)

Dec 22, 2015 at 2:21 pm #3371852I got one of those 100,000 BTU/hr weed burners. Toys for adult males. Occasionally something starts burning like the hedge out front. Need to have a garden hose ready and turned on, immediately ready. Maybe a video camera ready to catch anything interesting.

Romans had baths that were heated by burning wood. Just have a fire going on the other side of the tub.

Dec 22, 2015 at 2:36 pm #3371861I just bring 18-molar HCl and some caustic (NaOH) pellets. Instant, boiling salt water to cook your pasta in.

But the face shield and alkali/acid-resistent gloves weigh more than my BRS-3000T stove.Dec 22, 2015 at 4:02 pm #3371887Hydrochloric acid and lye, what a combination. I wonder what they weigh!?! Dump it in from their containers and run… ;)

I wonder if I could use it to heat my pool… ;)

-

AuthorPosts

- You must be logged in to reply to this topic.

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

HAPPENING RIGHT NOW (February 11-21, 2025) - Shop Hyperlite Mountain Gear's Biggest Sale of the Year:

Our Community Posts are Moderated

Backpacking Light community posts are moderated and here to foster helpful and positive discussions about lightweight backpacking. Please be mindful of our values and boundaries and review our Community Guidelines prior to posting.

Get the Newsletter

Gear Research & Discovery Tools

- Browse our curated Gear Shop

- See the latest Gear Deals and Sales

- Our Recommendations

- Search for Gear on Sale with the Gear Finder

- Used Gear Swap

- Member Gear Reviews and BPL Gear Review Articles

- Browse by Gear Type or Brand.