Topic

Heat Exchanger pots

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

Home › Forums › Gear Forums › Gear (General) › Heat Exchanger pots

- This topic has 53 replies, 19 voices, and was last updated 5 years, 9 months ago by

DAN-Y.

DAN-Y.

-

AuthorPosts

-

Dec 18, 2015 at 5:15 pm #3371166

I’d like to know what the gold standard heat exchanger pot is in the 500ml to 1L volume range. I’m planning a little MYOG project and I want to compare my crappy little homemade pot to the most efficient commercially available heat exchanger pot. Measurement methods vary, and reports might conflict, but I’d like to identify the heat exchanger pot that is considered to be the most efficient (shortest boil times or lowest fuel consumption). Is it one of the Jetboil models? The Olicamp XTS? The Fire Maple S2? I believe Primus, Optimus, and MSR also have marketed heat exchanger pots. Which of these is thought to be the most successful in using their heat exchanger design to reduce fuel consumption? Subjective assessments are welcome. Thanks.

Dec 18, 2015 at 10:58 pm #3371216I’ve wondered the same. If I had to guess it would be a jetboil flash.

Actually kinda surprised there’s not more options available. I’d love to get a ti 500-600 ml cup with exchanger. Please share pics/specs of your project!

Dec 19, 2015 at 6:53 am #3371241Heat exchanger pots are really no more than increasing the surface area of the outside of the pot to allow the metal conduction to perform at it’s higher value. Metal, in general gold, copper & aluminum, perform about the best at transferring heat. Convection and Infrared transfer perform about the worst. So, a well tuned heat shield, pot, and stove combination will perform as well.Heat exchangers only trap “excess” heat and deliver it to the pot to work at heating the water. A slow, 10 minute boil with a small alcohol stove and a half ounce of alcohol is often more efficient. In fact, they can loose efficiency due to additional mass and radiative cooling at low heat values. So, there really isn’t any one “best.”

Alcohol stoves (the entire system) use a low efficiency fuel to boil small amounts of water. If it is running efficiently, you can put and hold your hand on the top as you start heating things. There is simply not enough heat being lost to hurt efficiency. Adding a heat exchanger pot will accomplish nothing.

Commercial JetBoils perform about as good as any. But they are not optimized for heat transfers alone. A wider heat exchanger ring, more pleats, and less heat delivered to them would perform better with fuel. But, JetBoils are optimized along three variables: size, input heat, time to boil. If any one of these is optimized, it usually means something else pays. The over all size is good. The input heat matches their size and is good. And they deliver excellent boil times if over driven on a warm day. If you change one of the variables, say with a 1.7 L pot, you might find that the MSR works “better.”

Dec 19, 2015 at 8:19 am #3371252MYOG version:

Aluminum from hardware store for flashing. #18 steel wire.

One thing heat exchanger does is keep hot exhaust close to pot for longer so more heat transfers. Worst case – windy without windscreen – most of the hot exhaust gets blown away with no heat transfer

I’ve measured maybe 10% better efficiency – measuring change in temperature of water, weight of canister before and after,… I can see burn marks in the pot where the aluminum touches it so I can tell it’s transferring heat. Also, it keeps the exhaust closer to the pot so it has more chance to transfer heat.

You can get another 10% by running slow like James said – maybe 5 minutes to boil rather than the normal 3. When you run fast, the hot exhaust kind of piles up on itself and more blows away. If you do this in full sun, and look at the shadow, you can see where the hot exhaust is going.- kind of a poor man’s Schlieren photography. If you know you’re short on fuel, you could do this.

Dec 19, 2015 at 9:14 am #3371263Thanks for the pick, Jerry & for the thread, Colin.

I, too have been thinking a lot aobout the efficiency of using heat exchangers, either integrated into a pot or into a windscreen. In particular, I was imagining pretty much what Jerry made, but using even lighter aluminum, steel wool, or something extraordinarily light with lots of surface area.

Regardless, I would suspect that at some point during any given thermaldynamic process, “retaining” the heat becomes more important than actually “conducting” it into the pot. While we have many lightweight & durable heat conducting materials, I am equality interested in what’s out there in regards to lightweight/durable insulative materials (and in particular: heat resistant).

Dont know where all this will go, but it fascinates me.

Dec 19, 2015 at 11:57 am #3371284Mine weighs 1.3 ounces. Also serves as windscreen, but a bit of a compromise – it would be better if it was bigger, but then it would weigh more.

I can stand the pot with windscreen/heat exchanger on a table or rock or whatever. If the aluminum was much thinner, maybe that wouldn’t work so well.

Dec 19, 2015 at 3:32 pm #3371320My experience with a heat exchange pot (Fire-Maple 1 litre) on gas showed a 30% less fuel used, but even with that gain the savings in fuel did not counter the additional weight of the HE pot. With the gas setup the only time an HE pot meant less overall weight was on trips where one canister was carried when, with a normal pot, 2 canisters would be carried.

One of my thoughts still awaiting proof is that insulating the lid of a pot may produce reasonable fuel savings. The pot lid only passes heat out of the system, it is not bringing heat in. I use a 3 gram (1/10th oz) reflectix lid on my pot – just a disc of relectix with an aluminium tape flap for a knob. The only issue I have found is that the reflectix material slightly shrinks and domes and needs to be replaced after about 30-40 days use.

Dec 19, 2015 at 4:55 pm #3371332Echoing Mark’s comment, weightwise, unless you go on long trips, it may be hard to beat a relatively large-diameter standard pot like the Evernew ECA-252.

Dec 19, 2015 at 6:48 pm #3371342I have experimented with an Olicamp heat exchanger pot and a canister stove and found it to be only marginally better than a regular wide pot. Jetboil still beat that system by a factor of x2 on fuel efficiency. At that point I decided that a heat exchanger pot was not worth the trouble, considering that using it with a fire would be difficult or ruled out. I decided that when I wanted very high efficiency and didn’t mind the limited modes of use, Jetboil would be the solution. When I wanted flexibility (different stove, fire, cooking as opposed to just boiling) a regular pot would be choice. YMMV, of course.

Dec 19, 2015 at 11:46 pm #3371374This series on winter stove performance offers a little insight into the value that a heat-exchanger pot might have on fuel economy.

The data I don’t have yet is that which takes a look at small volume pots and heat exchangers, outside of my experience with integrated compressed gas systems like the Jetboil Sol Ti (which is the most fuel-efficient stove I’ve ever tested) and the MSR Windburner (which is the best-performing stove in high winds that I’ve ever tested). Wonder if anyone has looked at e.g., Jetboil pots w/EtOH or Esbit systems?

Primus used to make a small volume (< 1 L I think) “Eta” style pot with a heat exchanger on the bottom. I used it once with a Trangia and was very impressed by it. I don’t know if they still make it, I can’t find any info about it. I do remember it being a bit heavier (maybe +3 oz) than an equivalent volume Ti pot…

I’m very curious about how these heat-exchanger-integrated pots might work with alcohol / Esbit systems. Has anybody taken a look at this yet in some controlled studies, esp. in wind and/or cold temps, which seem like the environmental condition where a heat exchanger might be worth it?

Dec 20, 2015 at 4:49 am #3371385I’m very curious about how these heat-exchanger-integrated pots might work with alcohol / Esbit systems. Has anybody taken a look at this yet in some controlled studies, esp. in wind and/or cold temps, which seem like the environmental condition where a heat exchanger might be worth

Hiram Cooks channel on YouTube has done some testing with alcohol stoves and the Olicamp XTS pot.

I have the Olicamp XTS/Soto Windmaster combo and have been enjoying it these past few weeks in colder weather. It’s actually faster for me to use this combo at home when I need hot water fast (running late for work). Today I boiled 1 cup of water in 1:01 and used 2 grams of fuel. The downside is a 5oz weight penalty compared to my Toaks650ml/Snow Peak Litemax combo. I would love to see a 850ml heat exchanger pot with mug style handles.

Dec 20, 2015 at 6:18 am #3371387“Today I boiled 1 cup of water in 1:01 and used 2 grams of fuel.”

Wow…it takes me more than 2gm to get an alky stove going, let alone do any useful work. What kind of fuel? Trinitroglycerin? This simply points out the fact we need some sort of simple standardized testing. If you start with warm tap water, sure, it’s possible.

Yes, the Sol (aluminum version) is very efficient. It just drops off quickly as the temps near freezing. It runs best at 50F+. But, I get a rather wide variation in boil times between about 1 minute and 2 minutes. I used it on my alky stove but the fins started to get black from some soot and it was getting some longer boil times…rushing the warm-up means more soot. ‘Corse, it burns off on the JetBoil burner.

The pot works fine on the Caffin Stove, but doesn’t save any weight over a 3.25oz/1qt Grease pot. The extra ~3oz in weight doesn’t really pay for another can of gas or for a larger can of gas if I am only saving two ounces of fuel per week out. I never bring it on my backpack/canoe trips, but do carry it in my go box for car camping and as a second stove if my hiking partner didn’t bring one. We share a tarp, so can afford the extra weight for coffee and meals.

Dec 20, 2015 at 11:53 am #3371428Wow…it takes me more than 2gm to get an alky stove going, let alone do any useful work. What kind of fuel? Trinitroglycerin? This simply points out the fact we need some sort of simple standardized testing. If you start with warm tap water, sure, it’s possible.

I have to eat some crow. I just did a quick video to show the minimal fuel use and I did not achieve 2 grams. I’m guessing it was a fluke I got that earlier.

I did do a 1 cup and 2 cup boil with the Olicamp XTS and Soto Windmaster combo and got the following results, which I still think are really competitive.

Test Results:

1 cup boil – 1:00

Fuel used (by weight)- 5g2 cup boil – 1:54

Fuel used (by weight)- 7gHere’s the link to the video as well: Olicamp XTS & Soto Windmaster

Dec 20, 2015 at 12:22 pm #3371430I’ve played with a number of of the stand-along commercially available HX pots, but not any of the integrated (JetBoil, etc) systems. But all the HX pots I’ve gotten have been in the 2 to 3+ liter size and are used on family, group and snow-camping trips on the following logic:

Yes, HX pots weigh more. No, you’re not going to reduce fuel by as much on a short, solo trip*. But with 4 to 6 people, and when making meals that are more than boil water – put in bag (that helps keep my wife happy), then that added HX weight saves more than its weight in fuel. And it saves times. Even more so, when snow camping with the family: (1) the usual cooking, (2) plus all the melting of snow for drinking and cooking water, and (3) in cold weather, the longer the stove is in use, the more heat you use just fighting heat losses to the environment, so a little more flame is better and being faster due to HX is a triple win (less fuel, less time and even less fuel due to less time).

Another scenario where a HX pot shines is if you are being a good Samaritan or groups have combined for any reason. On a NZ tramp (Milford Sound) we were in a shelter on a misty, rainy pass with two fixed gas burners just as multiple groups arrived all hoping for a hot drink. I had two large HX pots (we were two families hiking, meal planning and cooking together) so I boiled the water for 20+ people in the next 30 minutes. “No, leave your pot in your pack, I’ve got water already boiling here.”

*There is a cost argument to be made in that you buy the HX pot once but ever after save on fuel costs. Really only a factor for canister stoves – WG and Alcohol are cheap in comparison.

Concurring with some above: Good HX fins, well-bonded to the pot, save about 30% in fuel. They save a similar amount of time, and I’ve had some big boiling-water tasks in the kitchen and got out the BP HX pots because they are noticeably quicker to boil water than non-HX kitchen pots. I agree there are few if any commercially available small HX pots. There’s some logic to that (see above), but it would be nice to see more options. If there was an Eta pot, I’ve had good luck with their larger one – it is the one I use most commonly.

While available HX pots do weigh a fair bit more than the lightest non-HX options, they don’t have to. If the underlying pot was as light, some fin configurations would add very little weight. I have a lot of design thoughts, but I’ll post that in another message.

Dec 20, 2015 at 1:02 pm #3371435Design thoughts:

It’s not simple. It’s not just increased surface area. I’ve done vortex generators that helped a lot while adding very little surface area or weight. While all commercial pots use fins of uniform thickness, really, fins should get thicker near the pot where they are carrying a greater flux of heat and so there is better thermal connection to the pot (alas, that requires some machining and not just bending sheet metal). Heat fins will interact with the windscreen and vice versa so factor that in. Think of them as a system.

To the extent that fins are vortex generators and “stir” the air around, taking already cooled air away from the pot’s surface and mixing in hotter air that would have bypassed the pot’s surface, fin material doesn’t matter. But for heat to conduct through the fin to the pot, the thermal conductivity of aluminum is much better than that of carbon steel, stainless steel, or titanium by cross-sectional area (steel 5x, SS 9x, Ti 10x worse by area) and even worse by weight (steel 14x, SS 26x, Ti 17x worse) Those other metals are so much worse than Al and commercial HX finds so thin, that I suspect an awful lot of what people (including the designers themselves at JetBoil, Primus, etc) think is conduction is actually from stirring up that insulating boundary layer.

I’ve found JB Weld to be workable for attaching heat fins / VGs. I’d love it if were just a little higher temperature rating, but if your pot never goes dry and your flame is not super hot (or you keep your fins out of the hottest part of the flame), I’ve gotten decent durability out of JB Weld attached fins.

Free design idea: Surface roughness also stirs up the boundary layer, so simply gluing any bumpy stuff on the outside of the pot (pumice is light and high temperature. Are there aluminum BBs?), could really help.

Free design idea #2: anything that will work on your BP stove, should work on your home cooktop. And it is much more comfortable working in your kitchen than on a mountainside. And you can use beater pots from the thrift store and not muck up your expensive Ti BP pot until you’ve ironed out the kinks.

Free safety idea: Consider that if you impede air flow, you are at risk of generating more CO, especially at high flame and at higher elevations.

Dec 20, 2015 at 1:29 pm #3371438Amazon has the following, smaller, HX pots for sale:

1L Fire Maple FMC-XK6, 1-liter, $27 with shipping, 220g / 7.8oz (hopefully including lid and handles)

Olicamp XTS 1-liter, $28.49 (Amazon Prime free shipping), 190g/6.7oz.

Optimus Terra HE .95L $31 “free shipping”, 9.7-ounce weight. While this weight is the highest, the “lid” is a whole other pot with handle and the handle on the HX pot looks to be steel and easily removable. I could imagine the HX pot only being 5.5 ounces, lidless.

Dec 20, 2015 at 5:26 pm #3371468This is a good discussion. Thanks for the input. It sounds like there is some agreement that the Jetboil systems are the most efficient (fuel-frugal) commercial packages. I’m inclined to pick up an aluminum Jetboil Sol 0.8L system to use as a standard. I’ll post results in the MYOG section as soon as I have anything to show. Thanks again for all the input.

Dec 20, 2015 at 6:32 pm #3371476The Primus Eta 1l is realistically more like a 0.85l because there is zero “headroom” with 1 liter of liquid in it. And the Eta 1.8l is about 1.6l for all practical purposes.

Nice pots with non stick treatment and not obscenely heavy, except for the lids… very heavy.

IMO HX of some sort is mandatory for winter when all water is obtained by melting snow and fuel requirements are about 3x what they are other times of the year.

Dec 20, 2015 at 9:14 pm #3371501Anonymous

InactiveM.D, “Regardless, I would suspect that at some point during any given thermaldynamic process, “retaining” the heat becomes more important than actually “conducting” it into the pot. While we have many lightweight & durable heat conducting materials, I am equality interested in what’s out there in regards to lightweight/durable insulative materials (and in particular: heat resistant).”

Stone Wool or Ceramic Wool (better) insulation sandwiched between an inner layer of titanium foil and an outer layer of aluminum flashing?

Fiber glass bonded with silica areogel–fabric, also sandwiched between a combo of the above?

Dec 21, 2015 at 7:57 am #3371537Asbestos. Oh, yeah… never mind.

OK then, Space Shuttle tile material. Looks like a fairly good insulator.

Dec 21, 2015 at 8:07 am #3371541

Dec 21, 2015 at 8:07 am #3371541I think lid insulation would have the same problem as heat exchanger – extra weight will not produce enough efficiency improvement to produce over-all weight reduction

Dec 21, 2015 at 8:40 am #3371548A small disk of carbon felt will help insulate the pot (12 grams at 6″ diameter). While the insulation has little impact on fuel efficiency in terms of time to boil, it will keep the internal goods warmer for longer. In my testing, a carbon finer lid will keep 4 cups of boiled water 5 F warmer after 10 minutes (190 F verses 185 F). Lid insulation helps when rehydrating food in your pot or when you are simmering. When dry baking, the insulation will keep the internal temperature 10 F to 15 F higher. My 2 cents.

Dec 21, 2015 at 9:05 am #3371553I was responding to Ryan’s question on alky stoves with HE pots. The stoves do not produce enough “excess” heat to bother with. You control the heat with stove size, generally. Around 1000BTU, compared to 8000-10,000BTU with canister stoves. Soot is a real problem with Esbit type fuels and HE pots. I was not clear on this, I see. The soot and brownish tar that Esbit & paraffin release cut into efficiency by providing an insulating barrier on the fins, not too good on efficiency after 8-10 burns. And they are difficult to clean in the field. Usually, I just hook them up to a canister stove, burn them off and blow the fins out. But in the field, this means carrying two stove systems. Try it, you’ll see why after 3 or four days you are no better off carrying the extra weight of the heat exchanger.

Yes, David is quite right. However there is a lot more we can do with commercial systems as simple “tweaks.”

Starting with the Sol and Flash series you could combine Jerry’s ideas with removal of the standard sleeve. Add a fully corrugated aluminum liner sized to fit around the cup and hang down over the normal exhaust vents on the bottom. By pinching the fins tight you create a fairly effective set of fins enclosed by a second layer of aluminum, channeling all the exhaust gasses up and along the sides with the fins in contact with the cup, itself. You could also add some insulation along the outer cup under a “Sumo” sleeve to to help hold heat in, eliminating the wire needed to hold the aluminum in place and provide a semi-handle and some heat retention, if you were careful about sizing. (Or simply add a piece of fiberglass around it, slit the old sleeve and wrap the sleeve around with a piece of duct tape to hold it.) The lid can be replaced with a simple disk of aluminum foil cut from an old pie tin then trimmed & worked around the edges with a spoon. You can add more insulation on top of this, with a disk of varnished cardboard. II would guess about a 25-30% performance increase at about 1.5-3oz increase in weight. Over a course of a week it would break even with the gas it saves, maybe to the point of eliminating that “extra” can of gas. You could get fancy and “spiral” the fins up and around the cup to induce some rolling/delay in the exhaust. Play with that one, though…it is not simple.

Another thought that I use is a heat exchanger built into the pot. This is no more than a series of rings depressed into a standard grease pot. It saves about 10% with NO increase in weight. It just boils water better. But, again, it saves negligible amounts of fuel on alky stoves. It only showed up as a 2% decrease in fuel usage after averaging (~50 burns.) On white gas it was an easy 10% (11.5% average.) On canisters it was a bit more at around 15%, but I think this was due to reduced pressure due to evaporative cooling inside the canister. (Before I thought of ice cubes in a water bath to hold a steady temp but at a reduced pressure.) But, it takes 45min to make all the ridges in the bottom of the pot.

Dec 21, 2015 at 9:06 am #3371555that makes sense – a cozy around the entire pot would be even better

if after 10 minutes the pot is 5 F warmer you could calculate efficiency

lets say you heat up your water 170 F total – go from 32 F to 202 F. and it takes 5 minutes to do this

then it would be 1/4 of 5/170 = 0.7% less fuel used if you had an insulated lid – insignificant – you’ll never notice it

1/4 because 5 minutes is 1/2 of 10 minutes, and 1/2 of this because at the beginning, when the water is 32 F, there’s no efficiency, gradually, as it warms up there’ll be more efficiency

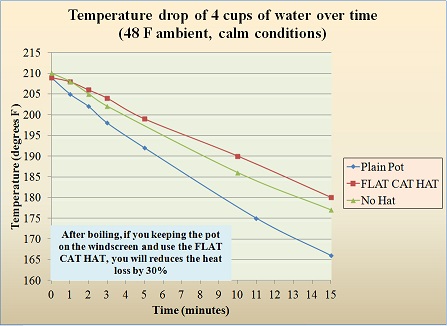

Dec 21, 2015 at 9:36 am #3371563Well, a good windscreen pretty much acts like a cozy (and no weight penalty). Here is a chart showing the temperature drops over time: bare pot, pot in a windscreen and pot in a windscreen with a lid insulator. The biggest gain comes from just leaving the pot in the windscreen after the heat is removed. The carbon felt lid will reduce the heat loss by about 4 watts. Best regards.

-

AuthorPosts

- You must be logged in to reply to this topic.

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

HAPPENING RIGHT NOW (February 11-21, 2025) - Shop Hyperlite Mountain Gear's Biggest Sale of the Year:

Our Community Posts are Moderated

Backpacking Light community posts are moderated and here to foster helpful and positive discussions about lightweight backpacking. Please be mindful of our values and boundaries and review our Community Guidelines prior to posting.

Get the Newsletter

Gear Research & Discovery Tools

- Browse our curated Gear Shop

- See the latest Gear Deals and Sales

- Our Recommendations

- Search for Gear on Sale with the Gear Finder

- Used Gear Swap

- Member Gear Reviews and BPL Gear Review Articles

- Browse by Gear Type or Brand.