Topic

Fall 2016 Fabric Samples Compared

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

Home › Forums › Gear Forums › Make Your Own Gear › Fall 2016 Fabric Samples Compared

- This topic has 40 replies, 15 voices, and was last updated 8 years, 4 months ago by

Sam Farrington.

Sam Farrington.

-

AuthorPosts

-

Oct 13, 2016 at 10:05 pm #3431073

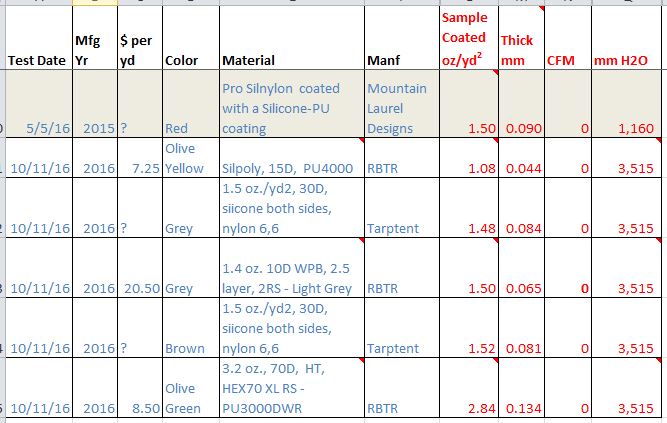

Henry Shires of Tarptent sent me two samples and Sam Farrington sent me three fabric samples. As a point of reference I also included the results of my last fabric test I previously published in the forums; that was the red Spring 2016 Duomid prior to MLD switching to a new fabric.

Oct 13, 2016 at 10:07 pm #3431075 Oct 13, 2016 at 10:12 pm #3431078

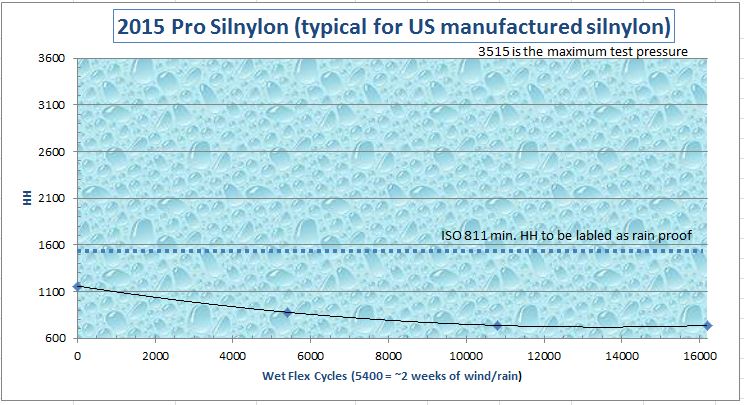

Oct 13, 2016 at 10:12 pm #3431078Red Pro Silnylon

Originally discussed in the forum https://backpackinglight.com/forums/topic/mld-pro-silnylon-2015-2016/

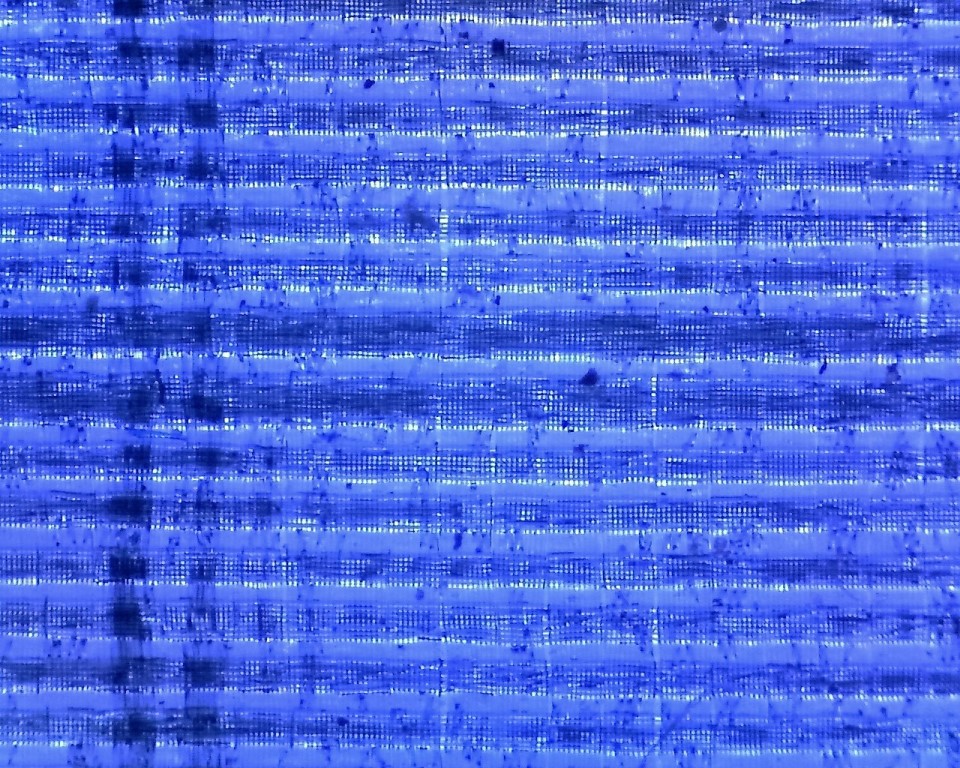

Oct 13, 2016 at 10:18 pm #3431080Oct 13, 2016 at 10:22 pm #3431081Grey Tarptent being phased in Fall 2016

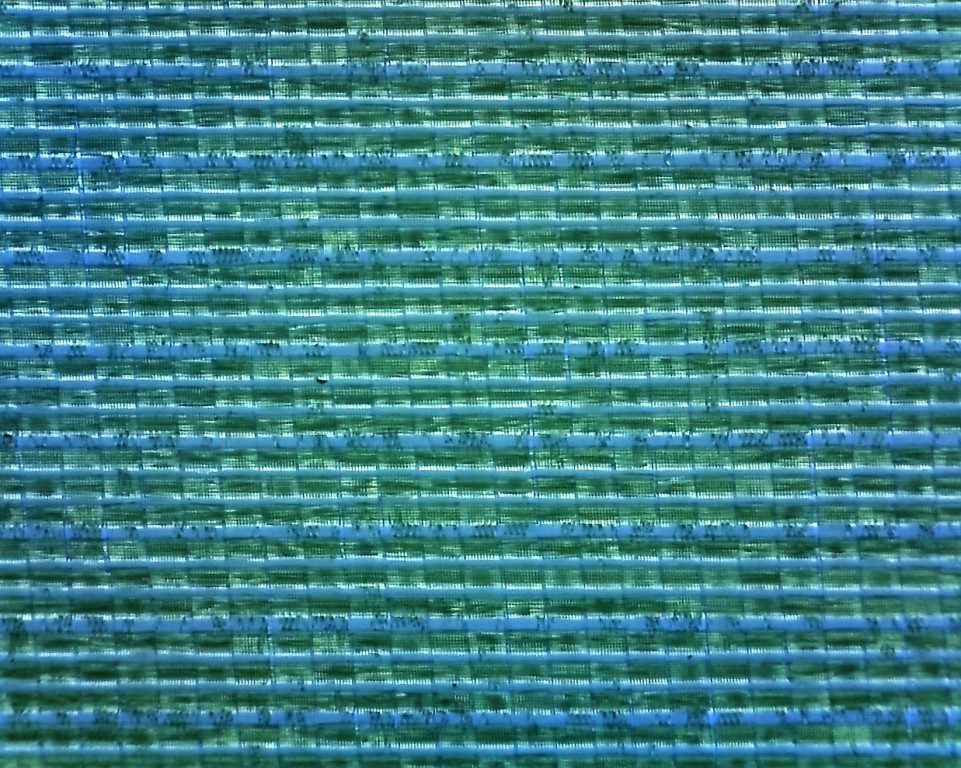

5mm FOV

Oct 13, 2016 at 10:26 pm #3431083Oct 13, 2016 at 10:31 pm #3431087

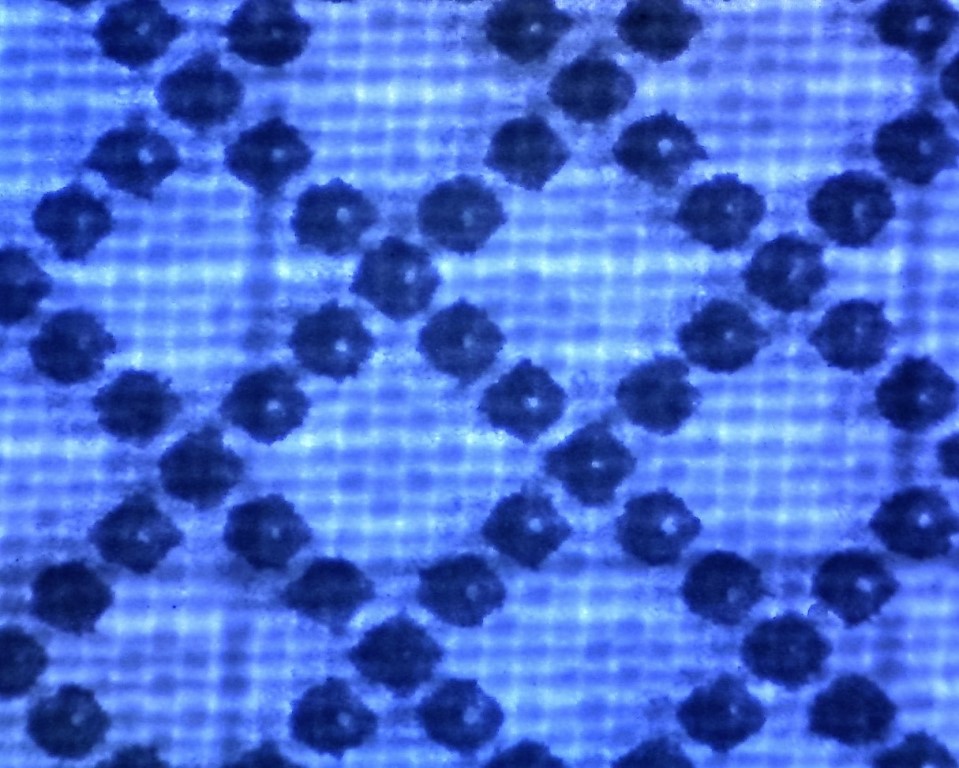

Oct 13, 2016 at 10:26 pm #3431083Oct 13, 2016 at 10:31 pm #3431087Tarptent Brown Vendor Sample (too slippery for volume production)

5mm FOV

Oct 13, 2016 at 10:35 pm #3431089

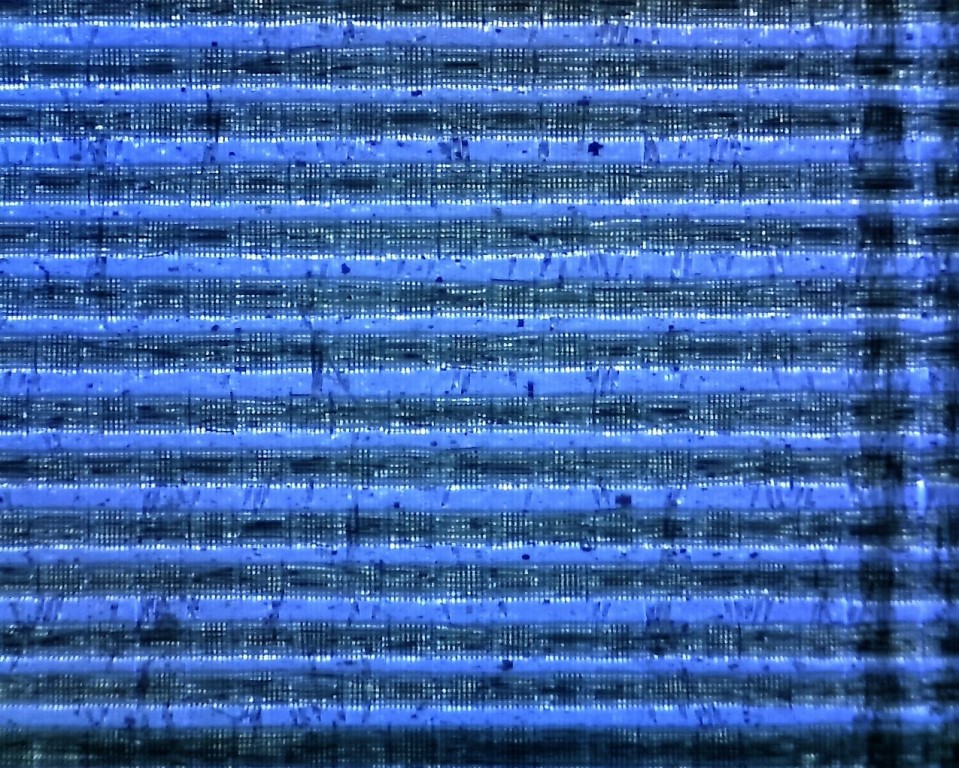

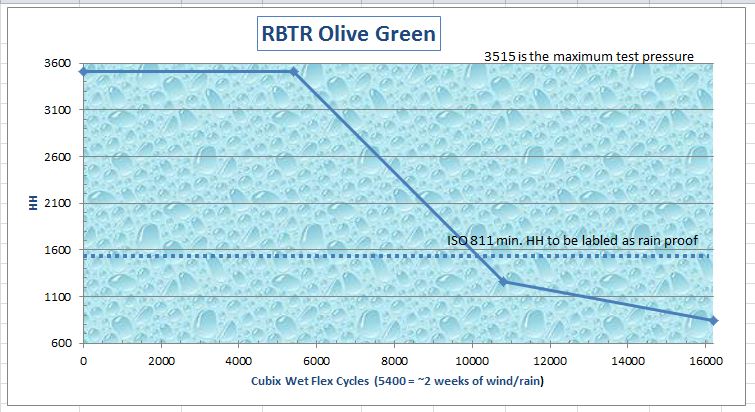

Oct 13, 2016 at 10:35 pm #3431089RBTR Olive Green

See https://ripstopbytheroll.com/products/2-2-oz-hex70-xl?variant=16395629185

5mm FOV

Oct 14, 2016 at 4:49 am #3431108

Oct 14, 2016 at 4:49 am #3431108Thank you for posting Richard.

Oct 15, 2016 at 8:52 am #3431270Richard,

Thanks for the testing. Also thanks to the fabric contirbutors for their transparency.

Oct 15, 2016 at 3:02 pm #3431329Thanks for all your work Richard. Could you explain the graphs and what we are looking at when you have the time, please? I know you must have covered this in the past so if there is a link to the post that explains this, can you direct me there?

Thanks

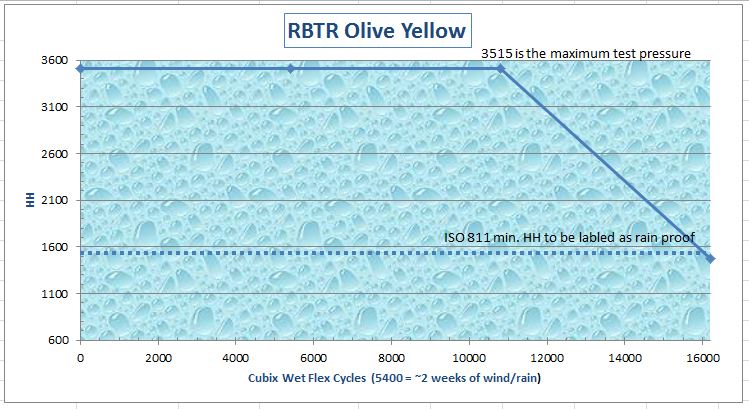

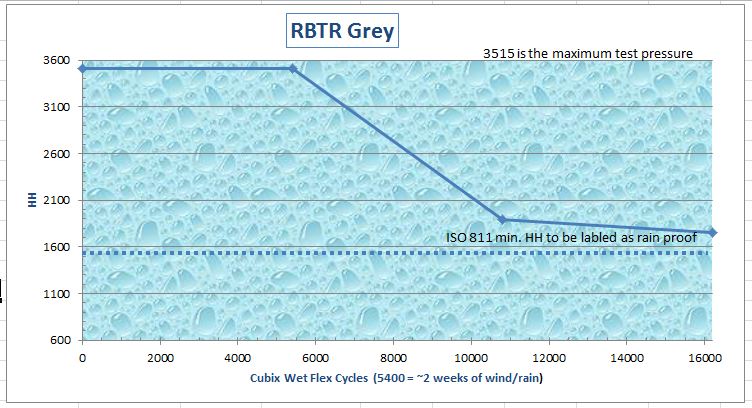

Oct 15, 2016 at 4:22 pm #3431351It shows how many wet flex cycles the material can go through before failing in the waterproof test… toi test longevity. 10800 would ‘equal’ one month of use in the rain. (if the 5400 = 2weeks per the chart)

So for the TT grey sample it will be fully (as advertised) waterproof after 2weeks and a day or so of constant use …~6000cycles. Then, for the next two weeks (untill ~10800 cycles) it gradually gets less waterproof. But all the time it stays above the 15xx mm test, meaning that it remains waterproof all the time.

The RBTR Olive works fine for two weeks then fails to below waterproof levels towards the tail end of the month.

The Pro silny is never waterproof and looks like is is a bad choice for shelters.

The magnifications are just cause Richard is a old school acid tester and it reminds him of the glory days. In the late 80’s Richard was known as Randy of the Redwoods. Then he bought a thermal camera and moved on to another trip.

But I’ll get by on my feet some day. The good Lord willin’, if he says I may.

BTW this could totally be wrong. I failed out of 3 colleges… But its what I think is going on.

Oct 15, 2016 at 7:18 pm #3431376Richard,

Thank you very much. Some great info here for upcoming projects.

The RBTR Membrane PU2000 (discontinued) and PU4000 are of equivalent weight, and both test out to over 3000mm HH after 5.400 wet flex cycles. I wonder if they are the same fabric, notwithstanding the labeling. Noticed that you did not test out to nearly as many flex cycles on the PU2000 in your test of a year ago. I think I would be OK with using this material for awnings and vestibules outside the occupied sleeping area inside a tent; that is, outside the bug-protected area. The polyester should be much less prone to sagging than nylon, thus preserving vestibule and awning space for storage, cooking and eating in extremely foul weather. I know – some will cry bear, and advise carrying a separate cook area tarp.The test of the RBTR WPB rip stop nylon is encouraging also, as its loss of HH levels out substantially around 11K flex cycles, maintaining above 1500HH; so I think I will try it for the canopy over the occupied sleeping area of a tent. Generally, WPBs will not work on a tent canopy, but after looking at the test specs published on RBTR, I think this may be worth a try.

The test of the RBTR very light hexstop fabric, intended for a SUL pack, was disappointing, however; given the rapid decline in HH after 5000 flex cycles to well below 1000HH – not the level of waterproofness I’m looking for on a pack.

All in all, very helpful to me, and I hope to other MYOGers.

Oct 16, 2016 at 9:09 pm #3431505Thanks Richard, once again. Do you think you will get a chance to test the breathability of the RBTR WPB stuff?

Oct 17, 2016 at 10:23 am #3431540Paul,

The WPB option I tested has a water vapor permeability value of ~26,507 g/m2/24 hrs (JIS L 1099 : 2012, B-1). It is a conventional 2.5 layer PU technology that utilizes solid state diffusion through the coating; it requires the moisture level in the jacket to be nearly saturated in order for the water molecules to optimally move through the PU.

Oct 17, 2016 at 10:55 am #3431546Would that work in a tent to move condensation outward?

Oh I just realized we’re talking WPB… prolly not nearly breathable enough

Oct 17, 2016 at 8:56 pm #3431671How is the old MLD silnylon that comparatively bad? Should I feel like my 2011 MLD Trailstar is unsafe? How does a guy like Andrew Skurka rely on it during a circumnavigation of Alaska?

Oct 17, 2016 at 10:53 pm #3431685Matthew S.,

It is not a binary issue of safeness. If you don’t experience misting with your Trailstar. then don’t worry about it. If you do, it is relatively cheap and fast to re-coat it yourself.

The group I packraft with uses three Golite SL5’s with two inverted packrafts per shelter. Those shelters were only 1,200 mm H2O when new. We didn’t bother to re-coat them because they are fairly large (more weight from re-coating than a smaller shelter) and just use our DWR bivys in them to deal with the occasional misting during heavy rains.

I bought my red Spring 2016 MLD Duomid to use primarily on a kayaking trip along the AK coast and generally will not have a DWR bivy with me to protect my down quilt. I expect high winds and rain to be common, So, when new, I re-coated it with a 3/1 MS and GE 57 (max UV protection) solution rather than just seam sealing it; that gave me a >3,500 mm H2O aged HH for a ~3 oz. weight increase.

Skurka used a Mountain Laurel Designs Spirit 30-deg (synthetic) which will mitigate moisture intrusion.

Oct 17, 2016 at 11:23 pm #3431687Can someone elaborate more on the meaning of wet flex cycles and the mentions of two weeks? Does silnylon age that much in 14 nights on the trail?

Oct 18, 2016 at 12:29 am #3431691Matthew K.,

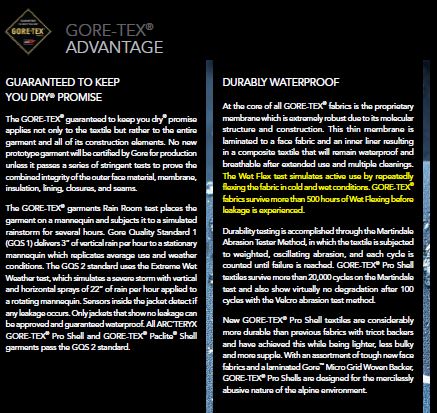

The following is an explanation from the Gore-Tex laboratories:

They test for up to 500 hrs because that is how how long it takes for a Gore-tex membrane to fall below 1,500 mm H2O. I only test for 9 hours because that is how long it takes to see the HH curves degradation in the best silnylons available. 5,400 cycles is 3 hours (30 cps) in a soft rubber tumbler filled with a few cups of water and 1′ square fabric samples. This is approximately the same degradation I measure to a new silnylon shelter during two weeks of a N CA winter storm cycle when stuffed/unstuffed each day and then set up each evening for 12 hrs.

Oct 18, 2016 at 6:38 am #3431699Thanks for the explanation, Richard. How much of the wear is from the stuffing/unstuffing and how much is from the rain? I’m wondering how this relates to my outdoor life where I’m out maybe 25 nights a year but only get rain on for a few of those (and typically none are NorCal winter storm strong).

Oct 18, 2016 at 10:26 am #3431738Good question!

Oct 18, 2016 at 10:50 am #3431744I agree

Oct 18, 2016 at 10:52 am #3431745FYI – No backpacking gear company I know of uses US manufactured Silnylon anymore – not for a year or two. If anyone wants to see a Suter test on our 2017 Pro SilNylon check out the MLD FB page. There is a short video near the top. The HUGE sphere of fabric getting pushed threatening to explode in my face will be all you need to see to fully understand the level of WP in that fabric – no numbers, math, ISO, ASTM, charts, stats, etc. needed -Sorry I could not figure how to post the video here.

Oct 18, 2016 at 2:11 pm #3431776Matthew K.,

“Your Mileage May Vary” as to how fast your HH degrades from just stuffing/unstuffing. It will always be less than what is caused by wind/rain but, these will be the major variables:

- Dirt, dust, or sand on the fabric when stuffed/unstuffed

- Dew and/or condensation on the fabric when stuffed/unstuffed

- UV light (Dark Blue, Black, and Red generally suffer less)

- Salinity increases degradation

- High storage heat increases degradation

If you want to be proactive, there is a simple test you can do to see if the fabric is less than 1200 mm:

- Locate a section of your shelter without seams and drape it into a large bowl

- Pour in about 2L of water

- Twist the top of the fabric to seal in the water

- Slowly increase the amount of pressure, by twisting, that would be about enough to pop a balloon

- If the pressure doesn’t create little droplets on the outside surface, you are OK.

Note that when the HH is marginally low, you will typically get little droplets that stay on the shelter ball outer surface (looks identical to condensation). Only rarely will major flaws in the weave and coating result in water squirting. When the wind or subsequent rain drops shake your shelter surface, the little HH pressure droplets come loose as does the condensation droplets and they both feel like mist.

-

AuthorPosts

- You must be logged in to reply to this topic.

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

Trail Days Online! 2025 is this week:

Thursday, February 27 through Saturday, March 1 - Registration is Free.

Our Community Posts are Moderated

Backpacking Light community posts are moderated and here to foster helpful and positive discussions about lightweight backpacking. Please be mindful of our values and boundaries and review our Community Guidelines prior to posting.

Get the Newsletter

Gear Research & Discovery Tools

- Browse our curated Gear Shop

- See the latest Gear Deals and Sales

- Our Recommendations

- Search for Gear on Sale with the Gear Finder

- Used Gear Swap

- Member Gear Reviews and BPL Gear Review Articles

- Browse by Gear Type or Brand.